Luminous cork and rubber composite floor and production process thereof

A composite floor and production process technology, applied in the field of building materials, can solve the problems of low production efficiency, poor tensile strength, complex production process, etc., and achieve the effects of improving production efficiency, reducing usage, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

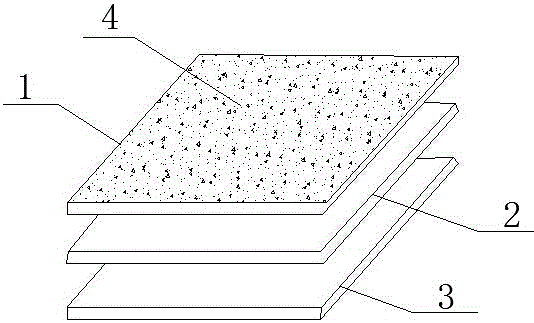

[0045] A luminescent cork rubber compound flooring comprises a three-layer structure, which is a cork decorative surface layer, a cork middle layer and a balanced bottom layer in sequence from top to bottom, and the surface of the cork decorative surface layer is coated with fluorescent powder.

[0046] A production process for luminescent cork rubber composite flooring, comprising the following steps:

[0047] (1) Preparation of cork decoration surface and balance bottom layer

[0048] A: crushing, screening

[0049] First dry the cork oak cork, and remove the sundries, then send it to the pulverizer to grind it into granules, and sift out the cork particles of different purposes through the screening machine for later use;

[0050] B: sizing

[0051] According to the target thickness and density of the slab, calculate the required amount of cork particles and adhesives, and add them to the glue mixer for stirring;

[0052] C: hot pressing

[0053] The specification of th...

Embodiment 2

[0077] A luminescent cork rubber compound flooring comprises a three-layer structure, which is a cork decorative surface layer, a cork middle layer and a balanced bottom layer in sequence from top to bottom, and the surface of the cork decorative surface layer is coated with fluorescent powder.

[0078] A production process for luminescent cork rubber composite flooring, comprising the following steps:

[0079] (1) Preparation of cork decoration surface and balance bottom layer

[0080] A: crushing, screening

[0081] First dry the cork oak cork, and remove the sundries, then send it to the pulverizer to grind it into granules, and sift out the cork particles of different purposes through the screening machine for later use;

[0082] B: sizing

[0083] According to the target thickness and density of the slab, calculate the required amount of cork particles and adhesives, and add them to the glue mixer for stirring;

[0084] C: hot pressing

[0085] The specification of th...

Embodiment 3

[0109] A luminescent cork rubber compound flooring comprises a three-layer structure, which is a cork decorative surface layer, a cork middle layer and a balanced bottom layer in sequence from top to bottom, and the surface of the cork decorative surface layer is coated with fluorescent powder.

[0110] A production process for luminescent cork rubber composite flooring, comprising the following steps:

[0111] (1) Preparation of cork decoration surface and balance bottom layer

[0112] A: crushing, screening

[0113] First dry the cork oak cork, and remove the sundries, then send it to the pulverizer to grind it into granules, and sift out the cork particles of different purposes through the screening machine for later use;

[0114] B: sizing

[0115] According to the target thickness and density of the slab, calculate the required amount of cork particles and adhesives, and add them to the glue mixer for stirring;

[0116] C: hot pressing

[0117] The specification of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com