High anti-corrosion coating suitable for high-pressure airless spraying

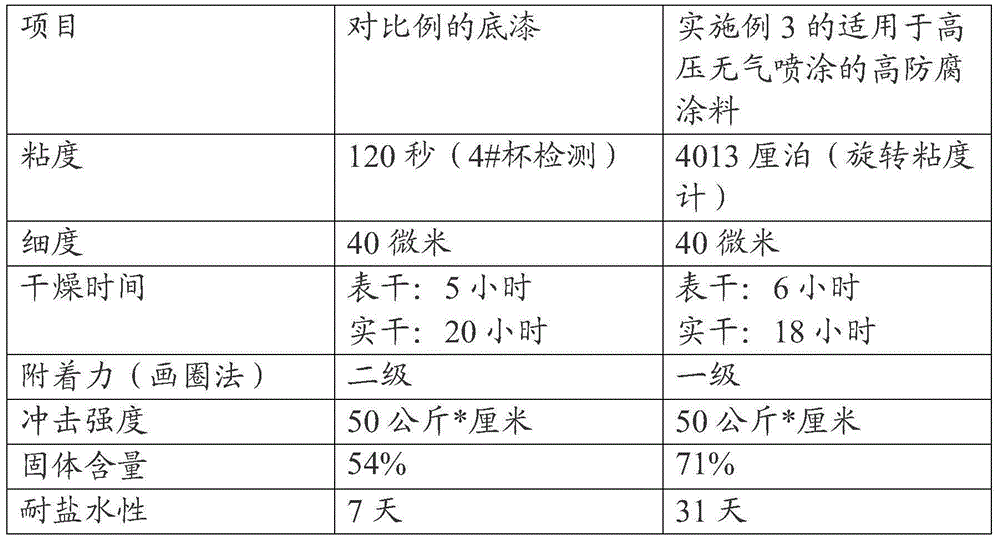

A high-pressure airless and anti-corrosion coating technology, applied in the field of coatings, can solve problems such as poor thixotropy, failure to satisfy customers, easy precipitation, agglomeration, etc., and achieve good thixotropy, chemical resistance and salt water resistance. good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of the above-mentioned high-corrosion coating suitable for high-pressure airless spraying comprises the following steps:

[0061] In parts by weight, add 18-22 parts of the first epoxy resin, 10-15 parts of magnet powder, 5-8 parts of iron oxide red and 0.1-0.2 parts of dispersant, stir until the fineness reaches 35 microns, and discharge, get the mixture;

[0062] Weighing xylene, and adding it into the mixture, under continuous stirring, adding 0.5-0.7 parts of modified bentonite, stirring evenly, adding ethanol, stirring into a paste, to obtain a paste;

[0063] Add 0.2-0.3 parts of additives, 0.2-0.4 parts of nano silicon dioxide, 18-24 parts of second epoxy resin, and 1-3 parts of diluent to the paste, and add 0.2-0.2- 0.5 parts of polyvinyl butyral resin are stirred evenly, and when the powder degree reaches a rotational viscosity of 4000 centipoise, the material is discharged to obtain component A;

[0064] Weigh 56-62 parts of the first ...

Embodiment 1

[0068] A high-corrosion coating suitable for high-pressure airless spraying, comprising component A and component B at a weight ratio of 5:1, and component A includes:

[0069] 18 parts of E44 resin (first epoxy resin), 18 parts of E20 resin (second epoxy resin) with a mass fraction of 60%, 10 parts of magnet powder, 2 parts of iron oxide red, 0.2 part of polyvinyl butyral resin , 0.1 parts of dispersant, 0.5 parts of R972 (nano silica), 0.5 parts of 881-B (modified bentonite), 0.2 parts of additives and 12 parts of diluent;

[0070] Component B includes:

[0071] Hexamethylenediamine (first amine curing agent) 56 parts, 651 polyamide (second amine curing agent) 12 parts, ethanol 20 parts.

[0072] The preparation method of the above-mentioned high-corrosion coating suitable for high-pressure airless spraying comprises the following steps:

[0073] In parts by weight, E44 resin, magnet powder, iron oxide red and dispersant are added, stirred until the fineness reaches 35 mic...

Embodiment 2

[0079] A high-corrosion coating suitable for high-pressure airless spraying, comprising component A and component B at a weight ratio of 5:1, and component A includes:

[0080] 22 parts of E44 resin (first epoxy resin), 24 parts of E20 resin (second epoxy resin) with a mass fraction of 60%, 15 parts of magnet powder, 10 parts of iron oxide red, 0.5 part of polyvinyl butyral resin , 0.2 parts of dispersant, 0.4 parts of R972 (nano silica), 0.7 parts of 881-B (modified bentonite), 0.3 parts of additives and 15 parts of diluent;

[0081] Component B includes:

[0082] Hexamethylenediamine (first amine curing agent) 62 parts, 651 polyamide (second amine curing agent) 18 parts, ethanol 30 parts.

[0083] The preparation method of the above-mentioned high-corrosion coating suitable for high-pressure airless spraying is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com