High solid content 0-3 type piezoelectric composite material paste and preparation method thereof and manufacturing method of structural member

A piezoelectric composite material and high solid phase technology, applied in the field of 3D printing, can solve the problems of low solid phase content and easy sedimentation of slurry, and achieve the effect of small solidification depth, preventing rapid sedimentation, and reducing the difference in refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

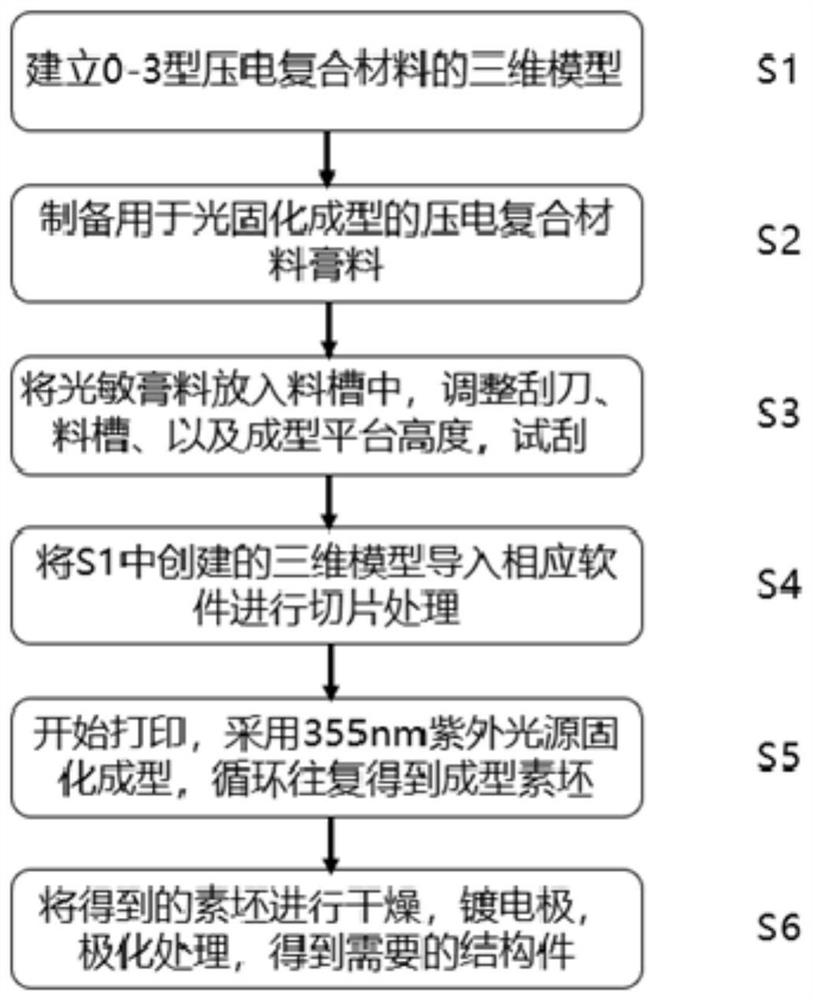

[0046] The first object of the present invention is to provide a method for preparing a high solid content 0-3 type piezoelectric composite material structure, comprising the following steps, such as figure 1 :

[0047] S1: Create a three-dimensional model of the corresponding structural part that needs to be formed;

[0048] S2: preparing piezoelectric composite material paste for photocuring molding;

