Method for producing cementing material through flue gas desulfurization and denitrification

A technology for desulfurization, denitrification, and gelling materials, which is applied in the field of gelling materials produced by flue gas desulfurization and denitrification by-products, and can solve problems such as air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0058]The desulfurization and denitration agent is added to the alkaline wastewater to make a desulfurization and denitrification agent slurry, which is sent to the desulfurization and denitrification tower to absorb sulfur dioxide and nitrogen oxides in the flue gas. The flue gas (with an oxygen content of 18vol%) enters the desulfurization tower from the flue gas inlet of the desulfurization and denitrification tower. After passing through the first absorption spray layer, the temperature of the flue gas is reduced and part of the sulfur dioxide gas is absorbed. Next, the flue gas enters the ozone spray absorption layer, where nitric oxide is oxidized into high-valence nitrogen oxides such as nitrogen dioxide and nitrogen pentoxide, and is absorbed by the slurry sprayed from the second absorption spray layer, while sulfur dioxide Continue to be absorbed in this area. Finally, the remaining small amount of sulfur dioxide and nitrogen oxides in the flue gas is absorbed by the ...

Embodiment 1

[0065] By-products of desulfurization and denitrification, steel slag from steel mills (with a specific surface area of 500m 2 / kg), coal-fired boiler fly ash, magnesium oxide and additives were mixed evenly, and stirred for 30 minutes to obtain a cementitious material. See Table 3 for the recipe. See Table 4 for performance test results.

[0066] Table 3, gelling material formula

[0067] Specification

Desulfurization and denitrification by-products

magnesium oxide

additive

kg

40

25

25

9

1

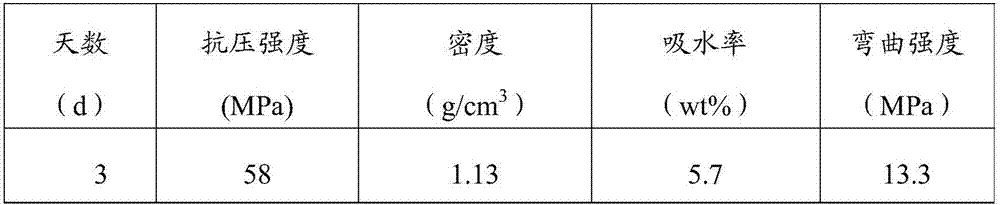

[0068] Table 4. Properties of cementitious materials

[0069]

[0070]

Embodiment 2

[0072] Except adopting the prescription of Table 5, all the other conditions are identical with embodiment 1. See Table 6 for performance test results.

[0073] Table 5, gelling material formula

[0074] Specification

Desulfurization and denitrification by-products

magnesium oxide

additive

kg

30

20

30

18

2

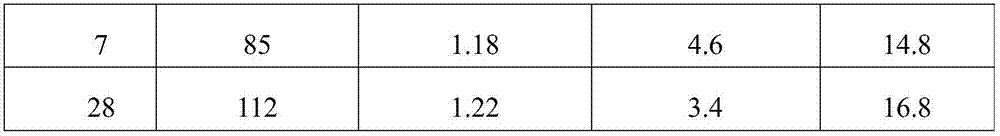

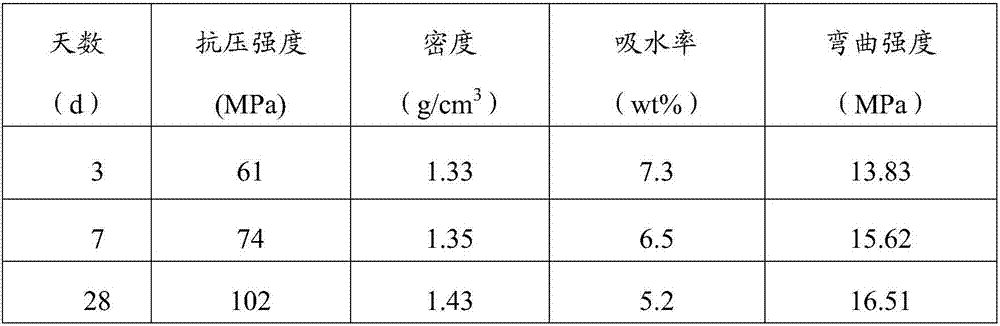

[0075] Table 6. Properties of cementitious materials

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com