Oxygen-enriched combustion flue gas purification device

A flue gas purification and oxygen-enriched combustion technology, which is applied in the direction of indirect carbon dioxide emission reduction, air quality improvement, chemical instruments and methods, etc., can solve the problems of complex system, low gas extraction purity, high energy consumption, etc., and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the drawings and embodiments.

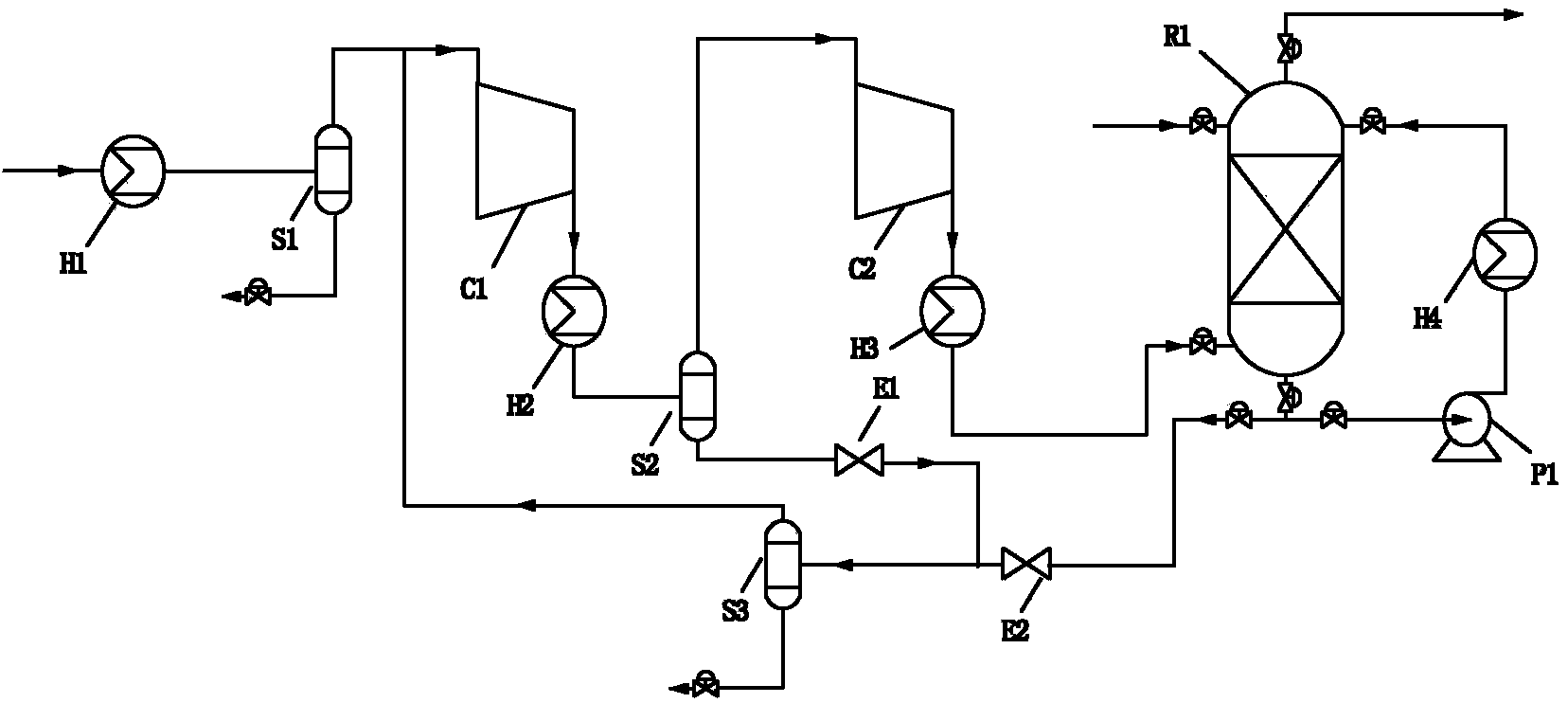

[0061] Such as figure 1 As shown, the embodiment of the present invention includes a first-stage compressor C1, a second condenser H2, a second-stage compressor C2, a third condenser H3, and a high-pressure reaction tower R1, and is characterized by:

[0062] It also has a first condenser H1, a first gas-liquid separator S1, a second gas-liquid separator S2, a third gas-liquid separator S3, and a fourth condenser H4;

[0063] The first condenser H1 is connected to the first gas-liquid separator S1 through a pipeline, and the gas outlet of the first gas-liquid separator S1 passes through the first stage compressor C1, the second condenser H2, and the second gas-liquid separator S2 in sequence Pipe connection, the liquid outlet of the first gas-liquid separator S1 drains through the pipe;

[0064] The gas outlet of the second gas-liquid separator S2 is connected to the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com