Grading oxidation and absorption type method for simultaneous desulphurization and denitration of sintering flue gas, and system

A technology of sintering flue gas and graded oxidation, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as high oxidant costs, no mature technical solutions for sintering flue gas, and large initial investment and operating costs. To achieve the effect of avoiding mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

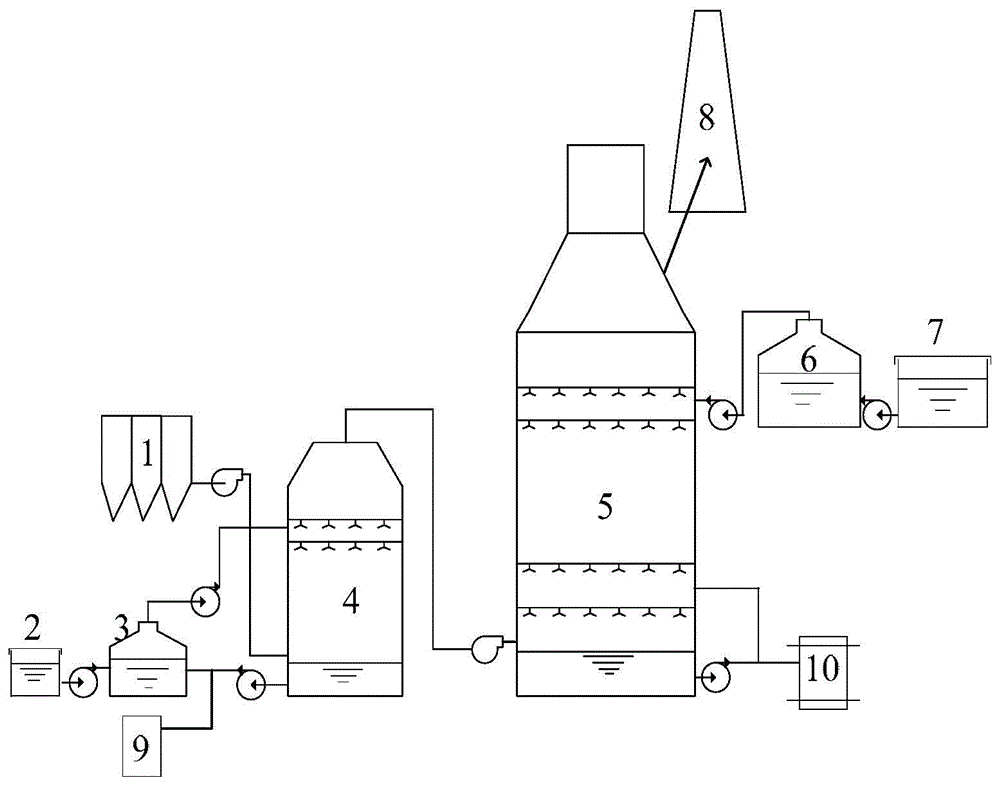

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

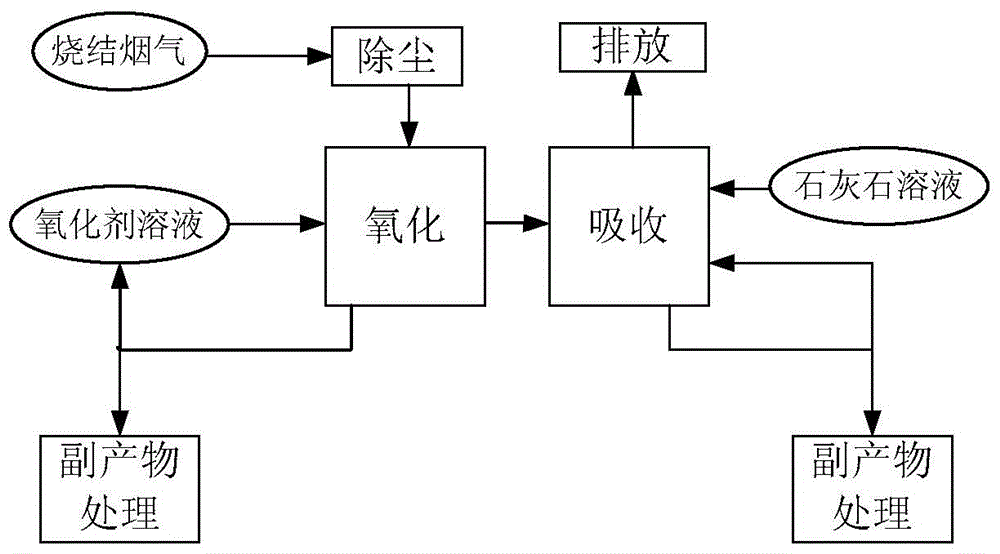

[0022] A method for simultaneous desulfurization and denitrification of sintering flue gas by graded oxidation absorption, using an oxidant solution in the primary oxidation tower to spray and oxidize the sintering flue gas to oxidize nitrogen oxides and sulfur dioxide into nitrogen dioxide and sulfur trioxide; The absorbent solution is used in the secondary absorption tower to spray and absorb the sintering flue gas after spray oxidation, and absorb nitrogen dioxide and sulfur trioxide; finally, the sintering flue gas after spray oxidation and spray absorption is discharged .

[0023] The oxidant solution is an oxidant combination solution of sodium hypochlorite and potassium permanganate, wherein the potassium permanganate is 0.1 mol / L, and the sodium hypochlorite is 0.3 mol / L; the receiver solution is a limestone solution.

[0024] Such as figure 1 , figure 2 Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com