Method for degrading organic dye in water by activating persulfate by using molybdenum disulfide synergized bivalent iron

A technology for activating persulfate and molybdenum disulfide, which is applied in the field of water pollution treatment, can solve the problems of reducing the usage of persulfate and ferrous iron, easy precipitation, and difficult to circulate, and achieves broad practical application prospects and low usage. , the effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

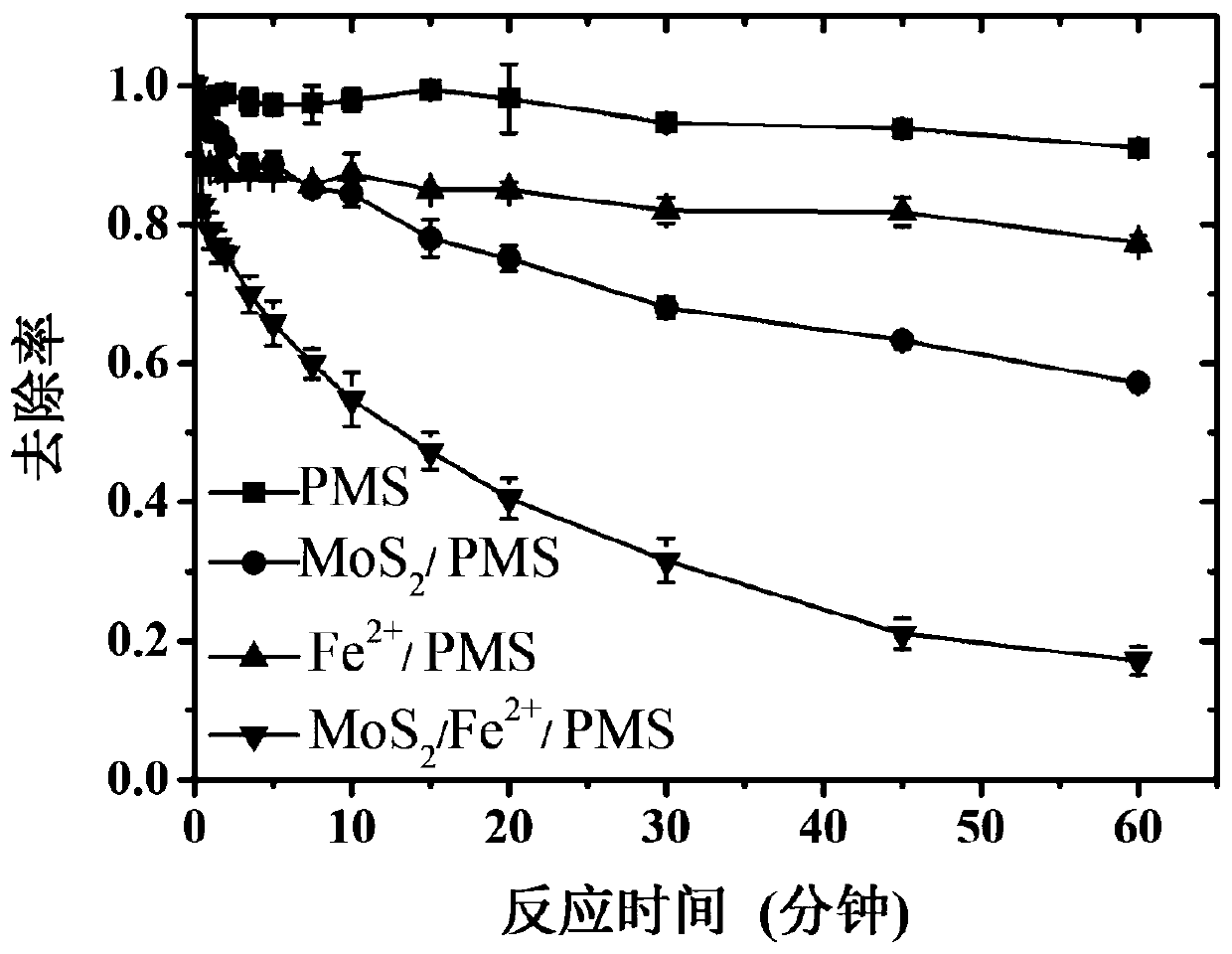

[0038] The present invention first investigates the persulfate itself, the persulfate oxidation technology based on ferrous iron and the persulfate oxidation technology effect based on molybdenum disulfide.

[0039] Add 10mL of 100mg / L Rhodamine B mother solution to the Erlenmeyer flask containing 90mL of ultrapure water, adjust the pH=3.0, stir evenly and take the sample before degradation, then add 1mL of PMS (C(PMS)=0.25mM) , after reacting for 60 minutes, take a water sample to test the Rhodamine B concentration and calculate its removal rate, the results are as follows figure 1 As shown, the removal rate was only 9%.

