Patents

Literature

34results about How to "Uniform void distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing magnesium silicate porous ceramic

The invention discloses a method for preparing a magnesium silicate porous ceramic, relates to a porous ceramic, and provides a method for preparing the magnesium silicate porous ceramic with high porosity and strength, low thermal conductivity, easy method and low cost. The method comprises the following steps: calcining a MgO raw material to remove CO2 and water content, and drying SiO2; mixing magnesium oxide with the silicon dioxide, and performing ball milling on the mixture to obtain mixed powder of the magnesium oxide and the silicon dioxide; drying, screening, presintering, ball-milling, re-drying and re-screening the mixed powder of the magnesium oxide and the silicon dioxide to obtain magnesium silicate powder; mixing the magnesium silicate powder with premixed solution to prepare ceramic slurry, adding corn starch and a dispersant to the ceramic slurry and then performing ball milling on the mixture, adding a catalyst and an initiator to the mixture, and injecting the mixture into a mould after mixing to obtain a formed green body; and sintering the formed green body after demoulding to obtain the magnesium silicate porous ceramic.

Owner:XIAMEN UNIV

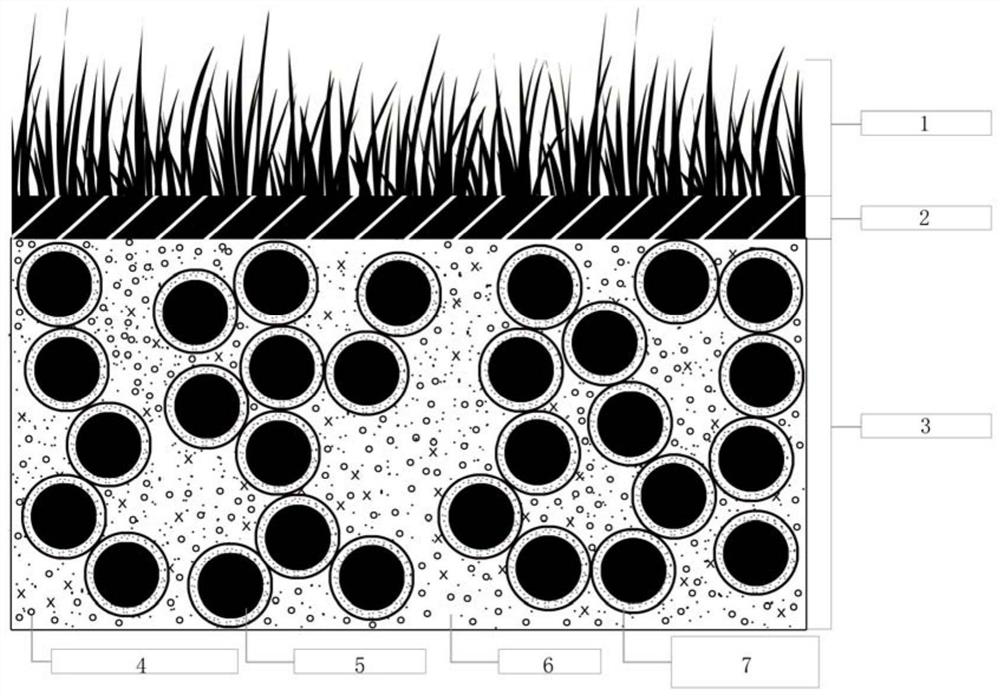

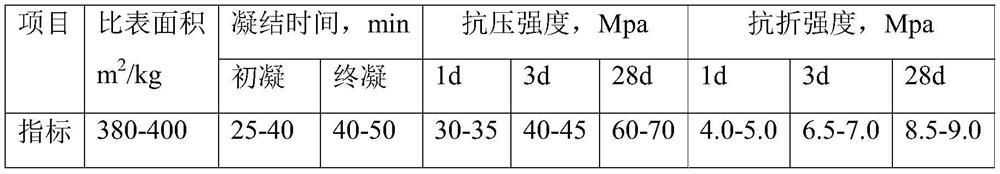

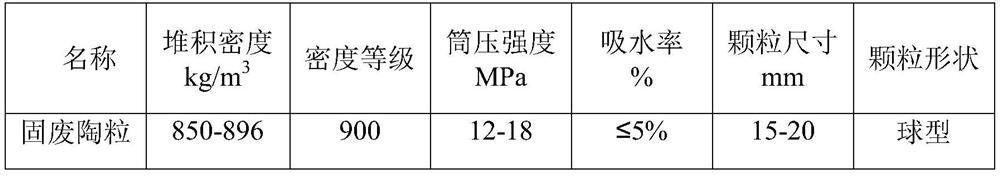

Low-alkalinity fertilizer efficiency slow-release ceramsite vegetation concrete and preparation method thereof

ActiveCN112079609ASuitable for growthLose weightSolid waste managementGrowth substratesAluminateVegetation

The invention belongs to the technical field of concrete, and particularly relates to low-alkalinity fertilizer efficiency slow-release ceramsite vegetation concrete and a preparation method thereof.The low-alkalinity fertilizer efficiency slow-release ceramsite vegetation concrete is prepared from the following raw materials in parts by weight: 90-130 parts of high-belite sulphoaluminate cement,45-60 parts of water, 250-320 parts of high-strength ceramsite, 1.2-2.0 parts of a water reducing agent, 25-40 parts of fly ash, 10-15 parts of silica fume, 3-5 parts of a slow-release full-nutrientfertilizer, 8-15 parts of pore filling soil and 8-15 parts of surface alien soil. The invention provides low-alkalinity fertilizer efficiency slow-release ceramsite vegetation concrete and a preparation method thereof. The fertilizer efficiency slow-release ceramsite vegetation concrete can meet the growth environment of plants, is beneficial to light weight of ecological concrete, utilizes solidwastes to a great extent, saves resources, can effectively reduce the environmental load, and can be coordinated with the ecological environment.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

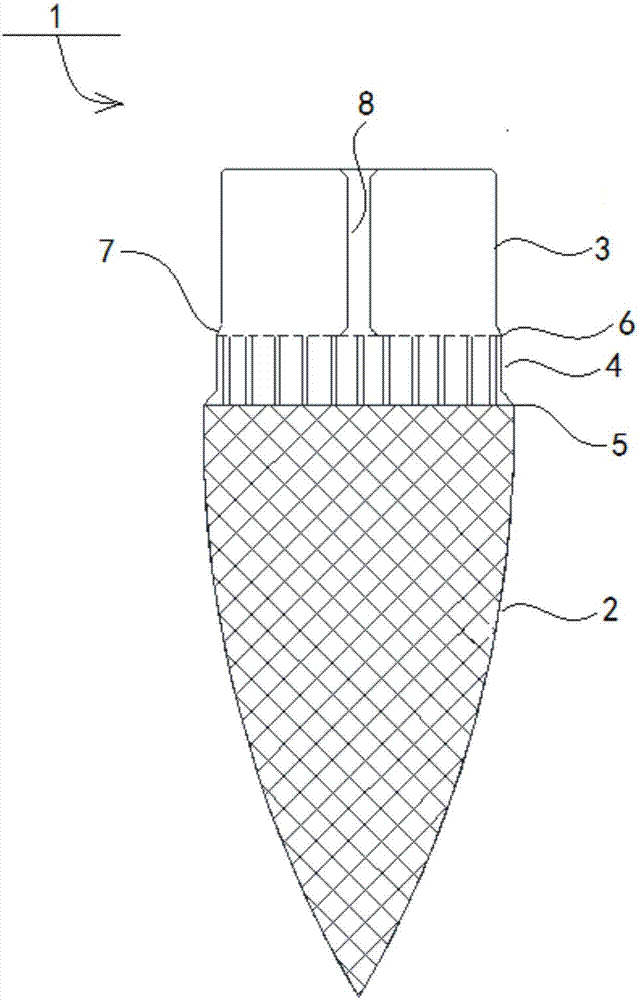

3D (three-dimensional) printing bionic dental implant and manufacturing method thereof

InactiveCN107260342AOvercoming difficulties in initial wound closureOvercome stabilityDental implantsAdditive manufacturing apparatusTooth neckDrug biological activity

The invention provides a 3D (three-dimensional) printing bionic dental implant and a manufacturing method thereof and belongs to the field of dental implants. Easy loosing and falling of an implant caused by relatively large difference between the elasticity modulus of the implant and the elasticity modulus of sclerotin can be avoided by the dental implant, the biological activity is relatively strong, and bone healing time can be greatly shortened. The 3D printing bionic dental implant comprises an implant body and also comprises a chitosan nanometer coating which is combined with the outer surface of the implant body into a whole. The implant body comprises a tooth neck base station and a tooth root which is positioned below the tooth neck base station and is integrally connected with the tooth neck base station, wherein the tooth root is of an all-layer three-dimensional network structure. The 3D printing bionic dental implant provided by the invention can be applied to immediate implantation of the dental implant.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

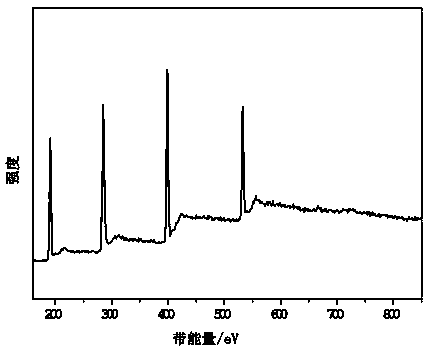

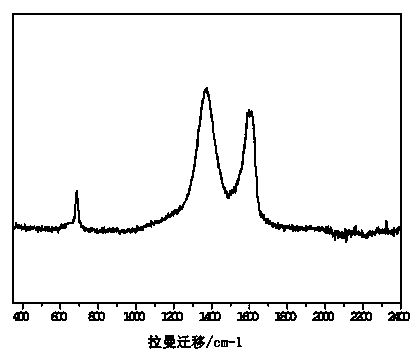

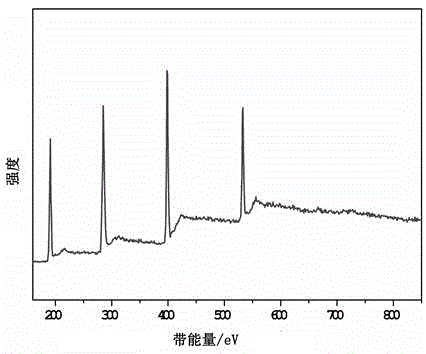

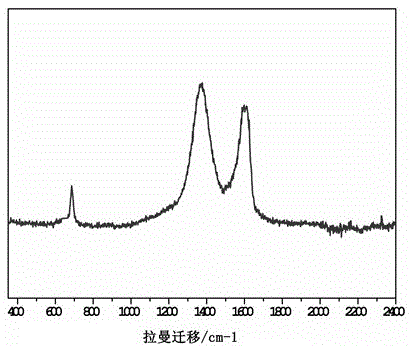

Doped carbon fiber net and preparation method thereof

The invention discloses a doped carbon fiber net and a preparation method of the doped carbon fiber net. The doped carbon fiber net is in a net-shaped structure formed by integrating carbon fibers, the carbon fiber has a doped element, the number of outermost electrons of the doped element is not 4, the doped carbon fiber net has the advantages of even distribution of gaps, and excellent overall integration property, electrical conductivity, plasticity and toughness, and the amount of the used carbon fibers is reduced greatly while the strength is guaranteed. The preparation method comprises the steps of preparing a polyacrylonitrile nanofiber or a polyacrylonitrile nanofiber membrane, carbonizing to obtain the carbon fiber or a carbon fiber membrane, doping at the high temperature, washing with acid to remove impurities or washing with alkaline to remove impurities, and the like. The preparation method has the advantages of simple preparation process, low cost, high easiness in operation and implementation, and the like, and precious metals and catalysts are not related.

