Automobile rearview mirror

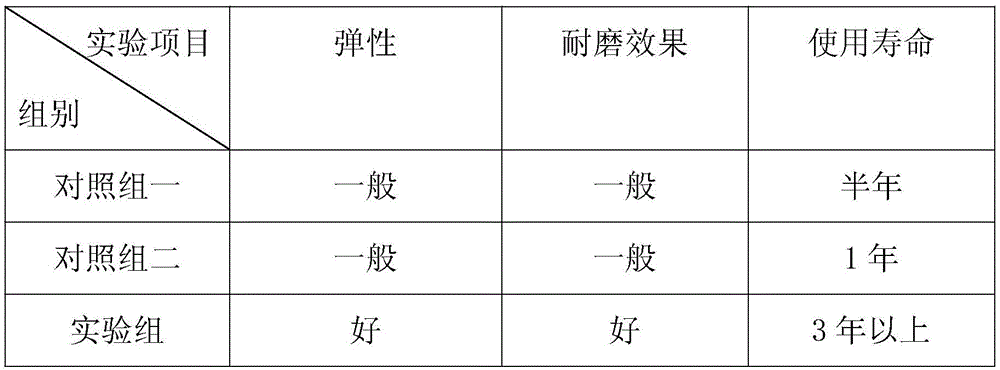

A technology for automobile rearview mirrors and housings, which is applied in the field of automobile rearview mirrors, and can solve the problems of the bushing being inelastic, not wear-resistant, and has a short service life, and achieves long service life, firm structure, and good elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

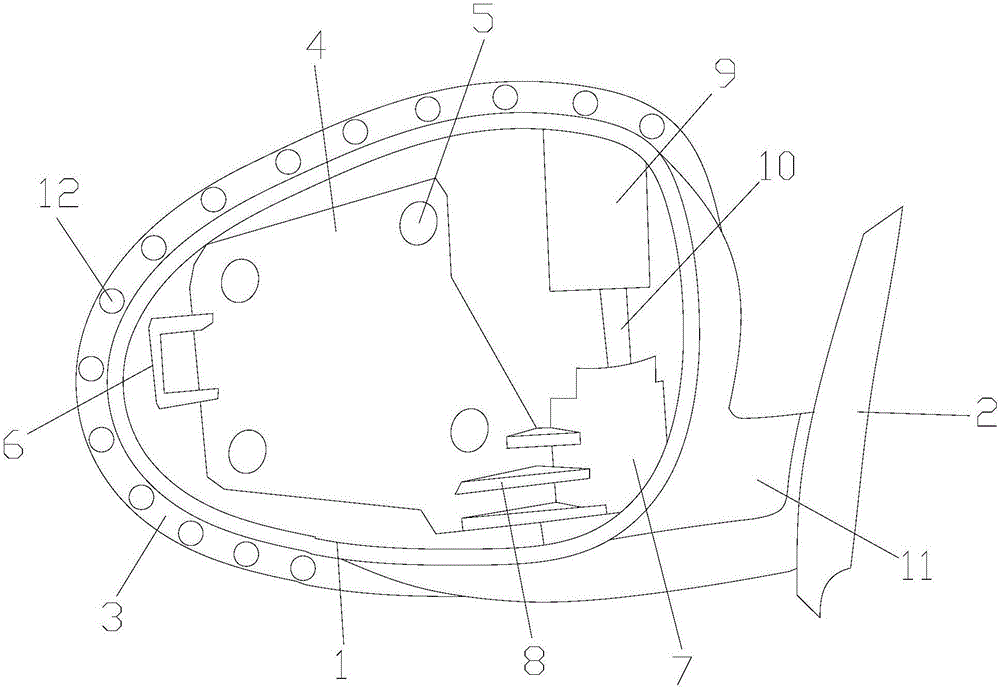

[0030] refer to figure 1 As shown, a car rearview mirror includes a housing 1, a bracket 2, a light strip 3 and a baffle 4, the bracket 2 is arranged on one side of the housing 1, the bracket 2 is connected to the housing 1, and the The light strip 3 is arranged outside the casing 1, the light strip 3 is fixedly connected with the casing 1, the baffle 4 is installed in the casing 1, the baffle 4 is provided with a rubber pad 5, and the rubber pad 5 is glued and connected with the baffle 4, and the two sides of the baffle 4 are respectively provided with a collar 6 and a sleeve 7, and the collar 6 and the sleeve 7 are respectively fixedly connected with the baffle 4, and the collar 6 is U type setting, one side of the casing 7 is provided with reinforcing ribs 8, and the reinforcing ribs 8 are fixedly connected with the baffle 4 and the casing 7 respectively, and a motor 9 is installed on the casing 7, and the motor 9 is connected to the shell The body 1 is fixedly connected, ...

Embodiment 2

[0050]A rubber pad 5 is provided, and the rubber pad 5 is glued and connected with the baffle plate 4. The two sides of the baffle plate 4 are respectively provided with a collar 6 and a sleeve 7, and the collar 6 and the sleeve 7 are connected with the baffle plate 4 respectively. Fixedly connected, the collar 6 is set in a U shape, and a reinforcing rib 8 is provided on one side of the casing 7, and the reinforcing rib 8 is fixedly connected with the baffle 4 and the casing 7 respectively, and the casing 7 is installed There is a motor 9, and the motor 9 is fixedly connected with the casing 1, and a rotating shaft 10 is installed at the bottom of the motor 9, and the bottom of the rotating shaft 10 is fixedly connected with the casing 7.

[0051] The collar 6 is made of the following materials in parts by weight, including 7.5 parts of glycerin, 13.5 parts of diethanolamine, 10 parts of triethylenediamine, 32.5 parts of polypropylene, 47.5 parts of silicon rubber powder, and ...

Embodiment 3

[0070] A rubber pad 5 is provided, and the rubber pad 5 is glued and connected with the baffle plate 4. The two sides of the baffle plate 4 are respectively provided with a collar 6 and a sleeve 7, and the collar 6 and the sleeve 7 are connected with the baffle plate 4 respectively. Fixedly connected, the collar 6 is set in a U shape, and a reinforcing rib 8 is provided on one side of the casing 7, and the reinforcing rib 8 is fixedly connected with the baffle 4 and the casing 7 respectively, and the casing 7 is installed There is a motor 9, and the motor 9 is fixedly connected with the casing 1, and a rotating shaft 10 is installed at the bottom of the motor 9, and the bottom of the rotating shaft 10 is fixedly connected with the casing 7.

[0071] The collar 6 is made of the following materials in parts by weight, including 5 parts of glycerin, 15 parts of diethanolamine, 12 parts of triethylenediamine, 35 parts of polypropylene, 50 parts of silicon rubber powder, and 9 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com