Patents

Literature

72results about How to "Promote international influence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All-forming front-back varying narrowing knitting method and fabric formed through method

ActiveCN110042546ABreak through limitationsImprove design meansFlat-bed knitting machinesBiomedical engineering

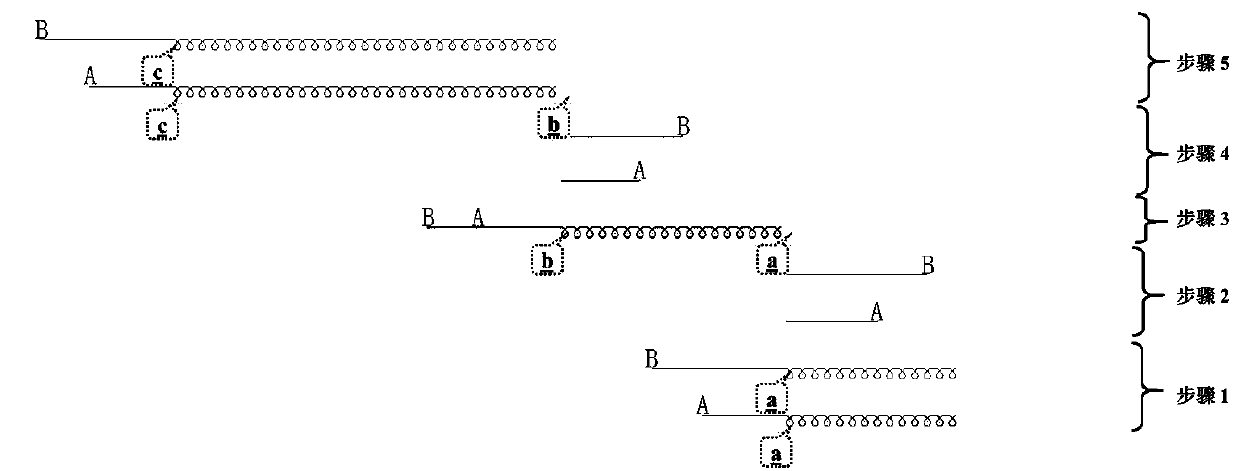

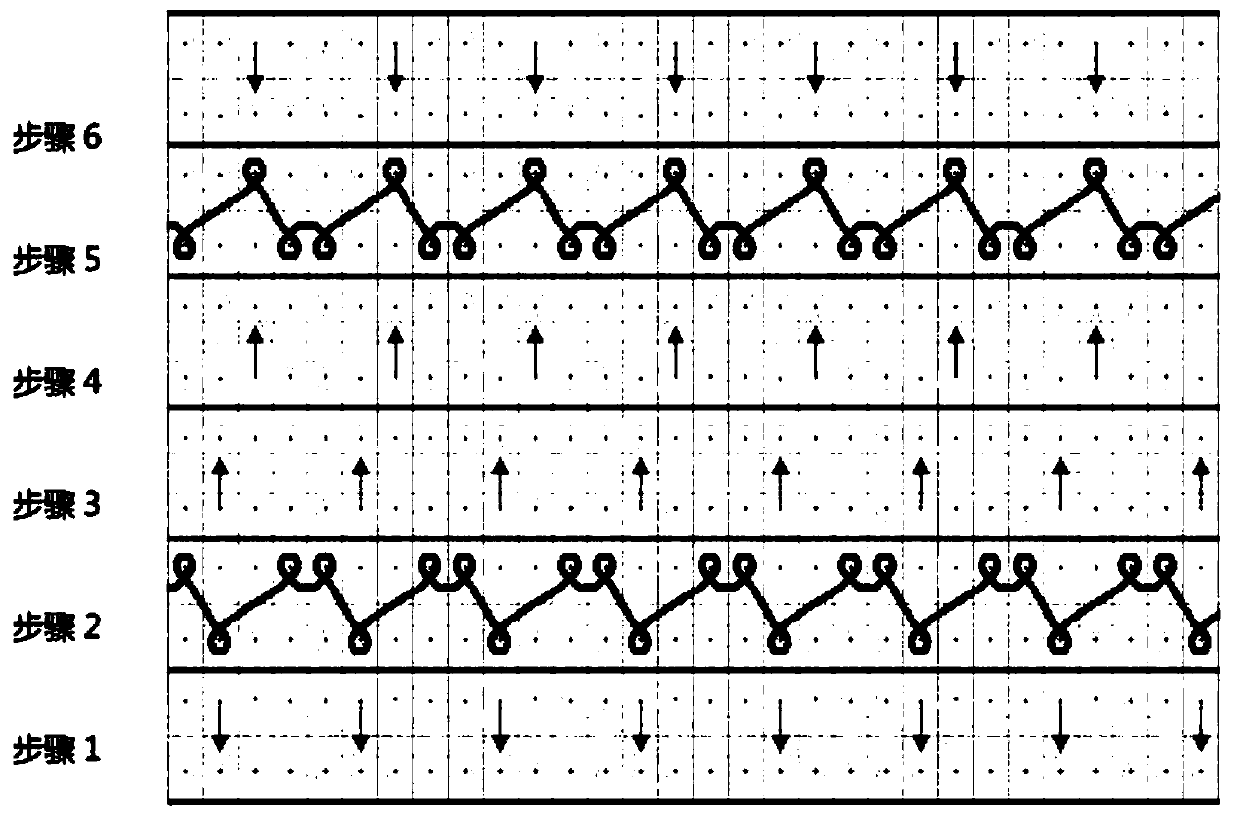

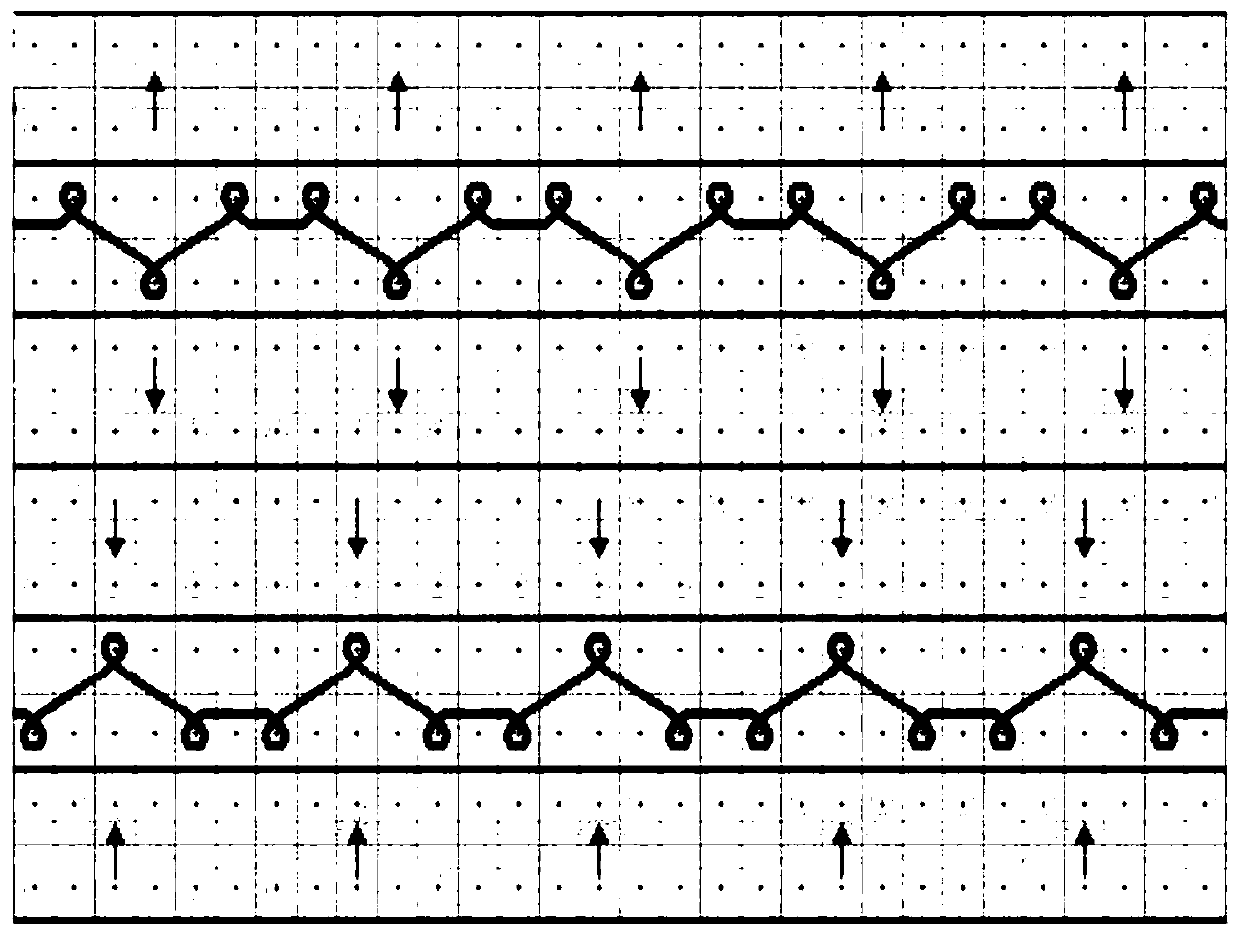

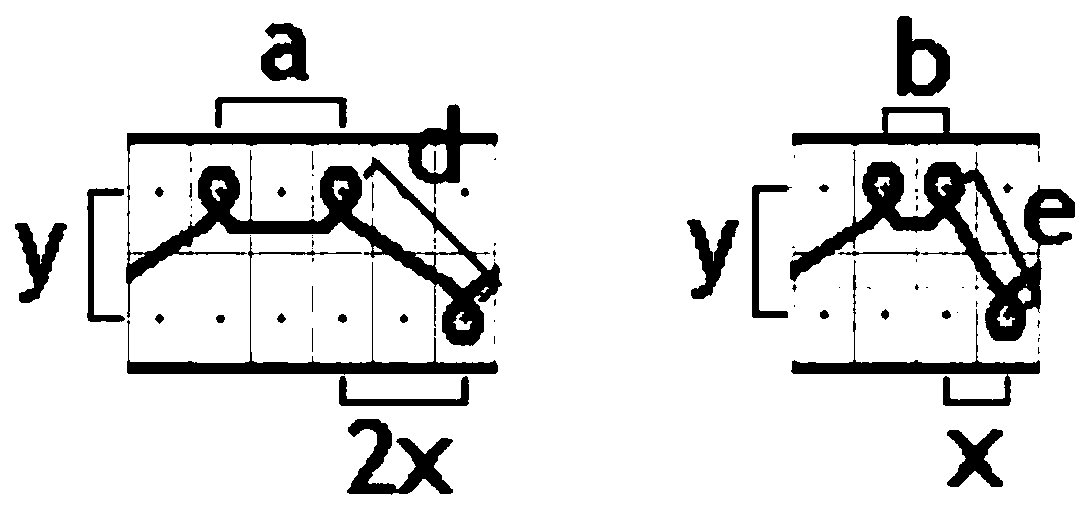

The invention discloses an all-forming front-back varying narrowing knitting method and a fabric formed through the method. An all-forming flat knitting machine is utilized for weaving, the all-forming flat knitting machine is provided with at least one pair of front-back needle beds which extend in the left-right direction and oppositely arranged in the front-back direction, the needle beds can transversely move left and right, and loop transferring of loops can be carried out between the front needle bed and the rear needle bed. The front face facing the front needle bed is adopted as reference in the left-right direction, knitting needle, participating in narrowing, of the front needle bed are sequentially named a, b, c, d, e, f, g and h from left to right in this way. The all-forming front-back varying narrowing knitting method breaks through the limitation of an existing all-forming traditional narrowing structure, a front-back varying narrowing effect with a visual effect is achieved for an all-forming knitted product, and the advantages of optimizing the habilimentation style and the like are achieved.