Owner:CENT SOUTH UNIV

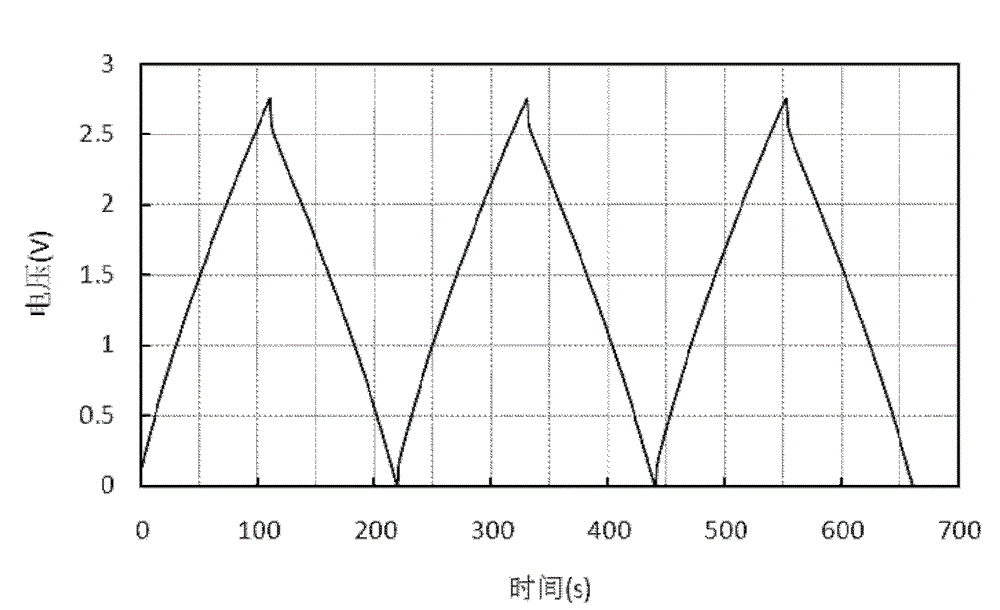

Preparation method and applications of electrode plate

The invention is suitable for the technical field of electronics and provides a preparation method and applications of an electrode plate. The preparation method of the electrode plate comprises the following steps: respectively providing active carbon, a conductive additive, carboxymethylcellulose and a binder; mixing the active carbon, the conductive additive and the carboxymethylcellulose to obtain a first mixture; mixing the binder with water to obtain a second mixture; under an agitating condition, mixing the first mixture with the second mixture, standing the mixtures for 2-8 hours, and drying, pressing and molding the electrode plate. According to the preparation method of the electrode plate, the carboxymethylcellulose (CMC) can enable the mixed size to form stable rubber mass by adding the carboxymethylcellulose, standing and emulsifying the carboxymethylcellulose; layering of the mixed size caused by different specific gravities of each constituent can be prevented; the distribution stability of each constituent in the size is kept, and the flexibility, the tensile strength, the absorbency and the electrical conductivity of the prepared electrode plate are also improved.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

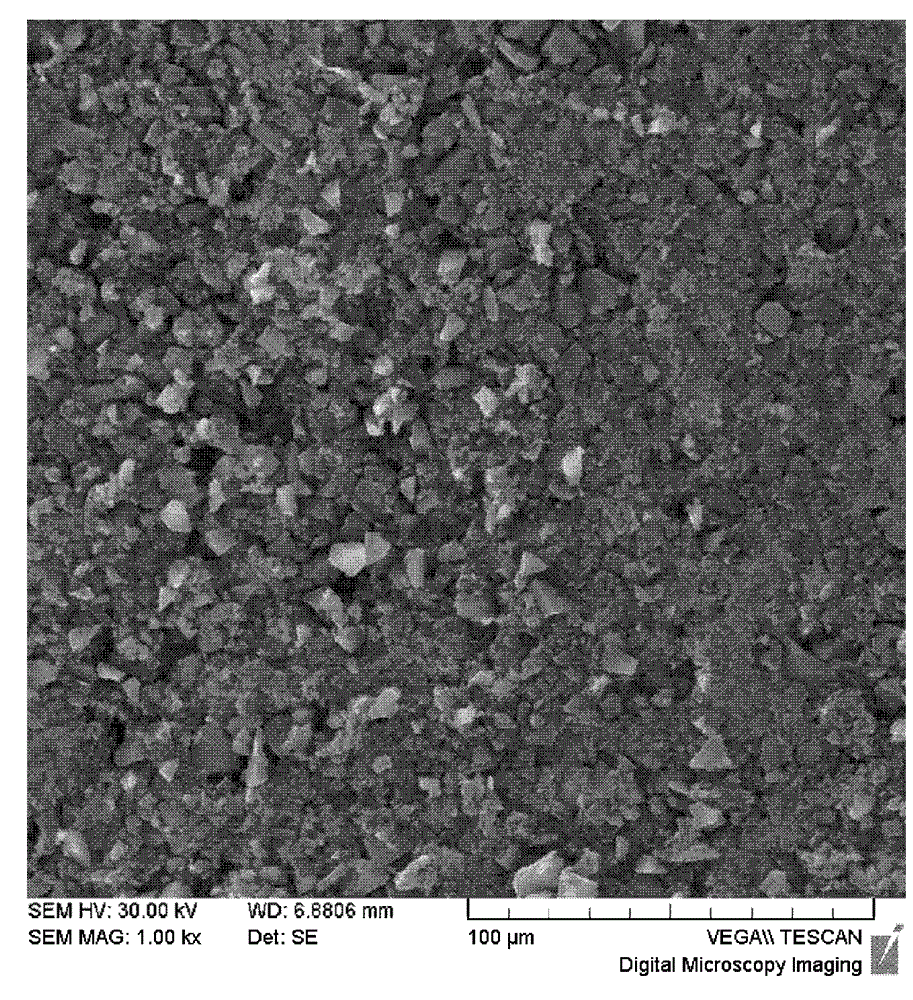

Glass polishing disk and manufacturing technique thereof

InactiveCN104759995ALong continuous grinding timeGrinding speed is fastAbrasion apparatusGrinding devicesSodium phosphatesMetallurgy

The invention discloses a glass polishing disk and a manufacturing technique thereof and belongs to the technical field of abrasive substance. The polishing disk comprises curing agent, pore forming agent, padding, initiating agent, cleaning agent and abrasive particles, the abrasive particles are Fe2O3 / SiO2 nanometer composite particles, and the padding comprises heat absorbent composed of sodium acetate trihydrate and sodium phosphate dibasic dodecahydrate. The manufacturing technique includes steps that 1, adding initiating agent-cobalt naphthenate, pore forming agent and heat absorbent to the curing agent; 2, adding the abrasive particles, initiating agent-cyclohexanone peroxied and cleaning agent; 3, pouring mixed slurry into a die, curing, and slicking the slurry. According to the glass polishing disk, the gap distribution in the polishing disk is uniform, the abrasive particle distribution is uniform, the workpiece polishing precision is high, the raw material cost is low, and the production technique is simple.

Owner:ANYANG INST OF TECH

Preparing method for wave-transparent closed-cell beryllium-containing silicon carbide foamed ceramic

ActiveCN105254304ALow dielectric lossSolve the problem of anisotropyCeramicwareRoom temperatureMechanical property

The invention relates to a preparing method for wave-transparent closed-cell beryllium-containing silicon carbide foamed ceramic, and belongs to the field of preparing special functional materials. The preparing method includes the steps that beryllium-containing polycarbosilane powder is used as a precursor of the beryllium-containing silicon carbide foamed ceramic and is evenly mixed with polyalcohol, a catalyst and the like at a certain ratio, then isocyanate is added, the mixture is fully stirred, injected into a mold, foamed and cured at the room temperature, and a finished product is obtained through pre-oxidation and ceramization treatment. The preparing method is simple in process, and the obtained product is high in wave-transparent performance and heat insulation performance and excellent in mechanical property.

Owner:CENT SOUTH UNIV

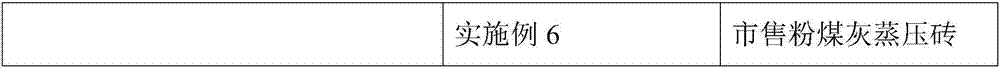

Preparation method of anti-compression autoclaved brick

The invention discloses a preparation method of an anti-compression autoclaved brick. The preparation method comprises the following steps: mixing chlorinated polyethylene glycol 400 and beta-cyclodextrin, carrying out ultrasonic dispersion, adding sodium hydroxide and sodium dodecyl benzene sulfonate under heating, stirring under the protection of nitrogen, cooling, adjusting the pH value of the system to the neutral region to obtain a prefabricated material; evenly mixing the prefabricated material, fly ash, cement, and water, adding limestone, a water reducer, and a curing agent, evenly mixing, pressing and moulding the mixture to obtain a blank; delivering the blank to an autoclaving chamber, and carrying out curing to obtain the autoclaved brick. Fly ash is taken as the raw material to prepare the autoclaved brick; a large amount of cultivated land is saved, the water pollution and air pollution are reduced, fly ash is converted into valuable resources and effectively recovered; moreover, the manufacturing cost is low, the loss of die is little, the anti-compression strength is high, and the structure is stable and is difficult to destroy.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

