Flue gas purifying device for fixed-bed

A technology of flue gas purification and fixed bed, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of difficulty in meeting the use requirements, limited diameter of filter tubes, and increased operating costs. It is beneficial to adsorption. The effects of removal, narrow and uniform void distribution, and reduced equipment construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will now be described in detail in conjunction with the accompanying drawings and examples.

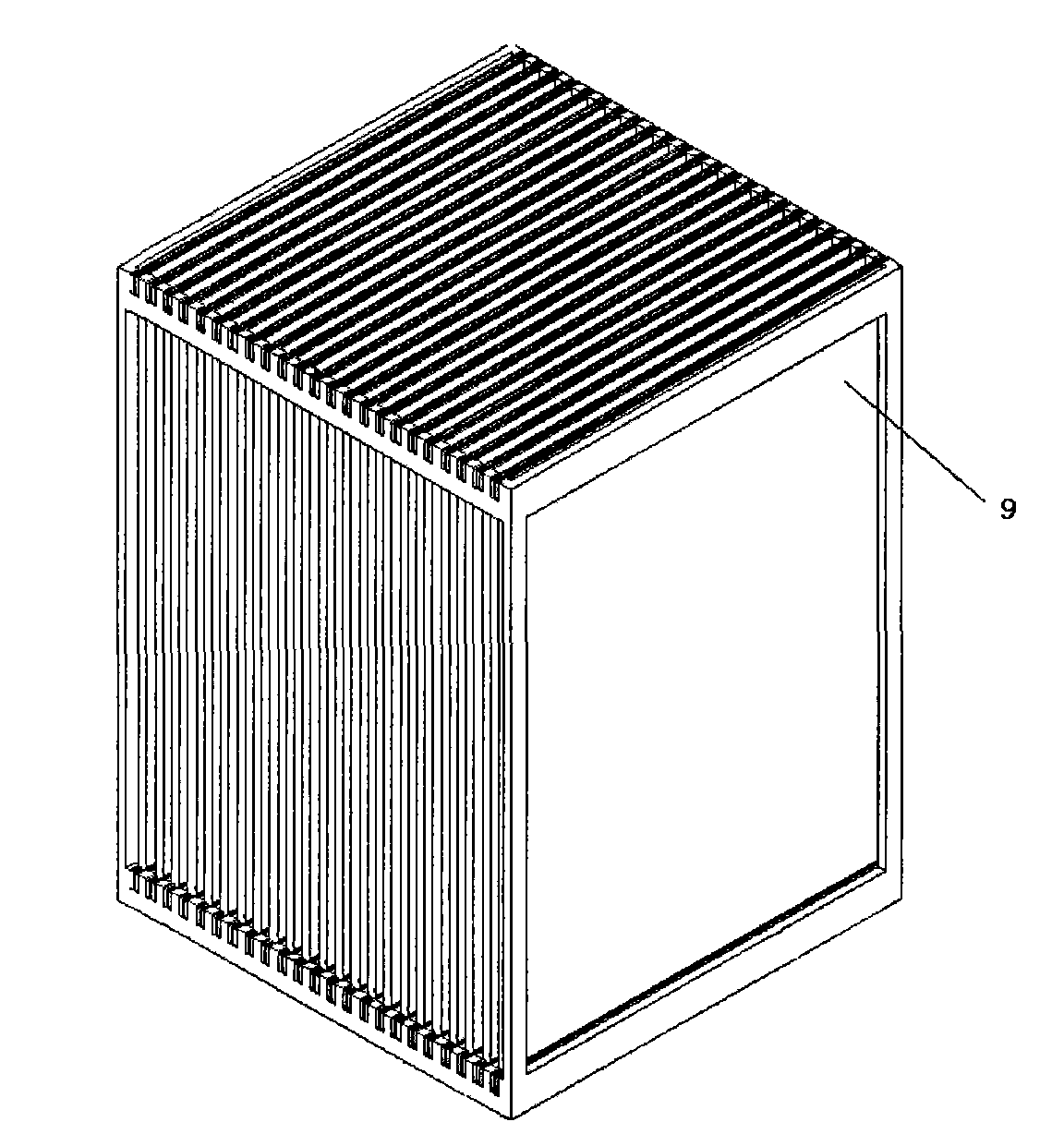

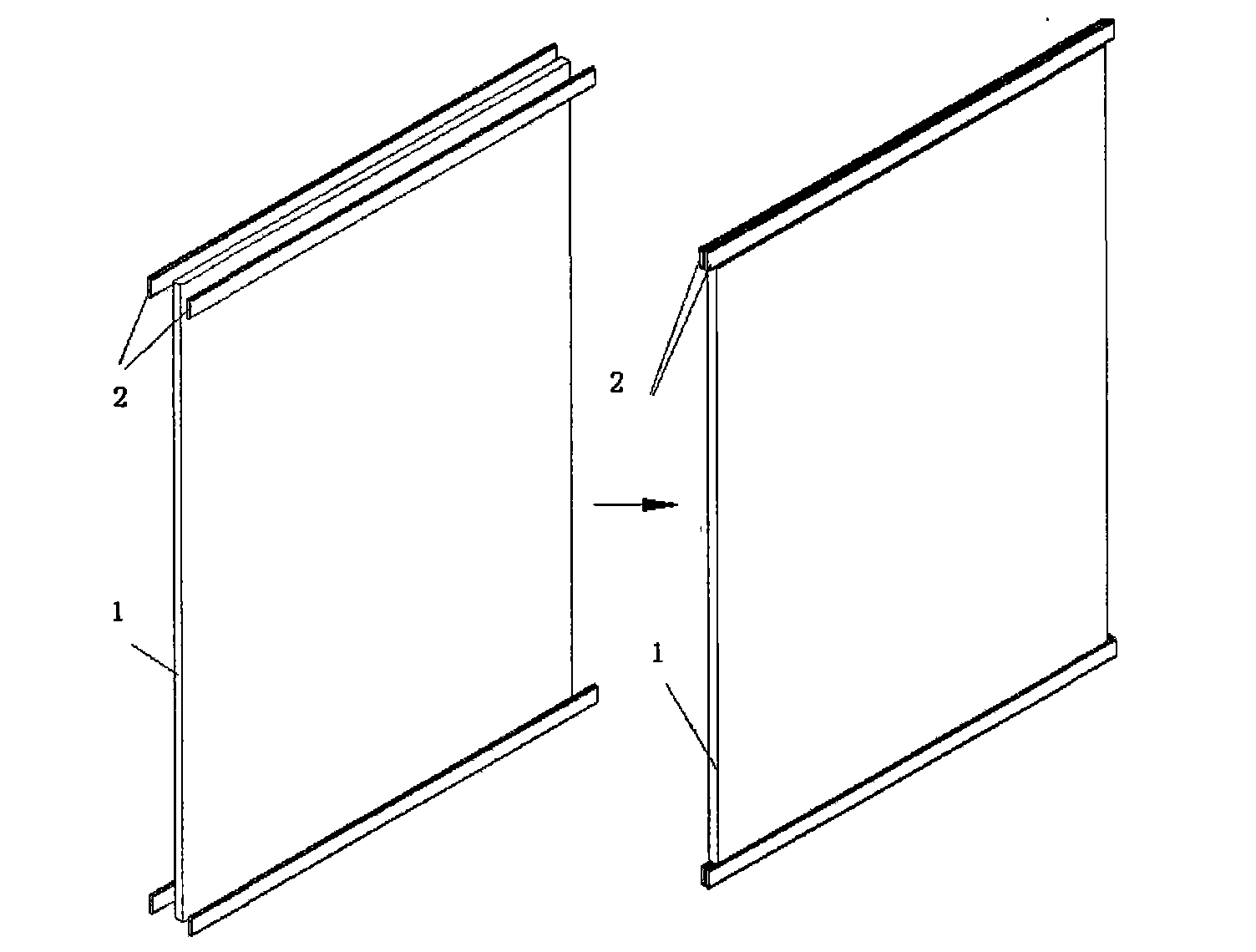

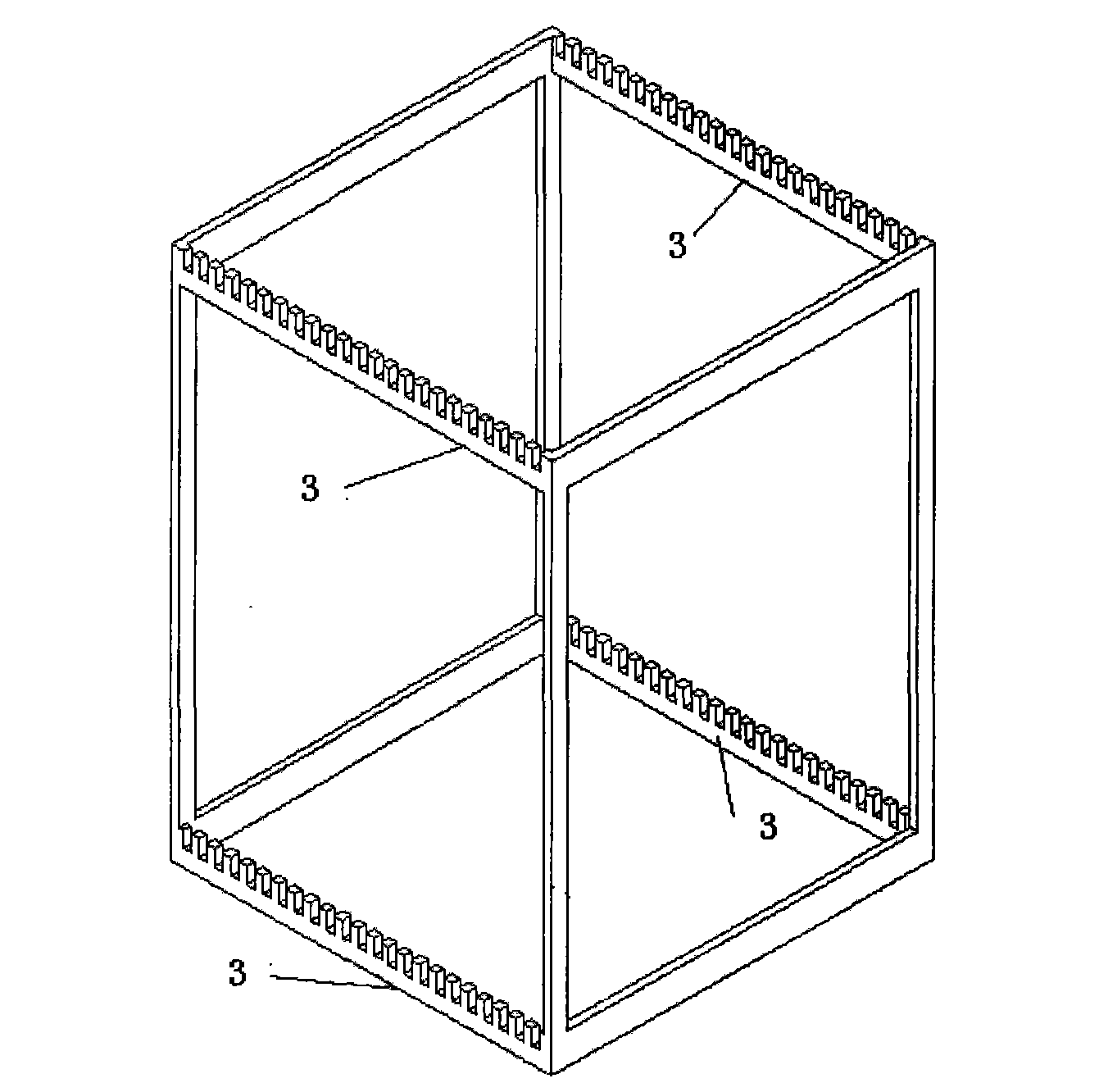

[0031] Such as Figure 1 to Figure 6As shown, the structure of the activated carbon fiber filling unit is as follows: the upper and lower ends of the fixed frame 7 respectively have two comb plates 3 parallel to each other, the comb plates have evenly distributed comb teeth 4, the comb teeth 4 on the comb plate 3 and the comb teeth 4 The gaps at port 5 are of the same size, evenly distributed, and aligned evenly. Cut the activated carbon fiber 1 into a regular sheet, then use the splint 2 to clamp its upper and lower ends, insert the upper and lower splint 2 of each fiber into the comb between the adjacent comb teeth 4 of the comb plate 3 on the fixed frame 7 In mouth 5, an interference fit is formed to clamp the two ends of the activated carbon fiber sheet firmly, and pull it up and down to keep it straight, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com