[0040] Add 10mL of rhodamine B mother liquor of 100mg / L in the Erlenmeyer flask that 89m ultrapure water is housed, ferrous iron solution 1mL (C(Fe 2+ )=10.8uM), adjust the pH=3.0, stir evenly, quickly take the undegraded sample, then add 1mL PMS (C(PMS)=0.25mM), after reacting for 60 minutes, take a water sample to test the concentration of rhodamine B an...

Embodiment 2

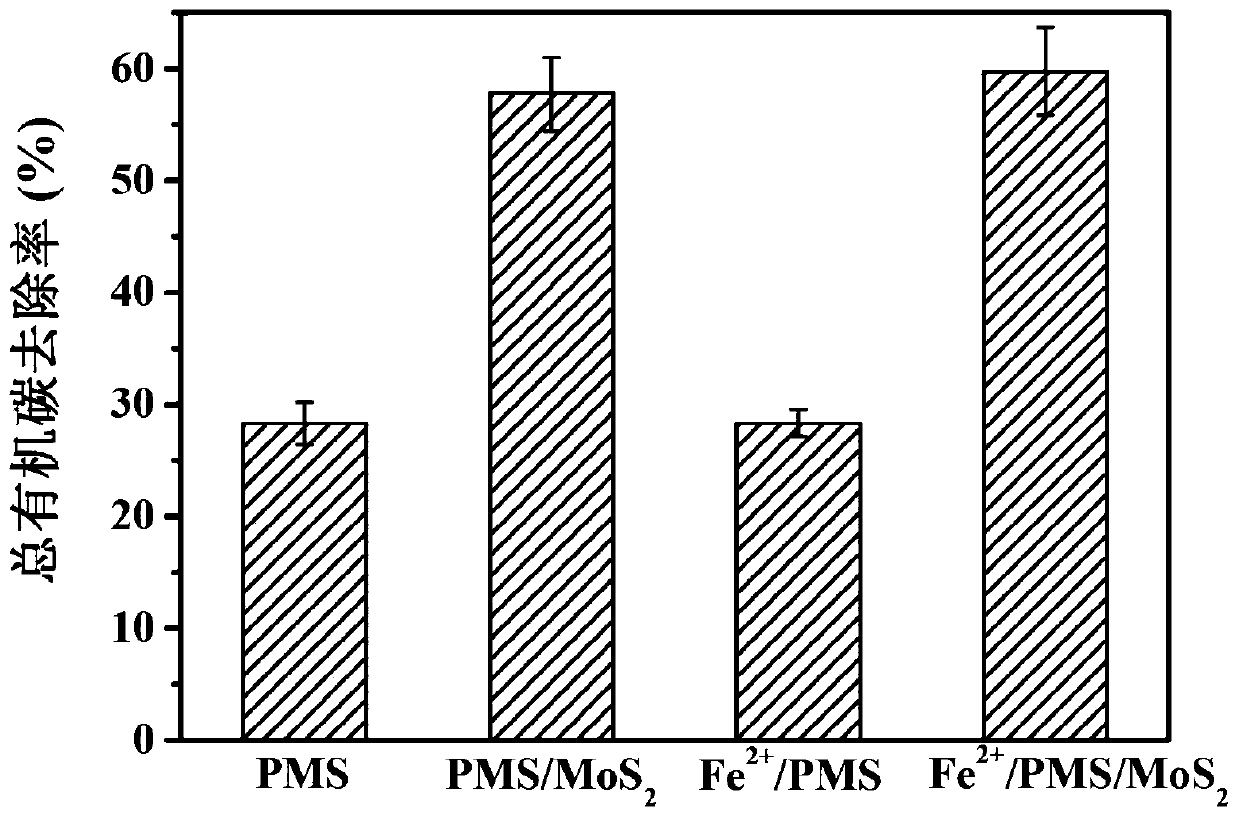

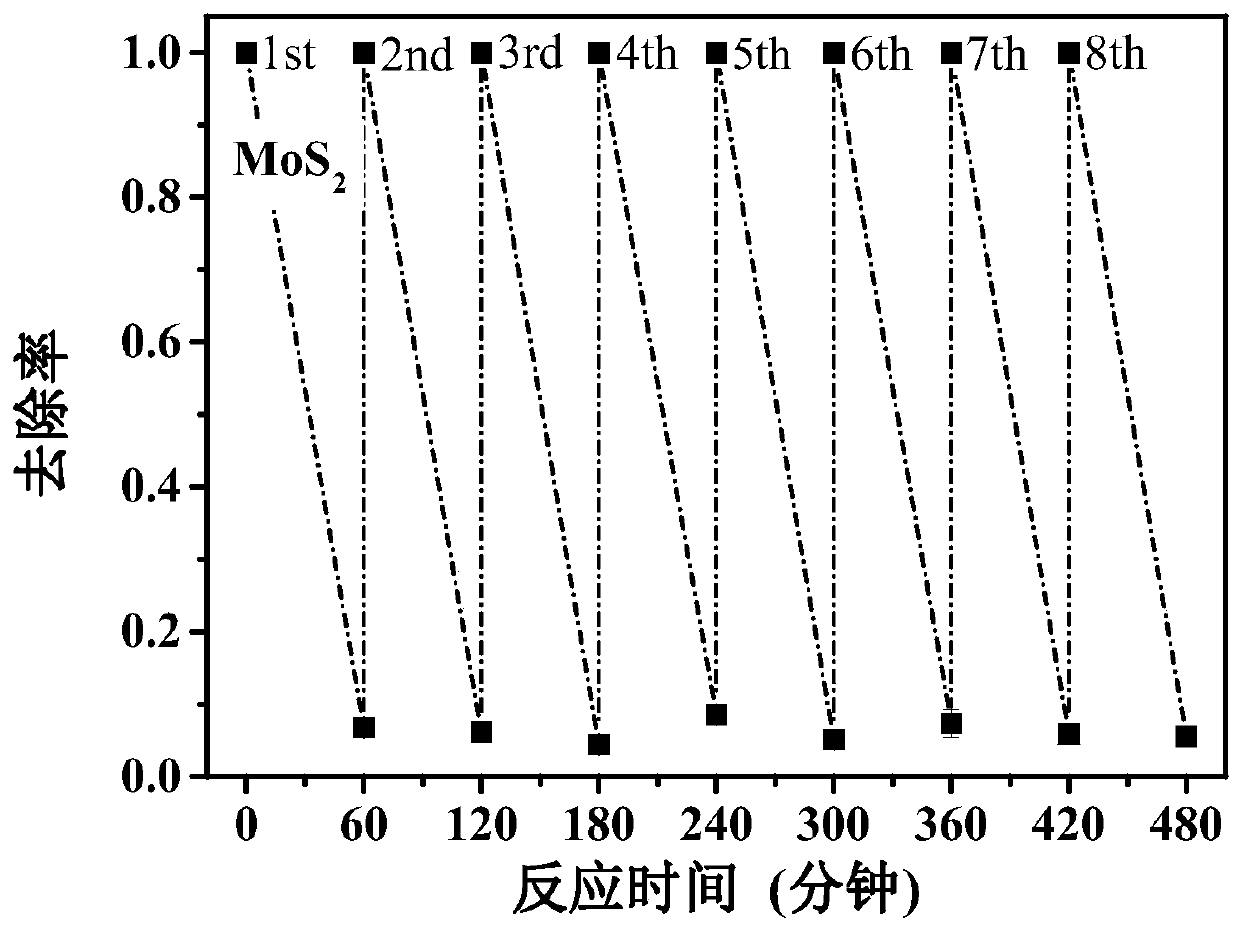

[0043] The present embodiment provides a method for treating sewage. The method specifically includes: adding 0.03 g of molybdenum disulfide cold water to an Erlenmeyer flask containing 89 mL of ultrapure water and ultrasonicating for 1 minute, and then adding 100 mg / L of rhodamine B Mother liquor 10mL, ferrous iron solution 1mL (C(Fe 2+ )=10.8uM), adjust the pH=3.0, stir evenly, quickly take the undegraded sample, then add 1mL PMS (C(PMS)=0.25mM), after reacting for 60 minutes, take a water sample to test the concentration of rhodamine B and Calculate its removal rate, and the results are shown in Table 1.