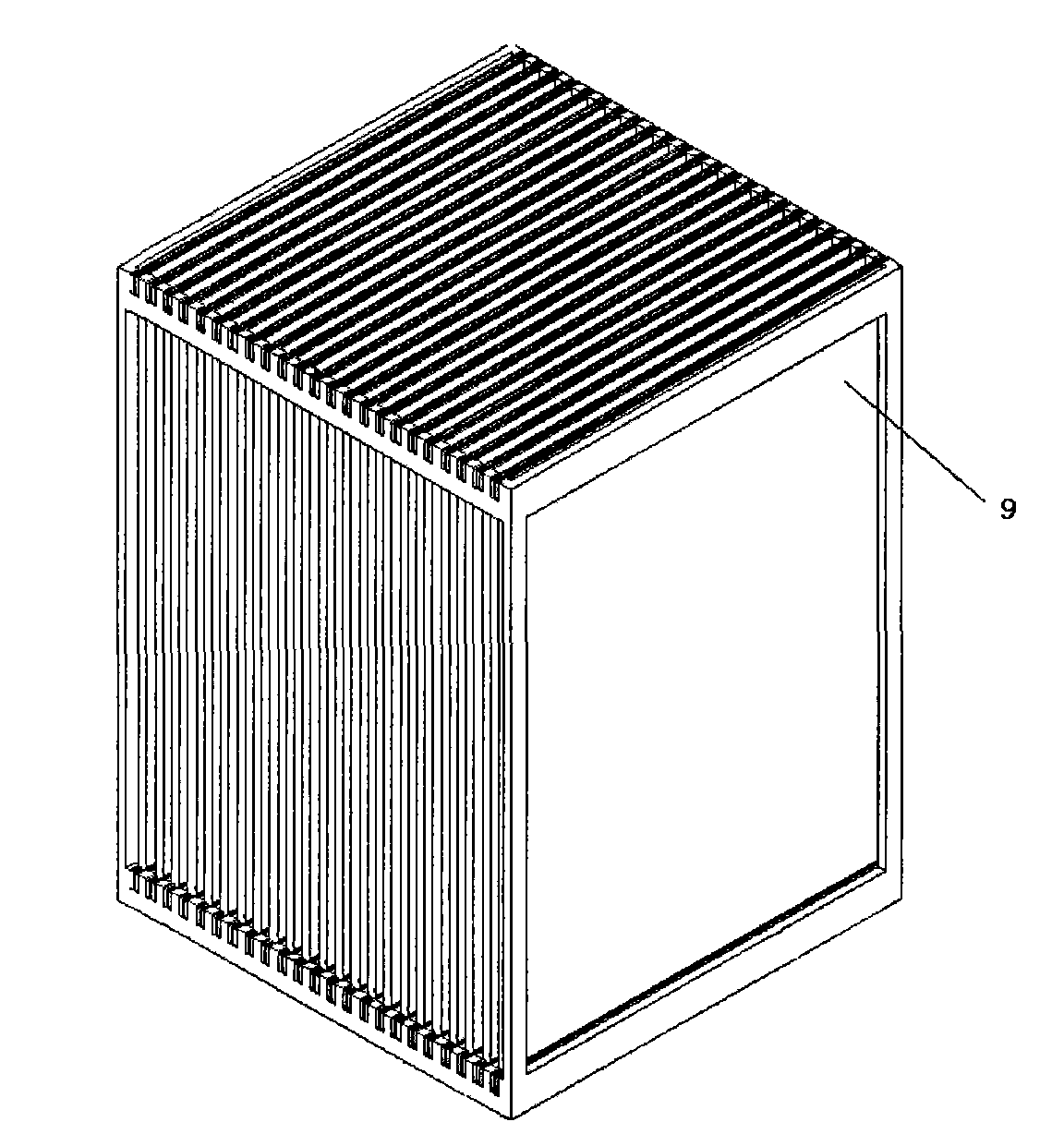

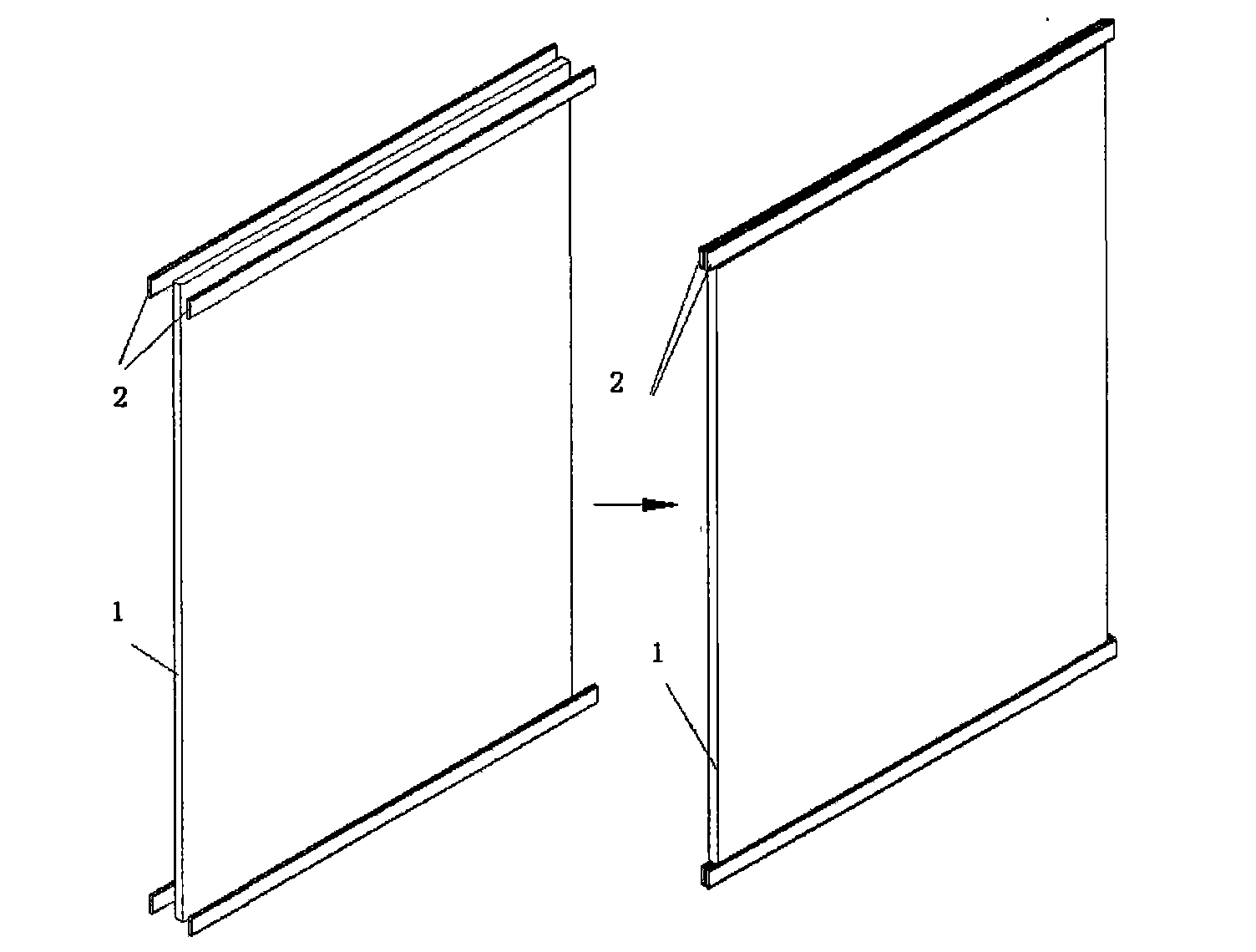

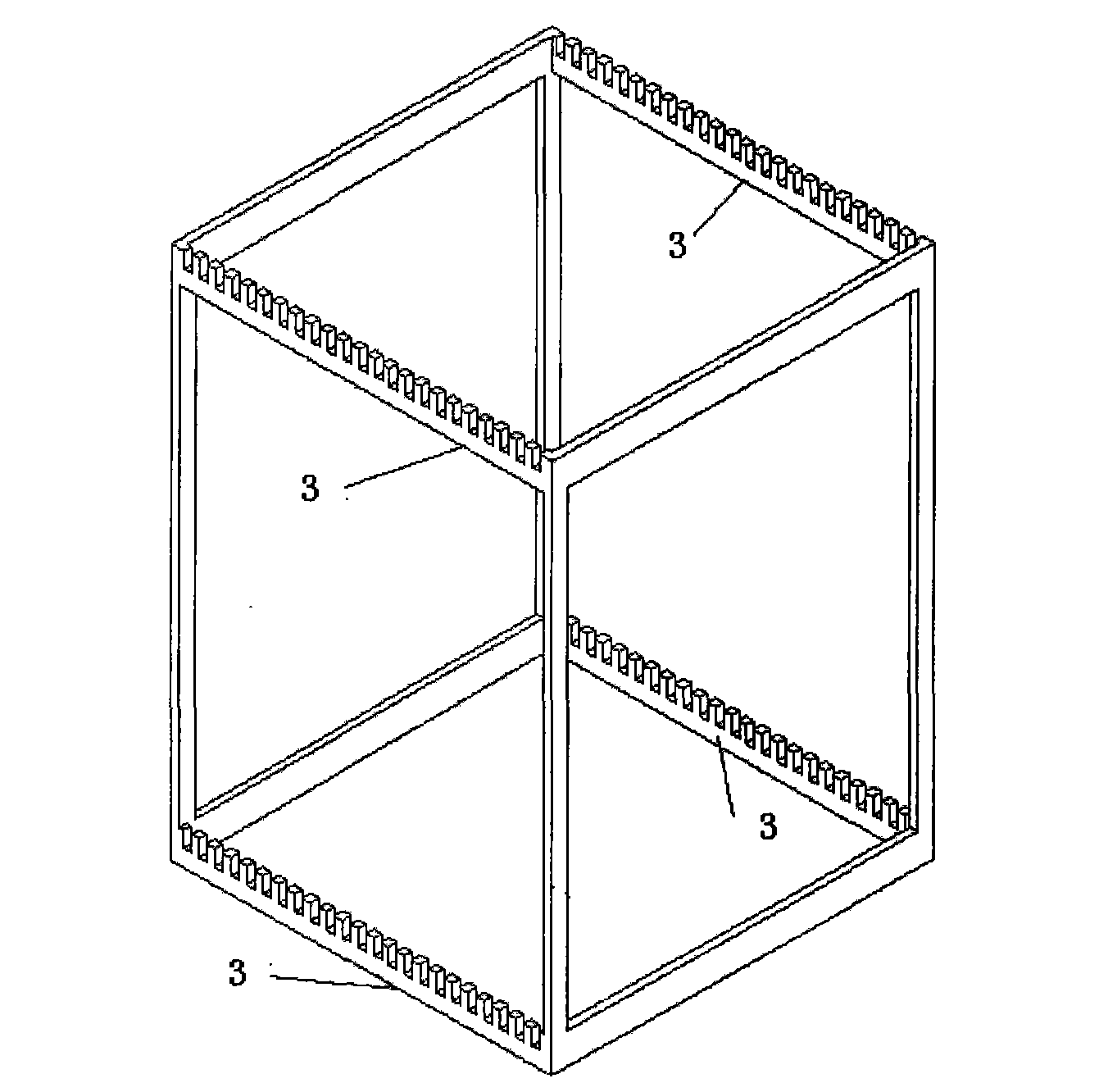

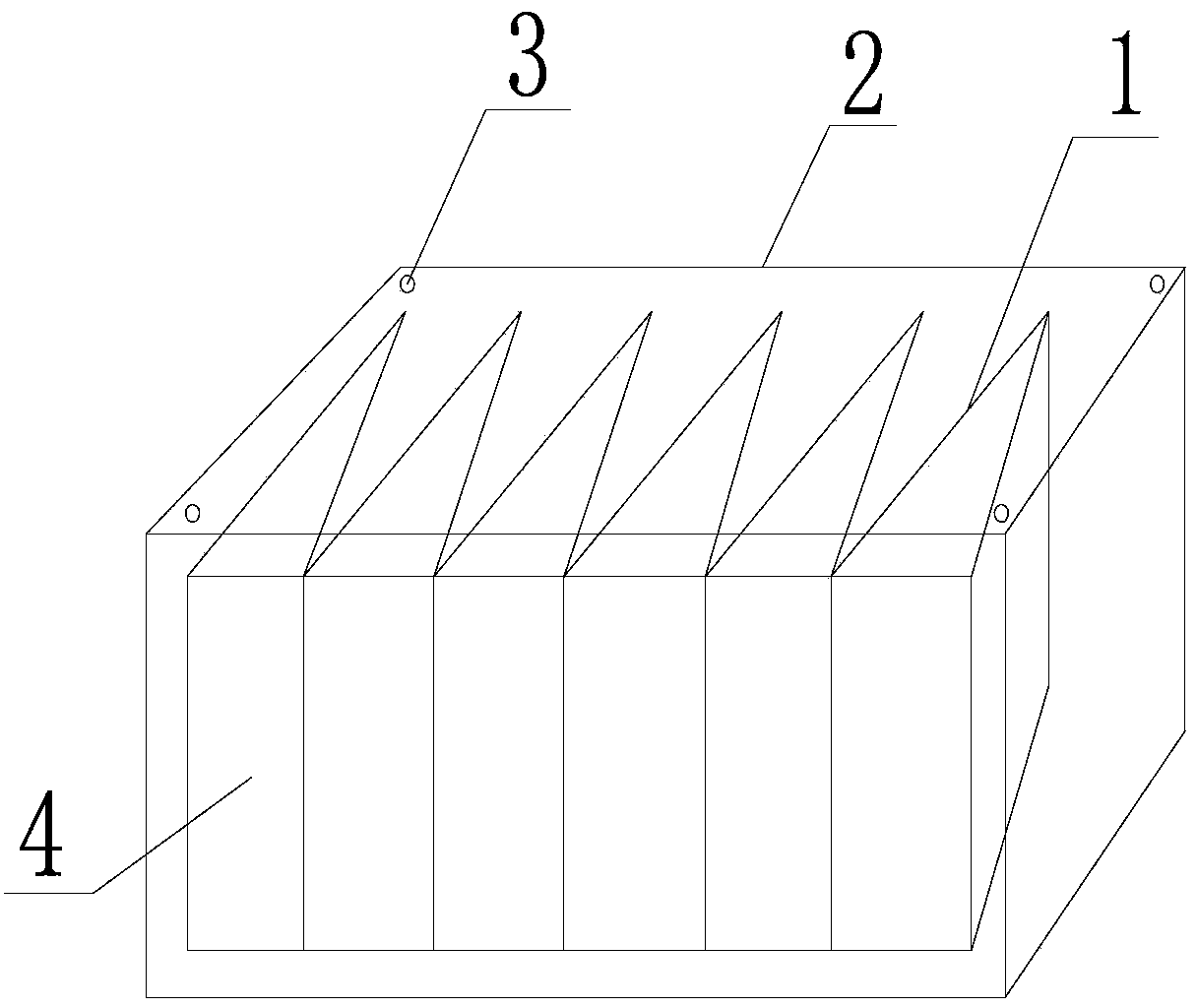

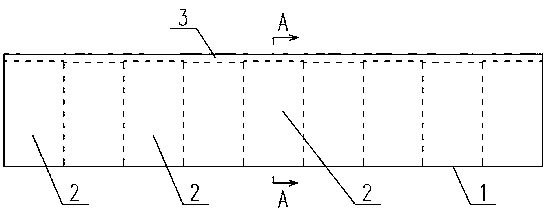

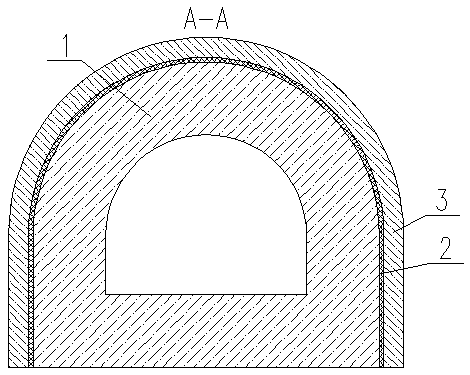

Flue gas purifying device for fixed-bed

The invention discloses a flue gas purifying device for a fixed-bed, which is filled with activated carbon fiber. The top part of a shell of the device is provided with an exhaust inlet and the bottompart is provided with an air outlet; the inner cavity of the shell is divided into a diversion section, a purification section and an air collection section from top to bottom; the diversion sectionis provided with a plate rectifier with holes and a diversion plate is arranged on the plate rectifier; and the purification section is provided with an activated carbon fiber filling cell. The upperend and the lower end of a fixed frame of the activated carbon fiber filling cell are provided with two parallel comb plates respectively; upper clamping plates and lower clamping plates are respectively inserted in various comb openings of the upper comb plate and the lower comb plate; sheet-shaped activated carbon fibers are fixed between the upper clamping plates and between the lower clampingplates; and the width of the spacing between the adjacent two activated carbon fibers is between 0.5 mm and 10 mm. In the invention, the activated carbon fiber can be tightly, reliably and fixedly installed in the purifying device for a long time. The device has the advantages of compact structure, high filling efficient of activated carbon fiber, low consumption of a reactor, convenient repair, installation, replacement and reproduction and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

