A kind of hydraulic high performance concrete and preparation method thereof

A high-performance concrete and hydraulic technology, applied in the field of concrete, can solve problems such as poor frost resistance of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

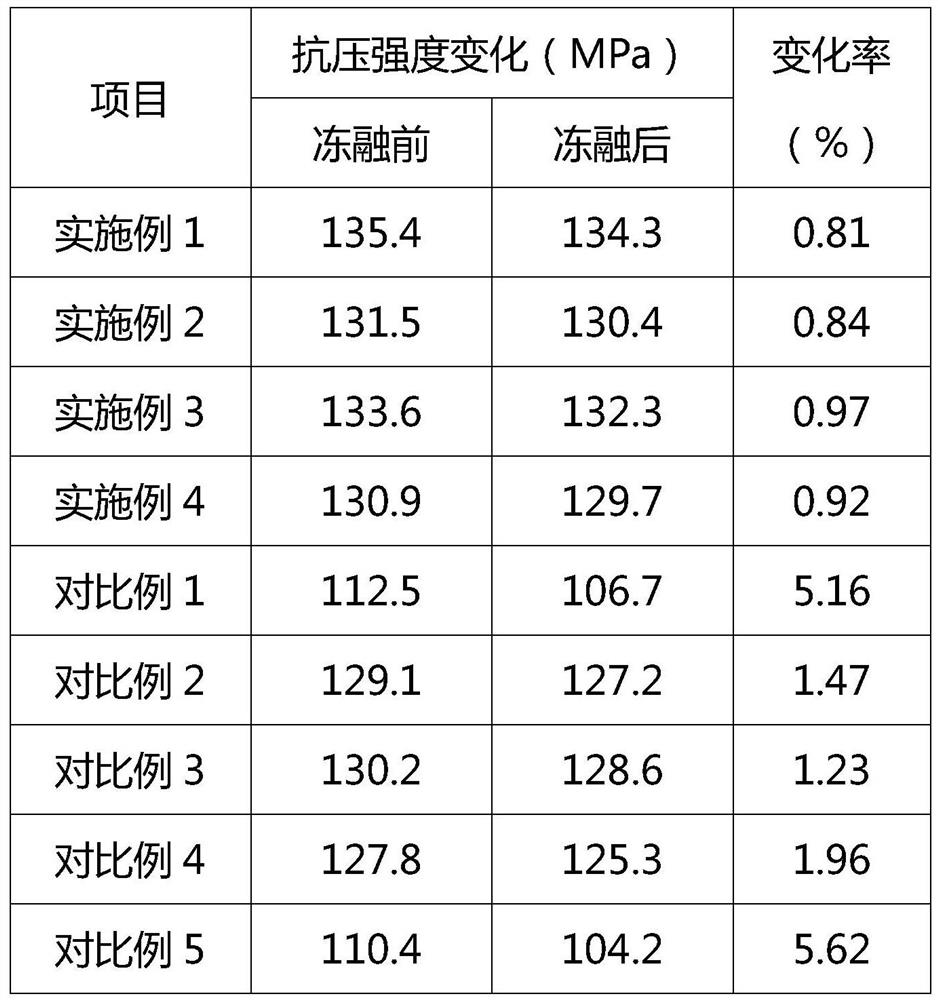

Examples

preparation example Construction

[0030] The preparation method of described hydraulic high-performance concrete comprises the following steps:

[0031] S1: Weigh the components of the concrete material in proportion;

[0032] S2: Superfine natural zeolite powder, gypsum, polymer emulsion, glycol compounds, modified lignosulfonate, sheet silicate mineral material, polysiloxane, oxalic acid, styrene-acrylic emulsion and Put the crystalline hydrated magnesium aluminum silicate mineral into a stirring container, stir at a speed of 600r / min-700r / min for 25-35min, add half the proportion of water while stirring, and finally stir evenly to obtain a mixture;

[0033] S3: Pour cement, fine aggregate, coarse aggregate, slag, fly ash, silica fume, tert-butyl peroxyvaleric acid tert-butyl peroxide, nano-gelatinite, ettringite-lime composite expansion agent and steel fiber Put it into the plastic sand mixing pot, then pour the mixture in step S2 into the plastic sand mixing pot, first stir at a speed of 100r / min-200r / min...

Embodiment 1

[0038] A hydraulic high-performance concrete, comprising the following components: 85 parts of fine aggregate, 95 parts of coarse aggregate, 70 parts of cement, 20 parts of slag, 22 parts of fly ash, 7 parts of silica fume, 1.3 parts of water reducer, 38 parts of water, 0.6 parts of superfine natural zeolite powder, 1.2 parts of gypsum, 0.5 parts of polymer emulsion, 0.8 parts of glycol compounds, 0.2 parts of modified lignosulfonate, 1.5 parts of phyllosilicate mineral material , 0.5 parts of polysiloxane, 0.8 parts of oxalic acid, 0.3 parts of styrene-acrylic emulsion, 2 parts of crystalline hydrated magnesium aluminum silicate minerals, 0.4 parts of superplasticizer, 0.05 parts of air-entraining agent, 1 part of steel fiber, tertiary peroxide 0.6 parts of tert-butyl valerate, 3 parts of nano gellingite, 0.6 parts of ettringite-lime composite expansion agent;

[0039] The fine aggregate is natural sand with a particle size of 5mm-20mm, the coarse aggregate is flaky granite w...

Embodiment 2

[0047] A hydraulic high-performance concrete, comprising the following components: 85 parts of fine aggregate, 90 parts of coarse aggregate, 80 parts of cement, 10 parts of slag, 22 parts of fly ash, 5 parts of silica fume, 2.3 parts of water reducer, 40 parts of water, 0.7 parts of superfine natural zeolite powder, 0.8 parts of gypsum, 0.4 parts of polymer emulsion, 1.2 parts of glycol compounds, 0.2 parts of modified lignosulfonate, 2 parts of phyllosilicate mineral materials , 0.2 parts of polysiloxane, 0.8 parts of oxalic acid, 0.5 parts of styrene-acrylic emulsion, 1 part of crystalline hydrated magnesium aluminum silicate mineral, 0.6 parts of superplasticizer, 0.04 parts of air-entraining agent, 0.9 parts of steel fiber, tertiary peroxide 0.4 parts of tert-butyl valerate, 4 parts of nano gellingite, 0.8 parts of ettringite-lime composite expansion agent;

[0048] The fine aggregate is natural sand with a particle size of 5mm-20mm, the coarse aggregate is flaky granite w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com