Patents

Literature

75results about How to "With light function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

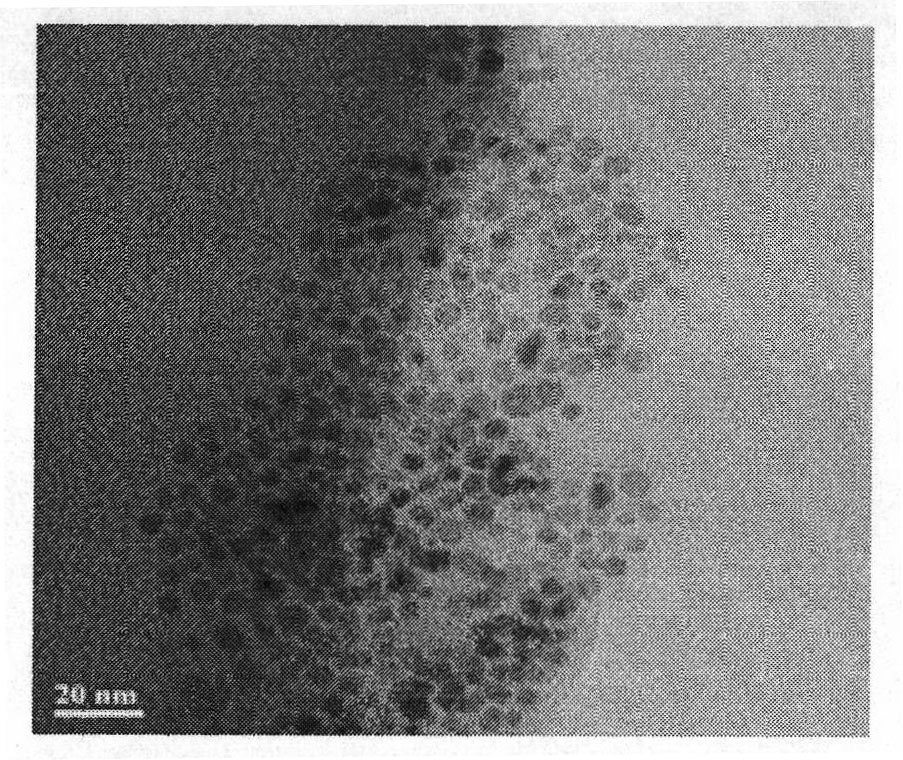

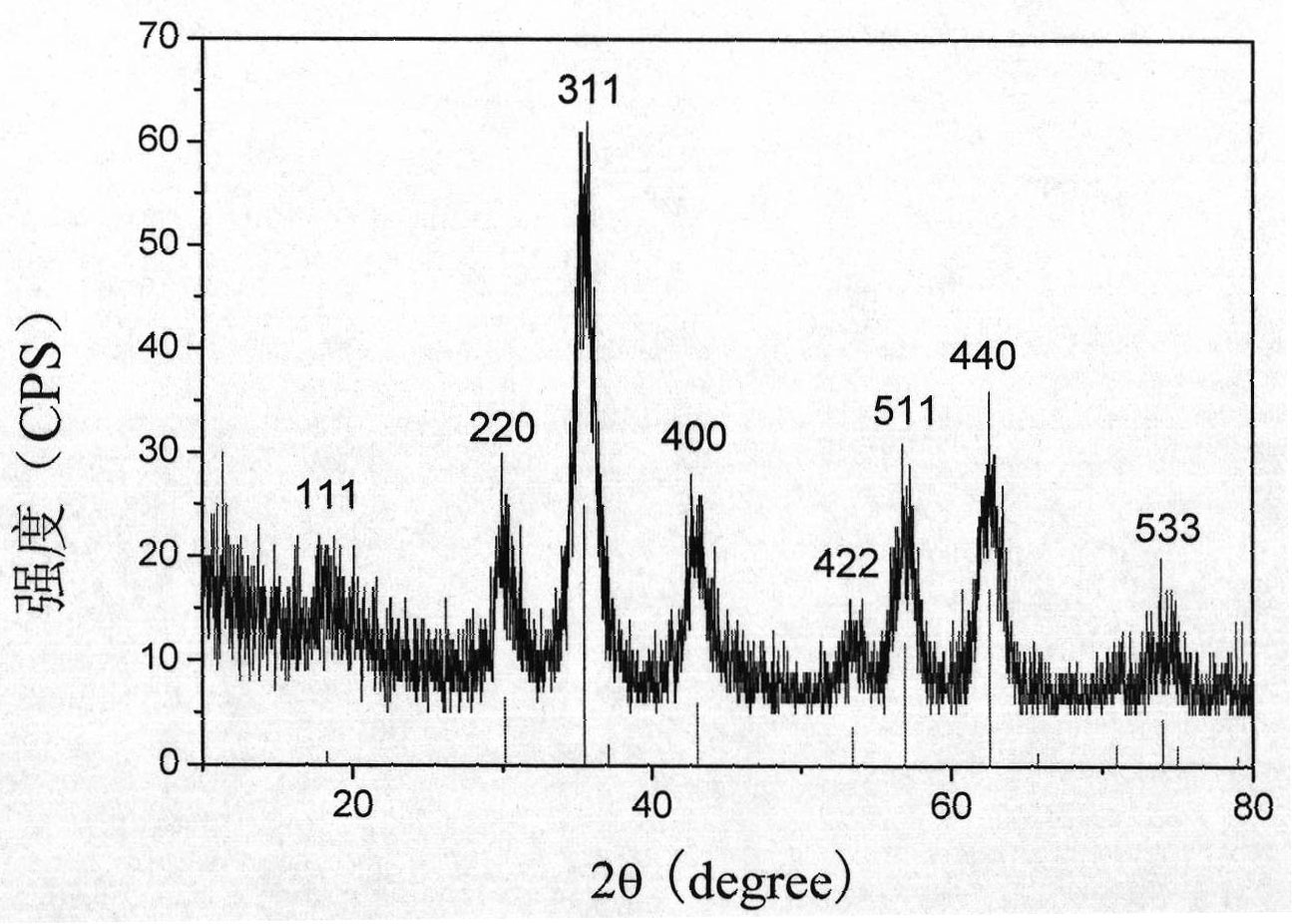

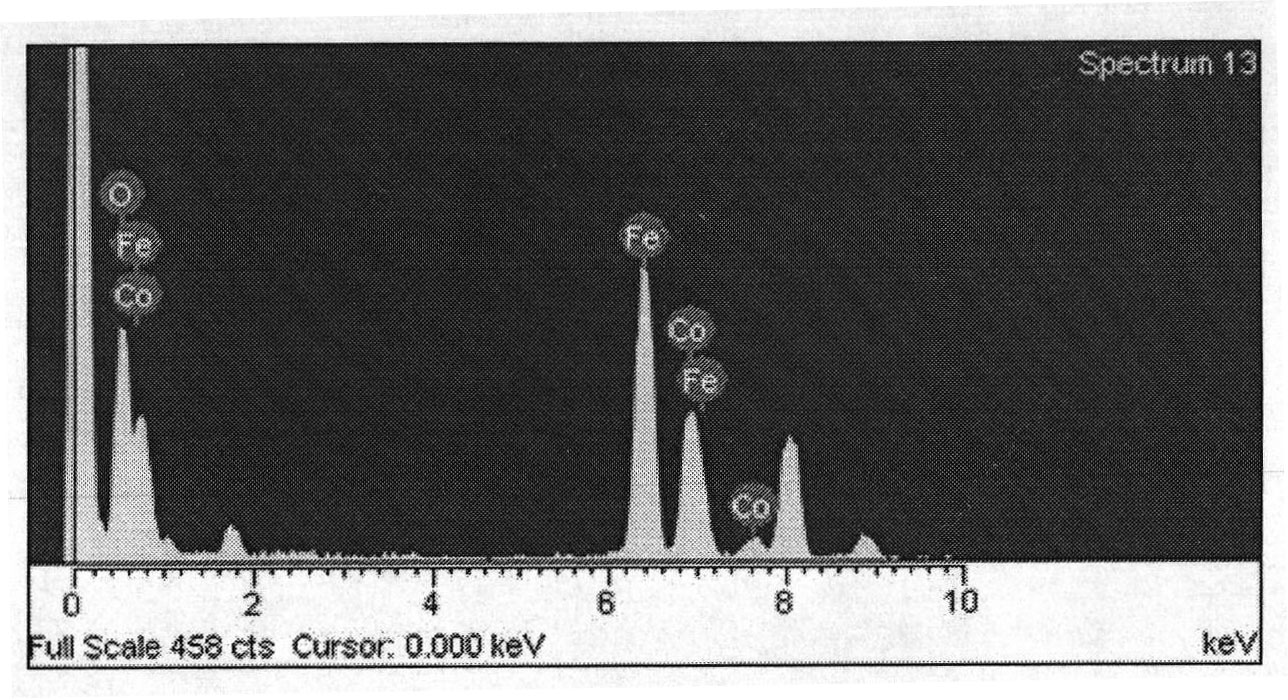

Water-soluble nuclear-shell magneto-optic dual-function nanoparticle and preparation method thereof

InactiveCN101775280AGood water solubilityGood dispersionInorganic material magnetismLuminescent compositionsSolubilityDansyl chloride

The invention relates to the technical field of the composite material, and discloses a water-soluble nuclear-shell magneto-optic dual-function nanoparticle. In the structure of the water-soluble nuclear-shell magneto-optic dual-function nanoparticle, magnetic CoFe2O4 is used as a core, amorphous SiO2 is used as a shell, the surface of the shell is connected with an organic light-emitting material dansyl chloride, and the particle size is 25-50nm. The preparation method comprises the following steps: preparing a monodisperse magnetic cobalt ferrite nanoparticle through thermal decomposition, coating silica on the surface of the nanoparticle, carrying out modification of amino on the surface of the silica, and connecting an organic light-emitting material through the amino on the peripheryof the magnetic nanoparticle. The nanoparticle of the invention has a nuclear-shell structure and a uniform particle size, and can be well dispersed in water. Moreover, the nanoparticle of the invention has good water solubility, good magnetic properties, light-emitting effect and good biocompatibility.

Owner:SHANGHAI NORMAL UNIVERSITY

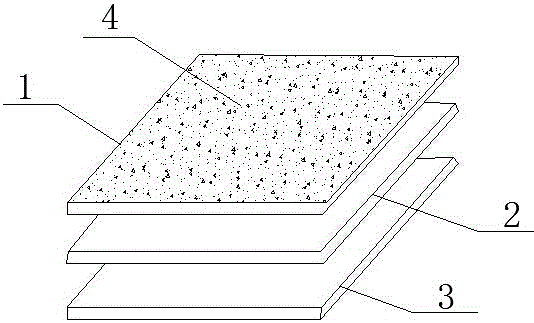

Luminous cork and rubber composite floor and production process thereof

InactiveCN105971233AImprove resource utilizationMake up for the lack of single appearance and poor decorationLaminationLamination apparatusPolymer scienceVulcanization

The invention discloses a luminous cork and rubber composite floor and a production process thereof and relates to the field of building materials, in particular to the luminous cork and rubber composite floor. The luminous cork and rubber composite floor comprises a three-layer structure including a cork decoration surface layer, a cork middle layer and a balance bottom layer from top to bottom sequentially, the surface of the cork decoration surface layer is coated with fluorescent powder, the luminous cork and rubber composite floor has a light emitting function and is formed by the cork decoration surface layer, the cork middle layer and the balance bottom layer through vulcanization and hot pressing, the water content, the tensile strength, the initial compression degree, the residual compression degree and other indexes of the luminous cork and rubber composite floor meet the requirements of LY / T1657-2006, a production process is simple, and the production efficiency is high.

Owner:安徽省申运木业有限公司

Alarming machine for intelligent automobile

The invention discloses an alarming machine for an intelligent automobile. The alarming machine comprises a lighting slab main body, an electrical appliance control body and a movement mechanism, and is characterized in that: I, the lighting slab main body consists of a lamp bank plate fixing body, a driving axle fixing boring mill, a lamp bank plate LED (Light-Emitting Diode) group, a soft wire and a back cover; II, the movement mechanism comprises a driving wheel, a driving axle, a driving motor, a guide wheel, a guide wheel fixing rod, a guide wheel fixing rod fixing pin, a spring and a spring cover; and III, the electrical appliance control body consists of a remote controller, a main receiving controller, a control board, a position detection switch, a motor, an LED lamp bank group and a power supply; the position detection switch comprises an ascending position detection switch and a descending position detection switch; and the motor comprises an elevating motor and a driving motor.

Owner:太仓鸿羽智能科技有限公司

Novel mobile telephone protecting case

The invention discloses a novel mobile phone protecting case. The case comprises a back plate contacted with the back surface of a mobile phone, and side plates contacted with side edges of the mobile phone, wherein the side plates and the back plate are formed integrally, and are perpendicular to each other. The novel mobile phone protecting case is characterized in that a plurality of transparent elastic bulges are formed on the surface of the back plate contacted with the back surface of the mobile phone; LED light sources are arranged in the elastic bulges. The novel mobile phone protecting case has complete functions.

Owner:聂晓鸿

Frame adhesive raw material of liquid crystal display panel and sealed adhesive frame

ActiveCN105542666AEasy to makeWith light functionNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveLiquid-crystal displayEngineering

The invention relates to a frame adhesive raw material of a liquid crystal display panel and a sealed adhesive frame of the liquid crystal display panel which is manufactured by the frame adhesive raw material. The frame adhesive raw material comprises a base material and a non-rejected fluorescent agent. The frame adhesive raw material of the liquid crystal display panel contains the fluorescent agent, so that uncured sealed adhesive frames which are coated by the frame adhesive raw material have luminescence function, and coating status of the frame adhesive raw material is easy to observed or acquired by inspection personnel or inspection equipment through light of the frame adhesive raw material; during the period, external light sources are not needed, so that operation difficulty for the inspection personnel is reduced, the detection process becomes simple and rapid, zone to be checked is not easy to omit, and damage to eyes is greatly reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