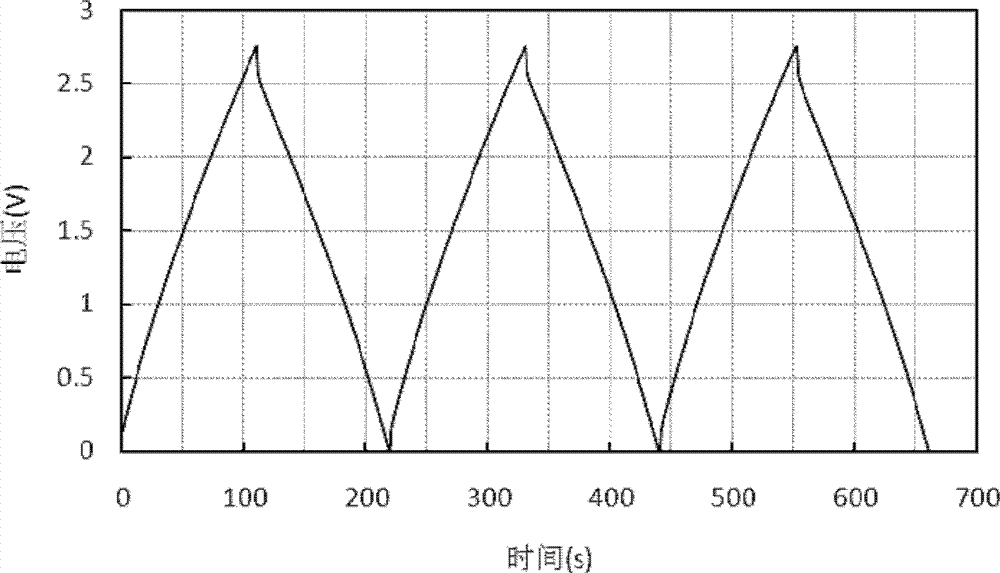

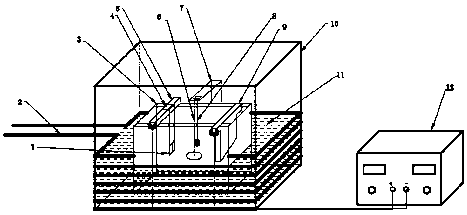

Aluminum alloy hard anodic oxidation device and method

PendingCN110724993ATimely heat dissipation and coolingEliminate adverse effects on performanceCellsTanksTemperature controlControl system

The invention discloses an aluminum alloy hard anodic oxidation device and method. The aluminum alloy hard anodic oxidation device comprises a temperature control and heat preservation system, an anode oxidation system, an auxiliary control system and a power supply. The temperature control and heat preservation system comprises a vacuum heat preservation container provided with a cooling medium.A cooling copper pipe is arranged in the vacuum heat preservation container. The anode oxidation system is arranged in the vacuum heat preservation container. An anodic oxidation device comprises an electrolytic cell. A cathode plate and an anode hanging tool are arranged in the electrolytic cell. The auxiliary control system is arranged between the cathode plate and the anode hanging tool and comprises an L-shaped supporting frame. The L-shaped supporting frame comprises a vertical plate and a transverse plate which are perpendicular to each other. The vertical plate is fixed to the electrolytic cell. A stirring device and a temperature sensor are mounted on the transverse plate. The power supply is an adjustable constant-current constant-voltage power supply. The aluminum alloy hard anodic oxidation device and method can be used for timely heat dissipation and cooling during anodic oxidation and reducing adverse effects of high temperature on the performance of an oxidation film in the anodic oxidation process.

Owner:HUNAN UNIV OF TECH

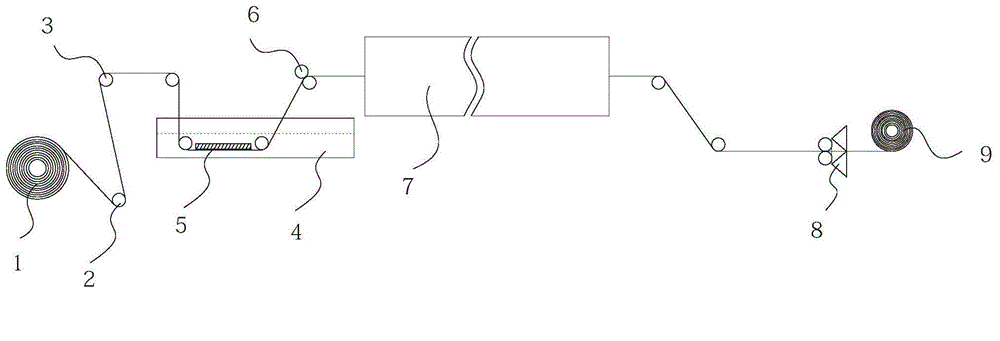

Novel production device for generator corona-proof belt

InactiveCN104410192ASimple and fast operationReduce manufacturing costSucessive textile treatmentsWindings insulation shape/form/constructionPulp and paper industryCorona

The invention discloses a novel production device for a generator corona-proof belt. The novel production device comprises a feeding device, a dipping groove, a milling device, a drying device, a cutting device and a rolling device. Grey cloth after pull is dipped and is then cut and subpackaged after milling and drying. The novel production device is advantaged in that, (1), the grey cloth after pull is dipped, textures and gaps are uniformly distributed, thickness of the corona-proof belt after dipping, drying and molding is uniform, after wrapping, the surface of workpieces has no obvious unevenness; (2), the grey cloth can be cut and subpackaged after drying, and secondary processing process is avoided; the grey cloth can be driven to realize circulation through two power motors till the grey cloth is subpackaged into finished products; (3), the novel production device is simple and convenient to operate, realizes energy saving and high efficiency, reduces production cost and is suitable for industrialized mass production.

Owner:天津玉华绝缘材料有限公司

Method for preparing porous alumina ceramic by gel casting method

The invention discloses a method for preparing porous alumina ceramic by a gel casting method. The method comprises the following steps: adding aluminum isopropoxide into isopropanol, and uniformly stirring to form a dissolving solution; spraying distilled water into the dissolved solution, and carrying out ultrasonic reaction to obtain an emulsion; adding polyvinyl alcohol into distilled water, uniformly stirring, then adding hyaluronic acid and high-substituted hydroxy propyl cellulose, carrying out constant-temperature ultrasonic treatment, and cooling to obtain a gel solution; dropwise adding the gel liquid into the emulsion, carrying out microwave reaction and heating treatment to form a suspended dispersion liquid, and then carrying out distillation treatment to obtain viscous slurry; and transferring the viscous slurry into a grinding mold, slowly heating, carrying out heat preservation treatment, cooling, demolding to obtain a biscuit, and sintering the biscuit to obtain the porous alumina ceramic. According to the preparation method, the defects of the existing aluminum oxide ceramic are overcome, aluminum isopropoxide is used as an aluminum source to form an emulsion of aluminum hydroxide as a precipitate and an aluminum isopropoxide liquid film, and a porous ceramic structure is formed through a gel system, so that the connectivity and the overall firmness of the aluminum oxide ceramic are greatly improved.

Owner:无锡特科精细陶瓷有限公司

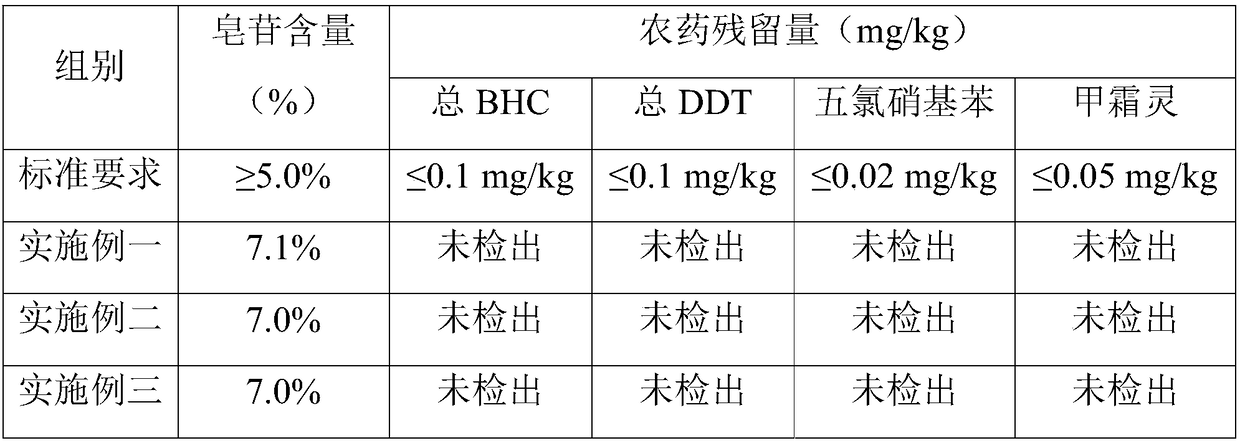

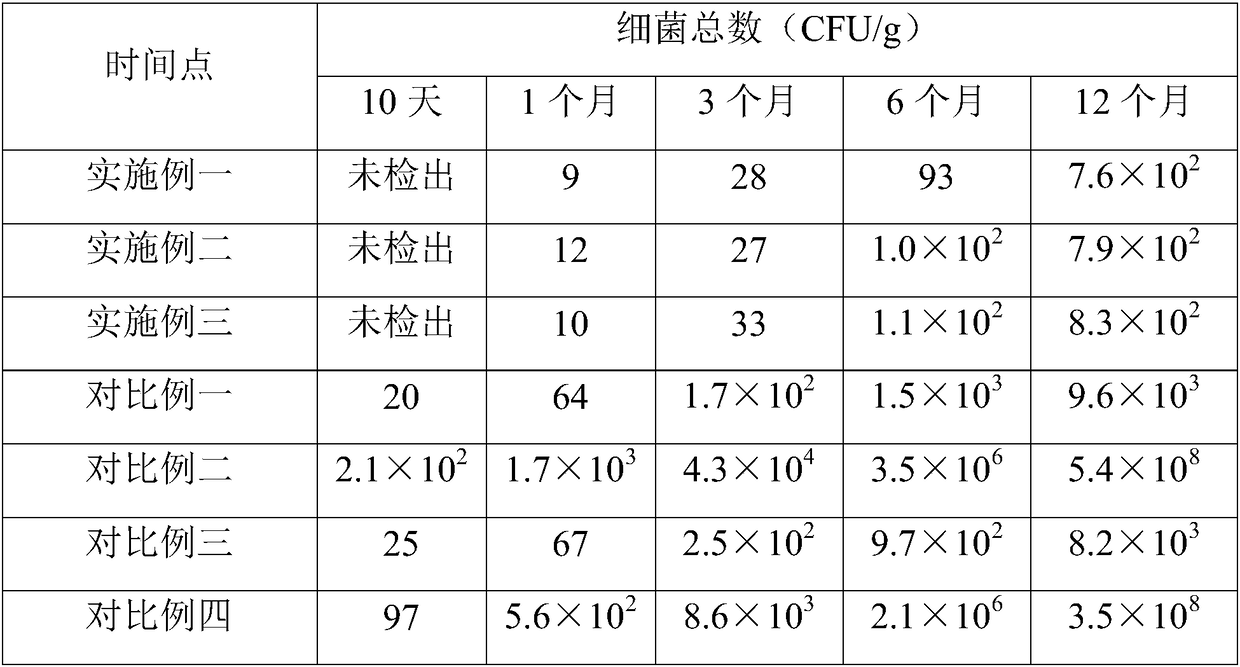

Fresh pseudo-ginseng freeze-drying processing method and product thereof

InactiveCN108578455AFull effectAvoid destructionDrying solid materials without heatPlant ingredientsActive componentFreeze-drying

The invention relates to a fresh pseudo-ginseng freeze-drying processing method and a product thereof. The method comprises the following steps: cleaning fresh pseudo-ginseng roots and removing attachments on the surface, and then draining moisture; performing refrigeration on the pseudo-ginseng roots after the moisture is drained; and performing freeze drying on the pseudo-ginseng roots after freezing to obtain the freeze-dried pseudo-ginseng. The freeze-drying processing method can avoid the destroy on pseudo-ginseng active component and mouthfeel due to long-time heating and drying, and cangreatly keep the natural and original fresh degree, color, flavor and nutrient composition of the pseudo-ginseng; the prepared freeze-drying pseudo-ginseng presents a porous loosening structure, thegap distribution is uniform, the reconstitution property is good, and the active component can be easily dissolved in water.

