Double-sided knitted fabric capable of being added with special functional yarns and weaving method of double-sided knitted fabric

A knitted fabric and functional technology, applied in the field of double-knitted fabric and its weaving, can solve the problems that cannot be realized, affect the safety of wearing comfortable clothing, and achieve the effect of broad development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

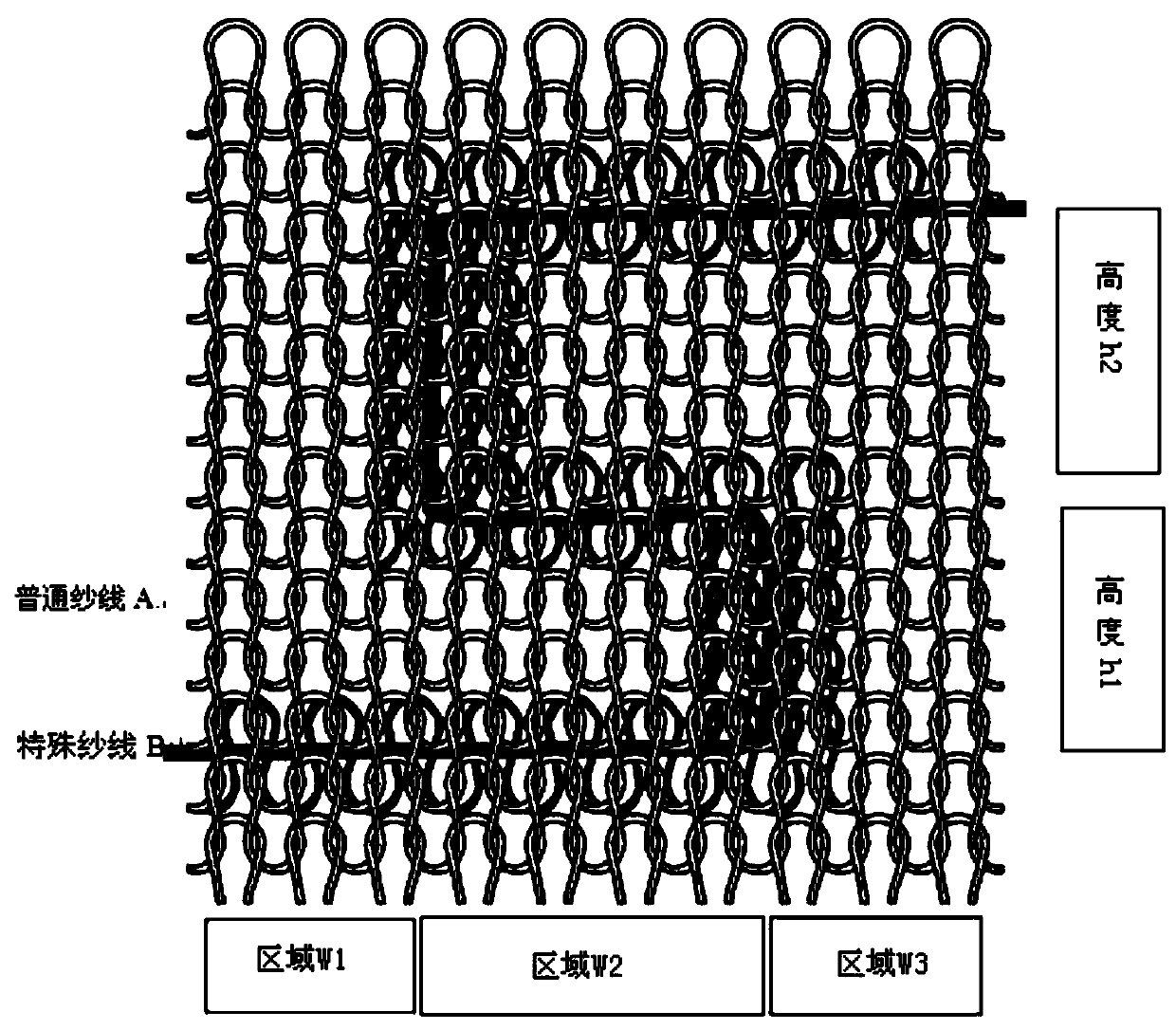

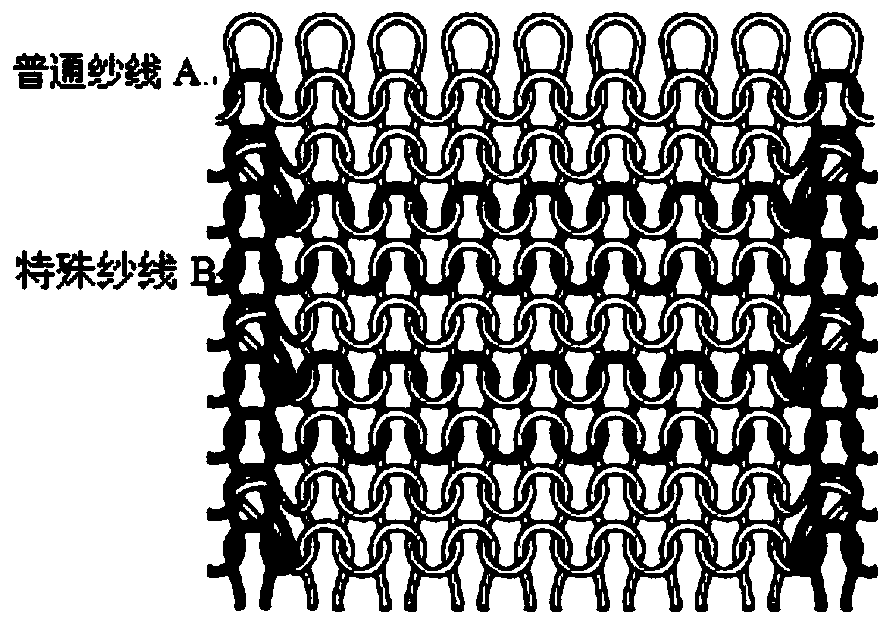

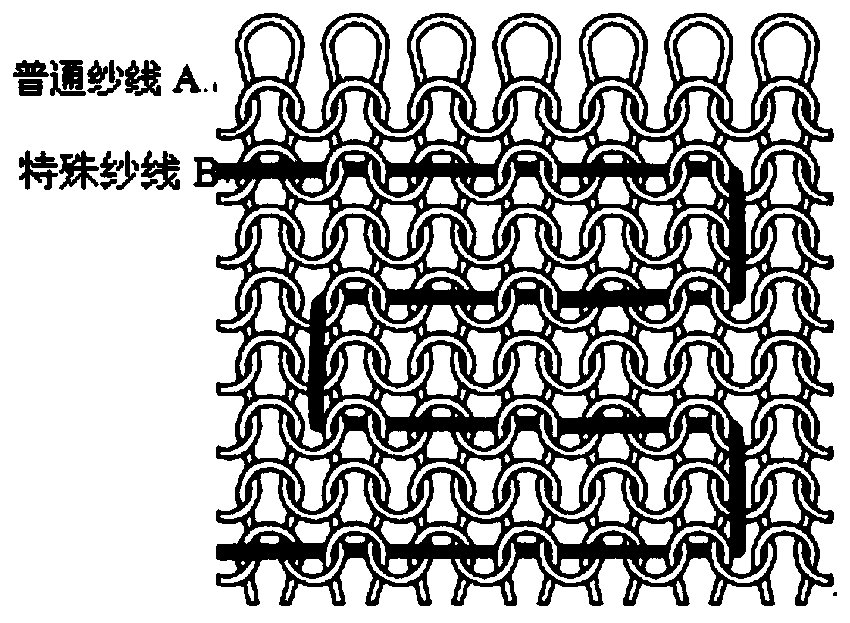

[0049] A double-knitted fabric that can be added with special functional yarns, such as figure 1 As shown, it includes yarn-wrapped knitted fabrics wrapped on both sides. Special functional yarns are provided on the yarn-jammed knitted fabrics. Wrap it with special functional yarn to avoid direct contact with human skin.

[0050] In this embodiment, the special functional yarn is used as the conductive heating yarn for illustration. The relative position between the conductive yarns is accurately controlled by the number of yarn clamping needles and the number of interval rows, so as to adjust and design the resistance of its conductive structure to achieve different conductive heating effects. In order to make it more widely used in different fields, the market potential is huge.

[0051] The knitting method is as follows, using a flat knitting machine having a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-rear d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com