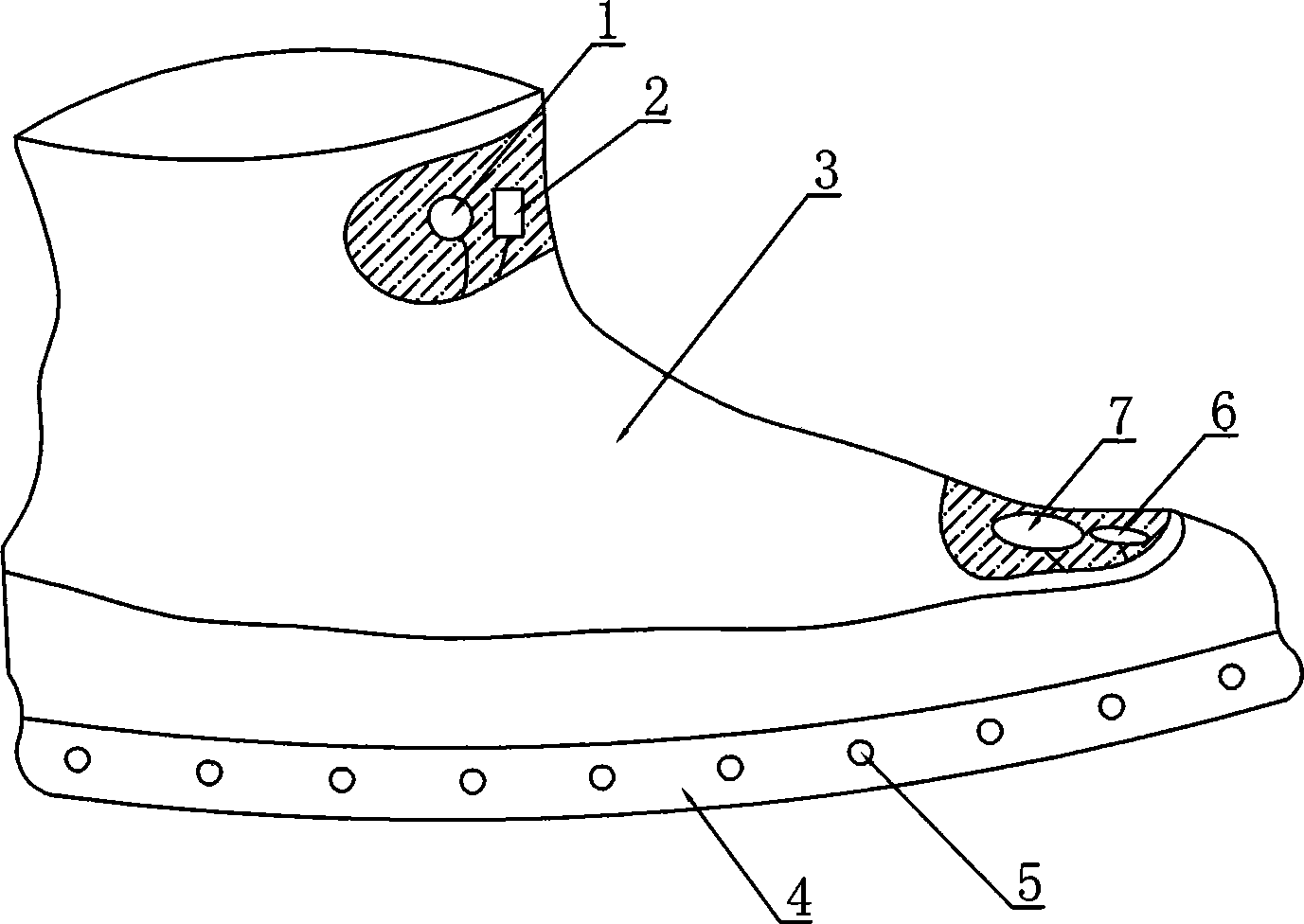

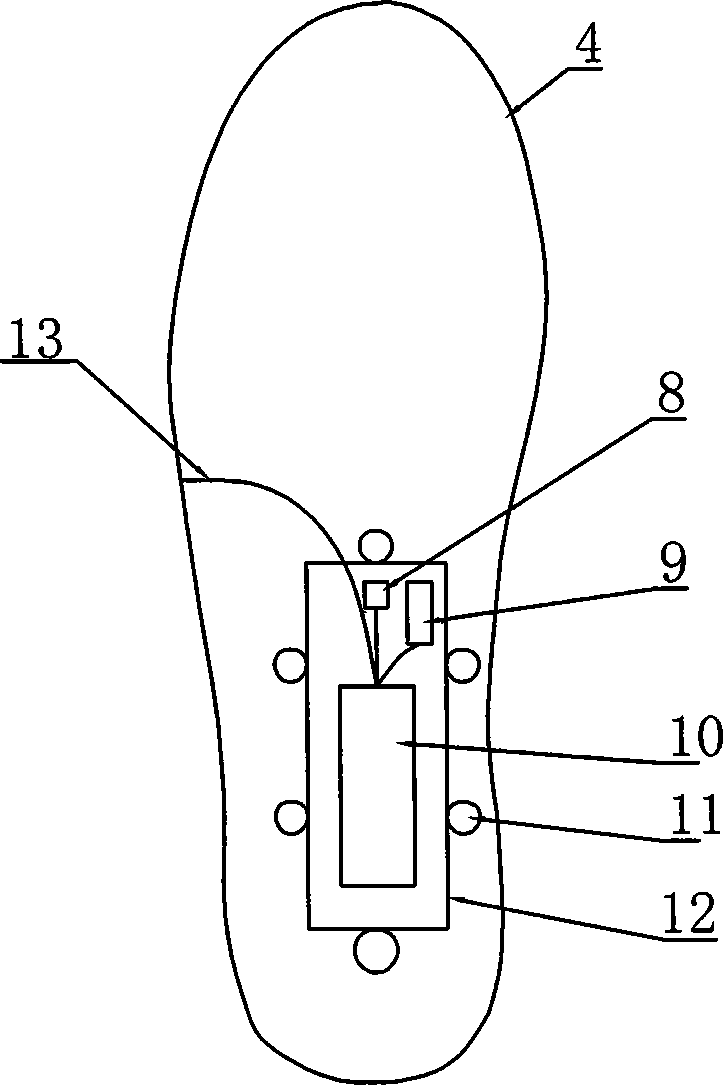

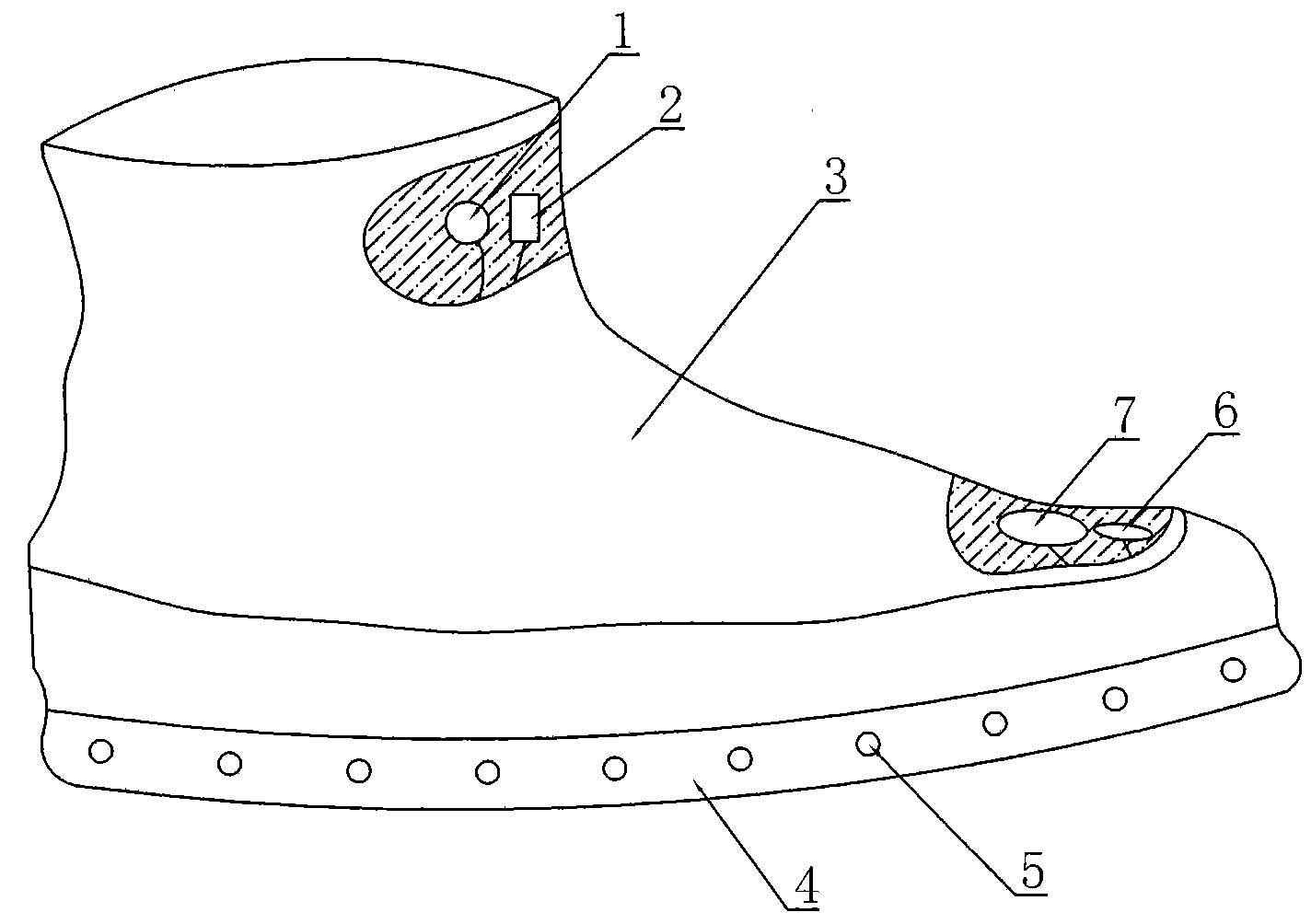

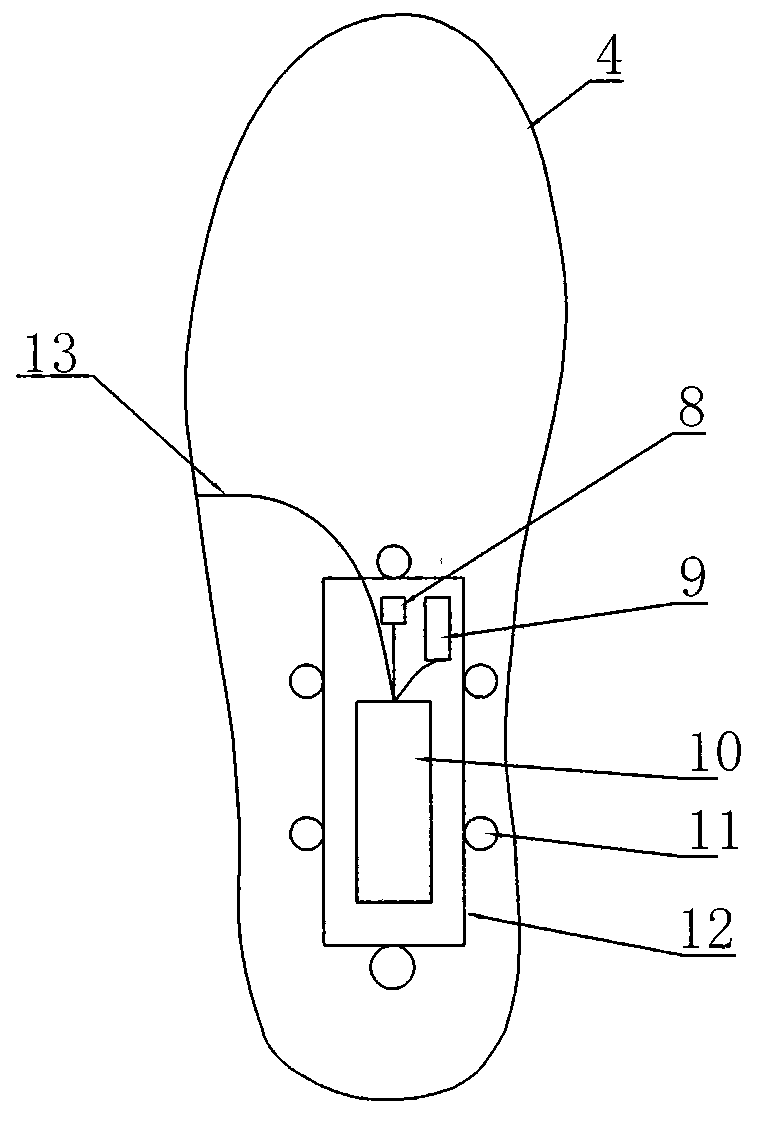

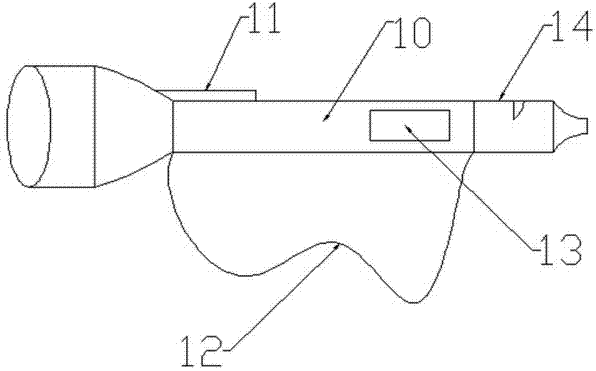

Multi-functional shoe

InactiveCN104287277AAvoid lossTo prevent people from getting lostFootwearTemperature controlEngineering

The invention belongs to the technical field of shoes, and provides a multi-functional shoe. The multi-functional shoe is composed of a sole and a vamp. A foot inlet is formed in the top of the vamp. A storage battery, a GPS positioning block and a temperature controller are arranged inside the sole. A power switch, a charging interface, LED lamps, a heating chip and a temperature control probe are arranged on the vamp. The storage battery, the GPS positioning block and the temperature controller are arranged in a square box which is arranged at the heel position of the sole.The power switch and the charging interface are arranged in the portion, at the foot inlet, of a vamp interlayer. The LED lamps are arranged on the portion, on the periphery of the sole, of the vamp. The heating chip and the temperature control probe are arranged on the portion, at the front sole, of the vamp. The multi-functional shoe has the advantages that the structure is simple, and functions are practical; the positioning function is realized, so that a child user or an elder user is prevented from getting lost; the heating function is achieved, the multi-functional shoe can realize heating in winter, and therefore the foot of a user is prevented from being frostbitten; the illuminating function is achieved, so the user no longer worries about walking at night.

Owner:王者香

Litracon park rest bench

The invention discloses a litracon park rest bench which comprises a rest bench main body, wherein a cavity is formed in the rest bench main body, a light transmitting assembly is arranged in the cavity, the rest bench main body is prefabricated by concrete, light transmitting holes are formed in the rest bench main body, the light transmitting holes penetrate through the cavity and the outer surface of the rest bench main body, and light guiding medium are arranged in the light transmitting holes. The litracon park rest bench disclosed by the invention has the advantages of simple structure,better rest function, light emitting function and higher practical value.

Owner:BEIJING MUNICIPAL ENG RES INST

Laminated glass functional glue film and preparation technology thereof

InactiveCN105985738AWith light functionGood weather resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAluminateSulfate

The invention relates to a preparation process of a functional adhesive film for laminated glass and its product. The composition and weight ratio are as follows: (1) EVA resin is 92% to 97%, and the VA content in the EVA resin is 24% to 28%. , melt flow rate 20g / 10min~45g / 10min; (2) liquid peroxide crosslinking agent, the content is 0.3%~1.5%; (3) benzophenone UV aging resistance additives, UV aging resistance additives (4) Liquid silane coupling agent, with a content of 0.1% to 1.0%; (5) Rare earth-doped sulfate or aluminate Afterglow powder fluorescent powder, the powder particle size is between 100 nanometers and 20 microns, and the content is 0.5% to 5%; (6) Inorganic materials or pearlite coloring pigments with a temperature resistance above 200 ° C, the powder particle size is between Between 500 nanometers and 20 microns, the content is between 0.5% and 5.0%. Through kneading, granulation, melting and extruding into a film form, the finished EVA film is obtained through pressure roller pressing, cooling and shaping, and winding.

Owner:浙江利昌科技有限公司

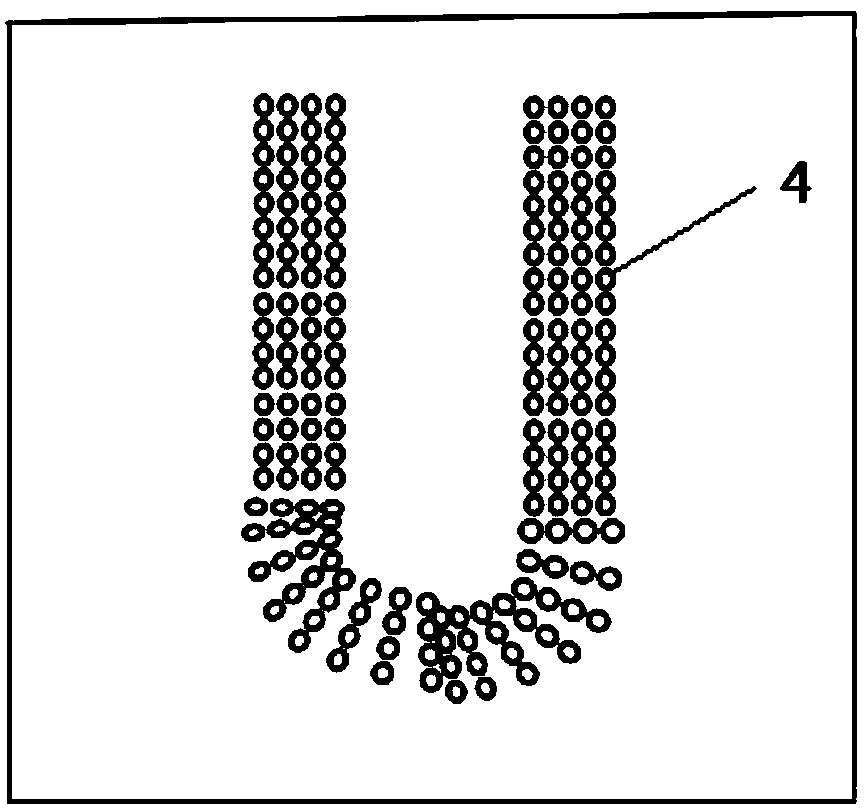

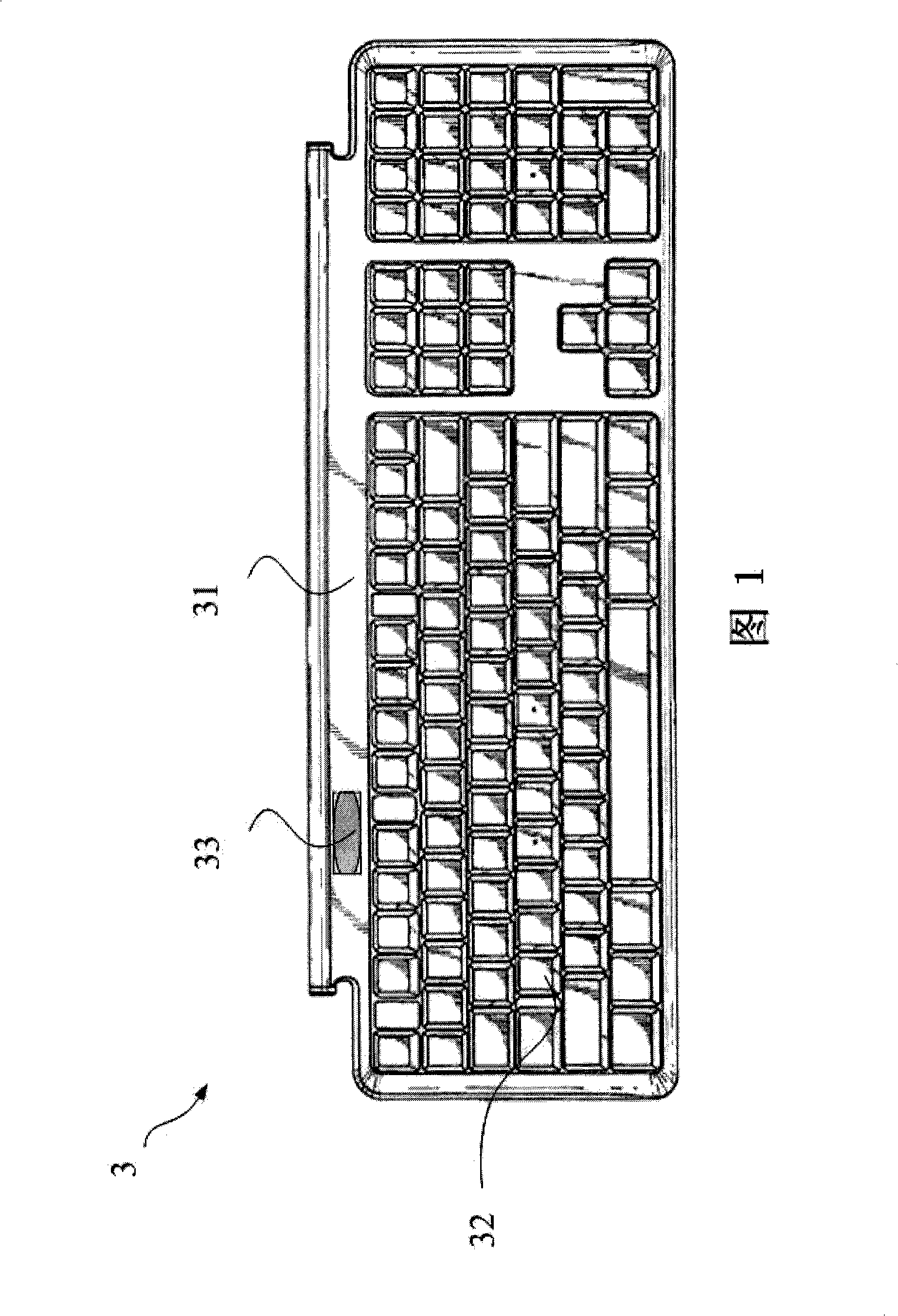

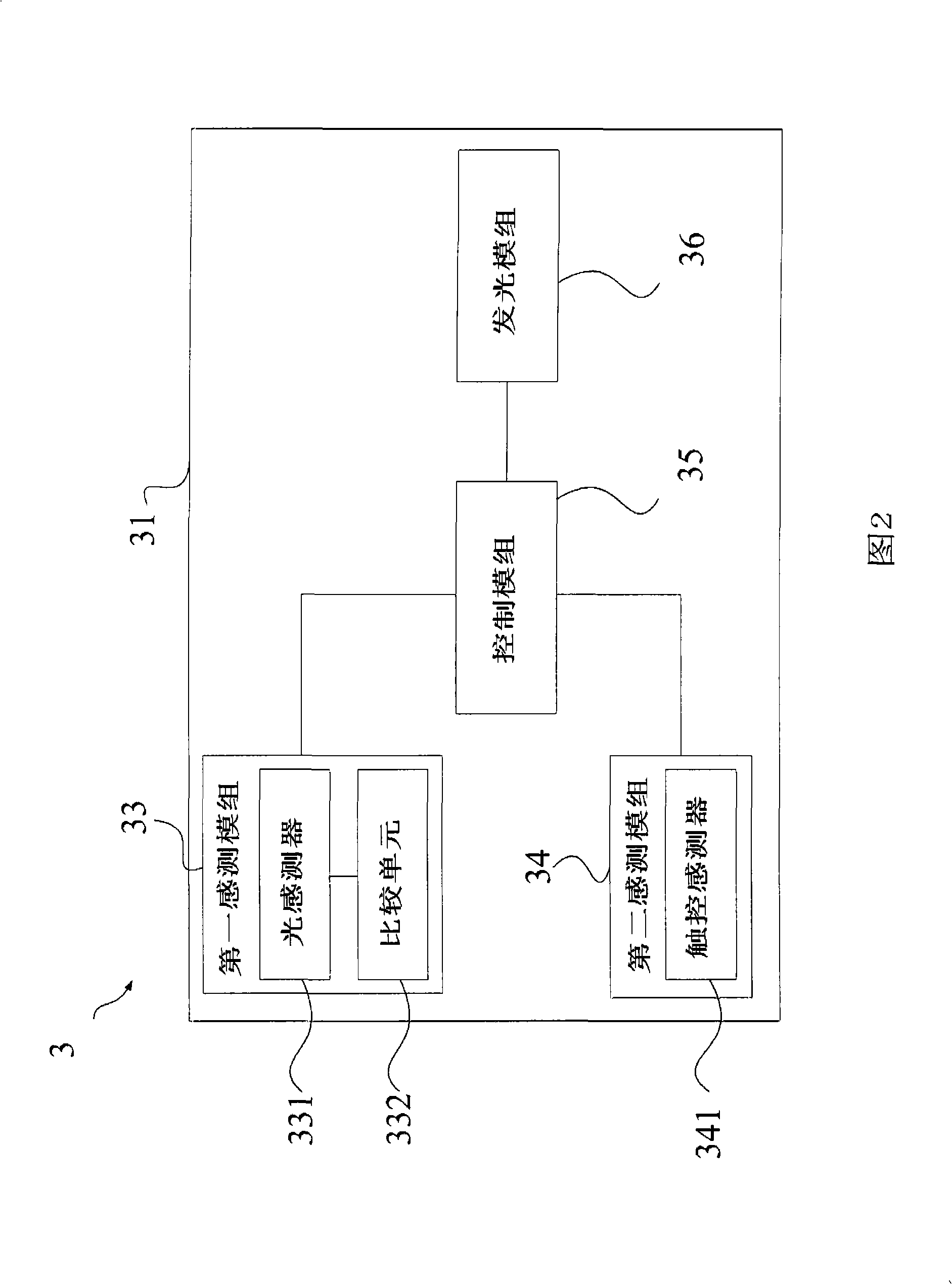

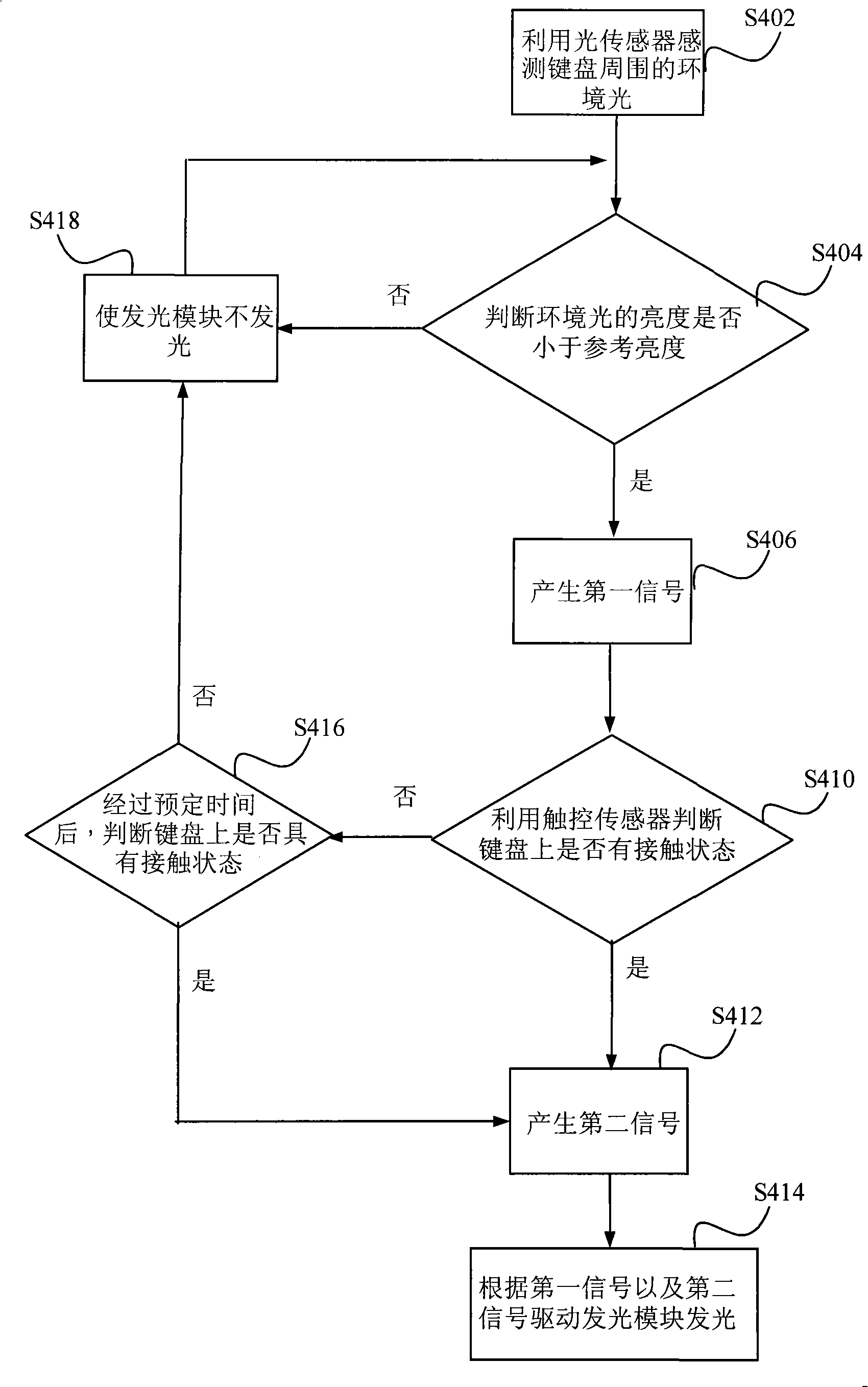

Illuminant keyboard and illuminating method for keyboard

InactiveCN101515201AWith light functionSave energyInput/output for user-computer interactionElectric light circuit arrangementComputer science