Owner:嘉兴市蒂维时装有限公司

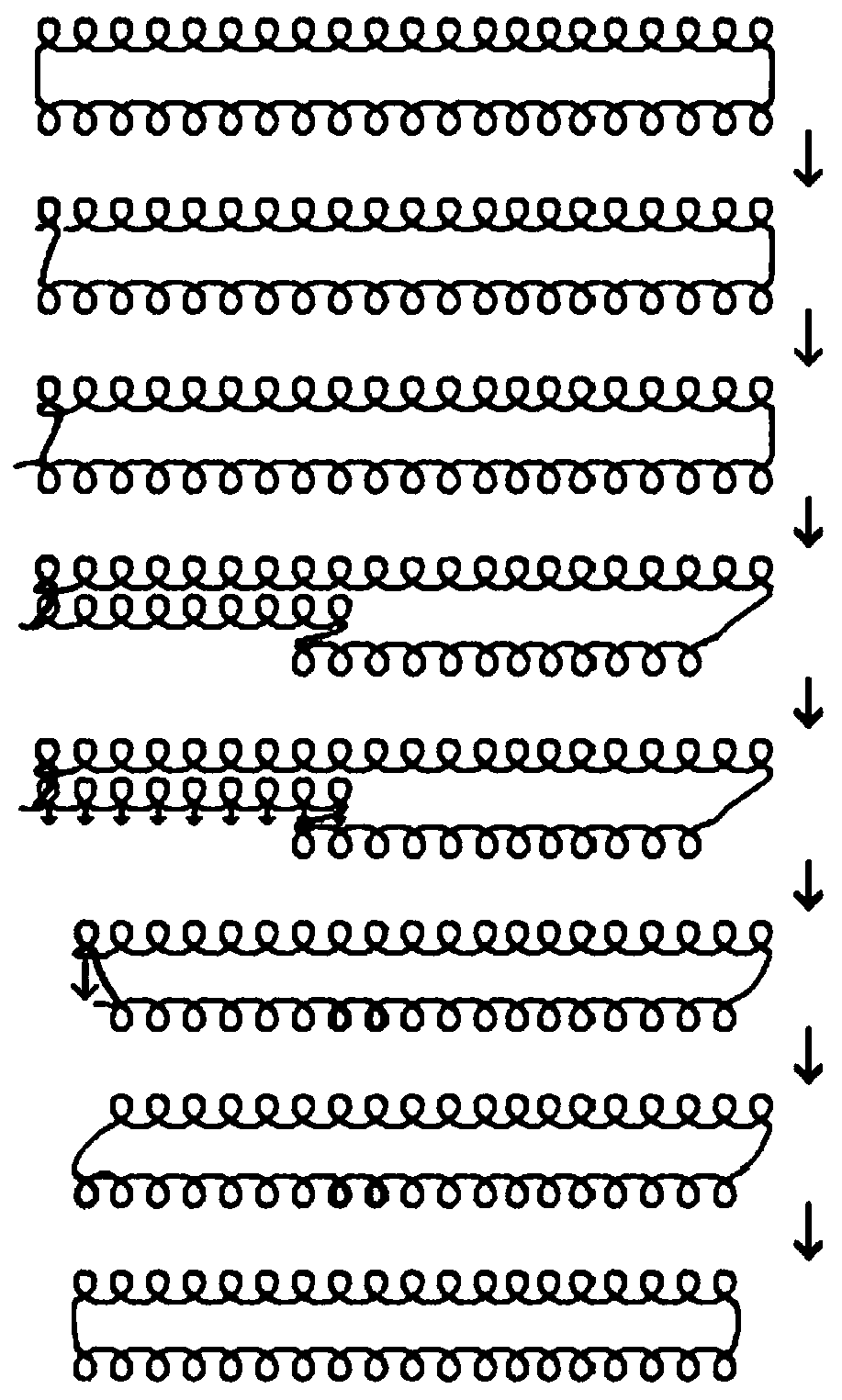

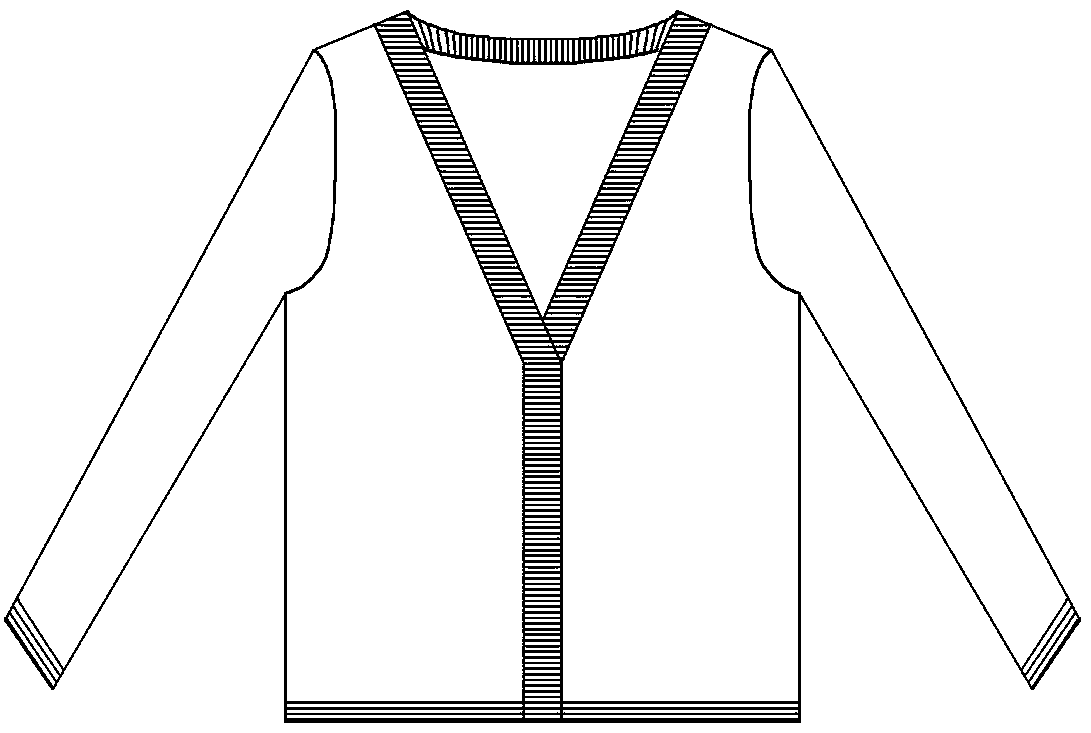

