Hybrid cured light-induced blackened acrylate adhesive

An acrylate and hybrid curing technology, which is applied in the direction of ester copolymer adhesives, adhesive types, etc., can solve the problems of incompatibility between pigments and systems, shading rate and curing thickness, etc., to improve the curing thickness , Improve the effect of body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

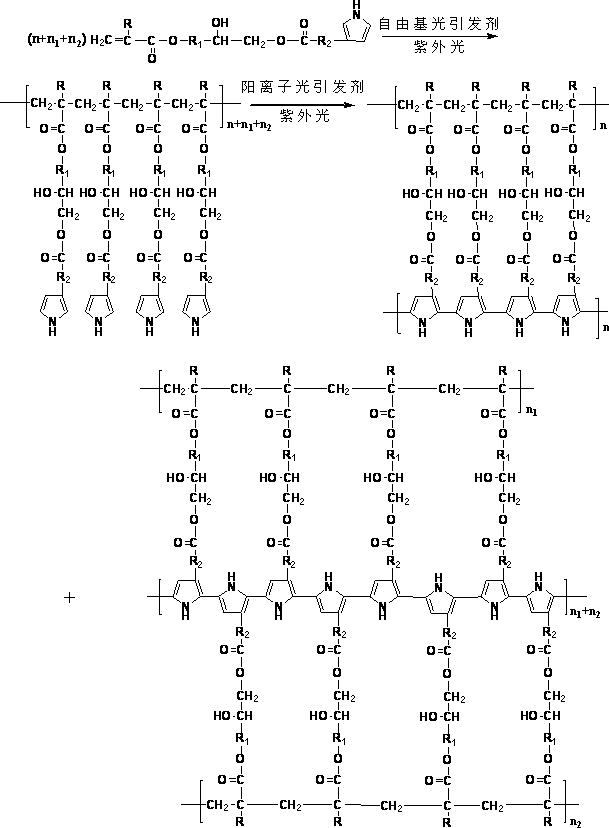

Method used

Image

Examples

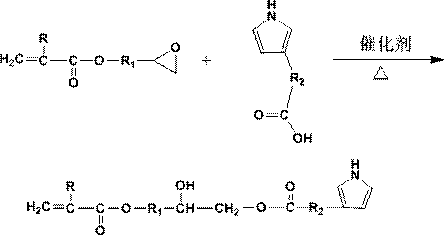

Embodiment 1

[0035] Example 1: Add 160g of glycidyl acrylate, 111.1g of 3-pyrrole carboxylic acid, 0.14g of p-hydroxyanisole, and 0.8g of triphenylphosphine into a three-necked flask, start stirring at the same time, and heat to 110°C under a dry nitrogen atmosphere to react When the acid value is ≤0.2mgKOH / g, stop the heating reaction to obtain acrylate functional resin; mix 13.56g 2,2-dimethoxy-2-phenylacetophenone (DMPA), 27g p-(octyloxy Phenyl)phenyliodonium hexafluoroantimonate (Ph 2 ikB 6 ) Photoinitiators are added to the above-mentioned acrylate functional resin in turn, and stirred at room temperature until the photoinitiators are completely dissolved.

Embodiment 2

[0036] Example 2: Add 142.15g of glycidyl acrylate, 111.1g of 3-pyrrolecarboxylic acid, 0.03g of phenothiazine, and 0.26g of dimethylaniline into a three-necked flask, start stirring at the same time, and heat to 110°C under a dry nitrogen atmosphere to react to When the acid value is ≤0.2mgKOH / g, stop the heating reaction to obtain the acrylate functional resin; mix 2.5g of ethyl-4-dimethylaminobenzoate (EDMAB), 12.67g of bis(4,4'-sulfide Triphenylsulfonium) hexafluorophosphate photoinitiator was added to the above-mentioned acrylate functional resin in sequence, and stirred at room temperature until the photoinitiator was completely dissolved.

Embodiment 3

[0037] Example 3: 170.58g of glycidyl acrylate, 111.1g of 3-pyrrole carboxylic acid, 0.28g of phenothiazine, and 1.4g of triethylbenzyl ammonium chloride were added to a three-necked flask, and stirring was started at the same time, and heated under a dry nitrogen atmosphere to Stop the heating reaction when the acid value is ≤0.2mgKOH / g at 110°C to obtain acrylate functional resin; mix 28g 2-methoxy-2-phenylacetophenone (BZME), 42.2g triaryl sulfur hexafluorophosphate The onium salt photoinitiator is sequentially added to the above-mentioned acrylate functional resin, and stirred at room temperature until the photoinitiator is completely dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com