The invention discloses an illuminant keyboard and an illuminating method for the keyboard. The illuminant keyboard comprises an illuminating module, a first sensing module, a second sensing module and a control module. The first sensing module is used for sensing surround light. When the luminance of the surround light is lower than the reference luminance, the first sensing module generates a first signal. The second sensing module is used for sensing the contact state of the illuminant keyboard and generating a second signal according to the contact state. The control module is respectively connected with the illuminating module, a first sensor and a second sensor and is used for driving the illuminating module to illuminate according to the first signal and the second signal.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

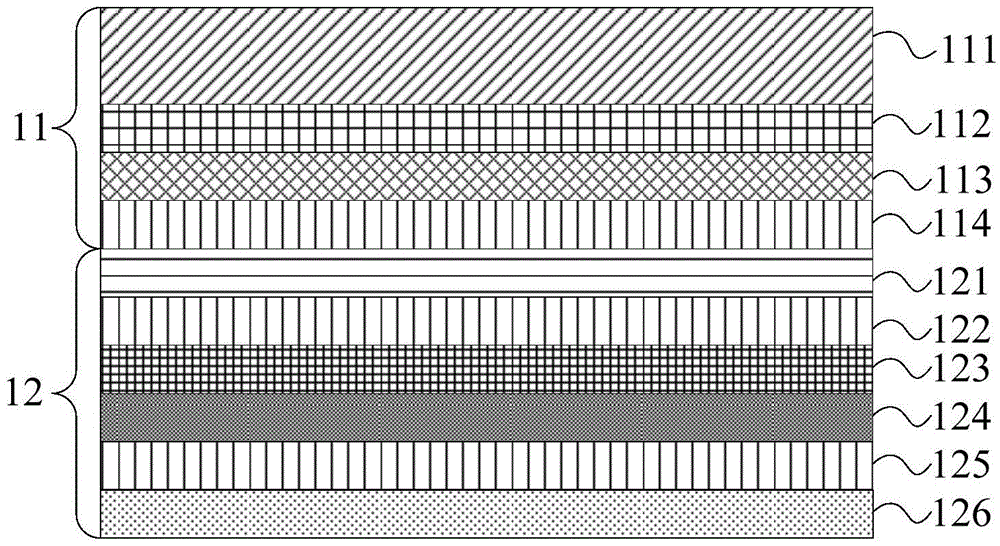

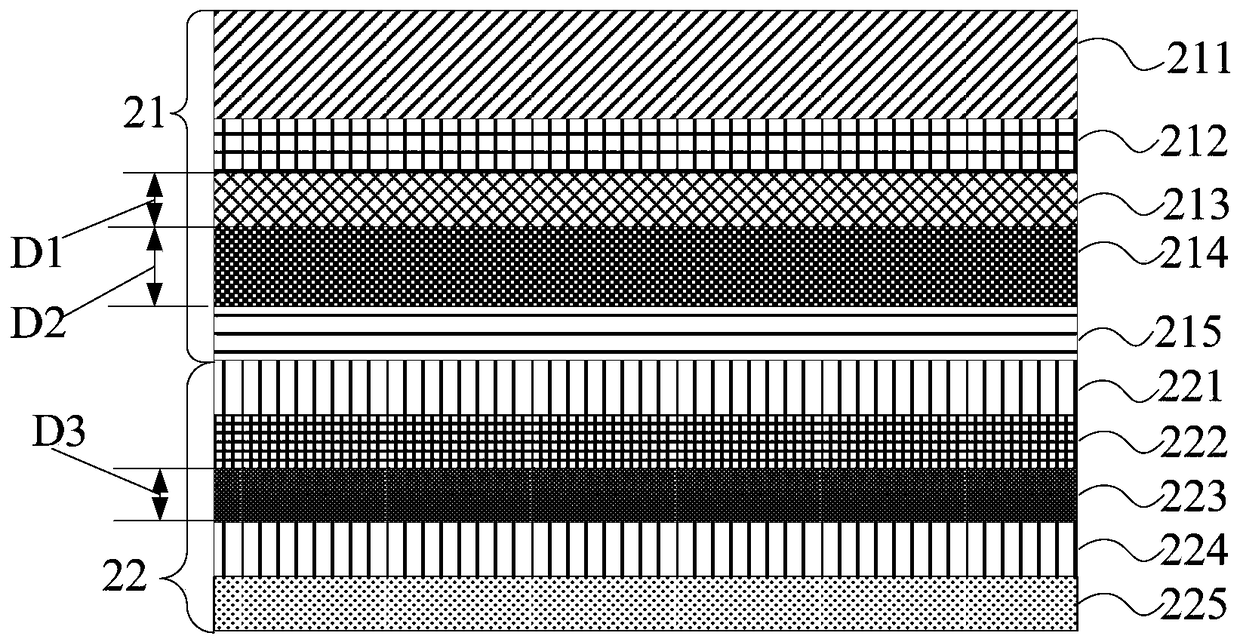

Luminous touch screen and display equipment

ActiveCN104598073AWith light functionReduce manufacturing costInput/output processes for data processingElectricityAlternating current

The invention discloses a luminous touch screen. The luminous touch screen comprises a touch structure and a luminous structure, wherein the touch structure is used for obtaining a track input by a user; the luminous structure is used for providing light to the touch structure; the touch structure comprises a touch layer, a first conductive glass layer, a first transparent base material layer, a second conductive glass layer, a second transparent base material layer, an electricity shielding layer and a third transparent base material layer, the touch layer is used for obtaining the track input by the user; the first conductive glass layer is used for obtaining one of a transverse coordinate or a longitudinal coordinate of the track in the touch layer; the first transparent base material layer is used for supporting the first conductive glass; the second conductive glass layer is used for obtaining the other one of the transverse coordinate or the longitudinal coordinate of the track in the touch layer; the second transparent base material layer is used for supporting the second conductive glass; the conductive shielding layer is used for shielding interference of alternating-current to the luminous touch screen; the third transparent base material layer is used for supporting the luminous structure. The invention further discloses display equipment. The luminous touch screen disclosed by the invention has a luminous function, and can be used for effectively reducing manufacturing cost of the display equipment.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

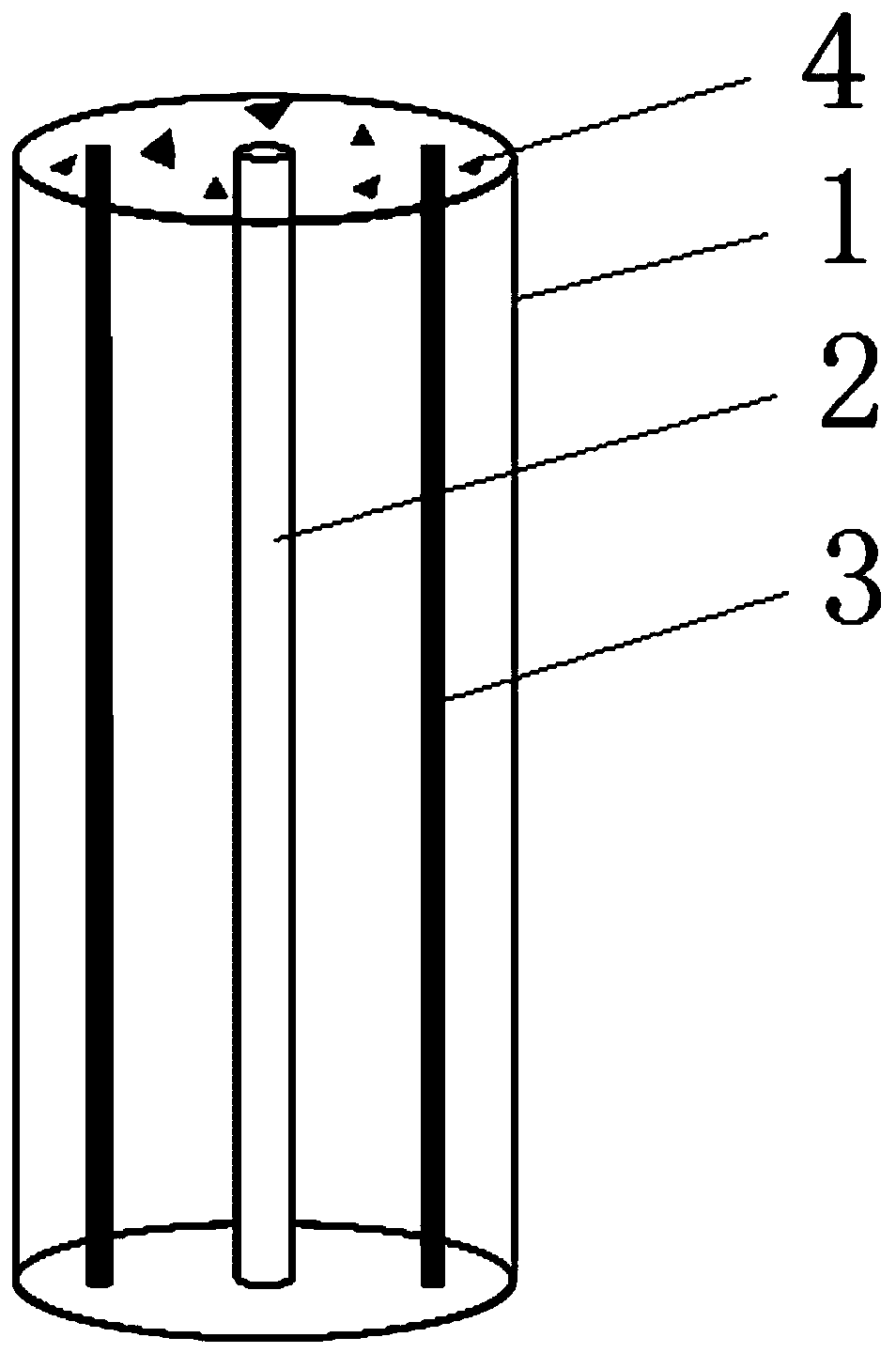

Composite glass optical fiber for synchronously detecting optical signals, electrical signals and chemical signals and preparation method of composite glass optical fiber

InactiveCN110776253ASmall difference in refractive index distributionGood light transmissionGlass making apparatusMeasurement devicesGlass fiberLight spot

The invention discloses composite glass optical fiber for synchronously detecting optical signals, electrical signals and chemical signals and a preparation method of the composite glass optical fiber. The composite glass optical fiber structurally includes glass cladding, a light-guiding glass fiber core, a conductive metal core and a noble metal micro-nano particle end surface, wherein the light-guiding glass optical fiber core layer is located at an optical fiber axis, and the conductive metal core is located in the middle area of the light-guiding glass fiber core and the outer cladding. The composite glass optical fiber can be used for realizing efficient transmission and recording of the optical signals, the electrical signals and the chemical signals, and the composite glass opticalfiber is expected to be widely used in the fields of neuroscience, biosensing, environmental monitoring and the like. Compared with current glass optical fiber and silica optical fiber, the compositeglass optical fiber has optical functions, electrical functions and chemical detection functions. Compared with polymer optical fiber, the composite glass optical fiber has high mechanical strength,uniform refractive index distribution, small light spots and good light transmittance performance.

Owner:SOUTH CHINA UNIV OF TECH

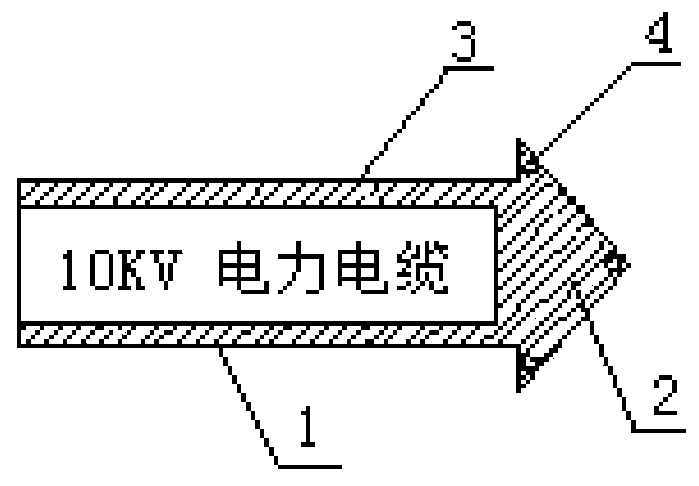

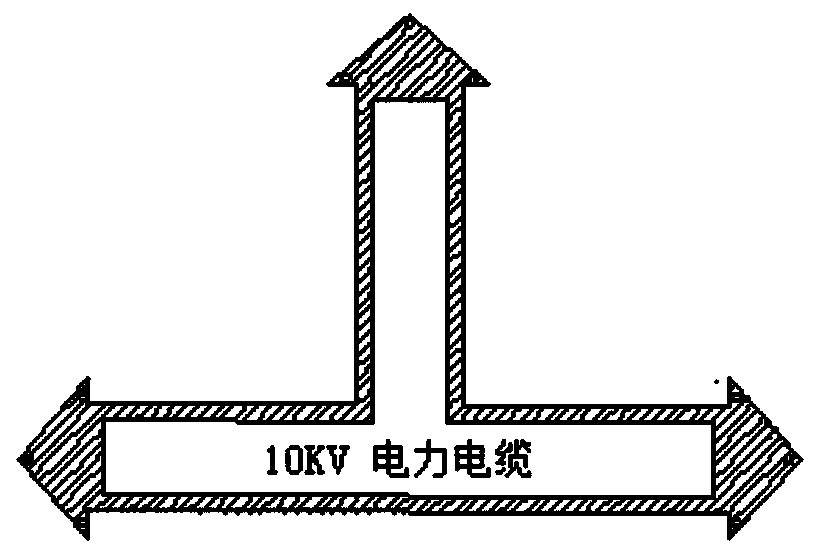

Noctilucent cable path indicating board

The invention relates to the field of electricity, and in particular relates to a noctilucent cable path indicating board. For the noctilucent cable path indicating board, a board body is arrow-shaped, and a long-afterglow material layer covers the surface profile of the board body. For the board body of the noctilucent cable path indicating board, due to the long-afterglow material layer which covers the board body, even under the dark light rays, the light-emitting function is still available in the night without a light source, therefore, the indicating board can play a reminding role evenin the environment without light, then a worker can clearly see a cable identifier even when working at night, therefore, the phenomenon that a cable is dug through or damaged during the constructionprocess is avoided, and further, the power supply safety and reliability are not influenced.

Owner:GUANGDONG POWER GRID CO LTD +1

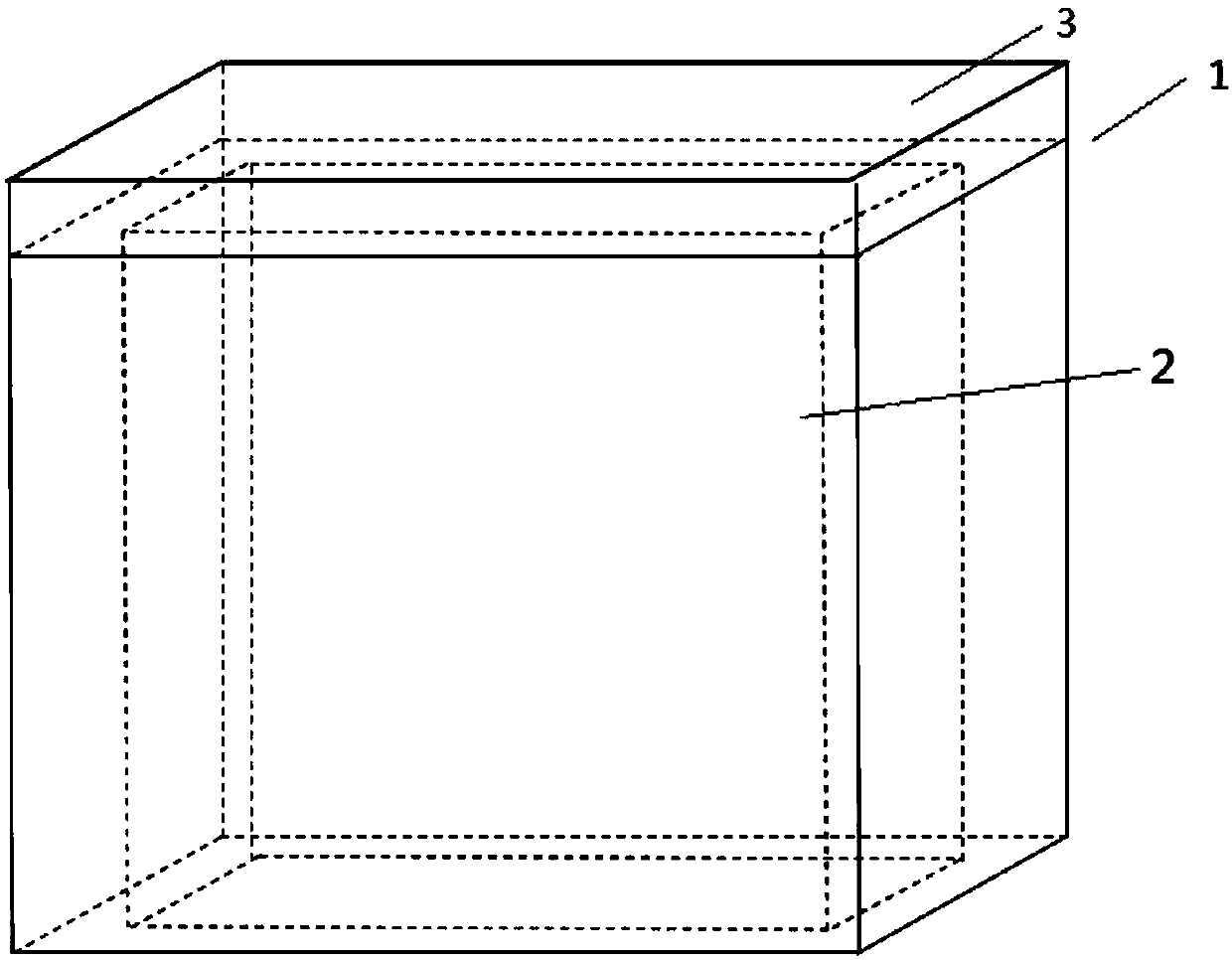

Fluorescent display fire hydrant

InactiveCN102284169AWith light functionConvenient for firefighting at nightFire rescueFluorescenceFirefighting

The invention discloses a fluorescent fire hydrant, which comprises a hexahedron-shaped box body surrounded by metal plates. There are fire hydrant valves, water inlet and outlet joints and soft water spray pipes in the box body. A door is connected to the front of the box body through a hinge. A fluorescent layer is arranged on the front of the door, and a fluorescent layer is arranged on the side of the box body, and the fluorescent layers are strip-shaped and multiple. Because there is a fluorescent layer on the outer surface of the box body, it has a luminous function, and it is easy to be found especially in the dark, which provides convenience for fighting fires in the dark.

Owner:大连金州登沙河鑫金机械厂

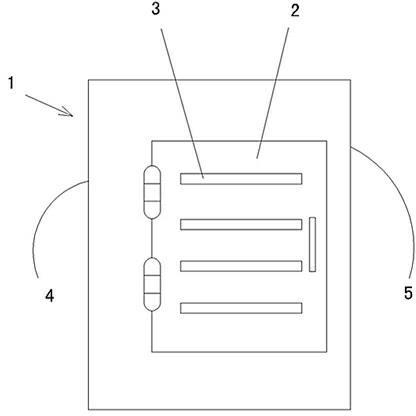

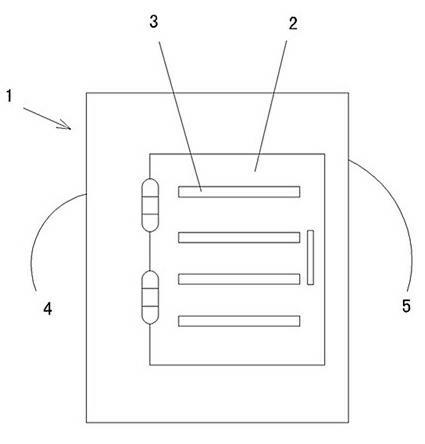

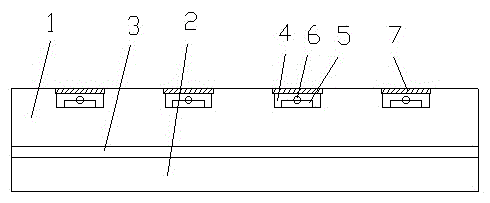

Light-emitting type floor tile structure

InactiveCN105002806ASimple structureImprove crack resistanceLighting elementsSidewalk pavingsCrack resistanceEngineering

The invention discloses a light-emitting type floor tile structure. The light-emitting type floor tile structure comprises a first roasting floor tile base body and a second roasting floor tile base body; the first roasting floor tile base body is arranged at the upper portion, and the second roasting floor tile base body is arranged at the lower portion; the first roasting floor tile base body and the second roasting floor tile base body are combined together through a viscose layer, and a meshed anti-cracking layer is embedded inside the viscose layer; a plurality of parallel long-strip-shaped grooves are distributed on the upper surface of the first roasting floor tile base body, circuit boards are arranged inside the long-strip-shaped grooves, and a plurality of LED lamp beads are connected to the circuit boards; openings of the long-strip-shaped grooves are covered with long-strip-shaped glass plates matched with the long-strip-shaped grooves, and gaps are sealed through a sealant; and electric leads extend out from the two ends of the long-strip-shaped grooves, and a sealing structure is arranged. By means of the mode, the light-emitting type floor tile structure is simple and reasonable in structure, good in crack resistance and low in damage rate, and has the light-emitting function; and the light-emitting type floor tile structure is paved on a road so that the lighting effect can be achieved at night.