Owner:云南金不换生物科技有限责任公司

Method for preparing a hollow cement product based on superabsorbent resin

InactiveCN109235172ALow costDensity can be adjustedIn situ pavingsPaving gutters/kerbsPolymer scienceProduct base

The invention discloses a method for preparing a hollow cement product based on a superabsorbent resin, which comprises the following steps: S1, taking a certain amount of superabsorbent polymer resinin a certain form to fully absorb water and expand into a corresponding solid hydrogel; S2, taking a certain amount of superabsorbent polymer resin in a certain form to fully absorb water and expandinto a corresponding solid hydrogel; S2, according to the mass ratio of the obtained solid hydrogel to cement is 1: 0.2-10, adding proper amount of water to adjust the consistency of the cement to obtain hydrogel cement; S3, adding the obtained hydrogel cement into any mould, solidifying, dismantling the mould, and leaving a large number of pores inside the cement after the hydrogel inside the cement is completely dehydrated, thereby obtaining a hollow cement product. As that proces of the invention does not nee professional production equipment, the cost is low; the density, size and shape ofthe pores in cement can be controlled, and the voids are evenly distributed.

Owner:LESHAN NORMAL UNIV

Porous ceramics

The invention discloses porous ceramics. The porous ceramics comprise, by weight, 6-10 parts of yttria, 1-3 parts of alkyl glucoside, 0.5-2 parts of sodium methallyl sulfonate, 2-6 parts of niobium pentoxide, 4-9 parts of antimony trioxide, 16-22 parts of zirconium dioxide, 5-7 parts of zinc oxide, 3-6 parts of polyester fibers, 3.6-7.4 parts of binders, 1-3 parts of triton, 4-9 parts of silicone resin polyether emulsion, 6-9 parts of sodium-potassium feldspar, 8-10 parts of aluminum hydroxide micro-powder, 1.5-3 parts of clay, 10-24 parts of porous ceramsite and 20-36 parts of emery. The porous ceramics have the advantages that gaps are uniformly reserved in the porous ceramics, the porous ceramics are in appropriate shapes, have appropriate sizes and can be used for diversified filter components, and good effects can be realized by the porous ceramics; the porous ceramics are high in mechanical strength.

Owner:青岛特澳能源检测有限公司

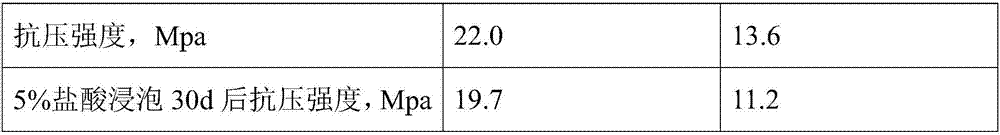

Hydraulic high-performance concrete and preparation method thereof

The invention discloses hydraulic high-performance concrete, and belongs to the technical field of concrete. The concrete is prepared from the following components: a fine aggregate, coarse aggregate,cement, slag, fly ash, silica fume, a water reducing agent, water, superfine natural zeolite powder, gypsum, a polymer emulsion, a dihydric alcohol compound, modified lignosulfonate, a lamellar silicate mineral material, polysiloxane, oxalic acid, a styrene-acrylic emulsion, a crystalline hydrated magnesium aluminosilicate mineral, a reinforcing agent, an air entraining agent, steel fibers, tert-butyl peroxypivalate, nano montmorillonite and an ettringite-lime composite expanding agent, wherein the dosage ratio of the tert-butyl peroxyvalerate to the nano montmorillonite to the ettringite-lime composite expanding agent is (0.4-0.8): (2-4): (0.5-0.8). According to the invention, a reinforcing system composed of the tert-butyl peroxypivalate, the nano montmorillonite and the ettringite-limecomposite expanding agent is adopted in the hydraulic high-performance concrete disclosed by the invention, so that the anti-freezing performance of the hydraulic high-performance concrete is improved.

