Pyrolysis furnace and pyrolysis system for treating dioxin in waste incineration fly ash

A technology for waste incineration fly ash and pyrolysis furnace, which is applied in the field of pyrolysis furnace and pyrolysis system, can solve the problem of low removal rate of fly ash dioxin, difficulty in realizing fly ash dioxin anaerobic atmosphere conditions, fly ash Heat agglomeration, poor discharge and other problems, to ensure uniform temperature, improve temperature field distribution, avoid heat agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

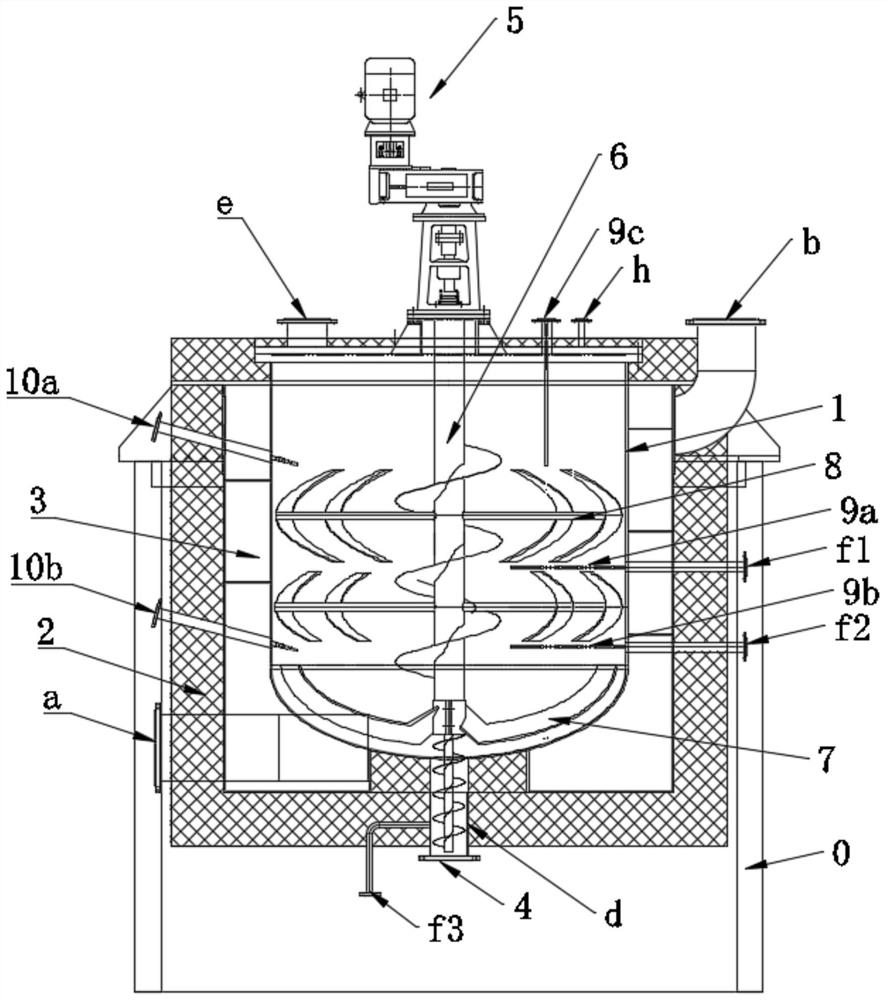

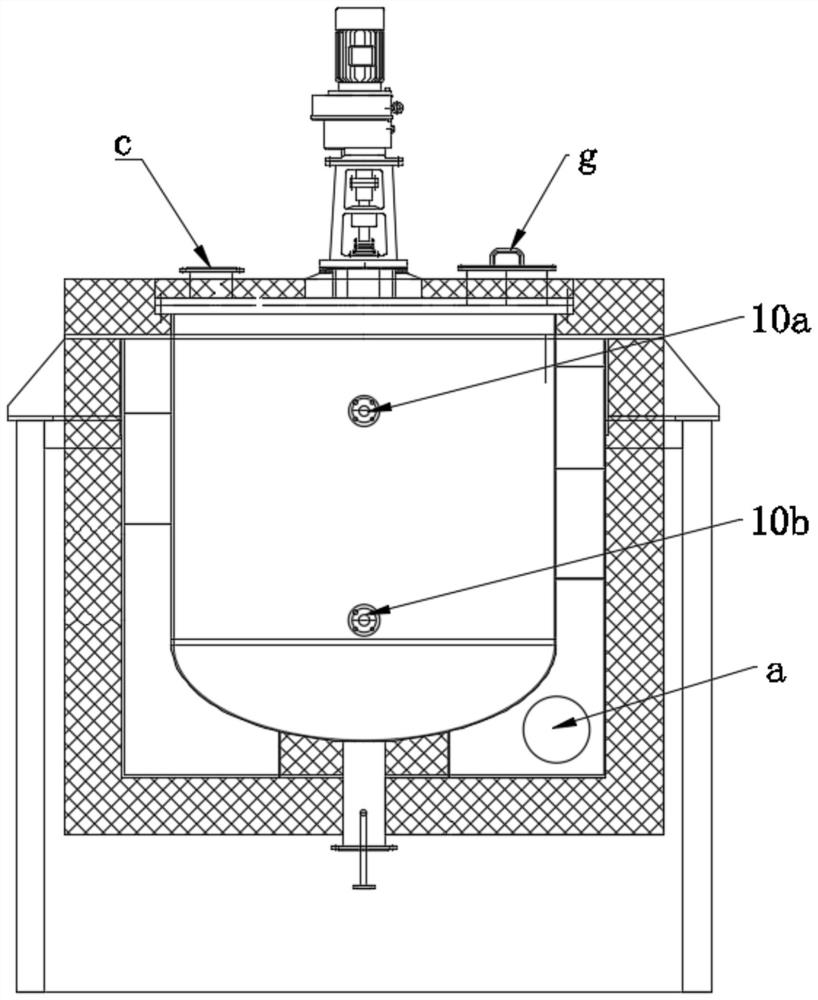

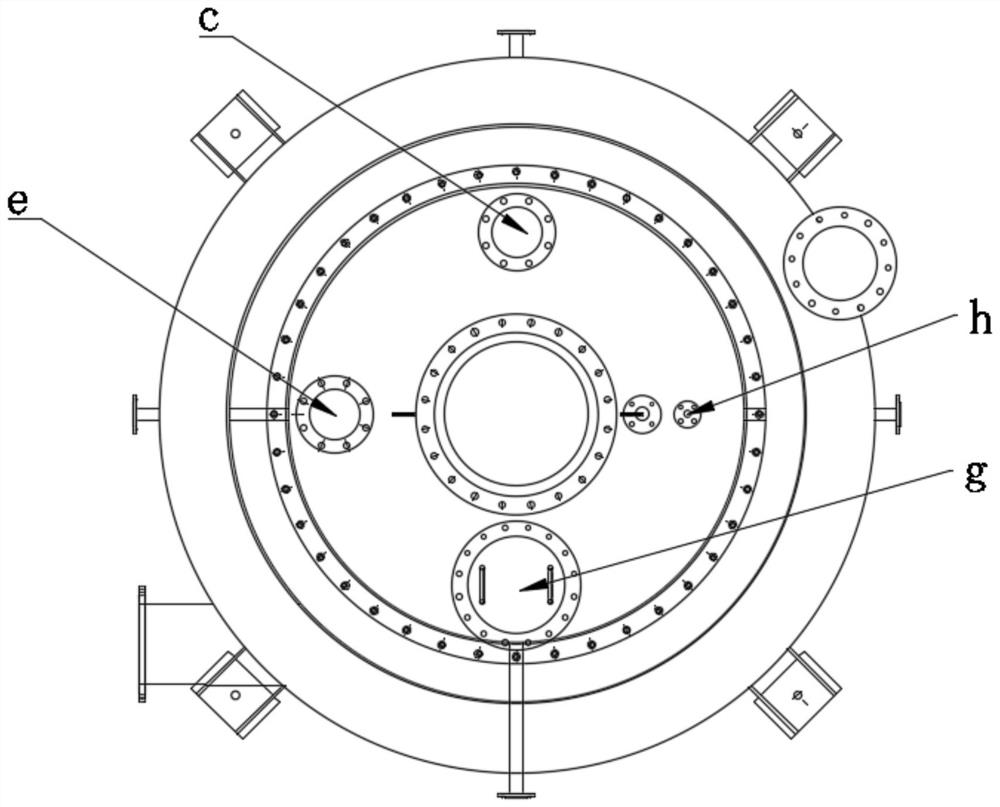

[0032] Such as Figure 1-3 As shown, the pyrolysis furnace for processing waste incineration fly ash dioxin in this embodiment is set up on the support 0. Specifically, the pyrolysis furnace includes a furnace hearth 1, which is a vertical structure; the outer sealing cover of the furnace hearth 1 is provided with a thermal insulation shell 2, and a sealed flue 3 is formed between the furnace hearth and the heat insulation shell, and the flue 3 It is a spiral structure extending along the axial direction of the furnace (that is, the height direction), thereby increasing the residence time of hot flue gas outside the furnace and the heat transfer area, and improving the utilization rate of heat energy.

[0033] The heat insulation shell 2 of this embodiment has a hot air inlet a and a hot air outlet b, both of which are connected to the flue 3 and are respectively located at both ends of the flue; that is, the hot air inlet a is located at the bottom of the flue , the hot air ...

Embodiment 2

[0056] The difference between the pyrolysis furnace of the present embodiment and embodiment 1 is:

[0057] A thermocouple temperature measurement module can also be added before the hot air inlet to ensure that the fly ash inside the furnace does not agglomerate and block by controlling the temperature of the hot flue gas.

[0058] Other structures can refer to Embodiment 1.

[0059] In addition, the pyrolysis system of this embodiment adopts the pyrolysis furnace of this embodiment, and other structures can refer to Embodiment 1.

Embodiment 3

[0061] The difference between the pyrolysis furnace of the present embodiment and embodiment 1 is:

[0062] The number of thermocouples is not limited to three in embodiment 1, and can also be one, two, four, five, etc., which can be set according to actual needs;

[0063] The quantity of material level meter is not limited to the two of embodiment 1, can also be one, three, four, five etc., specifically can be set according to actual demand;

[0064] The number of inert gas inlets is not limited to three in Embodiment 1, and can also be one, two, four, five, etc., which can be set according to actual needs;

[0065] Other structures can refer to Embodiment 1.

[0066] In addition, the pyrolysis system of this embodiment adopts the pyrolysis furnace of this embodiment, and other structures can refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com