Owner:CHANGZHOU NANXIASHU CONSTR

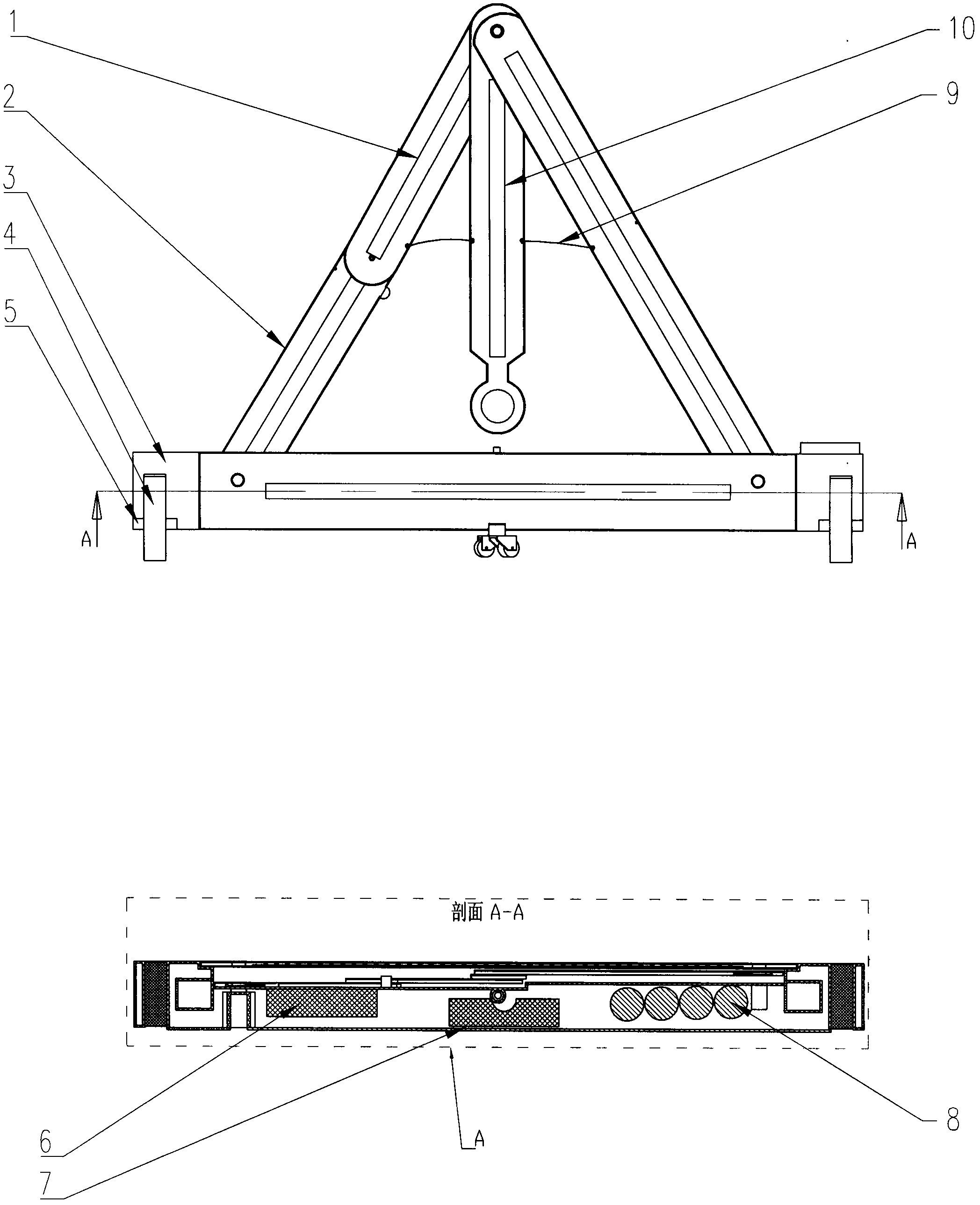

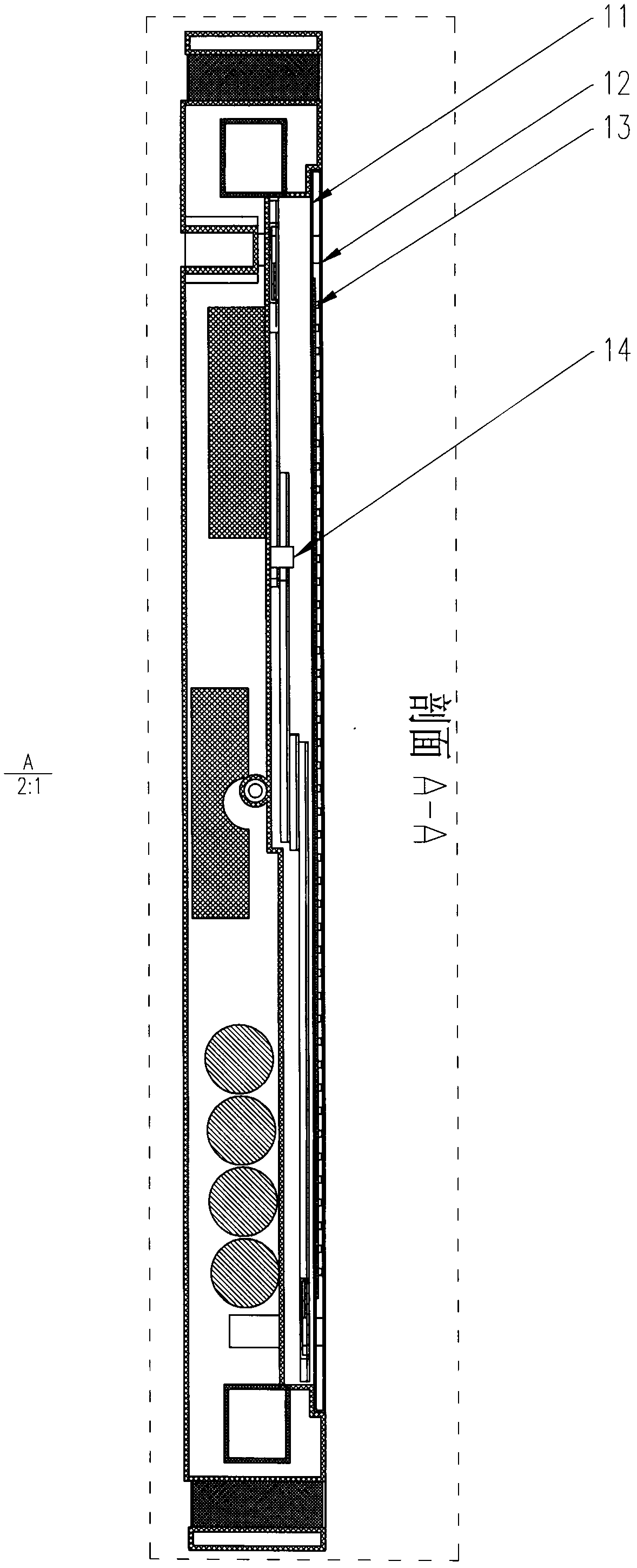

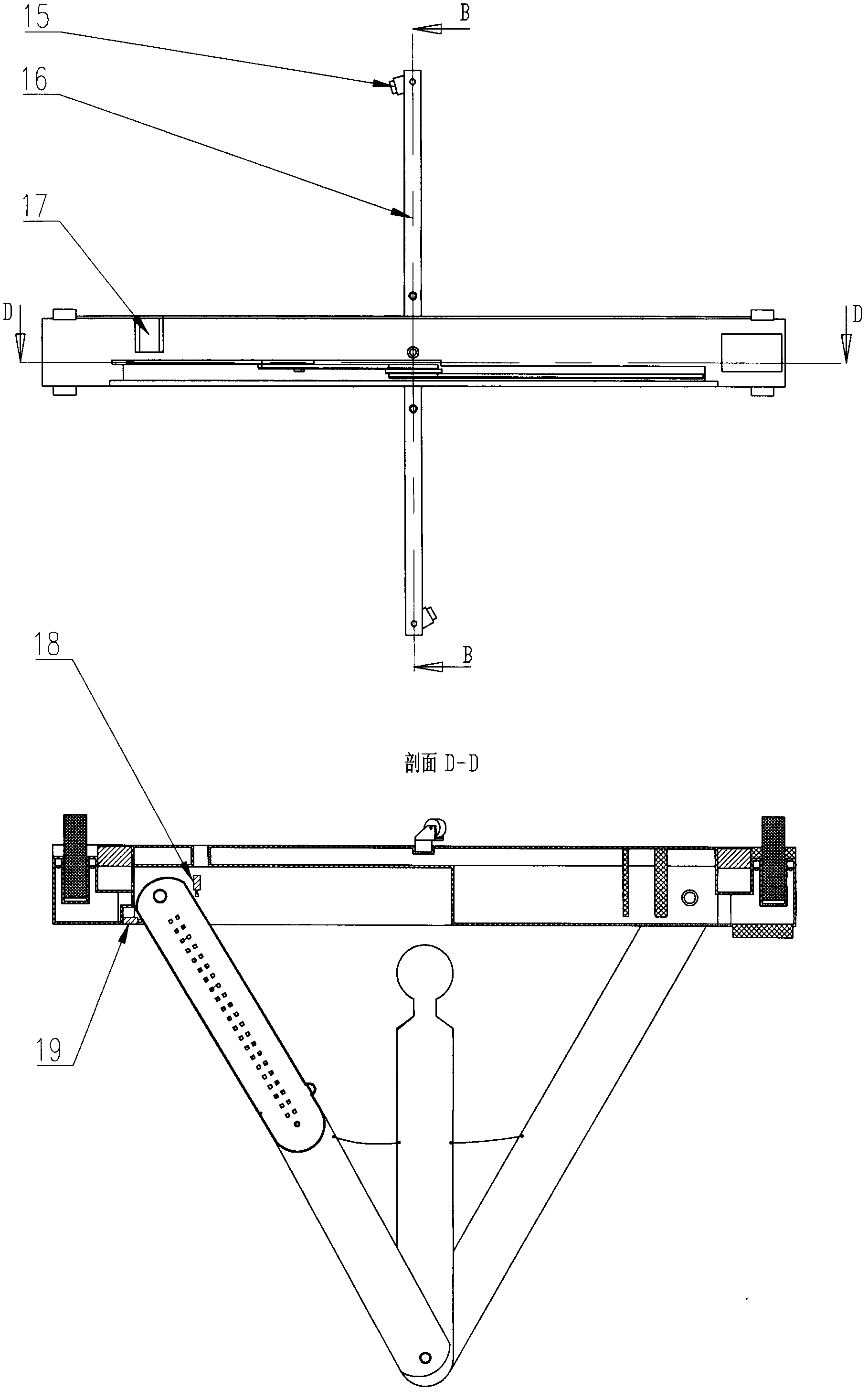

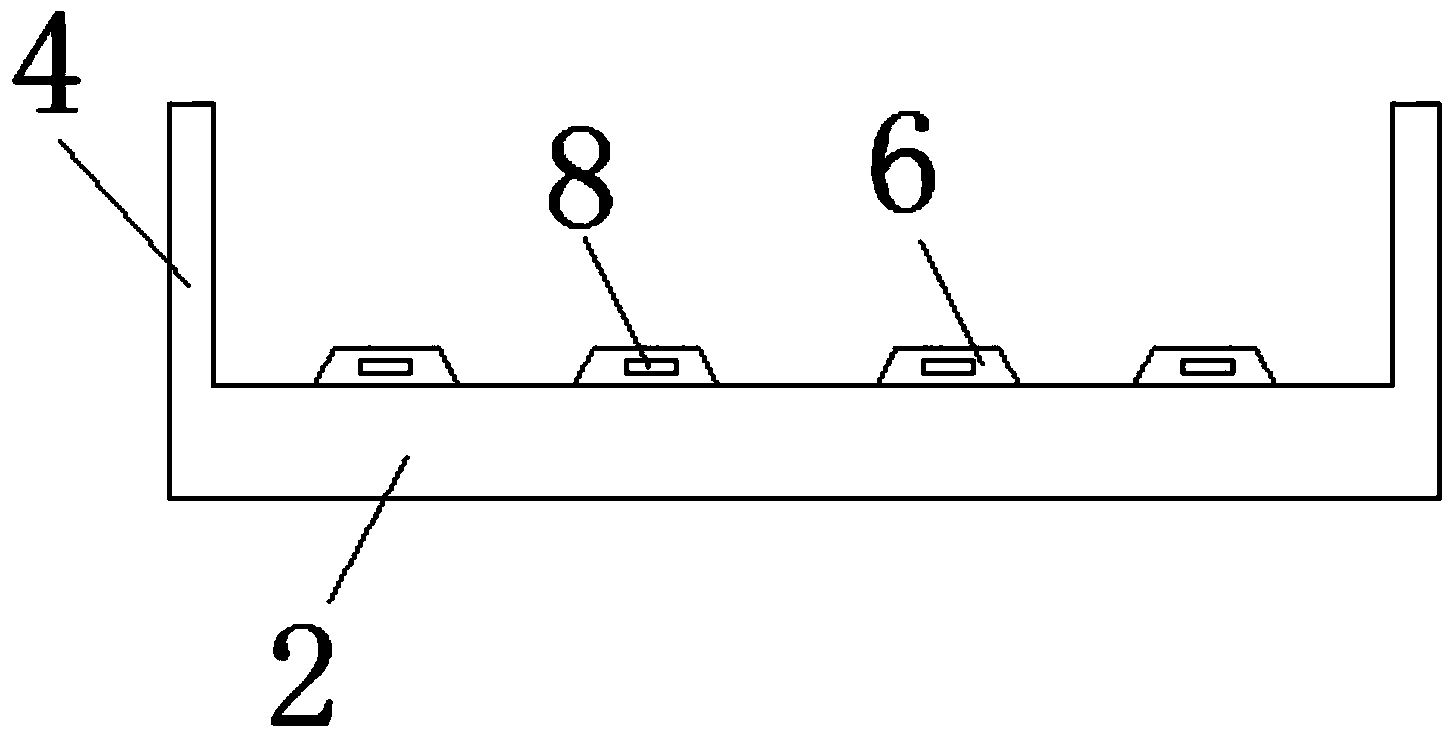

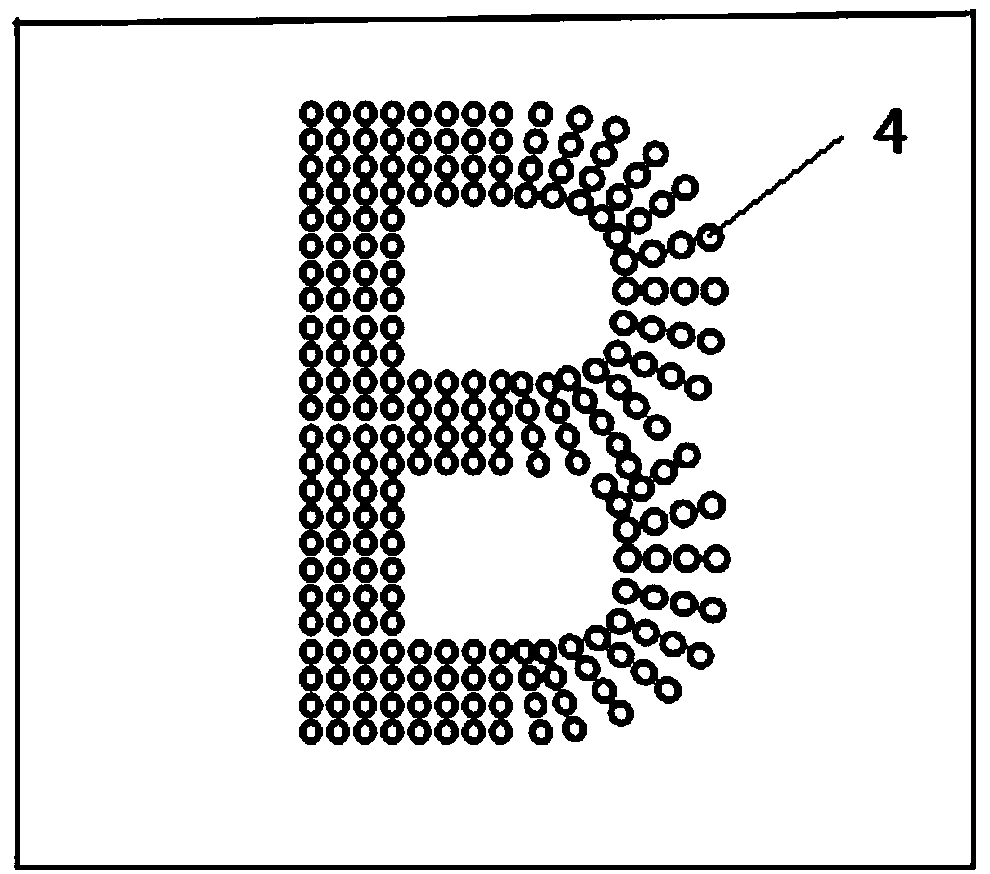

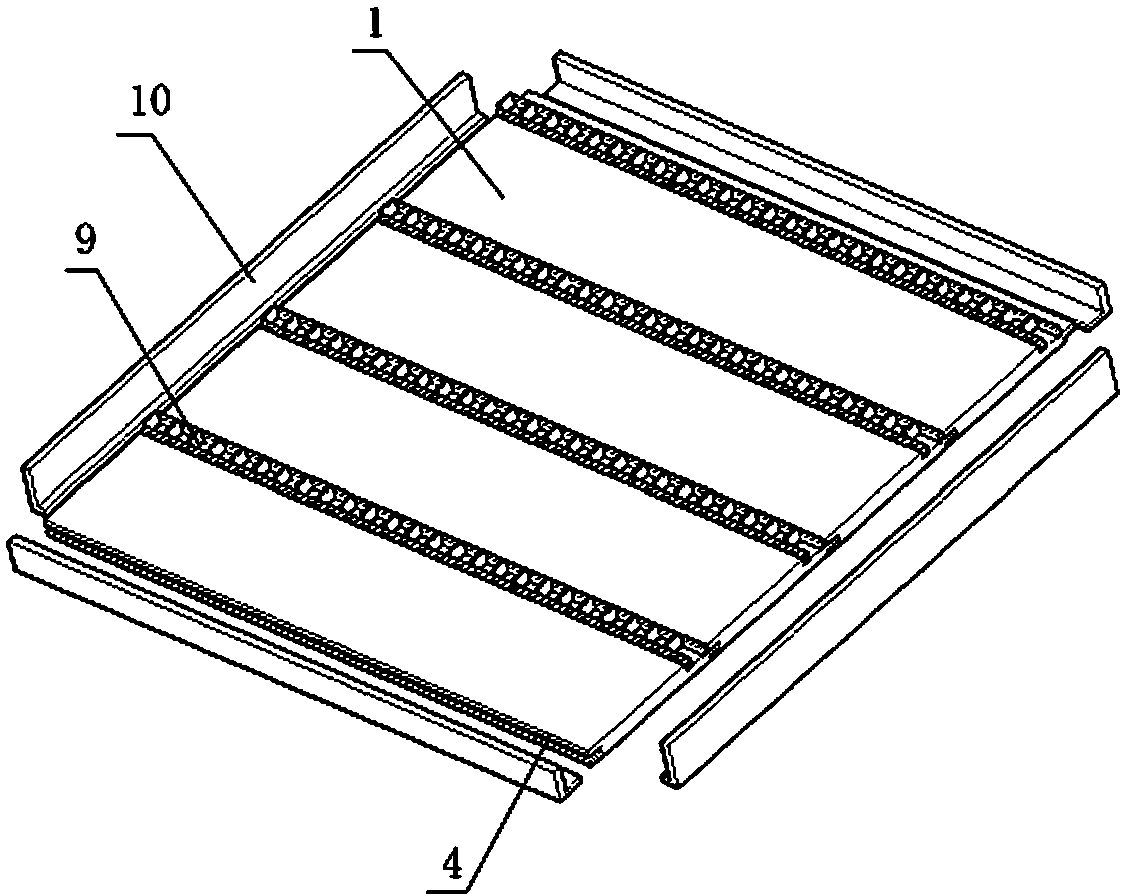

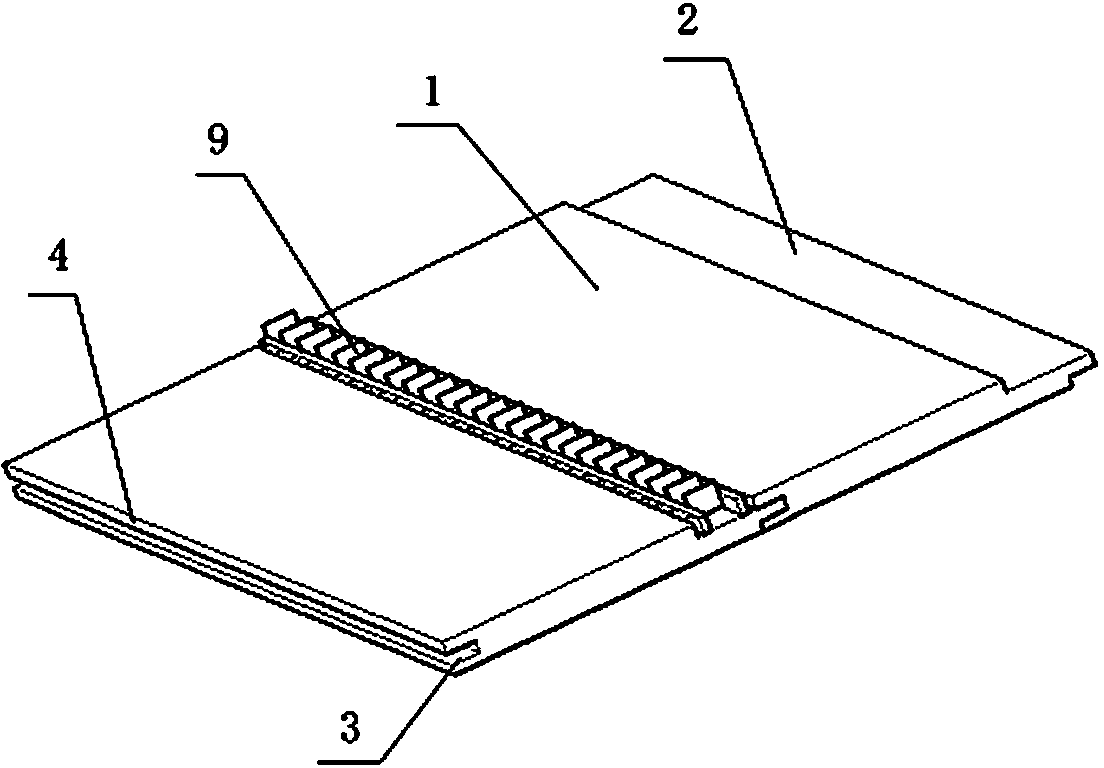

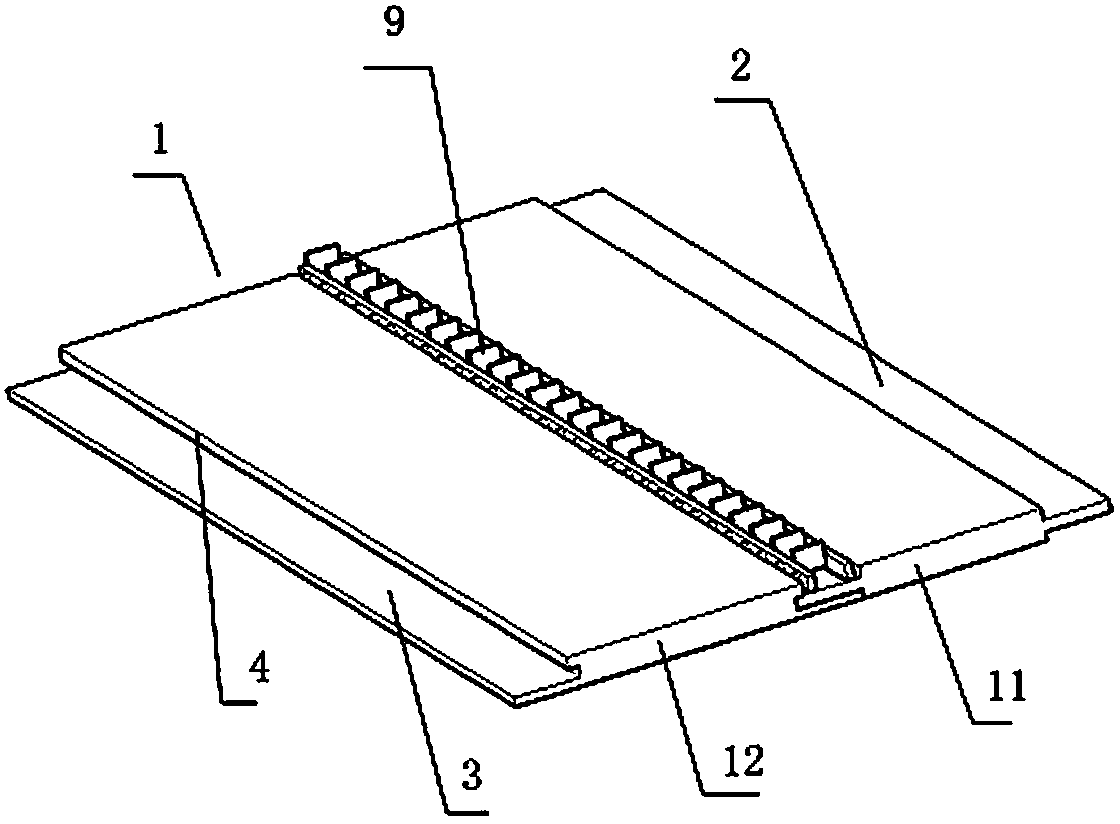

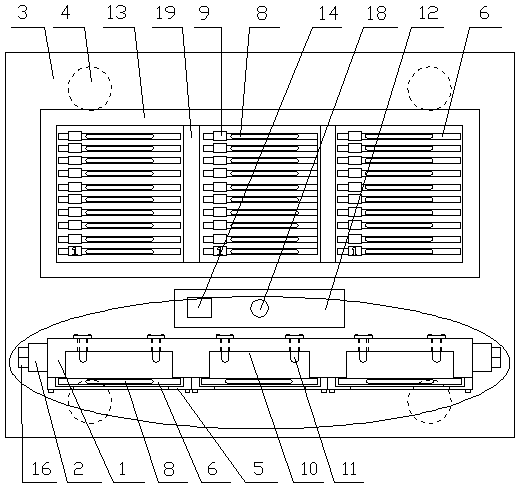

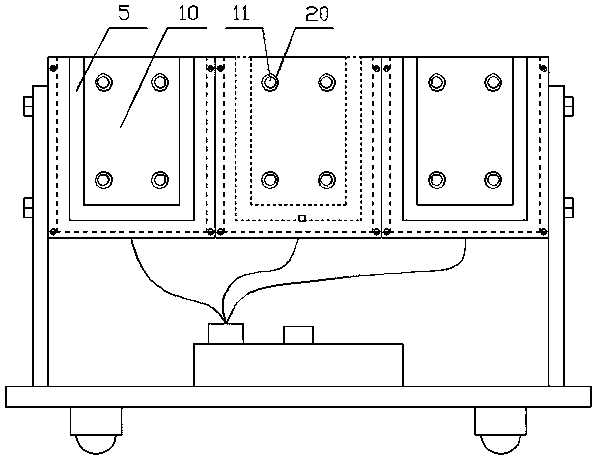

Ceiling with light emitting function

The invention discloses a ceiling with a light emitting function. The ceiling comprises bar-shaped ceiling plates and a frame (10) and is characterized in that the ceiling with the light emitting function further comprises light emitting lamp groups (9), the ceiling plates are light guiding plates (1), clamping structures and light incident planes are arranged on the two long edges of each long-bar-shaped light guiding plate (1), the light incident planes (4) are overlapped on the upper layers of the clamping structures, the light guiding plates (1) are connected to form a whole plate through the clamping structures, and each light emitting lamp group (9) is clamped between light incident planes of every two light guiding plates. The ceiling with the light emitting function is a novel indoor ceiling, has the decoration and lighting functions, and is novel and reasonable in structure.

Owner:CHENGDU XINMU YIJU FURNITURE

Novel intelligent shoes

The invention discloses a pair of novel intelligent shoes and belongs to the technical field of shoes. Each shoe is composed of a sole and a vamp, wherein a foot inlet is formed at the top of the vamp; a storage battery, a global positioning system (GPS) positioning block and a temperature controller are arranged in the sole; a power switch, a charging interface, light emitting diode (LED) lamps, a heating chip and a temperature control probe are arranged on the vamp; the storage battery, the GPS positioning block and the temperature controller are located in a square box, and the square box is arranged at a heel of the sole; the power switch and the charging interface are arranged in a vamp interlayer at the foot inlet; the LED lamps are arranged on the vamp around the sole; and the heating chip and the temperature control chip are arranged on a front sole of the vamp. The pair of intelligent shoes disclosed by the invention has the advantages of simple structure and practical function; by virtue of a positioning function, the intelligent shoes can prevent the old people and children from getting lost; by virtue of a heating function, the intelligent shoes can generate heat in the winter to protect feet from cold injury; and by virtue of a lighting function, people wearing the novel intelligent shoes do not worry about walking in night.

Owner:周生旭

Outdoor portable flashlight

InactiveCN102889473AWith light functionPoint-like light sourceLighting elementsComputer hardwareComputer graphics (images)

The invention discloses an outdoor portable flashlight which comprises a flashlight main body, a compass, a strap and a temperature display screen, wherein the flashlight main body adopts an LED light source; the compass is fixed on the outer wall of the flashlight main body; the strap and the flashlight main body are removably connected; and the temperature display screen is powered by the power source of the flashlight main body. Through the combination of the components, the field portable flashlight not only has the common lighting function, but also can provide some auxiliary tools helping a user to live outdoors.

Owner:王丽

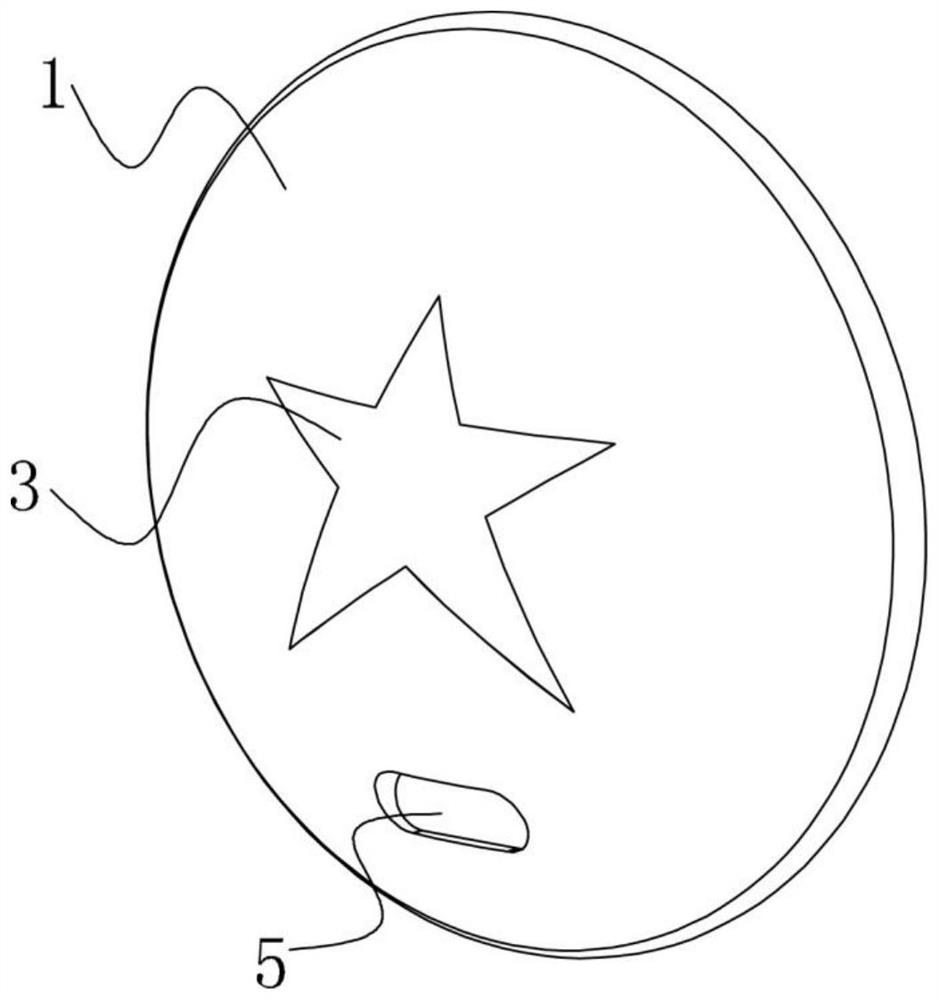

Multifunctional light-emitting decorative board

