High-efficiency energy-saving environment-friendly quenching column

A high-efficiency energy-saving, quenching tower technology, applied in the use of liquid separation agent, gas treatment, membrane technology, etc., can solve the problems of waste, high-temperature flue gas sensible heat not effectively utilized, etc., to achieve dust reduction, full utilization, high efficiency and rapid cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

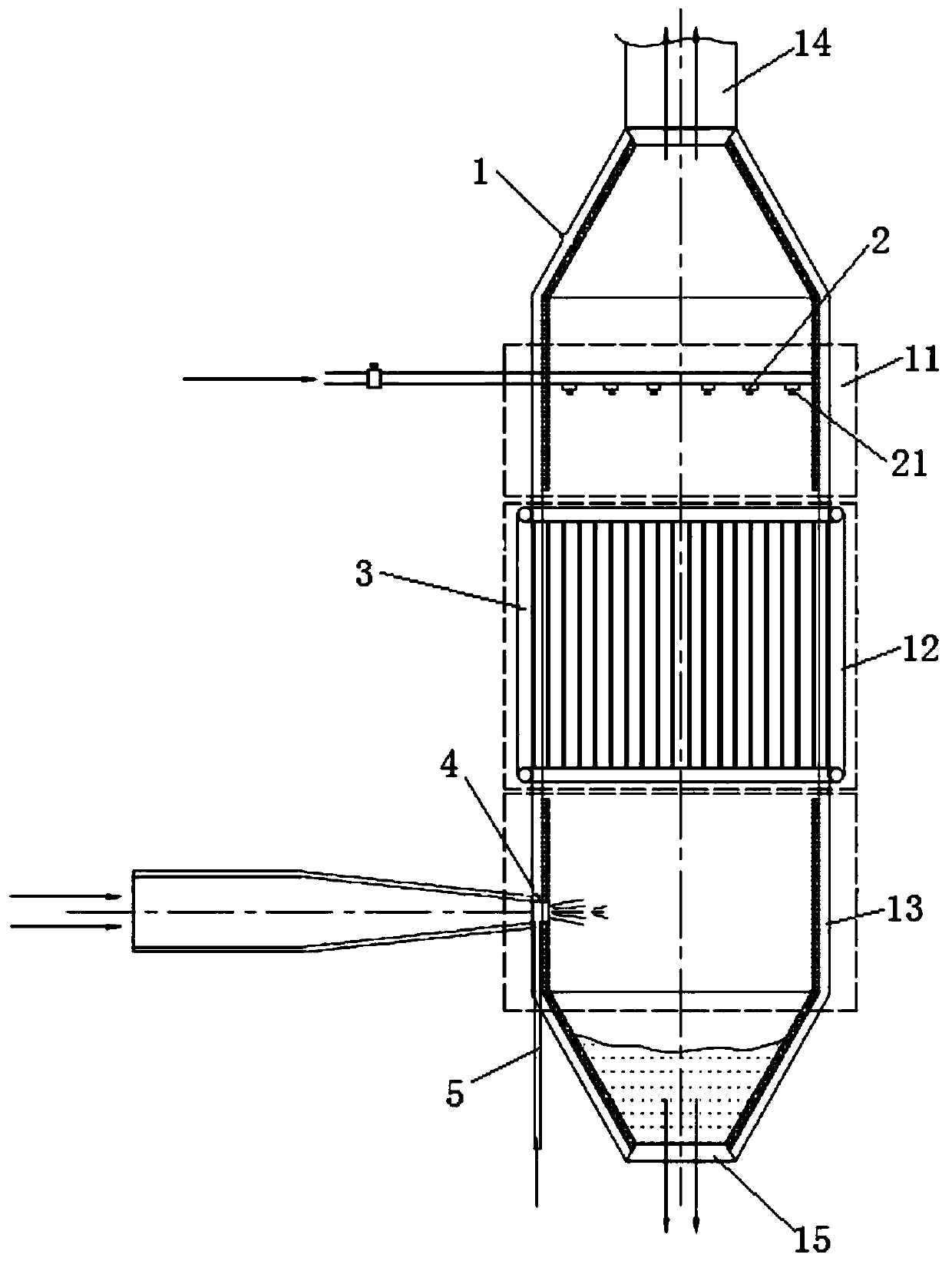

[0018] From figure 1 It can be seen that a high-efficiency, energy-saving and environment-friendly quench tower in this embodiment includes a quench tower body 1, which is composed of a spray section 11, a waste heat recovery section 12 and a high-temperature flue gas inlet section 13, and the spray section 11 1. The inner wall of the high-temperature flue gas inlet section 13 is built with refractory materials. In order to fully ensure the waste heat recovery effect, the inner wall of the waste heat recovery section 12 is not built with refractory materials. The top of the quench tower body 1 is provided with a low-temperature gas outlet 14. There is a dust discharge outlet 15 at the bottom of the spray section 11, and a spray head 2 is arranged at an interval inside the spray section 11. The input end of the spray head 2 is externally connected to an alkaline solution through a pipeline, and the alkaline solution is selected from NaOH, KOH, Ca(OH) 2 or ammonia water, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com