Method for producing building material by utilizing desulfurization and denitrification byproducts

A technology for desulfurization and denitrification and building materials, applied in the direction of separation methods, chemical instruments and methods, applications, etc., can solve the problems of high production cost, high energy consumption, unsuitable for industrial application, etc., and achieve the effect of high-efficiency desulfurization and denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

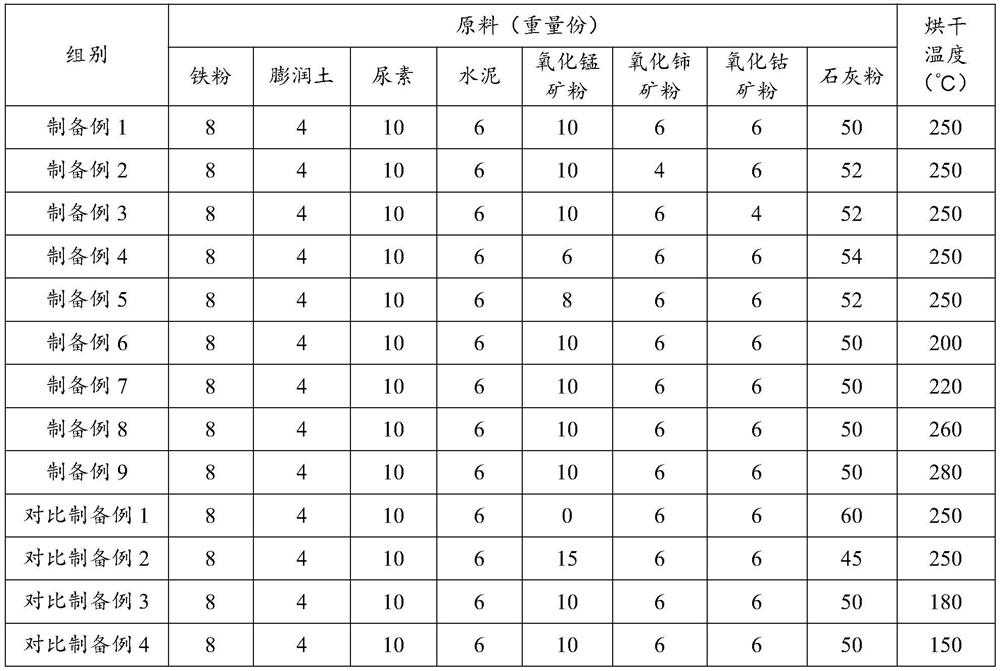

preparation example 1~9 and comparative preparation example 1~4

[0100] S1. according to the ratio of raw materials shown in table 2, take the raw materials and transport them to the kneader, dry mix for 10min, to obtain the first mixture; add deionized water three times in the first mixture (the volume ratio of the amount of water added to the raw materials is 0.12:1), wet mixing for 30min to obtain the second mixture.

[0101] S2. Transporting the second mixture to a granulator for granulation to obtain cylindrical granules to be dried (5-10 mm in diameter and 8-15 mm in length).

[0102] S3. Put the particles to be dried in an oven and dry them for 2 hours (the drying temperature is shown in Table 2) to obtain a desulfurization and denitrification absorbent.

[0103] S4. Place the desulfurization and denitration absorbent in an atmosphere containing sulfur oxides and nitrogen oxides to perform desulfurization and denitrification to obtain a used desulfurization and denitration absorbent. At the same time, the performance of the desulfur...

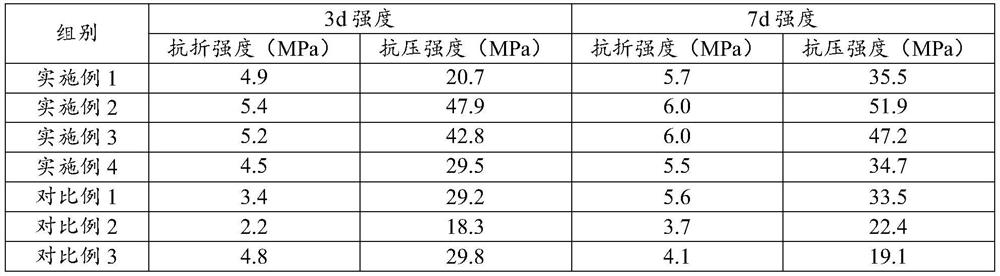

Embodiment 1~4 and comparative example 1~3

[0110] According to the ratio of raw materials shown in Table 4, desulfurization and denitrification by-products were weighed respectively (the used desulfurization and denitration absorbent of Preparation Example 1 was ground to 100-200 mesh), ore powder, fly ash, steel slag, silica fume and Alkali activator (sodium hydroxide), the above raw materials are transported to a horizontal ribbon mixer, and mixed evenly to obtain a gelled material.

[0111] Add water to the cementitious materials of Examples 1-4 and Comparative Examples 1-3 respectively and mix them in proportion, then pour them into a formwork of 40mm×40mm×160mm, and perform performance according to "GB175-2007 General Portland Cement" after molding The test results are shown in Table 5.

[0112] Table 4

[0113]

[0114] table 5

[0115]

[0116] It can be seen from Table 5 that the strength of the cementitious material produced in Examples 1-4 can reach the standard of grade 42.5 of ordinary Portland ceme...

Embodiment 5~6

[0118] First, grind the used desulfurization and denitrification absorbents of Preparation Example 1 and Preparation Example 4 (prepared according to the proportions shown in Preparation Example 1 and Preparation Example 4) to 100-200 mesh, and use them as the Desulfurization and denitrification by-products. Then follow the steps below to produce permeable bricks:

[0119]S1. According to the ratio of raw materials shown in Table 6, weigh desulfurization and denitrification by-products, mineral powder, fly ash, steel slag, silica fume, alkali activator (sodium hydroxide), coarse aggregate, fine aggregate, and transport Put it into the base material screw mixer for dry mixing, after mixing evenly, spray an appropriate amount of water to produce a semi-dry base material;

[0120] According to the ratio of raw materials shown in Table 7, desulfurization and denitrification by-products, mineral powder, fly ash, steel slag, silica fume, alkali activator (sodium hydroxide) and fine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com