The invention discloses a multifunctional light-emitting decorative board, which comprises a board body; a light-emitting assembly arranged on the board body; and a wearing assembly arranged on the back face of the board body and used for being worn. The light-emitting assembly comprises a light-emitting body arranged on the surface of the board body; a light-emitting control module arranged in the board body, in signal connection with the light-emitting body and used for controlling the light-emitting body to emit light according to a set mode; and a power supply arranged in the board body and electrically connected with the light-emitting control module. The multifunctional light-emitting decorative board has a light-emitting function, and the light-emitting control module can control light emitting of the light-emitting body according to a preset mode, so that the decorative board can attract attention of people better and can be used as a gift, a gift or a sales promotion product;or a merchant can customize the decorative board into a specific shape, and the decorative board is used for atmosphere foiling of entertainment venues such as merchant advertisement display and propaganda, concerts, musical notes, night activities, KTV and bars, so that the application range of the decorative board is greatly expanded, and the practicability is higher.

Owner:QINGDAO ARTON IND CO LTD

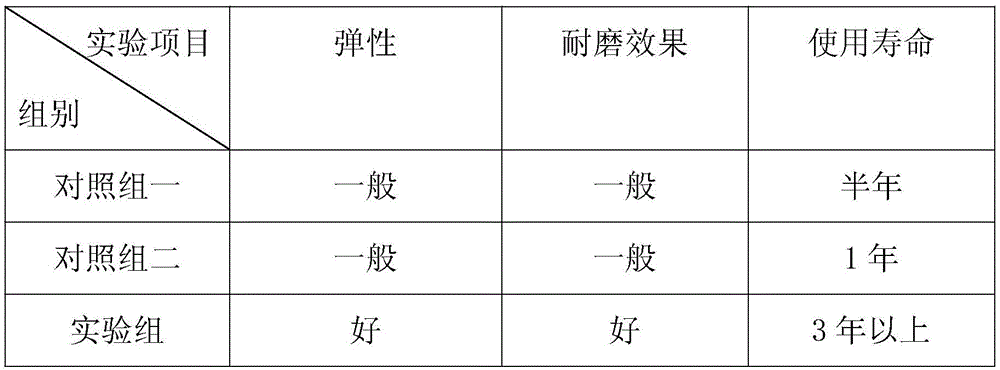

Automobile rearview mirror

The invention discloses an automobile rearview mirror. The automobile rearview mirror comprises a shell, a support, a light strip and a baffle, wherein the support is arranged on one side of the shell, the support is connected with the shell, and the light strip is arranged on the outer side of the shell and fixedly connected with the shell; the baffle is installed in the shell, and a rubber mat is arranged on the baffle and in gluing connection with the baffle; a lantern ring and a sleeve are arranged on the two sides of the baffle respectively, the lantern ring and the sleeve are both fixedly connected with the baffle, and the lantern ring is U-shaped; reinforcing ribs are arranged on one side of the sleeve and fixedly connected with the baffle and the sleeve respectively, a motor is installed on the sleeve and fixedly connected with the shell, a rotary shaft is installed on the bottom of the motor, and the bottom of the rotary shaft is fixedly connected with the sleeve. The automobile rearview mirror is firm in structure and has an illuminating function, and the adopted lantern ring is elastic, resistant to wearing and long in service life.

Owner:张晓鸣

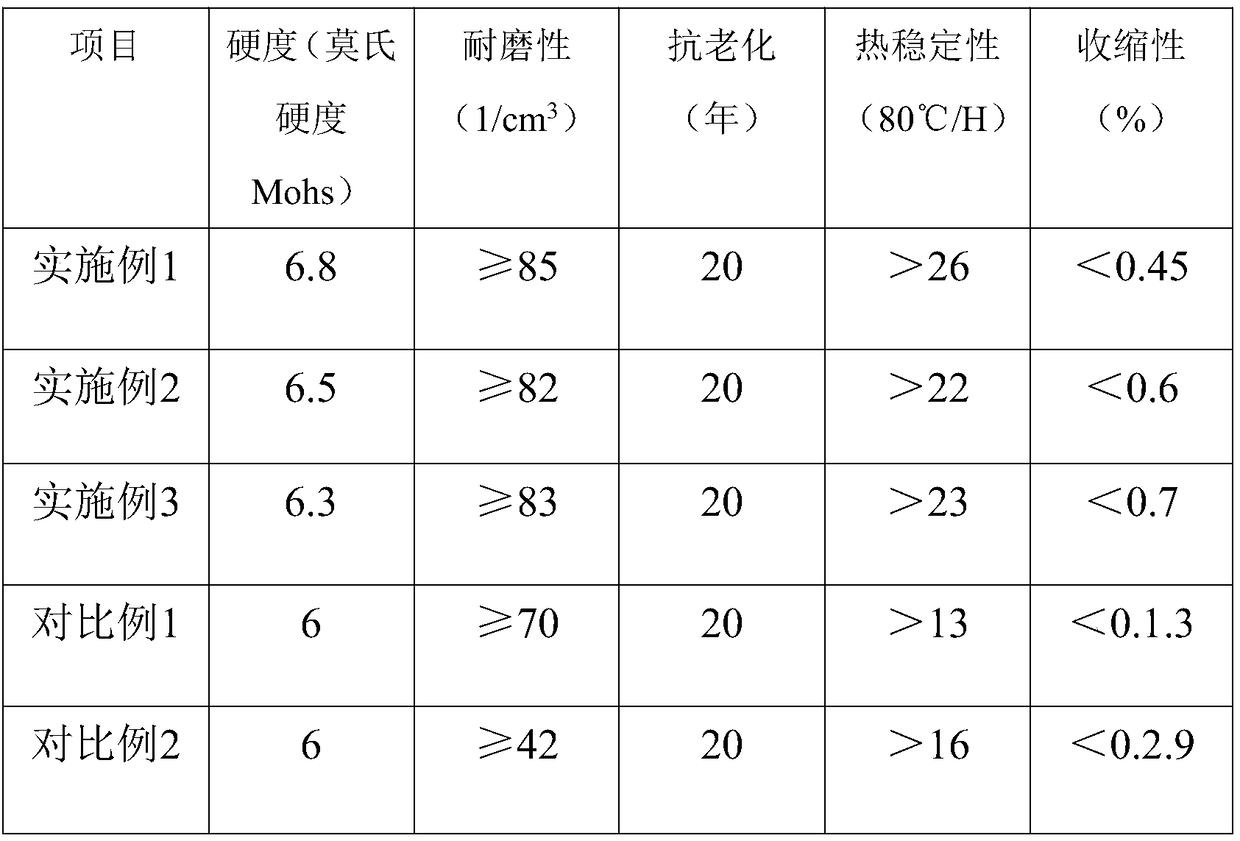

Toilet manufacturing process

The invention relates to the technical field of sanitary appliances and in particular relates to a toilet manufacturing process. The process comprises the following steps: S1, making a toilet seat glass fiber reinforced plastic mold, a liner glass fiber reinforced plastic mold and a wooden base mold according to the shape and size of the toilet seat, a liner and a base, and making an artificial stone toilet seat, an artificial stone liner and a PVC (Polyvinyl Chloride) base according to the molds; S2, connecting the seat ring of the toilet seat and the liner in a casting manner. Thus, the toilet prepared by utilizing a filling material provided by the invention has high glossiness, moisture resistance and excellent aging resistance. Moreover, since a luminous filler is arranged in the filling material, the prepared toilet has a luminous function, light storage is saturated by irradiating in the light for 5-20 minutes only, the toilet starts to give light when a light source does not exist, and the lighting time can reach 6-15 hours. After the toilet absorbs enough light in the daytime, a user can go to the toilet at night without turning on the light. The toilet has illuminating and indicating effects. Meanwhile, since the light does not need to be turned on, the energy-saving effect is achieved.

