Flue gas desulfurization and denitrification system and use method thereof

A technology for desulfurization and denitrification and flue gas, which is applied in the field of flue gas desulfurization and denitrification systems, can solve the problems that cannot be removed, and achieve the effect of repeated desulfurization and denitrification, prolonging the contact time, and high efficiency of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

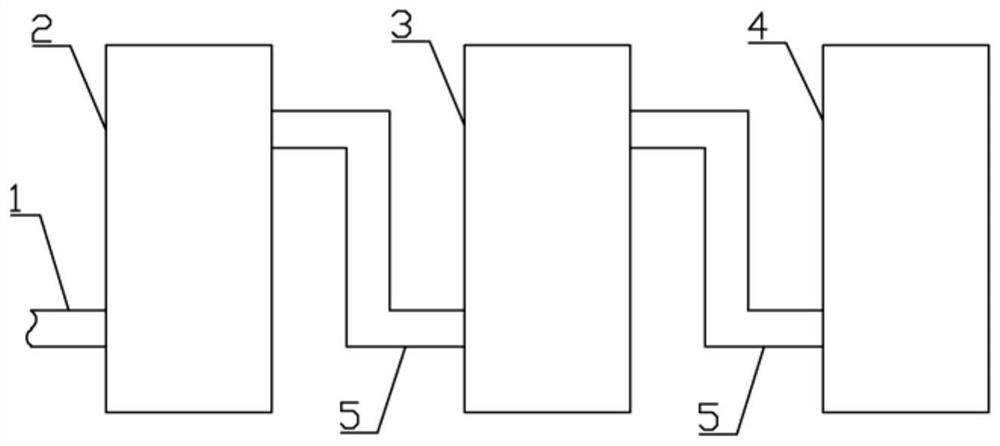

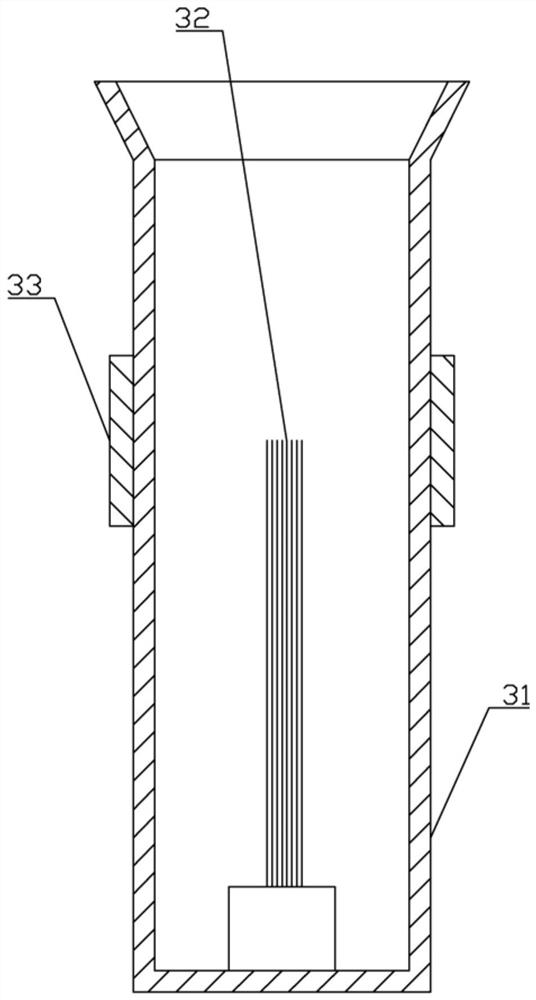

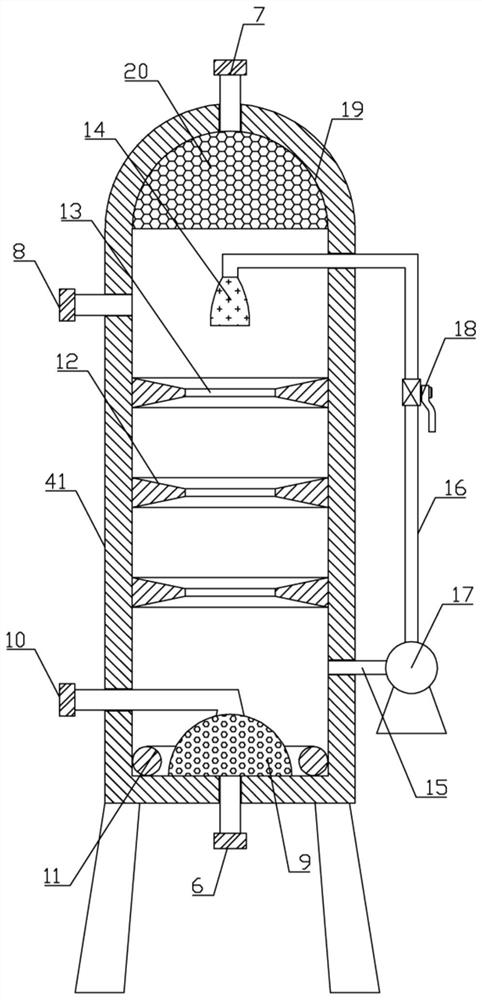

[0029] Such as figure 1 , figure 2 As shown, a flue gas desulfurization and denitrification system, the flue gas desulfurization and denitrification system includes a flue gas input pipe 1, an additive generator 2, a dielectric barrier coupling positive pulse corona discharge device 3, an absorption tower 4 and a connecting pipe 5, and the flue gas input The pipe 1 is connected to the additive generator 2, the additive generator 2, the dielectric barrier coupling positive pulse corona discharge device 3 and the absorption tower 4 are sequentially connected through the connecting pipe 5, the dielectric barrier coupling positive pulse corona discharge device 3 includes a quartz reactor 31 , the discharge needle beam 32 and the metal sheath 33 surrounding the outer wall of the quartz reactor 31, the discharge needle beam 32 is fixed in the center of the quartz reactor 31, and the tip of the discharge needle beam 32 is located in the middle of the metal sheath 33.

[0030] Such ...

Embodiment 2

