Boiler suitable for full load SCR denitration and working method

A full-load, denitration technology, applied in the field of boilers, can solve the problems of limited flue gas temperature, affecting boiler efficiency, insufficient fuel combustion, etc., to avoid low-temperature corrosion and ash blocking, ensure removal efficiency, and ensure heating temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

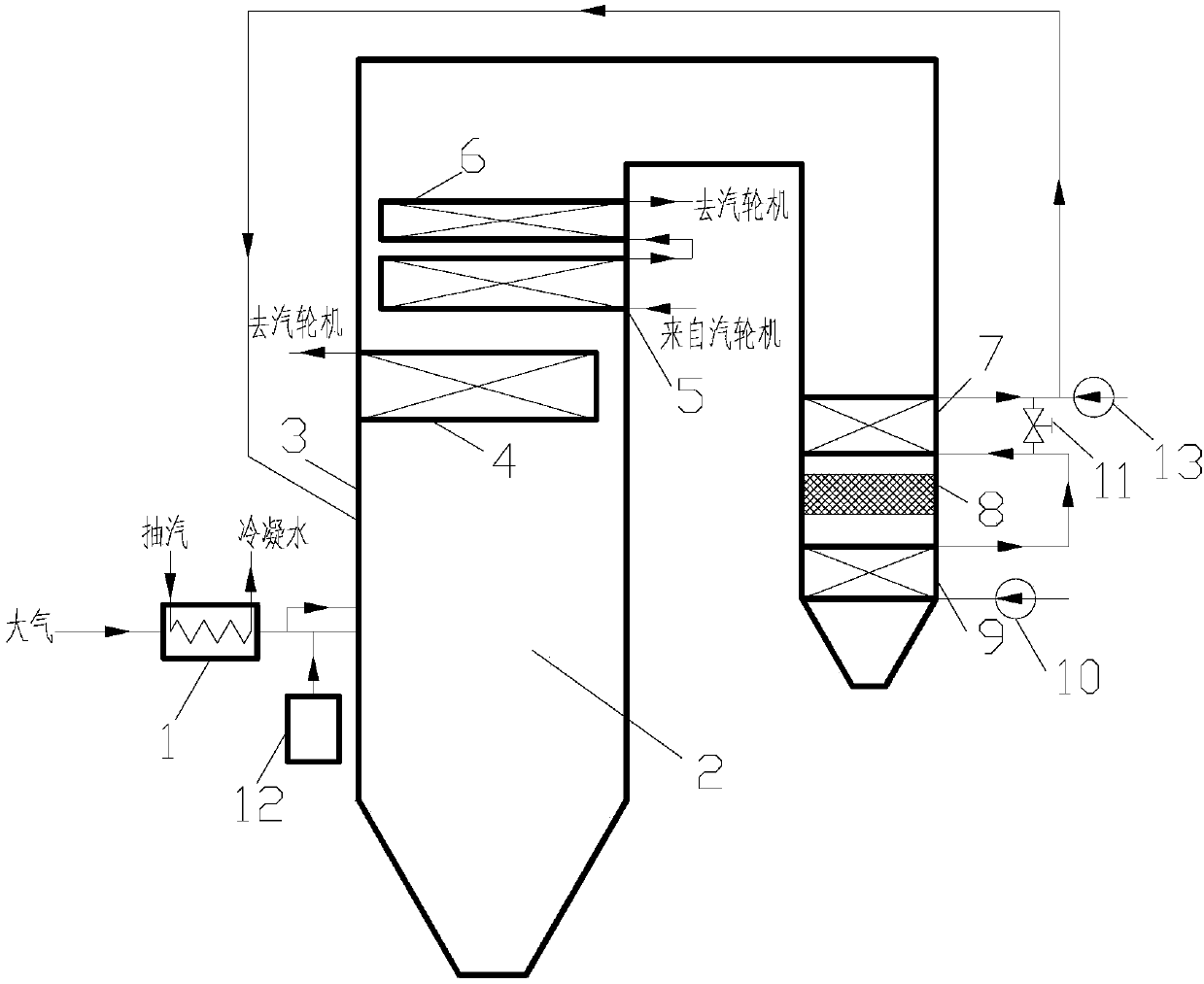

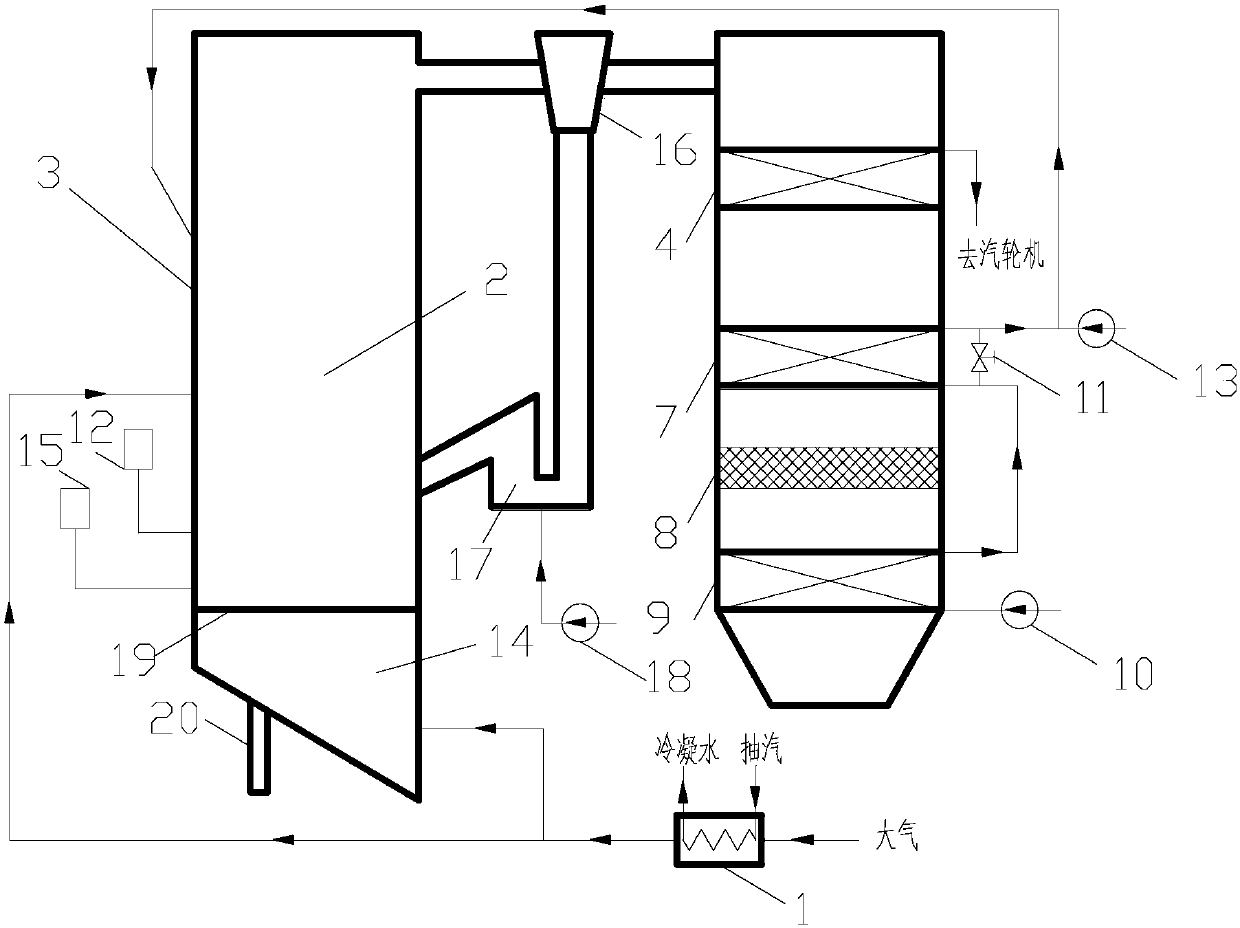

[0023] refer to figure 1 , a boiler suitable for full-load SCR denitrification, including extraction air heater 1, furnace 2, water wall 3, superheater 4, first reheater 5, second reheater 6, first flue gas condensate Heat exchanger 7 , SCR denitrification device 8 , second flue gas condensed water heat exchanger 9 , condensed water pump 10 , bypass valve 11 , fuel supply device 12 and feed water pump 13 .

[0024] The air is divided into two parts after being passed through the extraction air heater 1, one part is used as the primary air mixed with the fuel 12, and the other part is used as the secondary air, and the primary air enters the furnace 2 together with the fuel provided by the fuel supply device 12 and the secondary air; 2 and the boiler high-temperature flue gas section are provided with a water-cooled wall 3, a superhea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com