Toilet manufacturing process

A manufacturing process and toilet technology, applied in the field of sanitary ware, can solve the problems of unavoidable leftover materials, waste of natural resources, high processing costs, etc., and achieve the effects of improving production economic benefits, high product density, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

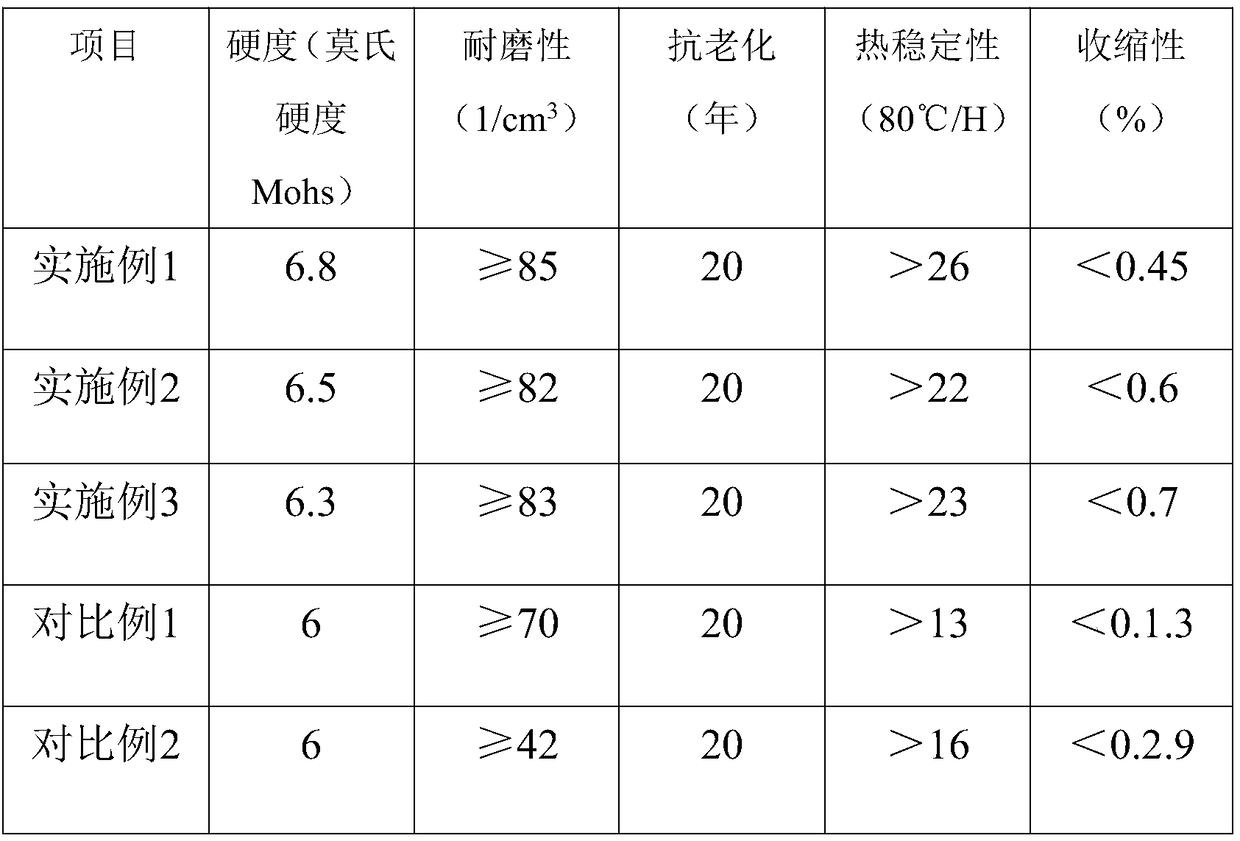

Examples

Embodiment 1

[0030] A manufacturing process for a toilet, prepared through the following steps:

[0031] S1: According to the shape and size of the toilet seat, liner and base, make a toilet seat FRP mold, liner FRP mold and base wooden mold, and make artificial stone toilet seat, artificial stone liner and PVC base according to the mold;

[0032] S2: Connect the seat ring of the toilet seat with the inner tank by casting, and connect the water channel of the toilet seat to the water tank with the inner tank;

[0033] S3: After connecting the base with the toilet seat, connect the sewer pipe with the drain hole of the liner, then seal the lower opening of the base through the PVC plate, and make the sewer pipe pass through the PVC plate at the bottom of the base;

[0034] S4: After assembling the flush assembly in the water tank of the toilet seat, assemble the water tank cover on the water tank, and then hinge the seat cover and the seat of the toilet seat;

[0035] Wherein, the manufact...

Embodiment 2

[0049] The content of embodiment 2 is basically the same as the content of embodiment 1, and the same part will not be repeated. The difference is: by weight, unsaturated epoxy resin is added to account for 2% of unsaturated epoxy resin in plasticizing agent, specifically the plasticizer is selected from phthalate esters, which account for 0.2% of the anti-aging agent of unsaturated epoxy resin, and the anti-aging agent is a derivative of tetramethyl and pentamethyl, stirring evenly, The stirring speed is 85 rev / min, then add the luminescent filler and modified water-based polyurethane accounting for 60% of the unsaturated epoxy resin, and the crosslinking agent accounting for 1.5% of the unsaturated epoxy resin, the crosslinking agent is ethylene The base derivative was continuously stirred at a stirring speed of 110 rpm and a stirring time of 120 minutes to obtain the filler.

Embodiment 3

[0051] The contents of this embodiment and Example 1 are basically the same, the difference is that by weight ratio, 30% of the unsaturated epoxy resin is added with a plasticizer accounting for 3% of the unsaturated epoxy resin, and the specifically described plasticizer is selected Phthalic acid ester compound accounts for 0.4% antiaging agent of unsaturated epoxy resin, and described antiaging agent is the derivative of tetramethyl and pentamethyl, stirs evenly, and stirring speed is 90 revs / min, then Add 80% of unsaturated epoxy resin luminous filler and modified water-based polyurethane, and 1.9% of unsaturated epoxy resin cross-linking agent, the cross-linking agent is a vinyl derivative of benzene, continuous stirring, stirring speed The stirring time is 120 rev / min and the stirring time is 120 minutes to obtain the filling material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com