[0036] On the basis of Example 1, using O 2 The volume content is 8%, the initial concentration of NO is 500ppm, and the SO 2 Mixed gas with an initial concentration of 1000ppm is used as flue gas, 0.5% by volume of methanol vapor is added as an additive, and 0.15mol / LNa is used 2 S 2 o 8 The solution is a wet oxidant, the temperature of the reaction solution is 50°C, the gas velocity is 600mL / min, and the discharge current is 2.5A to remove NO and SO from the flue gas. 2 experiment.

[0037] Nitrogen was used as the carrier gas, and the experiment was carried out under normal pressure. Each parallel experiment was carried out for 20 minutes, and the average value was obtained by repeating three times. NO, SO 2 The removal rate is calculated according to this formula: where C in and C out Respectively, the stable concentration of NO measured by the flue gas analyzer before and after the reaction, the measured NO removal rate was 98.9%, and the SO 2 The removal rate...

Embodiment 3

[0039] On the basis of Example 1, using CO 2 The volume content is 12%, O 2 The volume content is 8%, the initial concentration of NO is 500ppm, and the SO 2 Mixed gas with an initial concentration of 1000ppm is used as flue gas, 0.5% by volume of methanol vapor is added as an additive, and 0.15mol / L Na 2 S 2 o 8 The solution is a wet oxidant, the temperature of the reaction solution is 50°C, the gas velocity is 600mL / min, and the discharge current is 1.67A to remove NO and SO from the flue gas. 2 experiment.

[0040] Nitrogen was used as the carrier gas, and the experiment was carried out under normal pressure. Each parallel experiment was carried out for 20 minutes, and the average value was obtained by repeating three times. NO, SO 2 The removal rate is calculated according to this formula: where C in and C out They are the stable concentration of NO measured by the flue gas analyzer before and after the reaction, and the NO removal rate was measured to be 96.9%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com