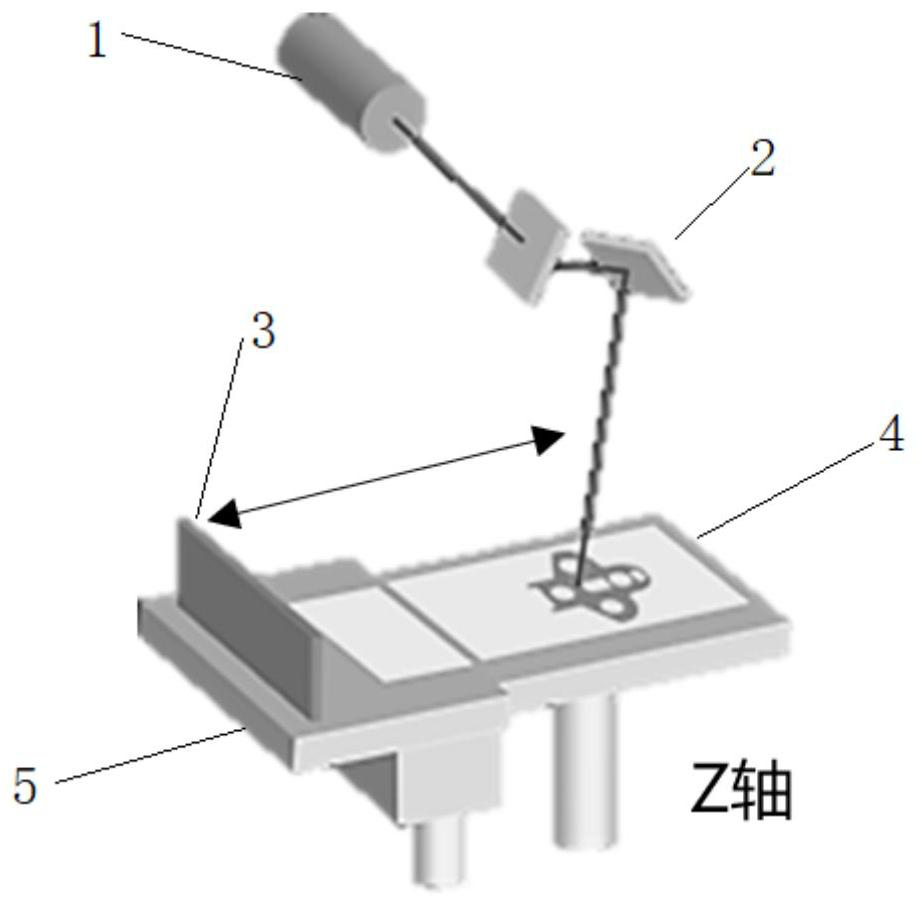

[0049] S3: Put the photosensitive paste prepared in S2 into the SLA printer hopper, adjust the height of the scraper, the hopper, and the forming platform according to the printing requirements, and carry out test scraping to ensure that the printing requirements are met;

[0050] S4: Import the 3D model created in S1 into the corresponding software for slicing processing;

[0051] S5: start printing, project the mask image of the two-dimensional cross-sectional slice of the three-dimensional model to the upper surface of the forming platform paste, and use a 355nm ultraviol...

Embodiment 1

[0077] S1: Establish a three-dimensional model of the 0-3 piezoelectric composite material;

[0078] S2: preparing piezoelectric composite material paste for photocuring molding;

[0079] Specific steps are as follows:

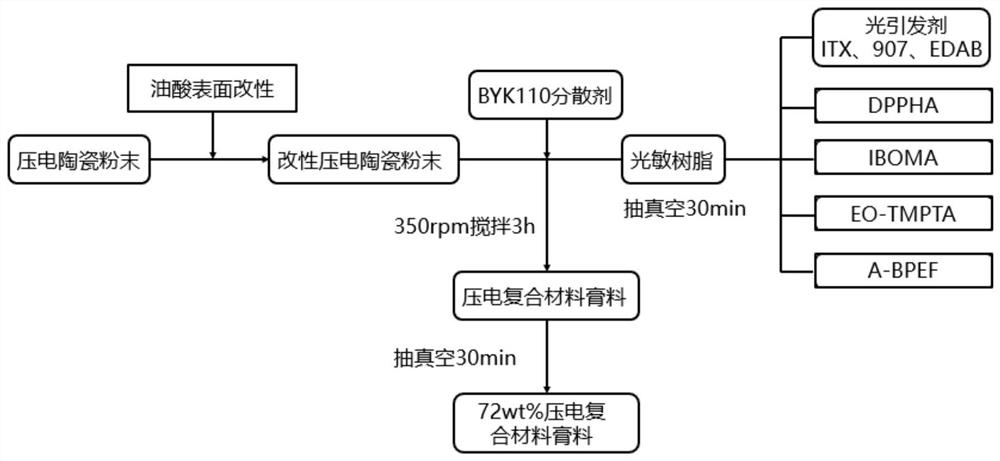

[0080] S21: Dry commercial PZT powder at 80°C for 12h to remove surface adsorbed water;

[0081] S22: Use oleic acid to modify the surface of the dried PZT powder: first prepare a mixed solution of deionized water and absolute ethanol with a mass ratio of 2:18; add piezoelectric ceramic powder and oil with a mass ratio of 20:1 acid, mixed in a Erlenmeyer flask, heated in a water bath at 65°C, magnetically stirred for 2 hours, washed with absolute ethanol for 3 times, centrifuged, and dried under vacuum at 100°C for 12 hours;

[0082] S23: uniformly mix the photosensitive resin and the photoinitiator with a mixer to obtain a uniform resin solution, and then vacuumize at room temperature for 0.5 h. Among them, the mass of photoinitiator accounts for 4wt% of t...

Embodiment 2

[0094] S1: Establish a three-dimensional model of the 0-3 piezoelectric composite material;

[0095] S2: preparing piezoelectric composite material paste for photocuring molding;

[0096] Specific steps are as follows:

[0097] S21: Dry commercial PZT powder at 80°C for 12h to remove surface adsorbed water;

[0098] S22: Use oleic acid to modify the surface of the dried PZT powder: first prepare a mixed solution of deionized water and absolute ethanol with a mass ratio of 2:18, and add piezoelectric ceramic powder and oil with a mass ratio of 20:1 acid, mixed in an Erlenmeyer flask, heated in a water bath at 75°C, magnetically stirred for 3 hours, washed three times with absolute ethanol, centrifuged, and dried under vacuum at 100°C for 12 hours;

[0099] S23: uniformly mix the photosensitive resin and the photoinitiator with a mixer to obtain a uniform resin solution, and then vacuumize at room temperature for 0.5 h. Among them, the mass of photoinitiator accounts for 3wt%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com