Production process of noctilucent landscape fender

A technology of production process and scenery, applied in the direction of coating, ship building, ship, etc., can solve the problems of high fender density, energy absorption effect, pressure resistance and wear resistance, poor anti-aging ability, safety hazards, etc., to achieve Balance the reaction rate and system viscosity, improve the vitality and vitality of the city, and promote the effect of curing and foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

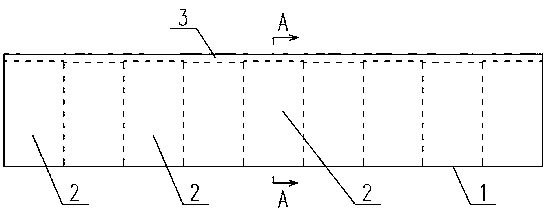

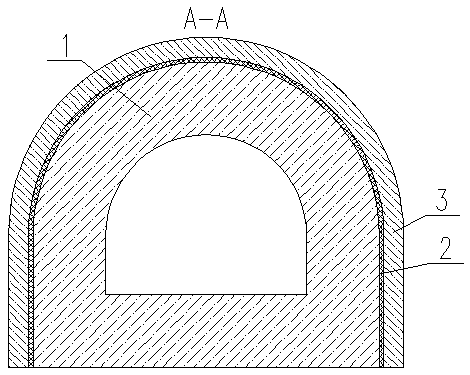

Image

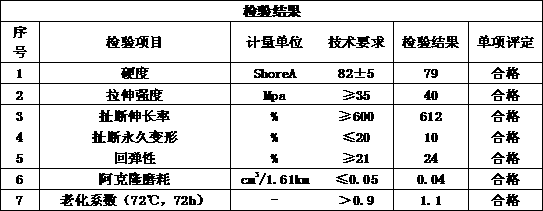

Examples

Embodiment 1

[0019] Embodiment 1: The production process of luminous landscape fender, its production process is as follows:

[0020]a. Preparation of pouring slurry: Take 63 kg of polytetrahydrofuran ether glycol and 8 kg of polycaprolactone according to the weight ratio and add them to the reaction kettle while continuing to stir. After the feeding is completed, the reaction kettle is sealed and the inside of the reaction kettle is evacuated , control the vacuum in the reactor to 300pa, then heat the temperature in the reactor to 75°C and keep it warm for 20 minutes, then use 12 minutes to raise the temperature in the reactor to 94°C and keep it warm for 31 minutes , then using 8 minutes, the temperature in the reactor was raised to 100°C, and kept for 28 minutes, and then used for 6 minutes, the temperature in the reactor was lowered to 92°C, and kept for 17 minutes, and then used for 11 minutes, the reaction The temperature in the kettle was raised to 112°C, and kept for 15 minutes. Fi...

Embodiment 2

[0026] Embodiment 2: The production process of luminous landscape fender, its production process is as follows:

[0027] a. Preparation of pouring slurry: Take 65 kg of polytetrahydrofuran ether glycol and 10 kg of polycaprolactone according to the weight ratio and add them to the reaction kettle while continuing to stir. After the feeding is completed, seal the reaction kettle and vacuumize the inside of the reaction kettle , control the vacuum in the reactor to 310pa, then heat the temperature in the reactor to 82°C and keep it warm for 21 minutes, then use 13 minutes to raise the temperature in the reactor to 95°C and keep it warm for 32 minutes , then using 9 minutes, the temperature in the reactor was raised to 102°C, and kept for 30 minutes, and then used for 7 minutes, the temperature in the reactor was lowered to 93°C, and kept for 20 minutes, and then used for 12 minutes, the reaction The temperature in the kettle was raised to 115°C, and kept warm for 18 minutes, and...

Embodiment 3

[0033] Embodiment 3: the production process of luminous landscape fender, its production process is as follows:

[0034]a. Preparation of pouring slurry: Take 67 kg of polytetrahydrofuran ether glycol and 12 kg of polycaprolactone according to the weight ratio and add them to the reaction kettle while continuing to stir. After the feeding is completed, seal the reaction kettle and vacuumize the inside of the reaction kettle , control the vacuum in the reactor to 320pa, then heat the temperature in the reactor to 90°C and keep it warm for 23 minutes, then use 15 minutes to raise the temperature in the reactor to 96°C and keep it warm for 34 minutes , and then using 10 minutes, the temperature in the reactor was raised to 105°C, and kept for 32 minutes, and then used for 8 minutes, and the temperature in the reactor was lowered to 95°C, and kept for 24 minutes, and then used for 13 minutes, the reaction The temperature in the kettle rose to 118°C, and kept warm for 22 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com