Integral sputtering-oxygenating-biofiltering waste water purifying apparatus and process

A technology for biological filtration and sewage purification, applied in the field of sewage treatment, can solve the problems of difficult and small-scale sewage treatment promotion and application, unsatisfactory removal effect, inability to meet requirements, etc., achieve good organic matter removal and denitrification effect, and facilitate large-scale promotion The effect of applying, reducing operating and administrative costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

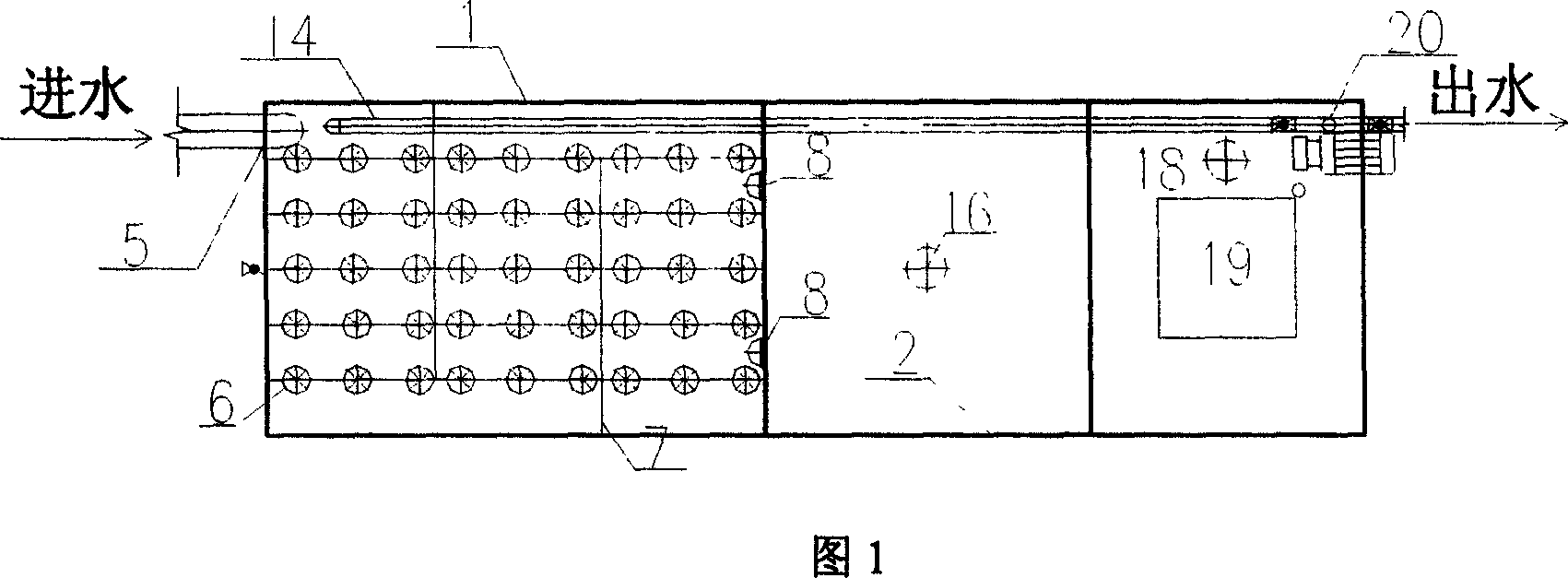

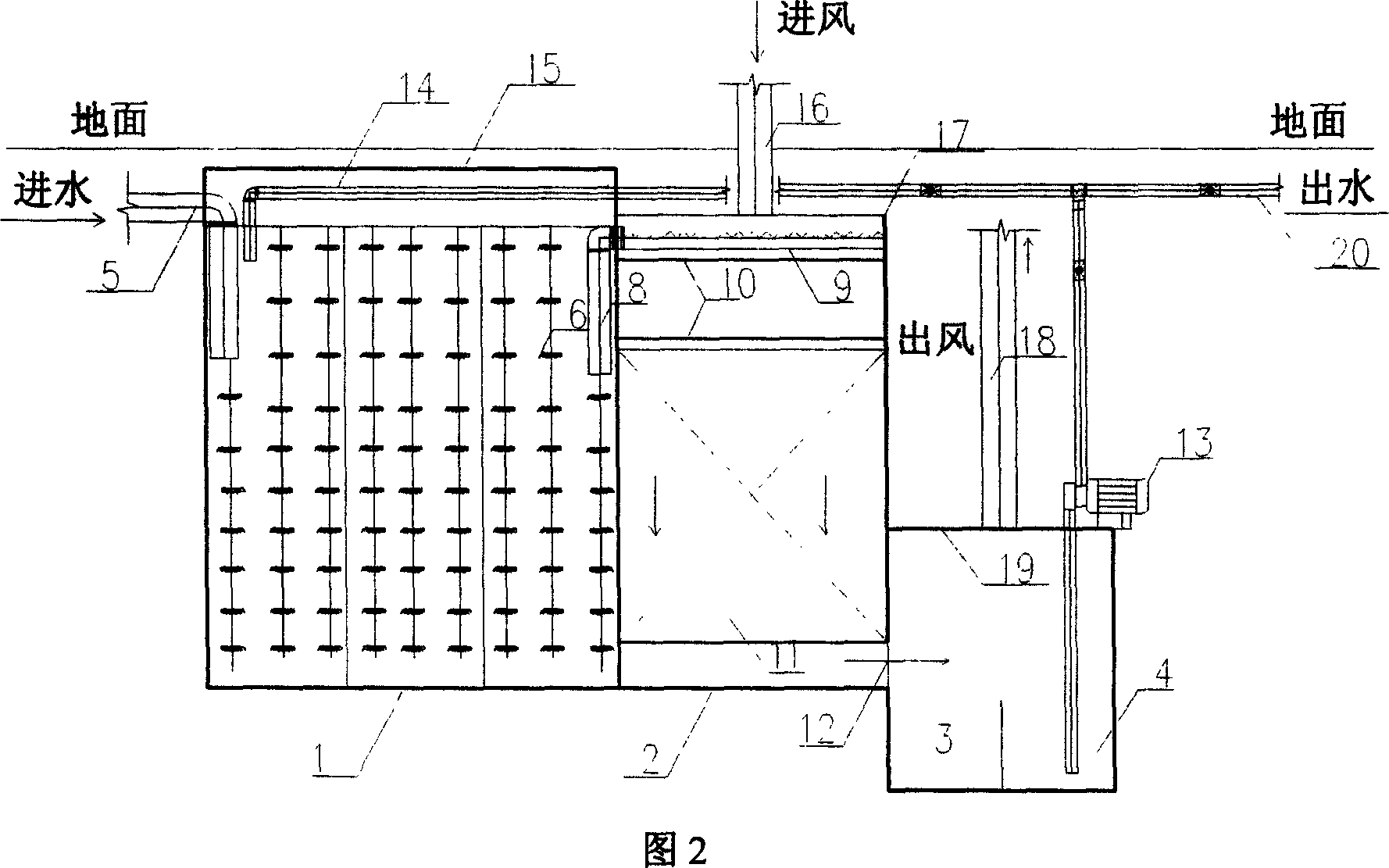

[0016] The device of the present invention mainly comprises an anaerobic denitrification reactor 1, a splashing water oxygenation biological filter reactor 2, and a sedimentation zone 3 arranged horizontally, and the upper part of the anaerobic denitrification reactor 1 is connected to the splashing water through a connecting pipe 8. The upper part of the oxygenated biological filtration reactor 2 is connected, and the lower part of the splashing water oxygenated biological filtration reactor 2 is connected with the sedimentation area 3 through the ventilation duct 12, the water outlet area 4 is located on one side of the sedimentation area 3, and the air outlet pipe 18 is located On the sedimentation outlet area cover plate 19 above the area 3, the water outlet 20 is connected with the anaerobic denitrification reactor 1 and the water outlet area 4 respectively through pipelines, and the water inlet pipe 5 is positioned at the top of the anaerobic denitrification reactor 1; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com