Owner:JIANGSU PROVINCE WATER ENG SCI TECH CONSULTING

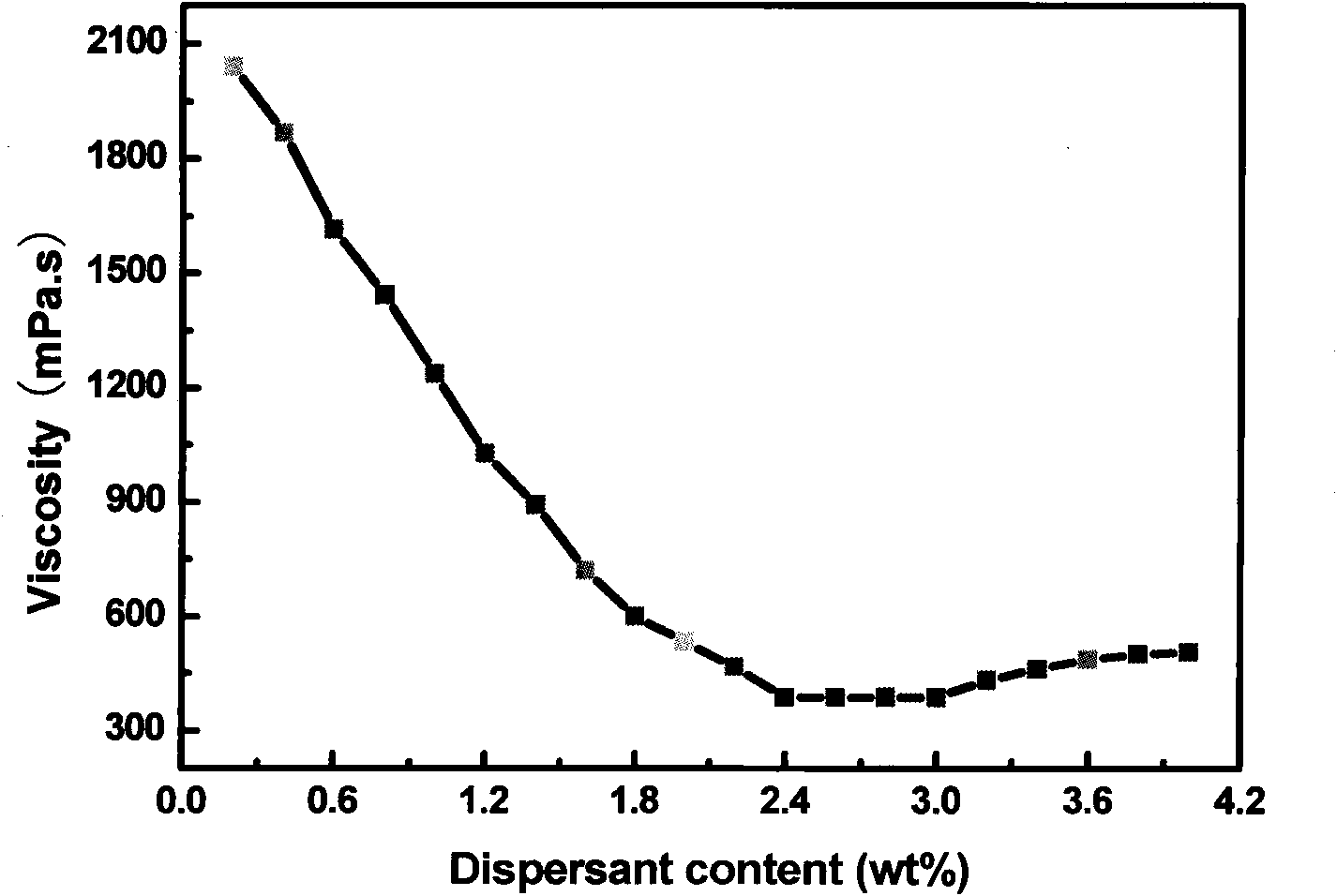

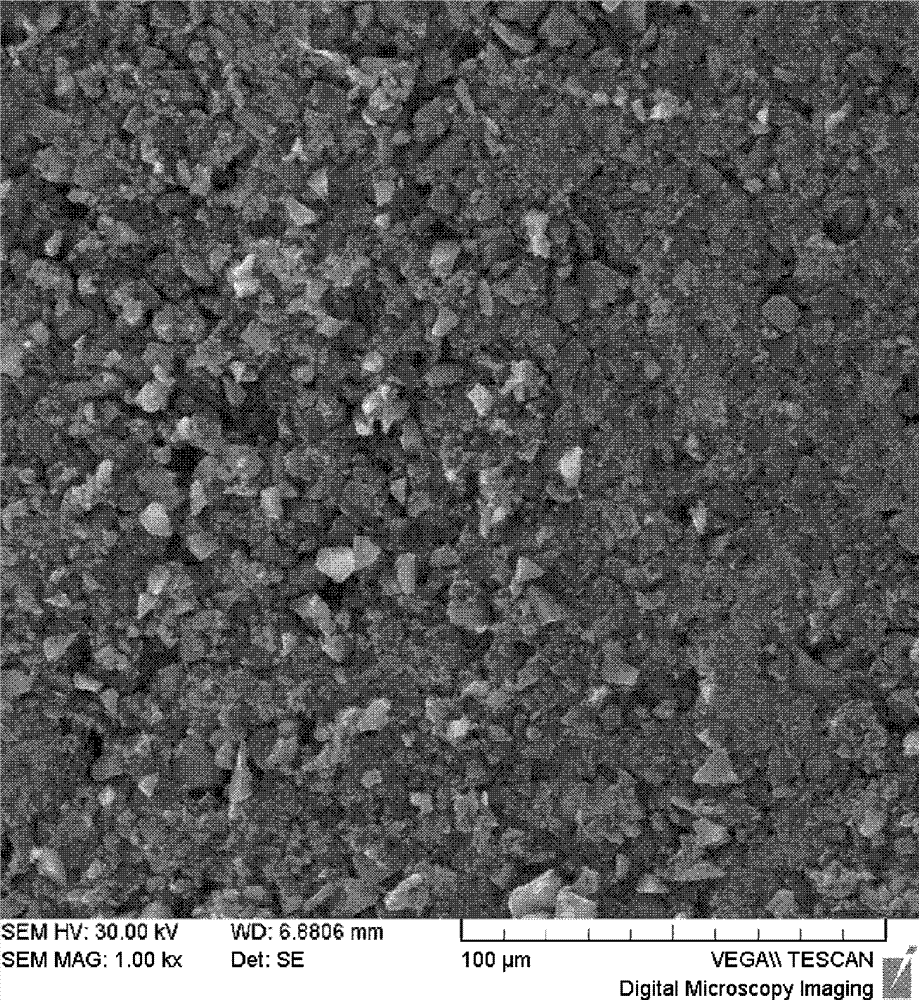

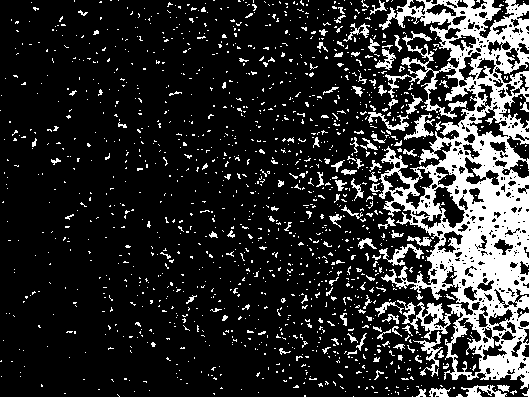

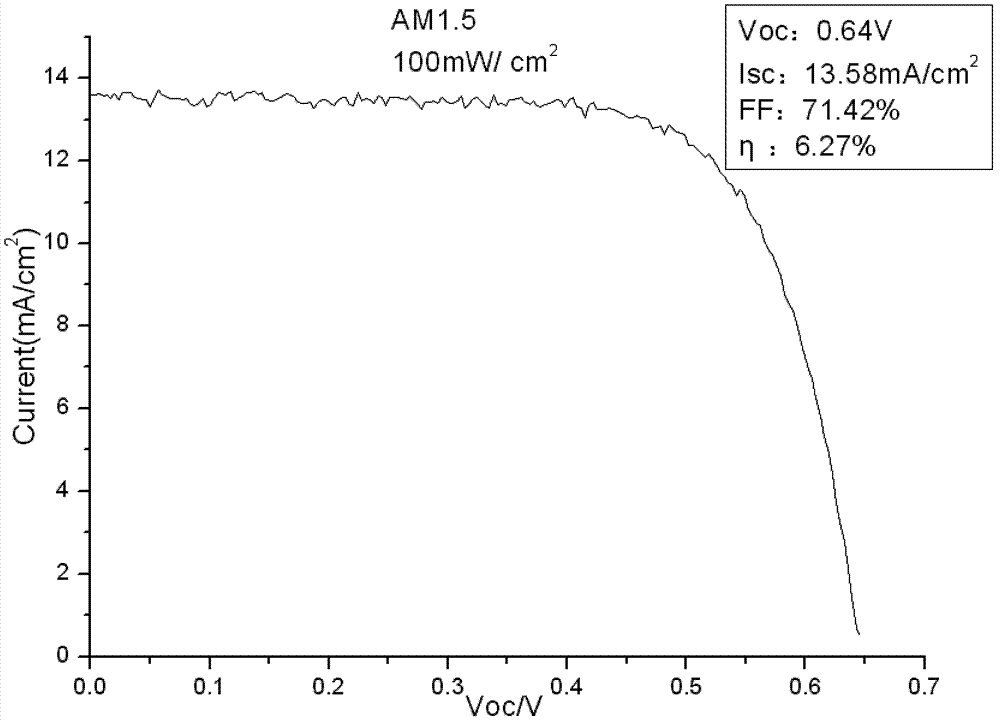

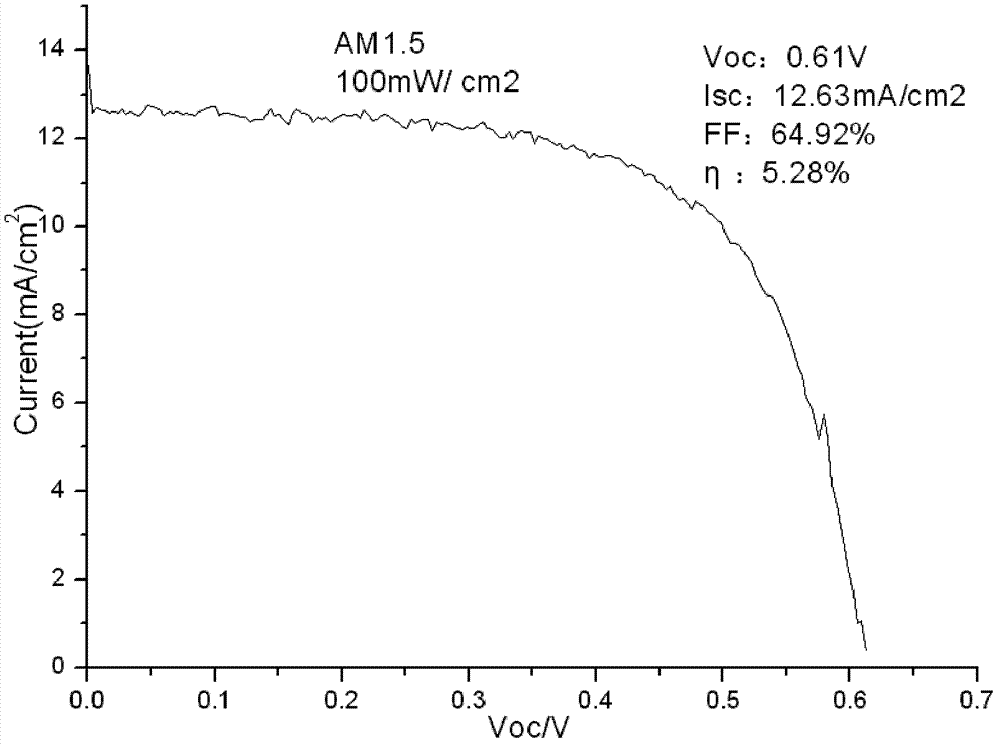

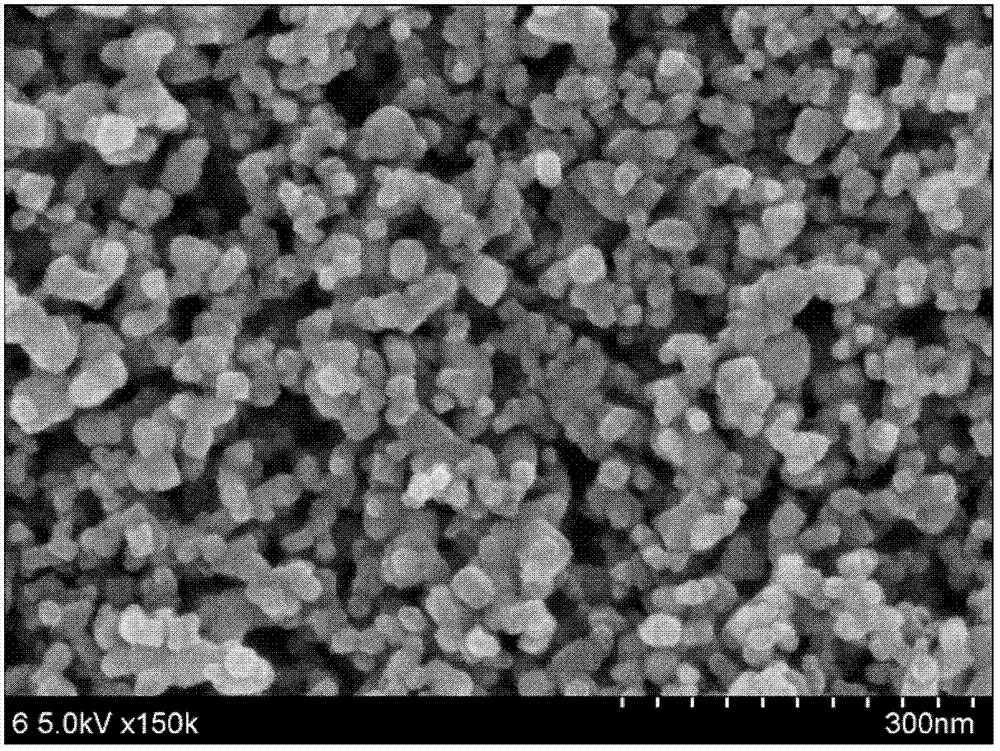

Optical anode slurry for dye-sensitized solar cell and preparation method thereof as well as optical anode for dye-sensitized solar cell and dye-sensitized solar cell

ActiveCN102446632BEasy to prepareGood dispersionLight-sensitive devicesFinal product manufactureDye absorptionGeneration rate

The invention discloses optical anode slurry for a dye-sensitized solar cell and a preparation method thereof as well as an optical anode of the dye-sensitized solar cell prepared by utilizing the slurry and the dye-sensitized solar cell, wherein titanium dioxide in the slurry for the dye-sensitized solar cell is the mixture of two kinds of nanoscale titanium dioxides with different particle sizes, the mixture is formed by mixing prepared nano titanium dioxide powder with the particle size of 8-16nm and the specific surface area of 90-100m<2> / g, and P25 titanium dioxide powder proportionally,the optical anode prepared from the slurry fully makes use of the respective advantages of the large particles and the small particles, which ensures that the optical anode has higher optical captureefficiency, but also the photosensitized dye absorption amount is improved, the generation rate and conveying capability of photon-generated carriers are intensified, and the recombination process ofthe photon-generated carriers is reduced, thus the photoelectric conversion efficiency of the dye-sensitized solar cell is improved. The optical anode slurry, the preparation method thereof as well as the optical anode and the dye-sensitized solar cell provided by the invention are suitable for the high-efficiency preparation of the dye-sensitized solar cell.

Owner:CHERY AUTOMOBILE CO LTD

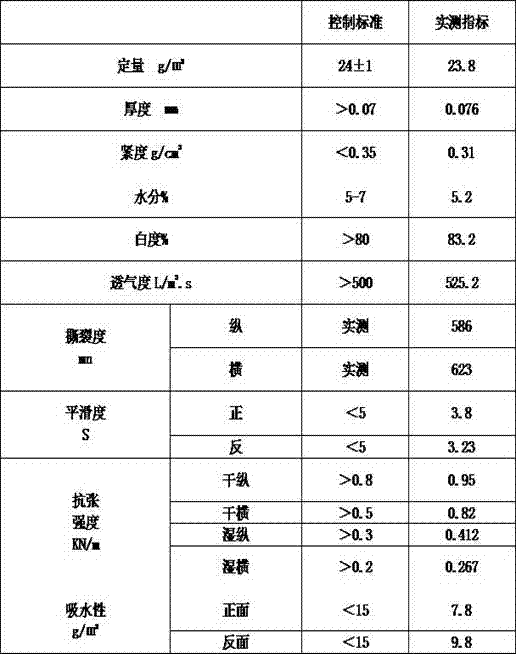

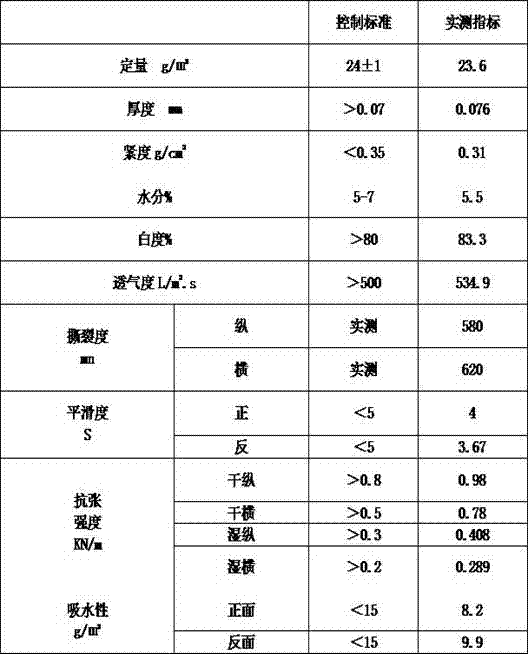

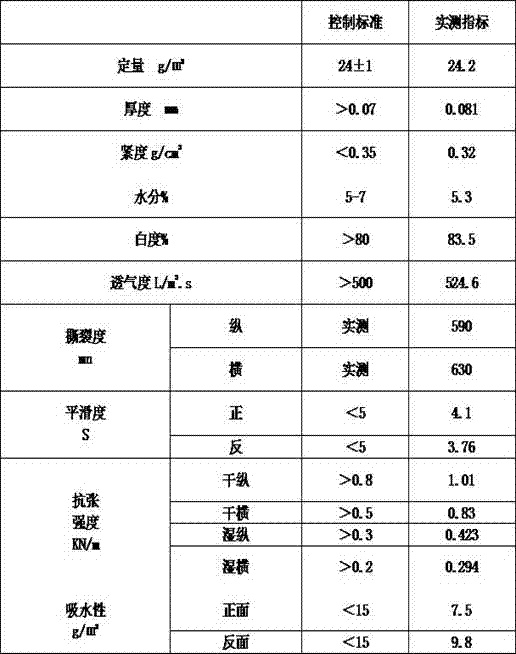

Air-permeable medical adhesive tape substrate and manufacturing method thereof

ActiveCN106012658BIntertwinedSoft and bulky textureOrganic non-cellulose fibresWater-repelling agents additionFiberPolyester

The invention relates to the field of base materials of medical supplies, in particular to a breathable medical adhesive tape base material and a manufacturing method thereof. The manufacturing method of the breathable medical adhesive tape base material comprises the following steps: (1) carrying out mild pulping treatment on wood pulp fibers, increasing degree of beating by 2-8 degrees of SR, mixing the wood pulp fibers with polyester fibers and water-soluble fibers, and adding a wet strength agent in mixed fibers; (2) manufacturing paper by using the mixed fibers through a cylinder paper machine or an inclined wire machine, carrying out enhancement through surface sizing, and drying and reeling to obtain finished products, wherein the mass percents of the wood pulp fibers, the polyester fibers and the water-soluble fibers respectively account for 50-75%, 20-45% and 1-5% of the mass percent of fibers in breathable medical adhesive tape paper, and the sum of the mass percents of the various components is 100%. A manufacturing process of the method is simple, and the prepared medical adhesive tape base material has the characteristics of high strength, good flexibility, high bulk, high breathability, good evenness and easiness in tearing.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

Frame type air filter

The invention relates to a frame type air filter which comprises at least one filter bag and a frame arranged outside the filter bag, wherein at least one filter bag is an integrated filter bag, and the frame is fixedly connected through a bolt structure. The frame type air filter disclosed by the invention has a good filtration effect, and is easy to dismount, convenient to maintain and capable of continuously working for a long time.

