System and technology for cleaning flue gas

A flue gas purification system and flue gas purification process technology, used in air quality improvement, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high transportation and storage costs, reduced catalyst activity, harsh use conditions, etc. Simple optimization of process flow, economic cost reduction, and the effect of reducing economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

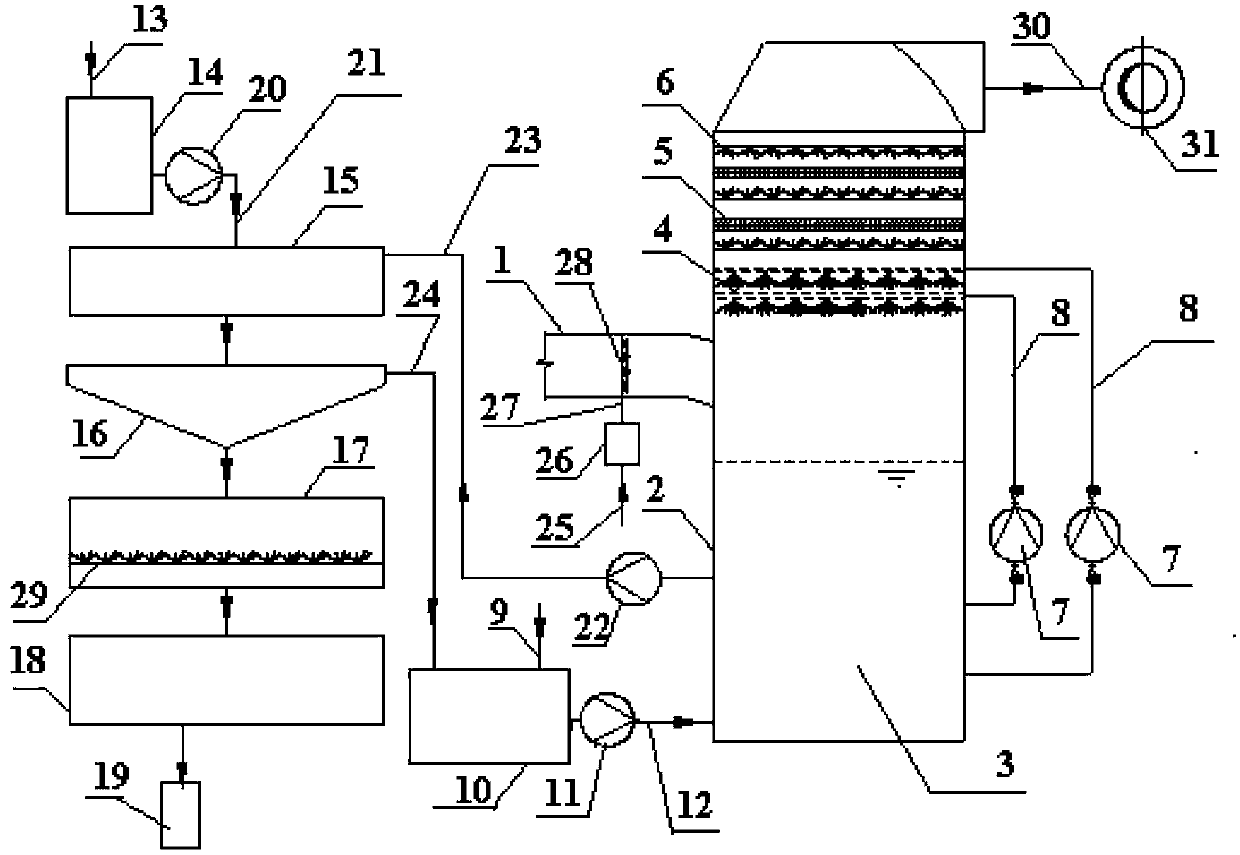

[0037] Such as figure 1 As shown, a flue gas purification system includes a connected raw flue gas input pipe 1, an absorption tower 2 and a net flue gas discharge device, and also includes an oxidation device connected to the raw flue gas input pipe 1, and an absorption tower 2 connected absorbent supply device and absorption liquid regeneration recovery device, in which:

[0038] In the absorption tower 2, a slurry pool 3, an absorbent spray layer 4, a demister layer 5, and a demister flushing water layer 6 are arranged from bottom to top;

[0039] An absorbent slurry circulation pump 7 is arranged outside the absorption tower 2, and the absorbent slurry circulation pump 7 is connected to the slurry pool 3 and the absorbent spray layer 4 through the absorbent slurry circulation pipeline 8;

[0040] The absorbent supply device includes an absorbent delivery pipeline 9, an absorbent slurry tank 10 connected to the absorbent delivery pipeline 9, an absorbent slurry input pump ...

Embodiment 2

[0067] Such as figure 1 As shown, the setting and distribution of a flue gas purification system are the same as in Embodiment 1.

[0068] Apply the flue gas purification system of the present invention to carry out flue gas purification treatment, the same as embodiment 1, except the following steps:

[0069] In step (1), the source of ozone generation is oxygen.

Embodiment 3

[0071] Such as figure 1 As shown, the setting and distribution of a flue gas purification system are the same as in Embodiment 1.

[0072] Apply the flue gas purification system of the present invention to carry out flue gas purification treatment, the same as embodiment 1, except the following steps:

[0073] In the step (2), the absorbent is sodium hydroxide;

[0074] In the step (4), the regeneration agent is quicklime.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com