Owner:安徽雅诺卫浴科技有限公司

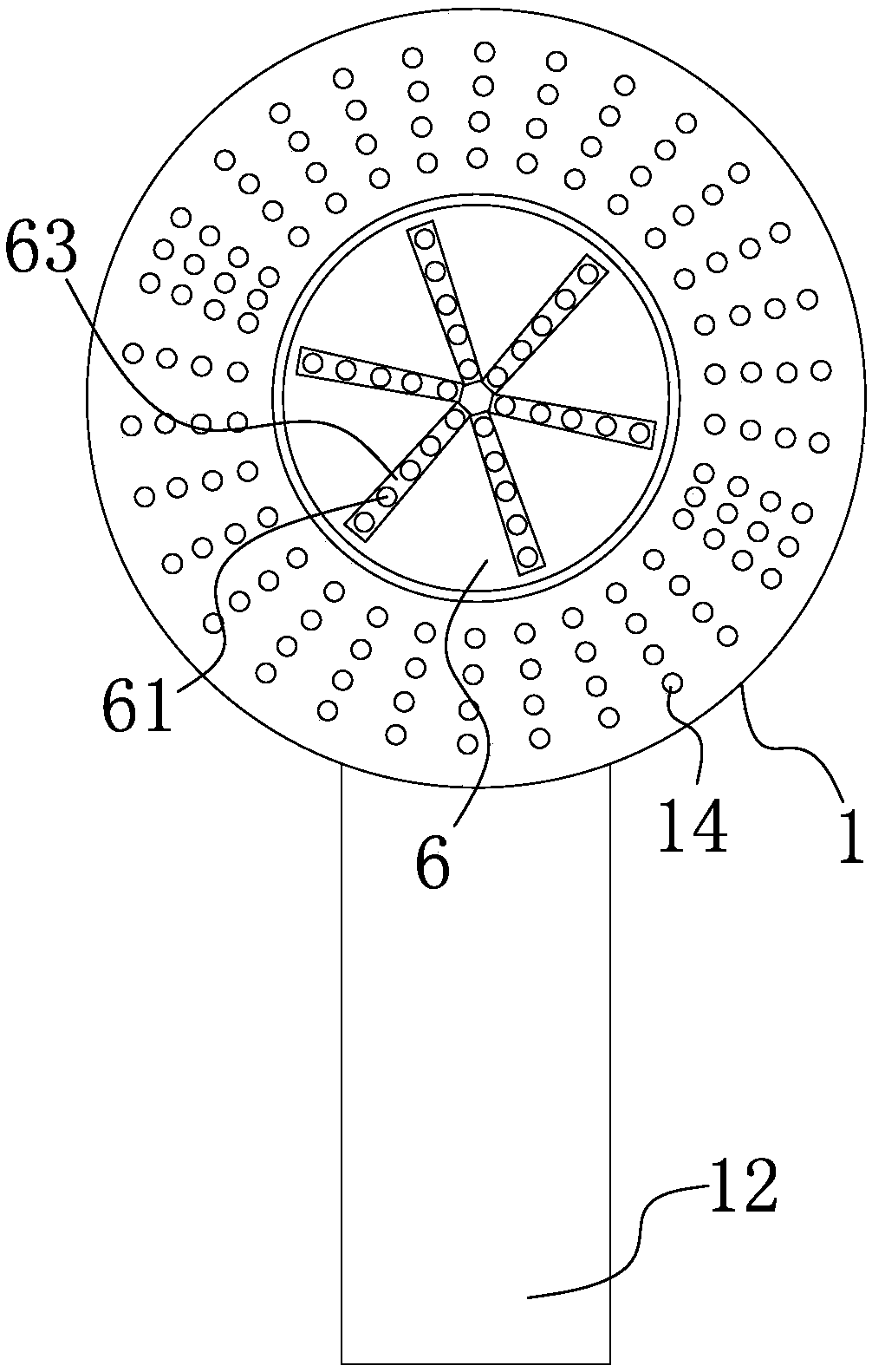

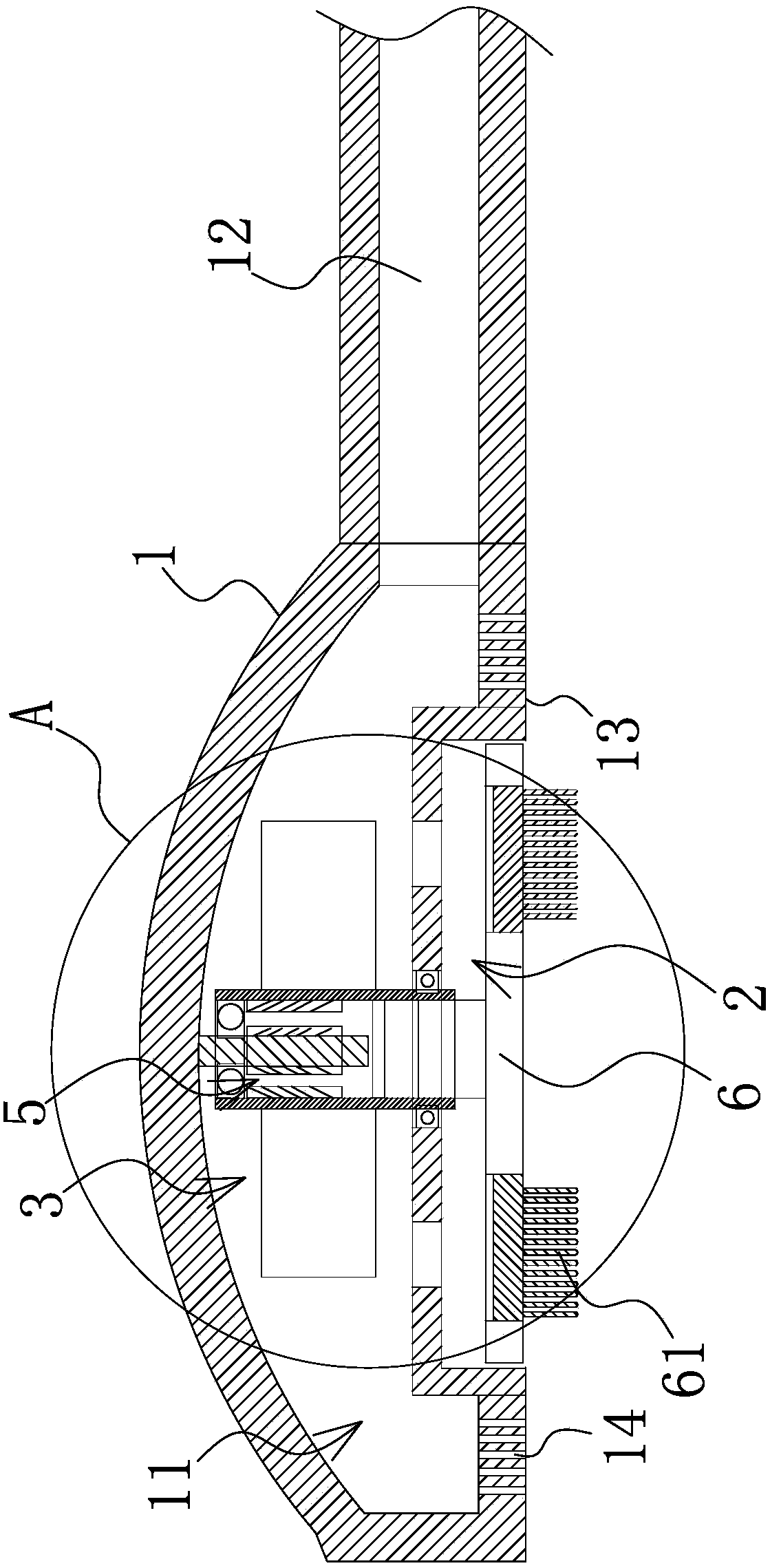

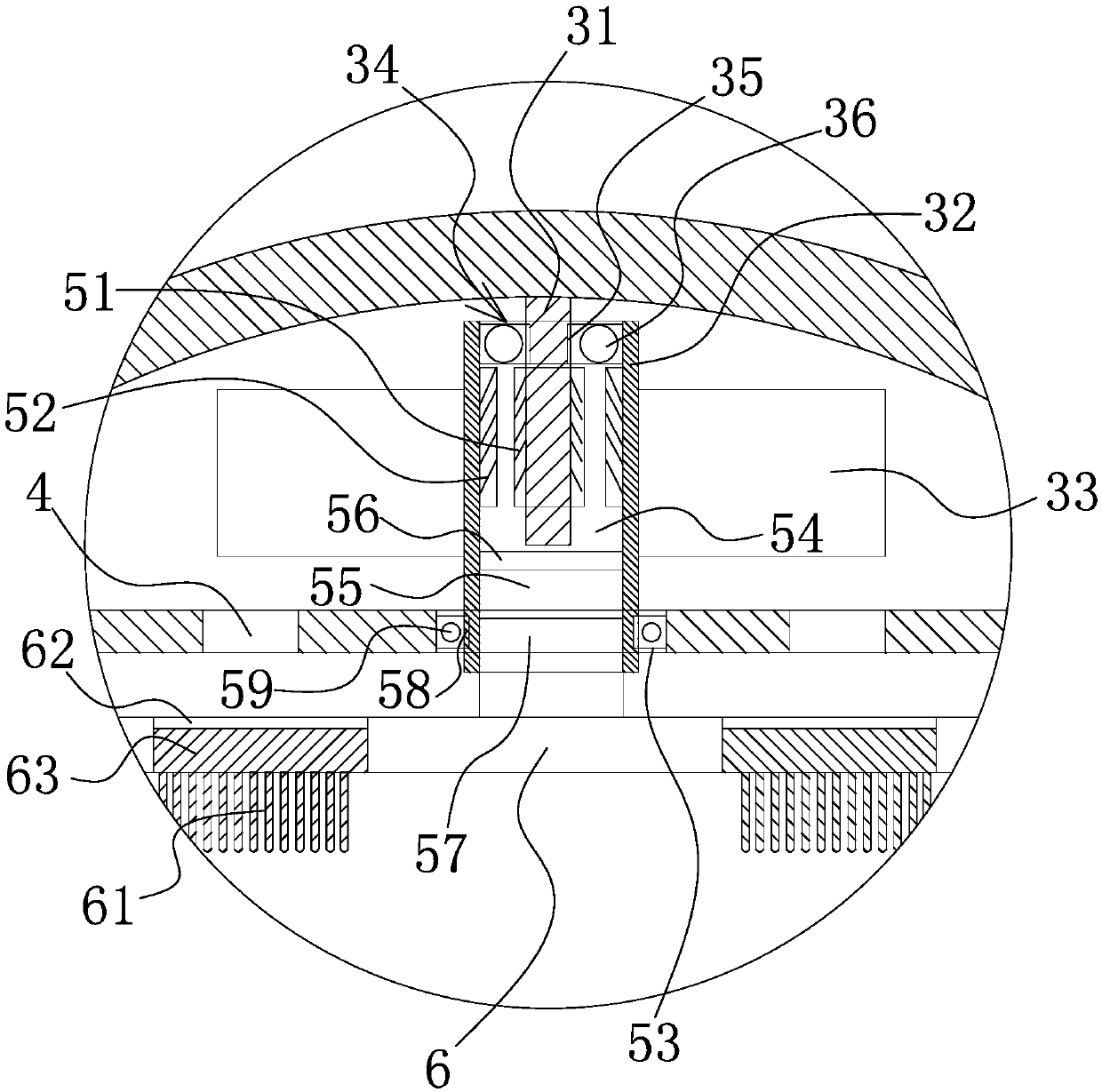

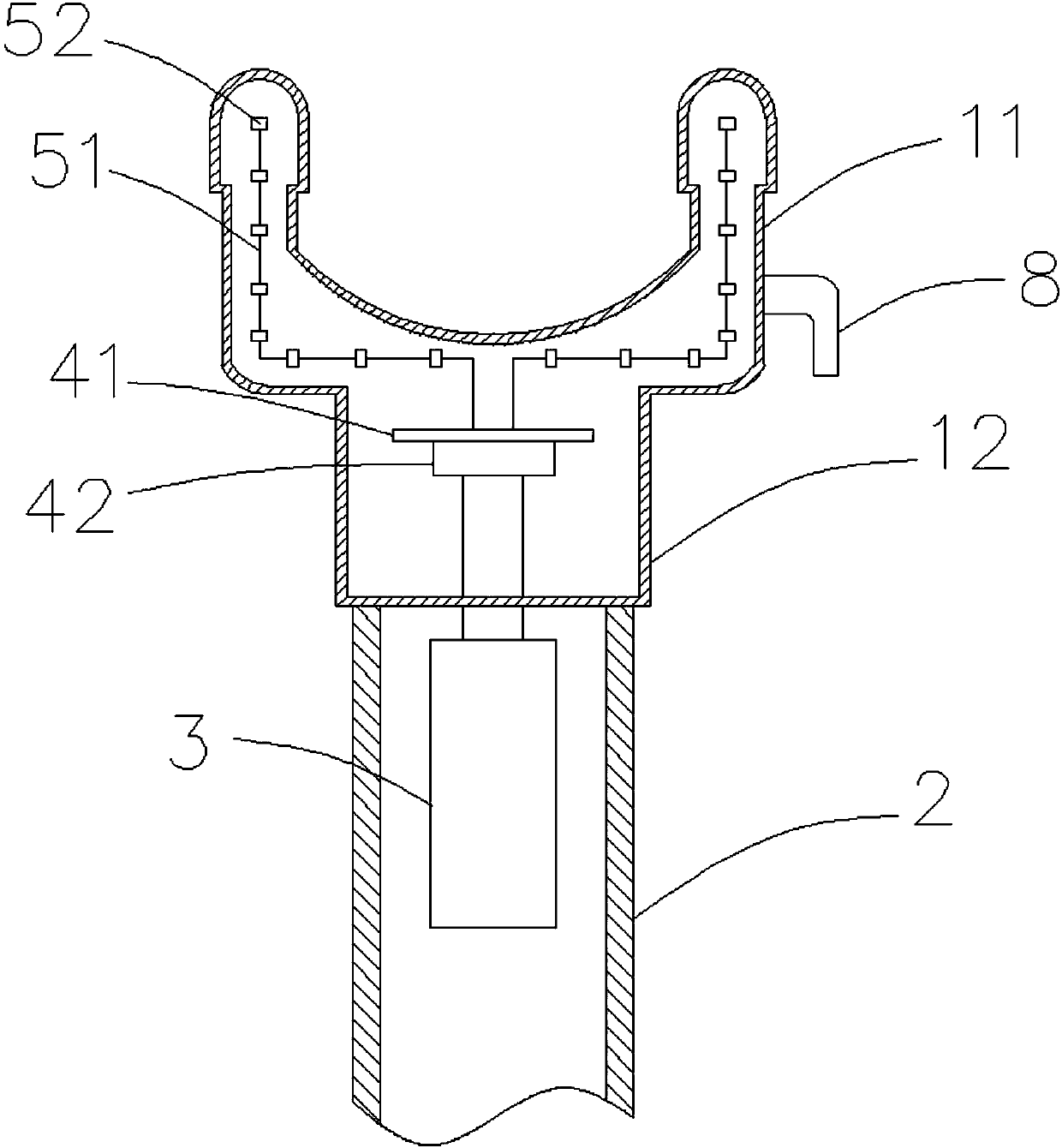

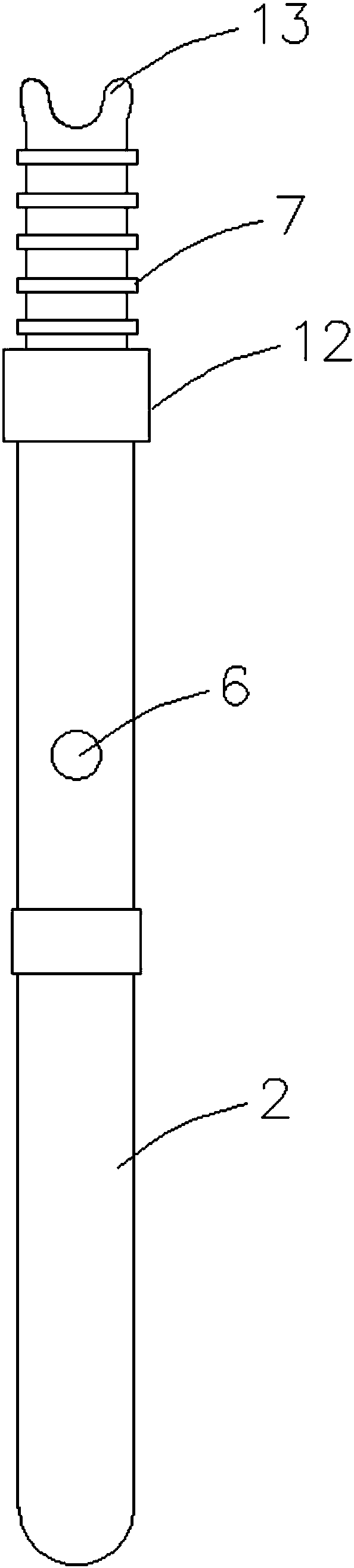

Self-light-emitting massage shower head

InactiveCN107837974ATo achieve the flickering effectSimple structureLighting elementsSpray nozzlesWater wheelBristle

The invention relates to a self-luminous massage shower head. The technical problem of unreasonable design in the prior art is solved. It includes the shower body, water inlet pipe, water outlet surface, water outlet hole and circular depression. The water wheel assembly is installed in the rotation of the shower body, and a number of luminous bodies are arranged on the inner side of the circular depression. The water wheel assembly is connected, and a rotating disk connected to the water wheel assembly is provided in the circular depression. A number of bristle bodies are provided on one side of the rotating disk, and at least one light-transmitting hole corresponding to the luminous body is provided on the upper circumference of the rotating disk. A blocking body made of transparent material is arranged in the light-transmitting hole. The advantage is that it has the function of lighting and massage, and can realize the rotation of the bristle body driven by the water flow. As the rotating disk rotates relative to the luminous body, the light source is blocked, and the flickering effect of the light source on the bristle body can be realized without circuit control. Realize the flickering effect of the light, the luminous effect is good, and the visual effect is more cool.