Owner:YIXING JIEGAO NON WOVEN FABRIC

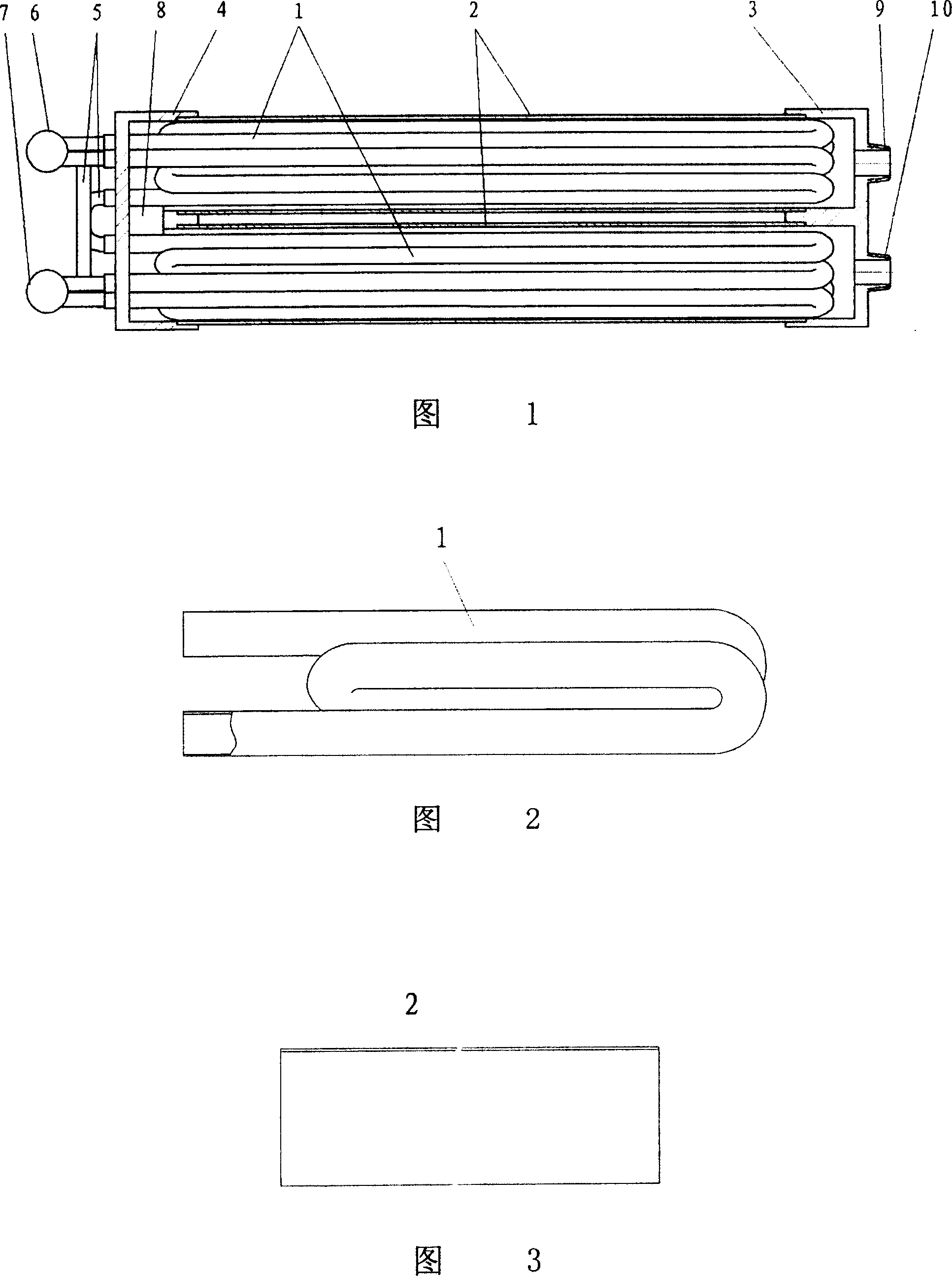

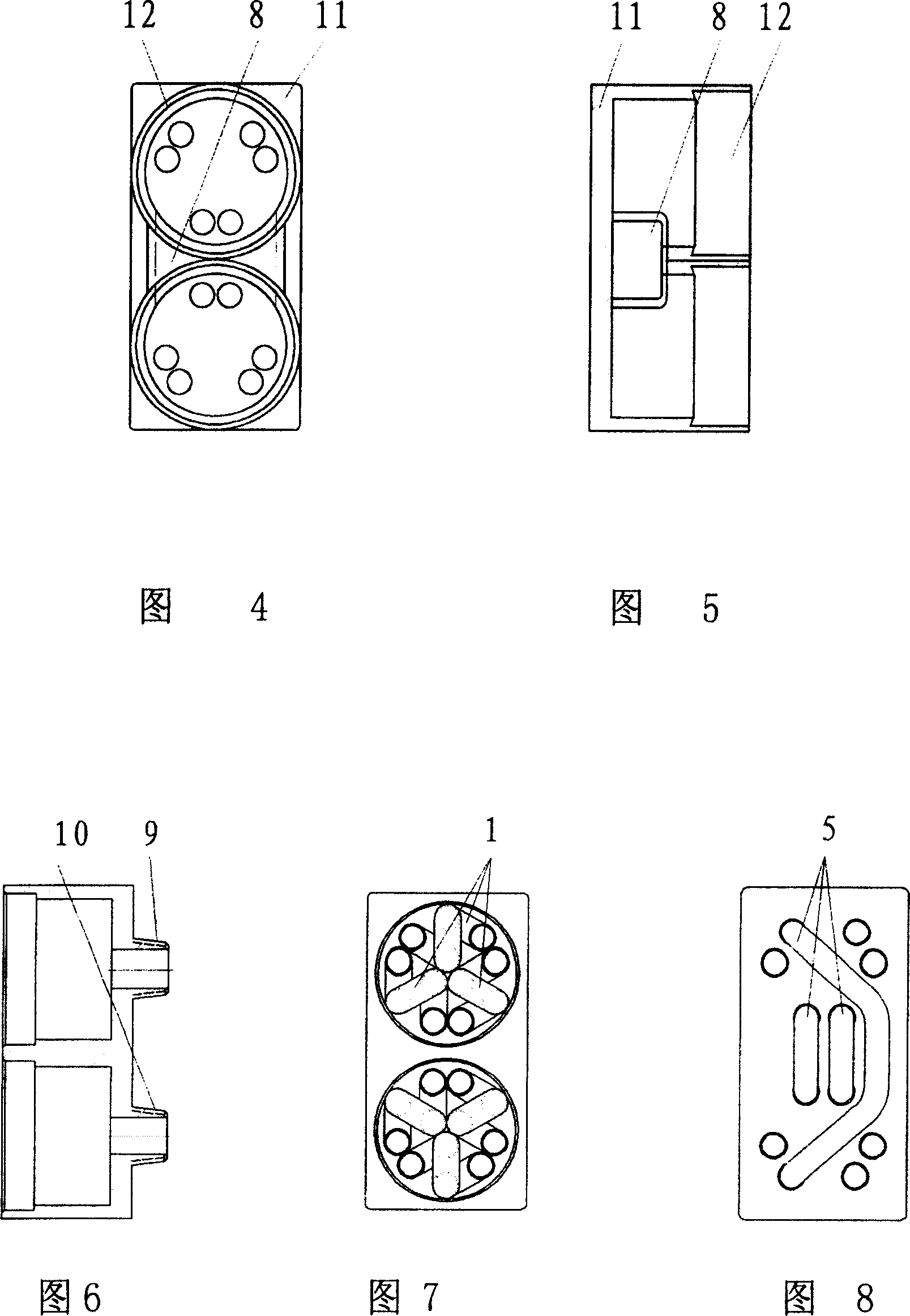

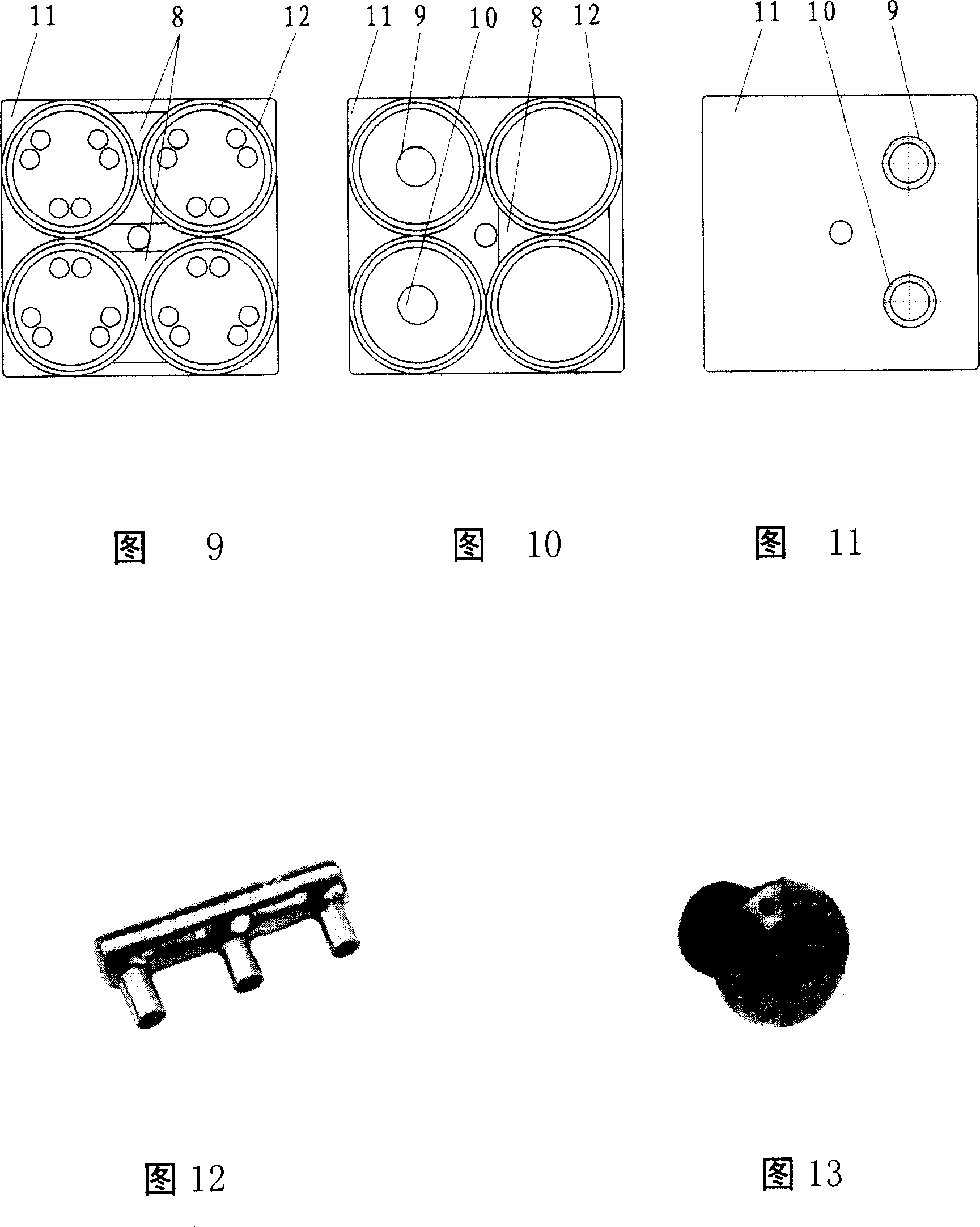

Return pipe heat exchanger

InactiveCN100362305CCompact structureReduce volumeStationary tubular conduit assembliesWater source heat pumpPlate heat exchanger

The present invention relates to a return pipe heat exchanger which can be used as condenser and evaporator and is applicable to medium / small water cooling air conditioner, water source heat pump, domestic central air conditioner and air source heat pump water heater, etc. Said invention includes the external shell of said heat exchanger and heat-exchanging pipe-return pipe mounted in the external shell. Said invention also provides their concrete structure and its working principle.