[0044] In this embodiment, on the basis of using the above-mentioned method to treat sewage, only the concentration of the PMS is adjusted to 0.1 and 1mM respectively to obtain another two groups of treated sewage, and the three groups of treated sewage above are treated. Data analysis, monitoring the concentration of Rhodamine B and calculating its removal rate, the res...

Embodiment 3

[0048] The present embodiment provides a method for treating sewage. The method specifically includes: adding 0.03 g of molybdenum disulfide cold water to an Erlenmeyer flask containing 89 mL of ultrapure water and ultrasonicating for 1 minute, and then adding 100 mg / L of rhodamine B Mother liquor 10mL, ferrous iron solution 1mL (C(Fe 2+ )=10.8uM), adjust the pH=3.0, stir evenly, quickly take the undegraded sample, then add 1mL PMS (C(PMS)=0.25mM), after reacting for 60 minutes, take a water sample to test the concentration of rhodamine B and Calculate its removal rate, and the results are shown in Table 2.

[0049] In this embodiment, on the basis of using the above method to treat sewage, only the Fe 2+ The concentrations were adjusted to be 5.4 and 54mM respectively, and another two groups of treated sewage were obtained. Data analysis was carried out on the above-mentioned three groups of treated sewage, the concentration of Rhodamine B was monitored and its removal rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com