Owner:黄芳

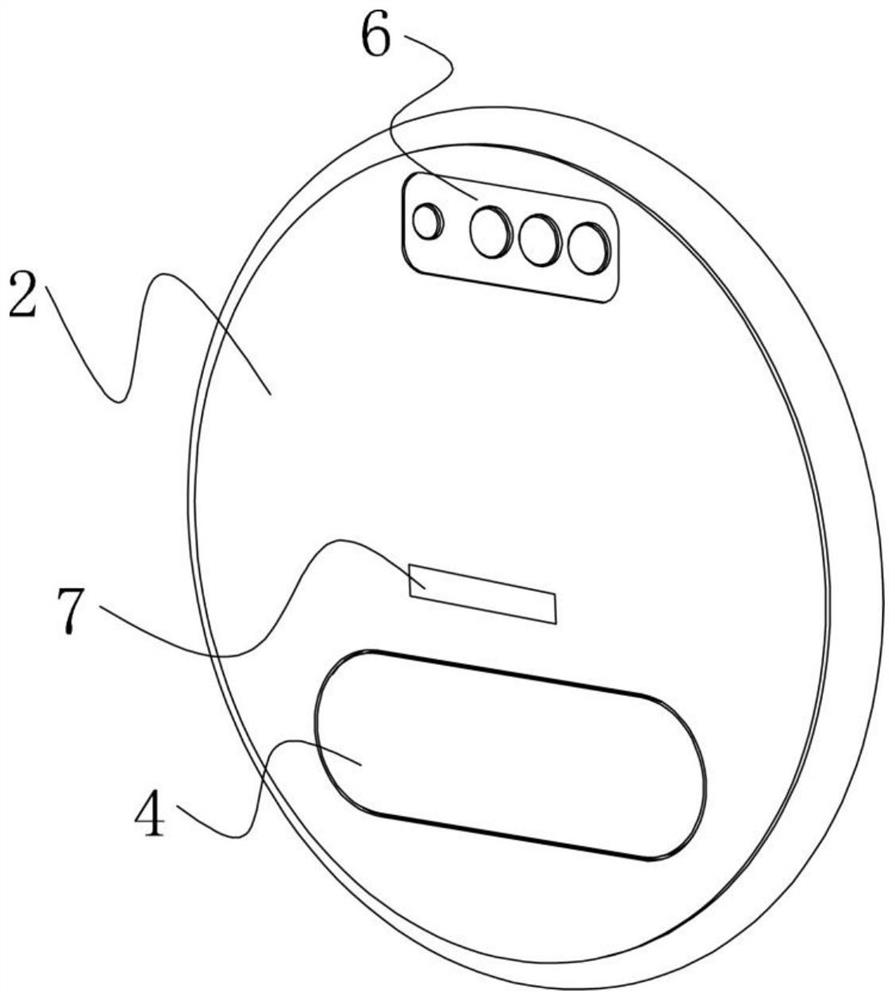

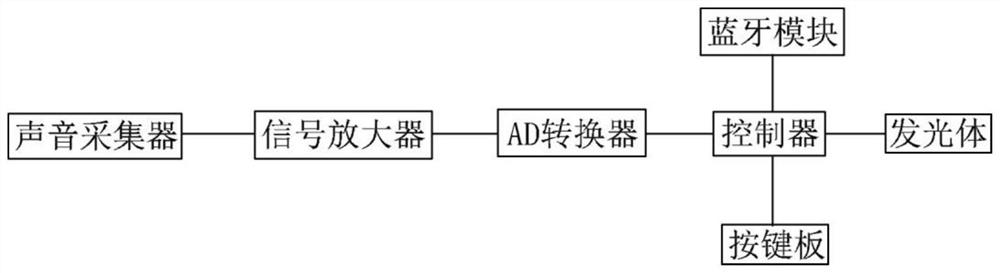

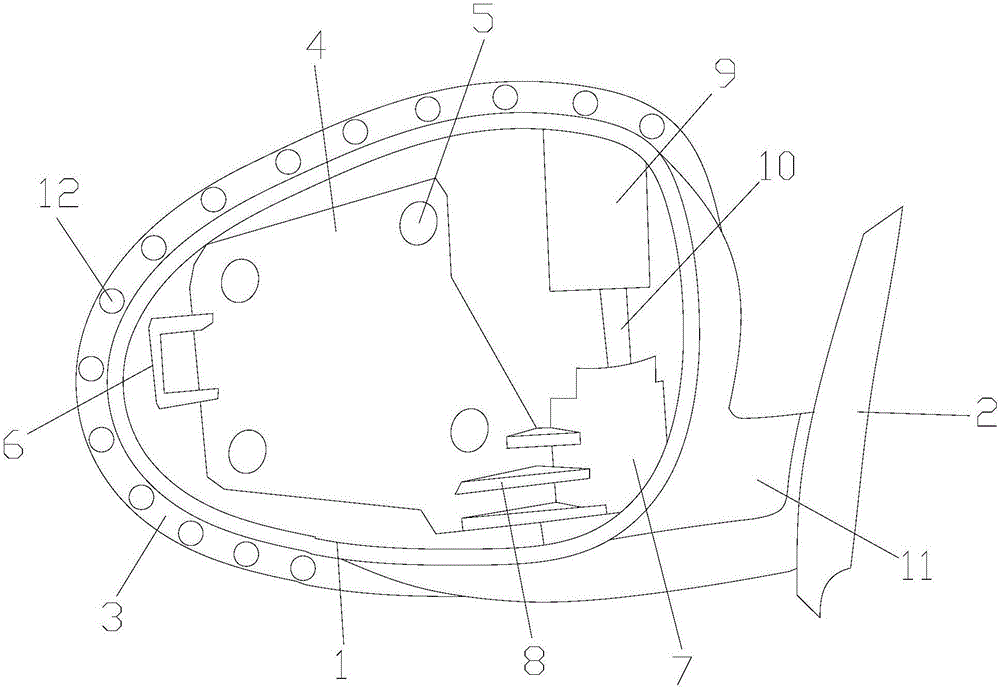

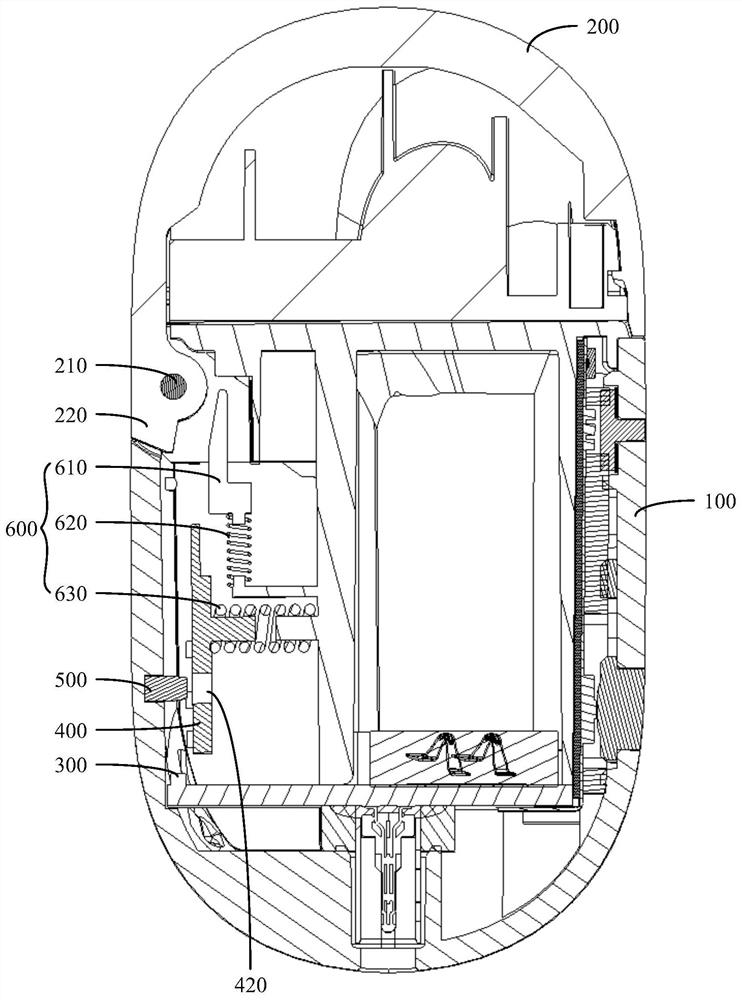

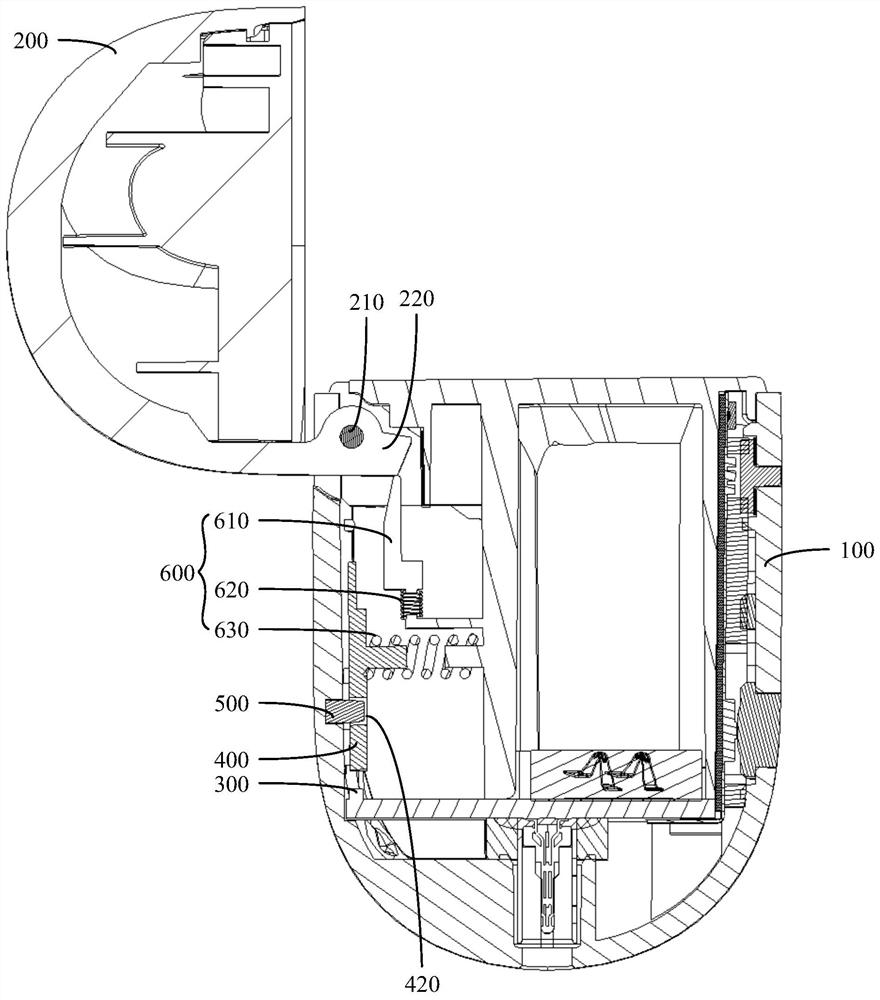

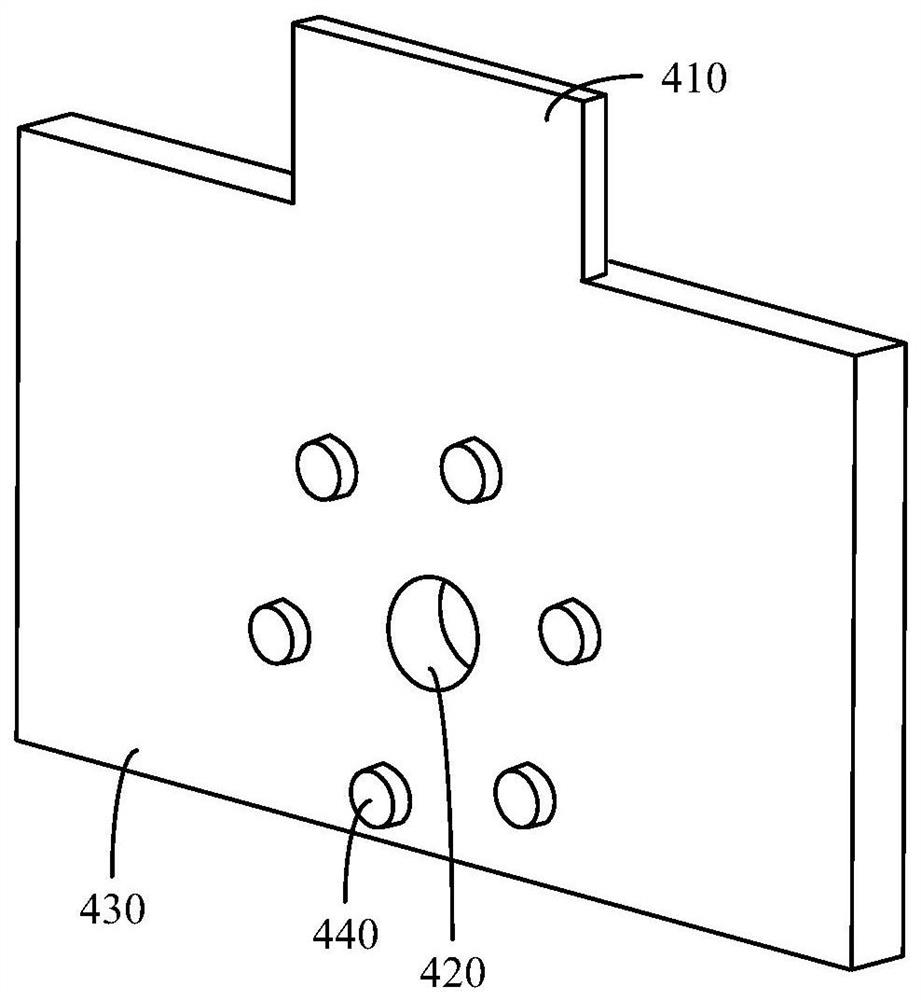

Charging box, control method and device thereof, earphone assembly and readable storage medium

PendingCN113676813AWith light functionVersatileBatteries circuit arrangementsOther accessoriesEngineeringHeadphones

The invention discloses a charging box and a control method and device thereof, an earphone assembly and a readable storage medium, and belongs to the technical field of wireless earphones. The charging box comprises a box body which is provided with a first light emitting area; a cover body which is rotationally connected with the box body; a light source which is arranged in the box body; under the condition that the cover body has a first angle relative to the box body, light rays emitted by the light source are guided out through the first light emitting area.

Owner:VIVO MOBILE COMM CO LTD

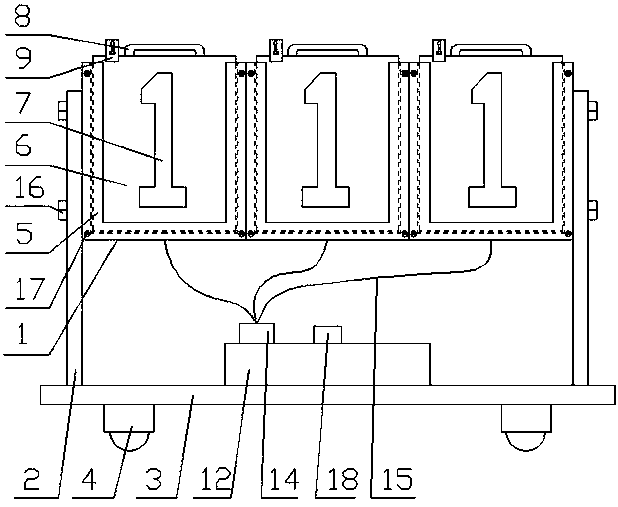

Scoring device special for athletic contests

The invention discloses a scoring device special for athletic contests. The device comprises a vertical plate frame, the two sides of the vertical plate frame are connected with supporting rods, the bottom of the supporting rods are connected with a base, a set of universal wheels are placed at the bottom of the base, a set of detachable sliding groove plates are detachably connected to the frontposition of the vertical plate frame, a number board is placed in a sliding groove between the vertical plate frame and the detachable sliding groove plates, number stickers are stuck to the front position of the number board, a handle is arranged in the middle of the top of the number board, a soft tag is stuck to one side of the top of the number board, a set of empty grooves are formed in the front portion of the vertical plate frame, a set of lamp beads are installed at the bottoms of the empty grooves, and a battery pack and a storage box are placed on the base. The scoring device specialfor athletic contests is convenient to move, easy to score, not likely to be damaged, good in display effect and capable of clearly displaying the score condition and has the light-emitting function.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

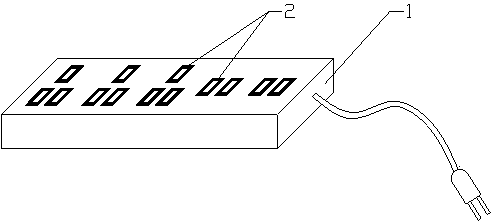

Socket with illumination function

The invention discloses a socket with the illumination function. The socket comprises a socket body and fluorescence strips. The fluorescence strips are arranged on the socket body and surround jacks in the socket body respectively. The socket with the illumination function has the advantages of being user-friendly, quite simple in structure, low in cost and easy to manufacture.

Owner:SHANGHAI GEZHI HIGH SCHOOL

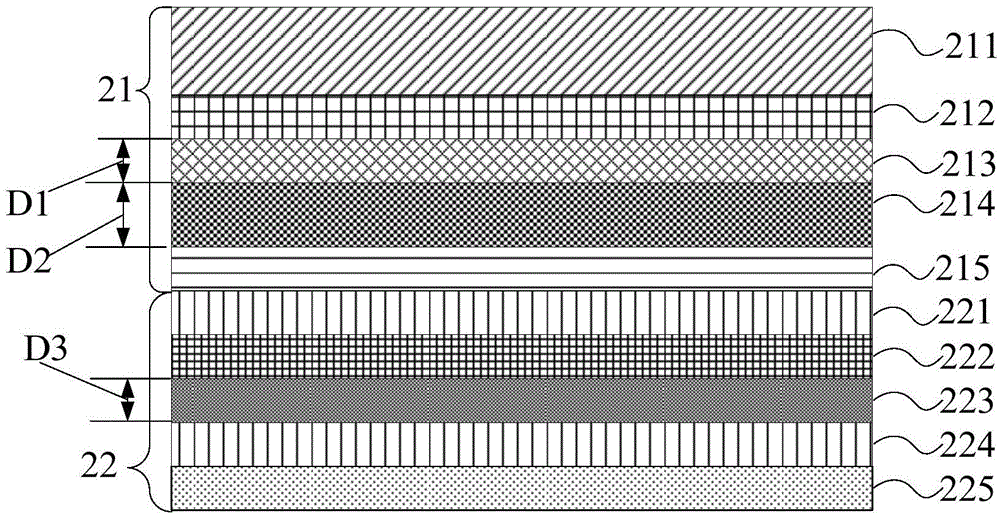

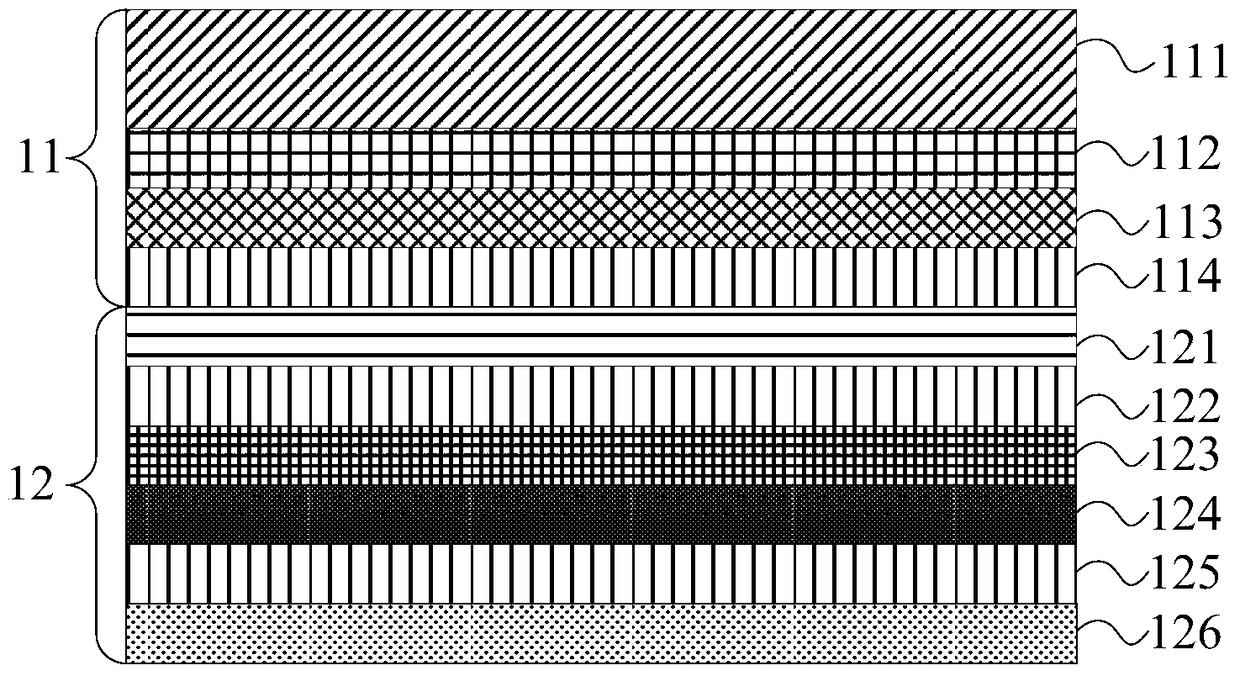

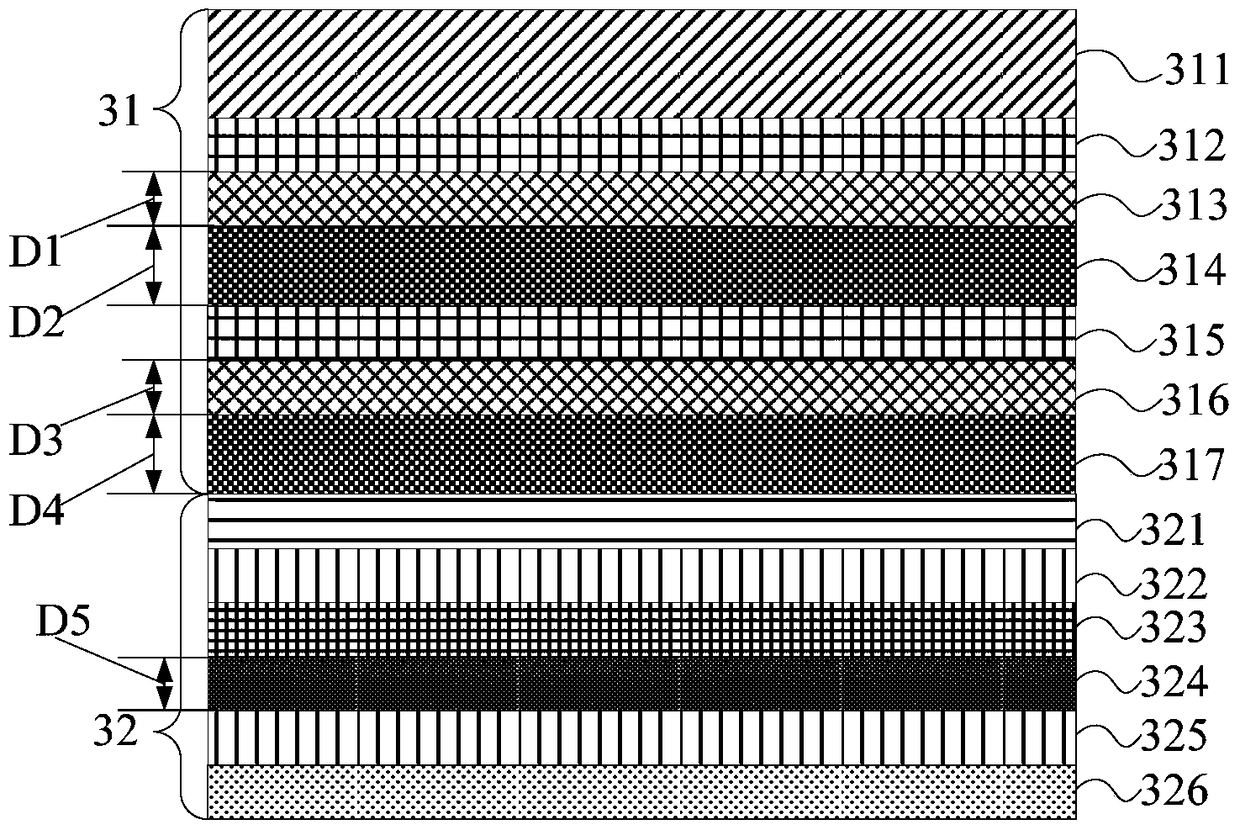

Illuminated touch screen and display devices

ActiveCN104598069BWith light functionReduce manufacturing costInput/output processes for data processingUser inputDisplay device

The invention discloses a light-emitting touch screen. The light-emitting touch screen comprises a touch structure used for acquiring the track input by a user and a light-emitting structure positioned under the touch screen and used for providing light for the touch structure. The touch structure comprises a touch layer, a conductive glass layer and a first insulation layer, wherein the touch layer is used for acquiring the track input by the user, the conductive glass layer is positioned under the touch layer and used for acquiring the coordinate value of the track on the touch layer, and the first insulation layer is positioned between the conductive glass layer and the light-emitting structure to make the conductive glass layer and the light-emitting structure insulated. The invention further discloses a display device. Therefore, the light-emitting touch screen has a light emitting function, and manufacturing cost of the display device can be effectively reduced.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