Owner:彭建华

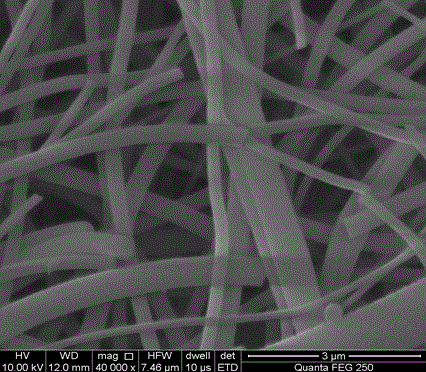

A kind of doped carbon fiber network and preparation method thereof

The invention discloses a doped carbon fiber net and a preparation method of the doped carbon fiber net. The doped carbon fiber net is in a net-shaped structure formed by integrating carbon fibers, the carbon fiber has a doped element, the number of outermost electrons of the doped element is not 4, the doped carbon fiber net has the advantages of even distribution of gaps, and excellent overall integration property, electrical conductivity, plasticity and toughness, and the amount of the used carbon fibers is reduced greatly while the strength is guaranteed. The preparation method comprises the steps of preparing a polyacrylonitrile nanofiber or a polyacrylonitrile nanofiber membrane, carbonizing to obtain the carbon fiber or a carbon fiber membrane, doping at the high temperature, washing with acid to remove impurities or washing with alkaline to remove impurities, and the like. The preparation method has the advantages of simple preparation process, low cost, high easiness in operation and implementation, and the like, and precious metals and catalysts are not related.

Owner:CENT SOUTH UNIV

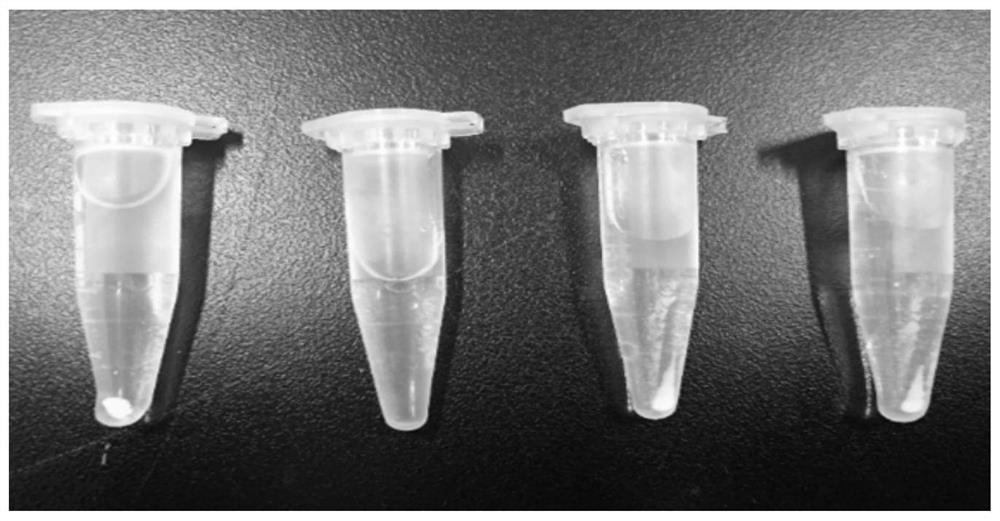

A kind of preparation method of sandwich-like multicellular sheet

InactiveCN104436299BHigh porosityUniform void distributionSkeletal/connective tissue cellsProsthesisSandwich likeMass ratio

The invention discloses a preparation method of a sandwich-shaped multicellular lamella. The preparation method comprises the following steps: an electrospinning liquid preparation step: adding chitosan and collagen in a trifluoroethanol solution, and stirring to obtain an electrospinning liquid, wherein the mass ratio of the chitosan to the collagen ranges from (1: 4) to (4: 1); an electrostatic spinning step: carrying out high-voltage electrostatic spinning on the electrospinning liquid to obtain a chitosan-collagen electrospinning biomembrane; and a cell-membrane-cell multicellular lamella construction step: respectively adhering two cell lamellas to the two surfaces of the chitosan-collagen electrospinning biomembrane to grow, so as to obtain a cell-membrane-cell multicellular lamella. According to the preparation method disclosed by the invention, the preparation process is simple and controllable; with the electrospinning biomembrane as a support membrane, as the two cell lamellas are adhered to the biomembrane to grow, the proliferation space of cells is enlarged, circulation of nutrients between the two cell lamellas is improved, and the integrity of the cell lamellas in the transfer process is also ensured, thus a simple, convenient and easy operation method is available for clinical multicellular lamella transplantation therapy.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

Preparation method and application of electrode sheet

ActiveCN102789904BGood flexibilityHigh tensile strengthCapacitor electrodesMaterials scienceNanotechnology

The invention is suitable for the technical field of electronics and provides a preparation method and applications of an electrode plate. The preparation method of the electrode plate comprises the following steps: respectively providing active carbon, a conductive additive, carboxymethylcellulose and a binder; mixing the active carbon, the conductive additive and the carboxymethylcellulose to obtain a first mixture; mixing the binder with water to obtain a second mixture; under an agitating condition, mixing the first mixture with the second mixture, standing the mixtures for 2-8 hours, and drying, pressing and molding the electrode plate. According to the preparation method of the electrode plate, the carboxymethylcellulose (CMC) can enable the mixed size to form stable rubber mass by adding the carboxymethylcellulose, standing and emulsifying the carboxymethylcellulose; layering of the mixed size caused by different specific gravities of each constituent can be prevented; the distribution stability of each constituent in the size is kept, and the flexibility, the tensile strength, the absorbency and the electrical conductivity of the prepared electrode plate are also improved.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

A preparation method for photodegradable organic toxic gas multilevel nanocomposite material

ActiveCN109821524BAchieve enrichmentUniform void distributionPhysical/chemical process catalystsDispersed particle separationGlycerolNanocomposite

The invention discloses a method for preparing a multi-stage nanocomposite material with photodegradable organic toxic gas, which comprises the preparation of porous layered nano-montmorillonite: the montmorillonite is pulverized to an average particle size of 50 to 50 by mechanical pulverization and air flow method. 200nm; preliminary preparation of nanocomposite materials: compound the montmorillonite and titanium-based photocatalyst materials at low temperature to obtain a compound, add the compound to water or alcohol, react at low temperature, and then add nitrogen source or carbon source for reaction , to obtain the primary nanocomposite material; multi-level nanocomposite material modification: after the primary nanocomposite material is cooled down, a modifier is added for modification, and the modifier accounts for the compound / water or alcohol / nitrogen source or carbon source 0.2-2% of the total mass of the system; the modifying agent includes glycerol or triethanolamine.

Owner:南京森之语新材料科技有限公司

A preparation method of wave-transparent closed-cell silicon carbide foam ceramics containing beryllium

ActiveCN105254304BLow dielectric lossSolve the problem of anisotropyCeramicwarePolyolRoom temperature

The invention relates to a preparation method of a wave-transmitting closed-cell beryllium-containing silicon carbide foam ceramic, which belongs to the field of preparation of special functional materials. In the present invention, the beryllium-containing polycarbosilane powder is used as the beryllium-containing silicon carbide foam ceramic precursor, and the polyol, catalyst, etc. are mixed uniformly in a certain proportion, and then isocyanate is added. After fully stirring, it is injected into the mold. After foaming and curing, the finished product is obtained by pre-oxidation treatment and ceramicization treatment. The preparation process of the invention is simple, and the obtained product has good wave transmission, high heat insulation and excellent mechanical properties.

Owner:CENT SOUTH UNIV

Production process of noctilucent landscape fender

The invention discloses a production process of a noctilucent landscape fender. The production process comprises the following steps: a, preparing pouring slurry; b, performing pouring molding; c, spraying a reflective layer; and d, pouring a surface transparent layer. The noctilucent landscape fender has the advantages that the noctilucent landscape fender has a very good visual effect in the daytime and at night, is very beautiful, has very good wear resistance, and still has relatively high transparency after being worn for a long time, and the noctilucent and reflective effects are not influenced.

Owner:钟祥市洛亚实业有限公司

High-efficiency low-resistance melt-blowing material and preparation process thereof

PendingCN112745578AEvenly distributed ingredientsUniform void distributionChemistryComposite material

The invention discloses a high-efficiency low-resistance melt-blowing material, which comprises 90-100 parts of PP resin, 1-5 parts of electret master batch, 1-5 parts of an antibacterial agent, 1-5 parts of a compatilizer and 1-3 parts of an antioxidant. The prepared melt-blown material has excellent filtering efficiency and relatively low initial resistance and final resistance.

Owner:SCD NEW MATERIAL TECH SHANGHAI CO LTD

Preparing method of light-degraded organic poisonous gas multi-stage nanometer composite

ActiveCN109821524AAchieve enrichmentUniform void distributionPhysical/chemical process catalystsDispersed particle separationAlcoholGlycerol

The invention discloses a preparing method of a light-degraded organic poisonous gas multi-stage nanometer composite. The preparing method includes the steps of preparing porous lamellar nanometer montmorillonite, smashing the montmorillonite through a mechanical smashing method and a gas flow method until the average particle size is 50-200 nm, primarily preparing the nanometer composite, compounding the montmorillonite and a titanium-series photocatalysis material at a low temperature to obtain a compound, adding the compound to water or alcohol for low-temperature reaction, adding a nitrogen source or carbon source for reaction to obtain a primary nanometer composite, modifying the multi-stage nanometer composite, cooling the primary nanometer composite, and then adding a modifier for modifying the composite, wherein the modifier accounts for 0.2-2% of the total mass of the compound, the water or alcohol and the nitrogen source or carbon source, and the modifier comprises glycerol or triethanolamine.

Owner:南京森之语新材料科技有限公司

Preparation method of anti-cracking autoclaved brick

The invention discloses a preparation method of an anti-cracking autoclaved brick. The preparation method comprises the following steps: evenly mixing modified chlorinated polyethylene glycol 400, fly ash, kaolin, and water, adding cement, a water reducer, and a curing agent, evenly mixing, pressing, moulding to obtain premix; delivering the premix to an autoclaving chamber, and carrying out curing to obtain the anti-cracking autoclaved brick. The modified chlorinated polyethylene glycol 400 is prepared by the following steps: mixing chlorinated polyethylene glycol 400 and oxidized starch, carrying out ultrasonic dispersion, heating, adding sodium hydroxide and sodium lignosulfonate, stirring under the protection of nitrogen gas, cooling, and adjusting the pH of the system to the neutral region to obtain the modified chlorinated polyethylene glycol 400. Fly ash is taken as the raw material to prepare the autoclaved brick, a large amount of cultivated land is saved, the water and air pollution is reduced, and the fly ash is converted into valuable resources and is effectively recovered and used. The manufacturing cost is low, the mould loss is little, the anti-compression strength of the brick is large, the structure is stable, and the brick is hard to break.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

A kind of hydraulic high performance concrete and preparation method thereof

The invention discloses hydraulic high-performance concrete, which belongs to the technical field of concrete. The concrete includes the following components: fine aggregate, coarse aggregate, cement, slag, fly ash, silica fume, water reducer, water, ultrafine natural zeolite powder, gypsum, polymer emulsion, glycols Compound, modified lignosulfonate, sheet silicate mineral material, polysiloxane, oxalic acid, styrene-acrylic emulsion, crystalline hydrated magnesium aluminum silicate mineral, superplasticizer, air-entraining agent, steel fiber , tert-butyl peroxy tert-valerate, nano gelatinite, ettringite-lime composite expansion agent; The dosage ratio of expansion agent is (0.4-0.8): (2-4): (0.5-0.8); In the hydraulic high performance concrete of the present invention, the reinforcement system composed of additives is used to improve the frost resistance of the hydraulic high performance concrete.

Owner:JIANGSU PROVINCE WATER ENG SCI TECH CONSULTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com