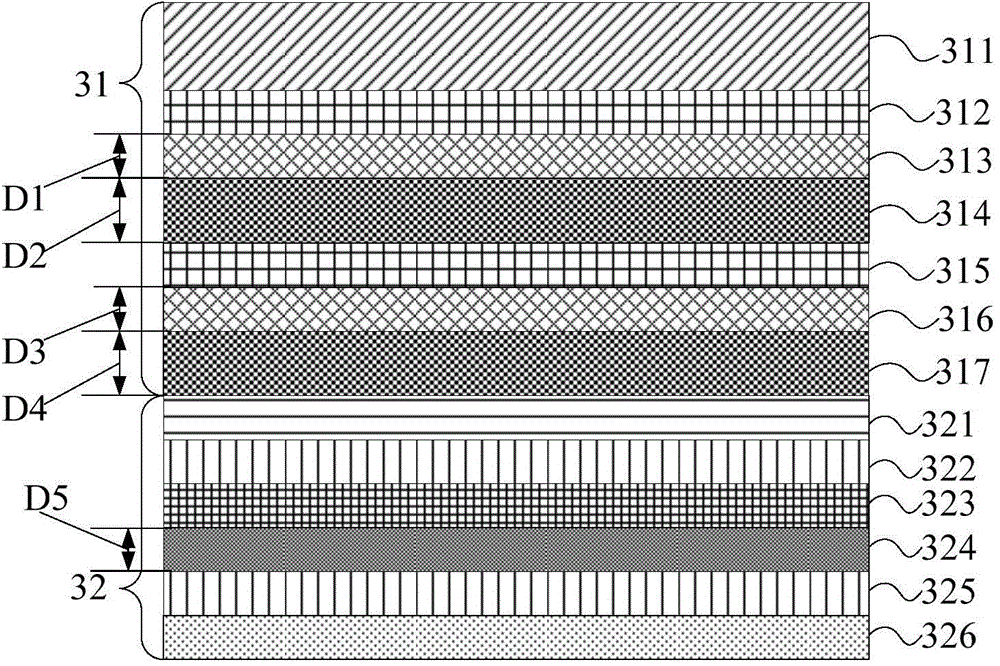

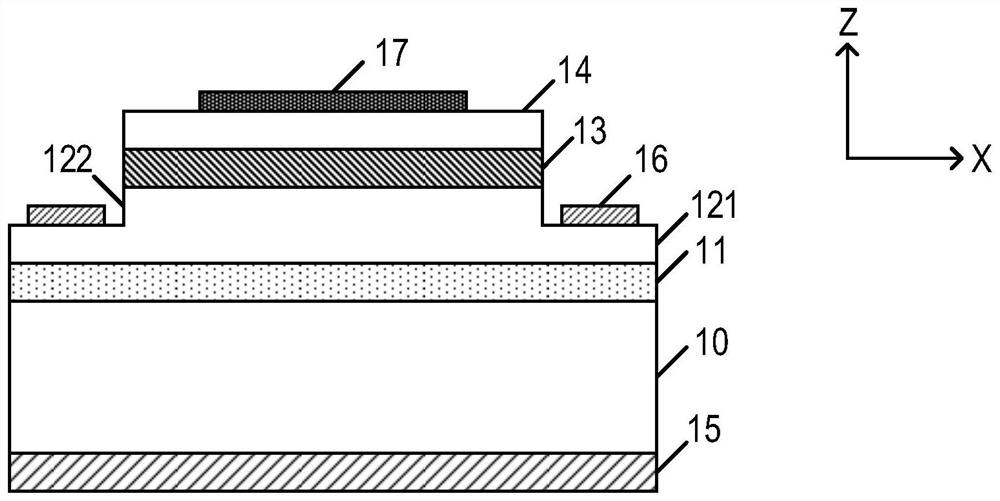

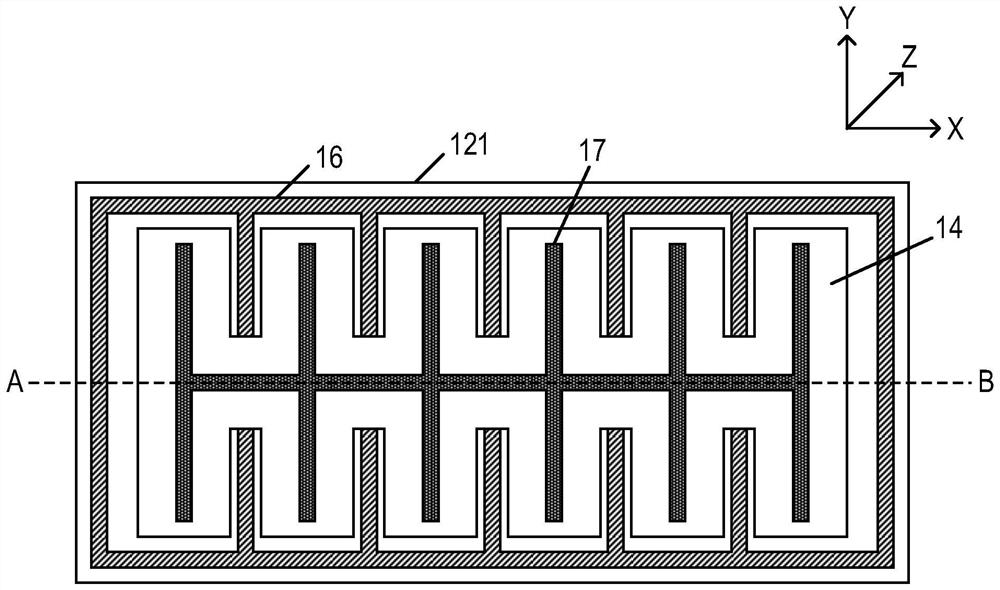

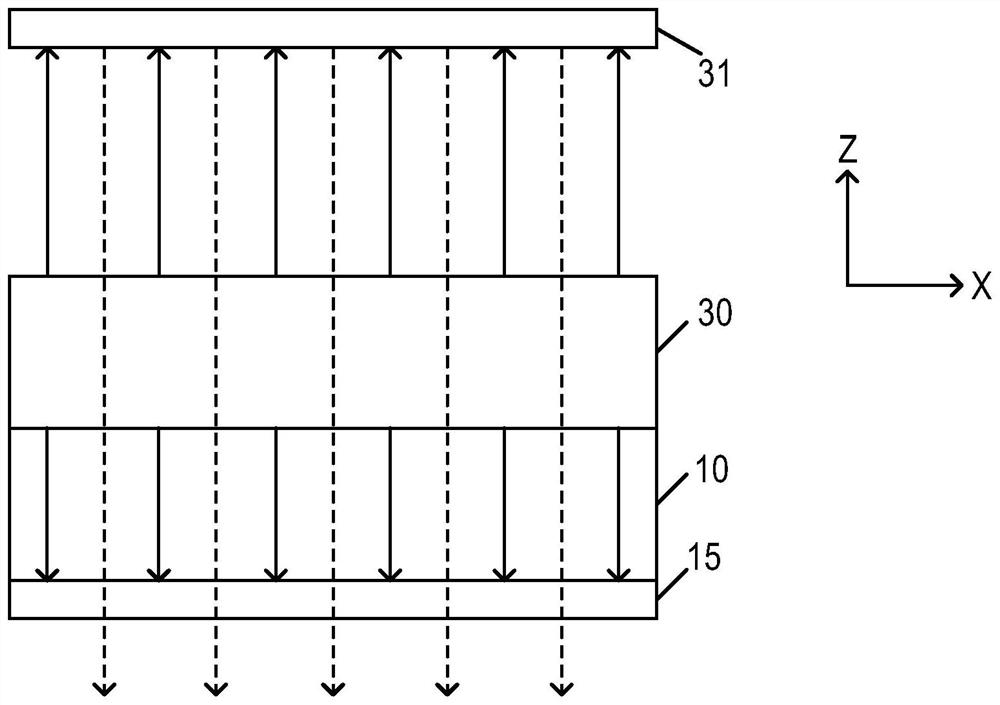

Light-emitting and light-filtering integrated optoelectronic chip and preparation method thereof

PendingCN114361313AWith light functionSimple structureOptical filtersSemiconductor devicesOptical pathLight filter

The invention relates to the technical field of semiconductors, in particular to a light-emitting and light-filtering integrated optoelectronic chip and a preparation method thereof. The light-emitting and light-filtering integrated optoelectronic chip comprises a transparent substrate which comprises a front surface and a back surface opposite to the front surface; the transparent LED device is located on the front face of the transparent substrate and comprises a buffer layer, an n-GaN layer, an InGaN / GaN quantum well layer and a p-GaN layer which are sequentially stacked in the direction perpendicular to the front face, and the transparent LED device at least can emit an emission light signal with a first wavelength in the direction from the back face to the front face; the light filtering device is located on the back face of the transparent substrate and used for transmitting an excitation fluorescence signal of a second wavelength and blocking the emission light signal, and the second wavelength is larger than the first wavelength. According to the invention, the light path structure in the fluorescence analysis process is simplified, and the accuracy and reliability of the fluorescence analysis result can be improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

Luminous clothes fork

InactiveCN107647743AWith light functionEasy to dryApparel holdersElectric circuit arrangementsElectricityEngineering

The invention relates to a luminous clothes fork. The clothes fork includes a fork head and a fork rod, the fork head comprises a light-transmittable shell, a light source and a fork rod connecting head, and the light source is arranged in the light-transmittable shell; the fork rod connecting head is fixedly connected to the bottom of the light-transmittable shell and communicated with the interior of the light-transmittable shell; one end of the fork rod is detachably connected to the fork rod connecting head, and a power supply is arranged in the fork rod and electrically connected to the light source. Not only can the luminous clothes fork achieve the clothes airing function of a common clothes fork, but also the fork head of the clothes fork has an illuminating function to provide convenience for people to air clothes at night. Moreover, since the fork head has the illuminating function and the illumination is even, people can clearly see the surrounding objects of the fork head without auxiliary light, and the clothes fork is simple and beautiful in structure.

Owner:张彩银

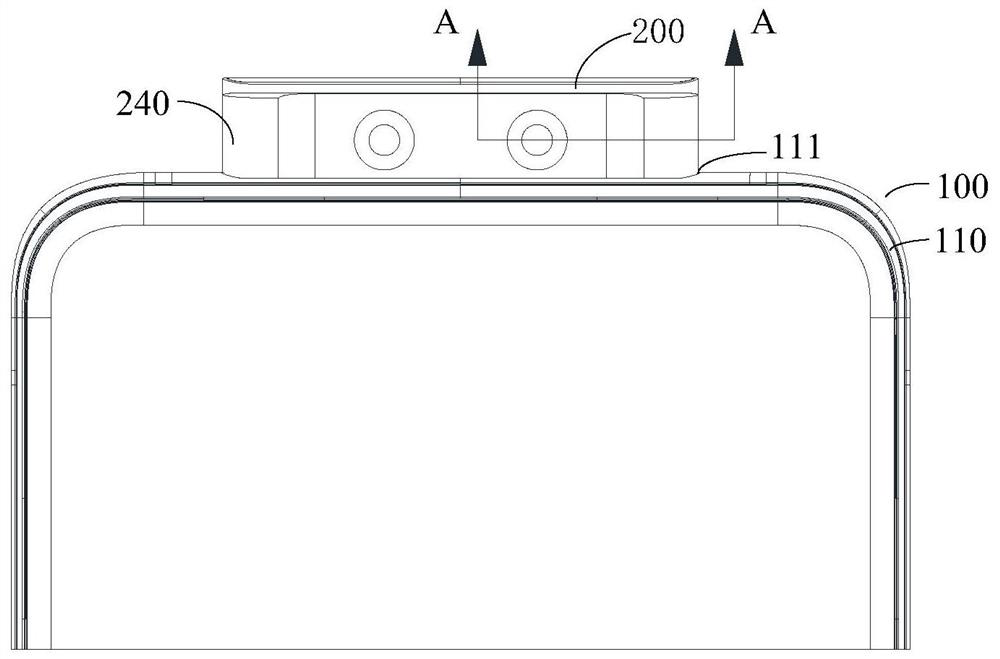

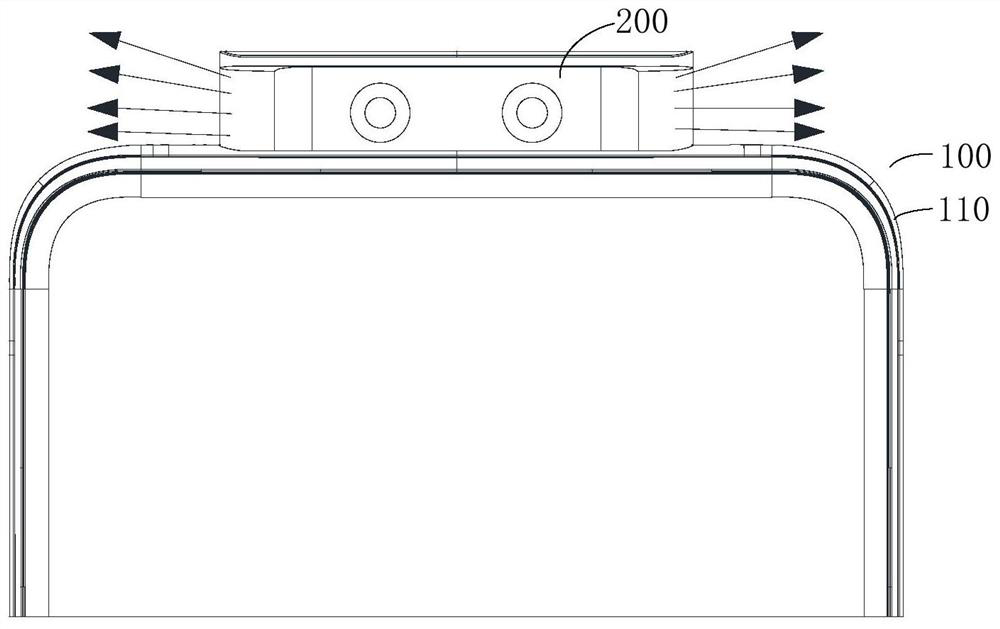

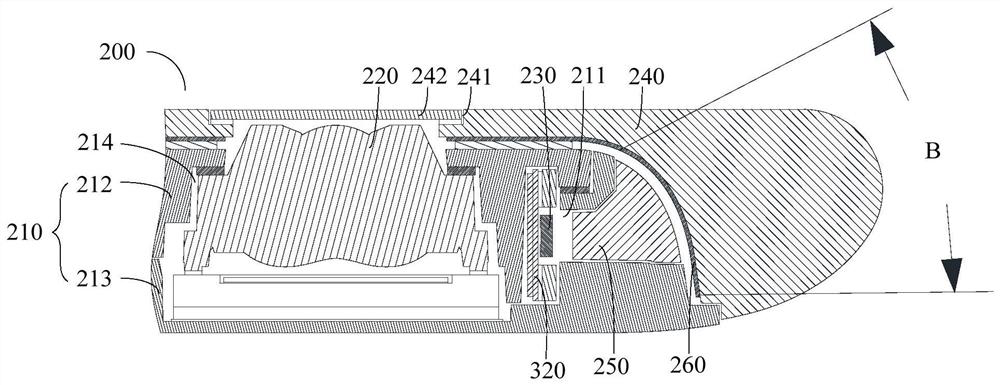

Terminal Equipment

ActiveCN109799670BSimple structureWith optical effectPrintersLighting elementsTerminal equipmentEngineering

The invention discloses a terminal device, which includes a casing, a camera and a driving mechanism arranged in the casing, the casing has an inner cavity and a perforation communicating with the inner cavity, the driving mechanism is connected to the camera connected, and the drive mechanism drives the camera to extend out of the housing or retract into the housing through the perforation, the camera includes a camera bracket and a camera mounted on the camera bracket A body, a light source and a light transmission cover, the light transmission cover is arranged on the light source. The foregoing solution can solve the problem that the camera of the current terminal device has relatively single functions.

Owner:VIVO MOBILE COMM CO LTD

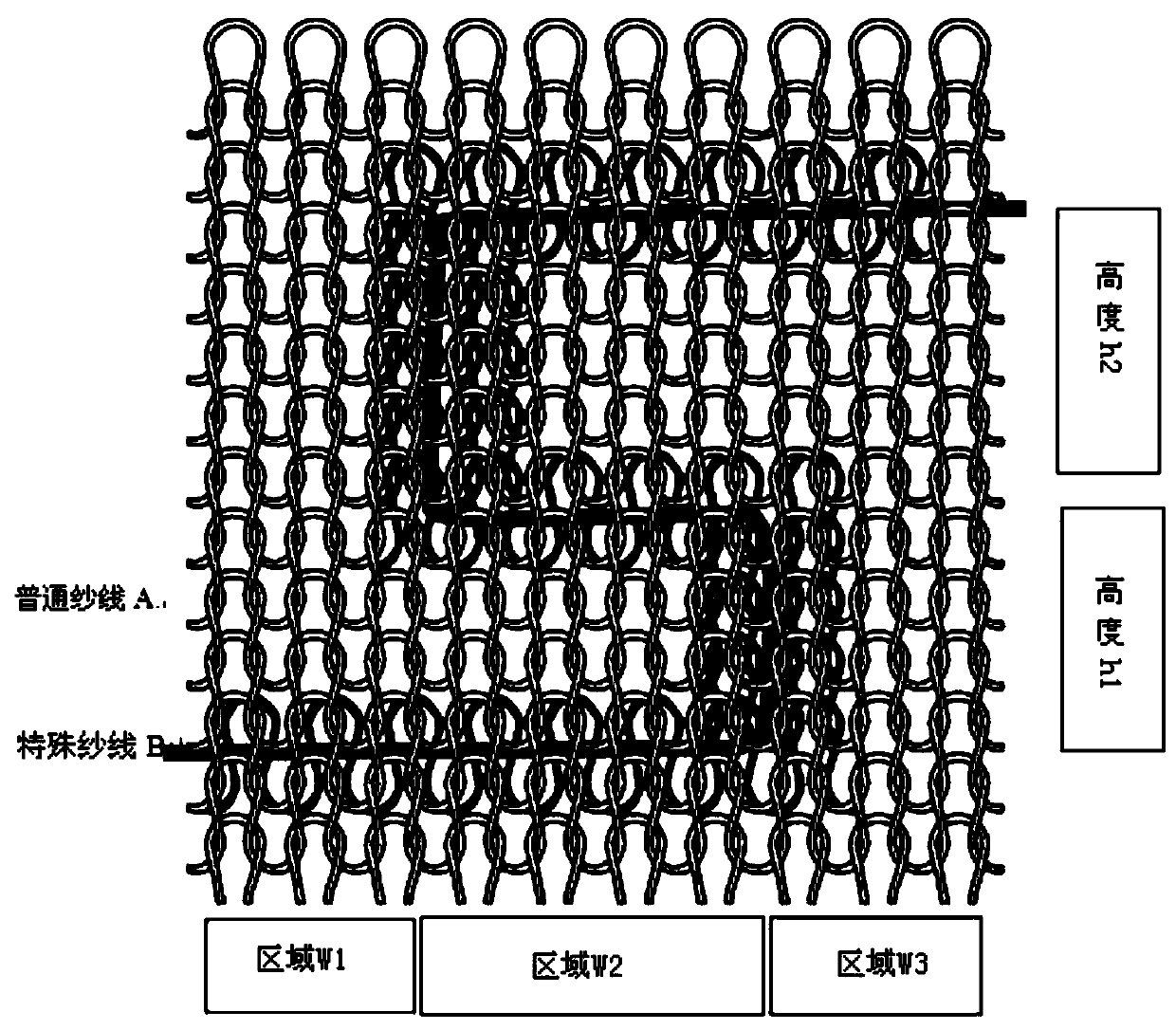

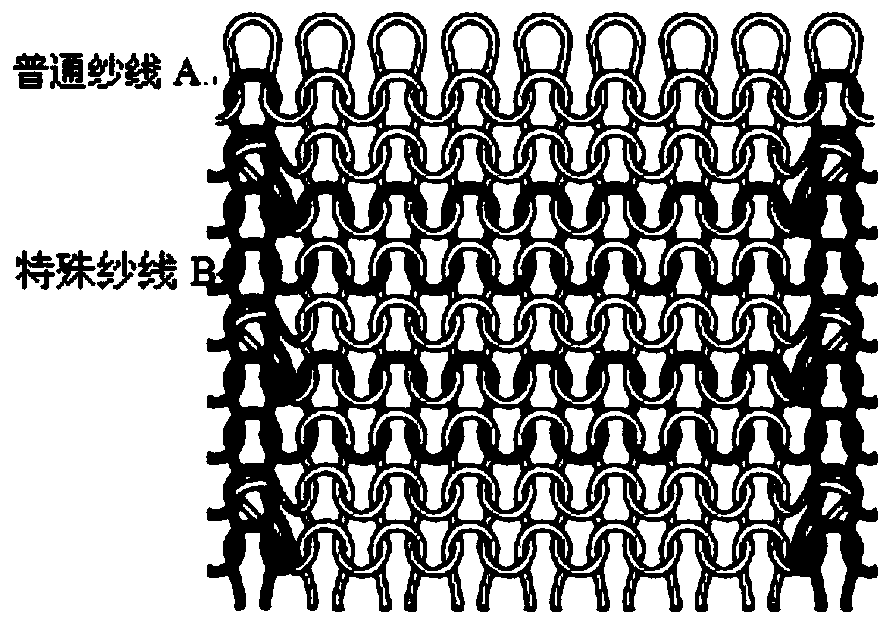

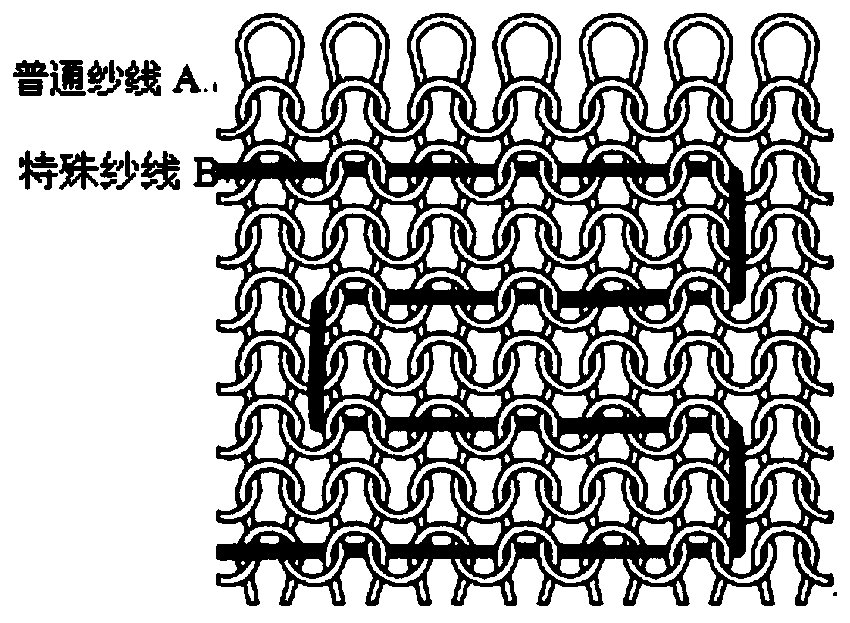

Double-sided knitted fabric capable of being added with special functional yarns and weaving method of double-sided knitted fabric

The invention discloses a double-sided knitted fabric capable of being added with special functional yarns and a knitting method of the double-sided knitted fabric. The double-sided knitted fabric comprises a double-sided wrapped yarn clamping knitted fabric which is provided with the special functional yarns, the special functional yarns form a weave structure with special functions in a yarn clamping mode, and meanwhile, the special functional yarns are wrapped in the yarn clamping knitted fabric in a double-sided wrapping mode. According to the weaving method, a conductive heating materialcan be formed into the conductive heating structure in a yarn clamping mode rather than a weaving mode, meanwhile, the conductive heating material cannot be directly in contact with the skin of a human body in a double-sided wrapping mode of the common yarns, the limitation of a traditional weaving method is broken through, a new path is opened for special functional knitted fabrics such as conductive heating, and products of the heating knitted fabrics can be enriched.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

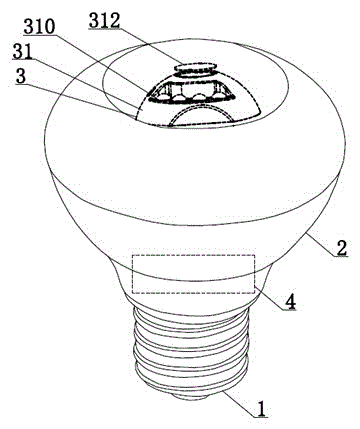

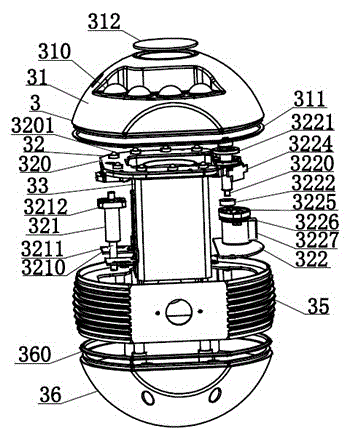

Bulb with cameras

InactiveCN105065930ASimple structureWith camera functionLighting elementsElectric lightingGlass coverEngineering

The invention provides a bulb with cameras. The bulb comprises a cap, a glass cover, a camera device and a control circuit board, wherein the glass cover is arranged below the cap; the control circuit board is arranged in the cap; the camera device is positioned in the glass cover; multiple cameras are arranged on the camera device, and are in signal connection with the control circuit board; and the control circuit board is in signal connection with the camera device. The bulb has the following beneficial effects: the bulb is simple in structure, has a camera function and a lamp function, can be installed in a park or a residential area, can serve as a camera and a street lamp, saves both materials and resources, and is low in cost.

Owner:陈宗坤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com