Weaving method for fully-fashioned cardigan top fly overlapping

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

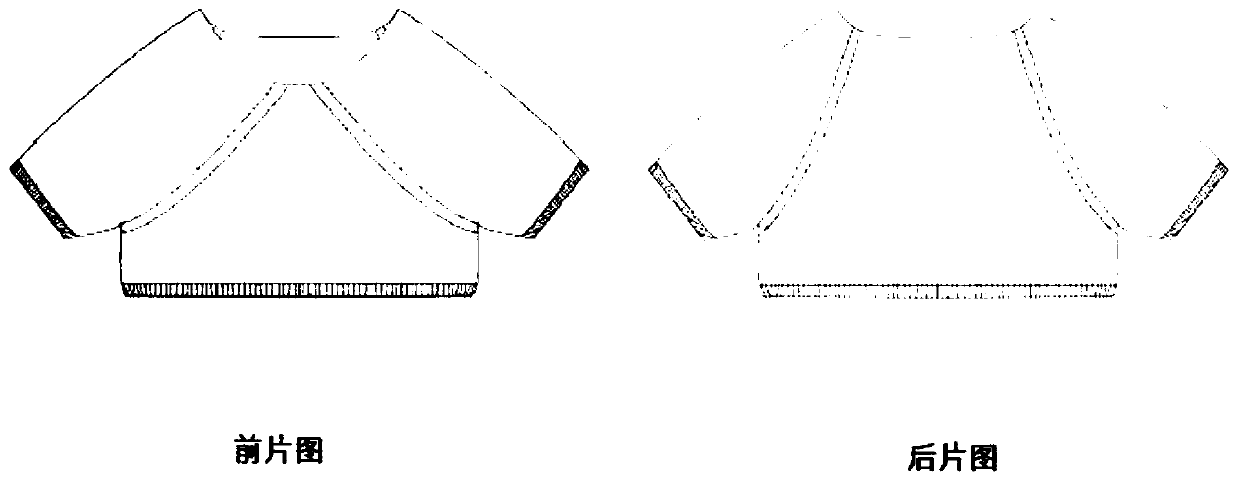

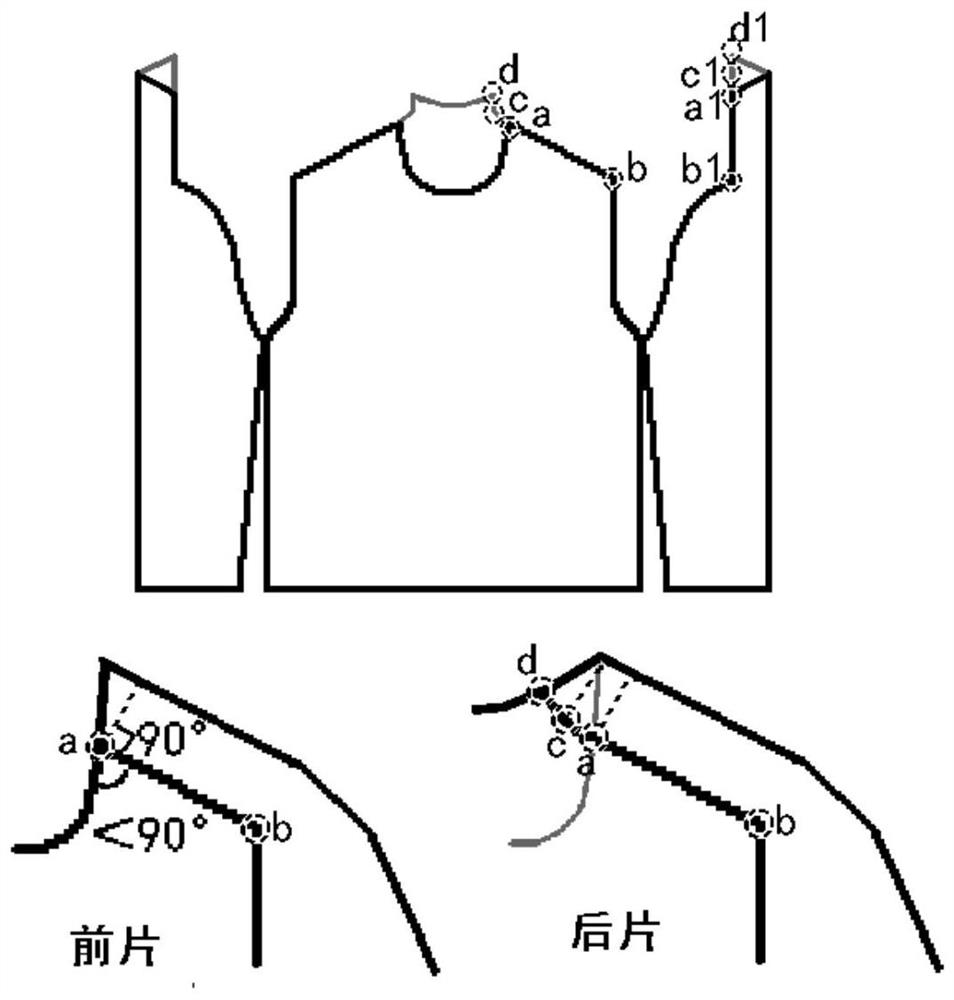

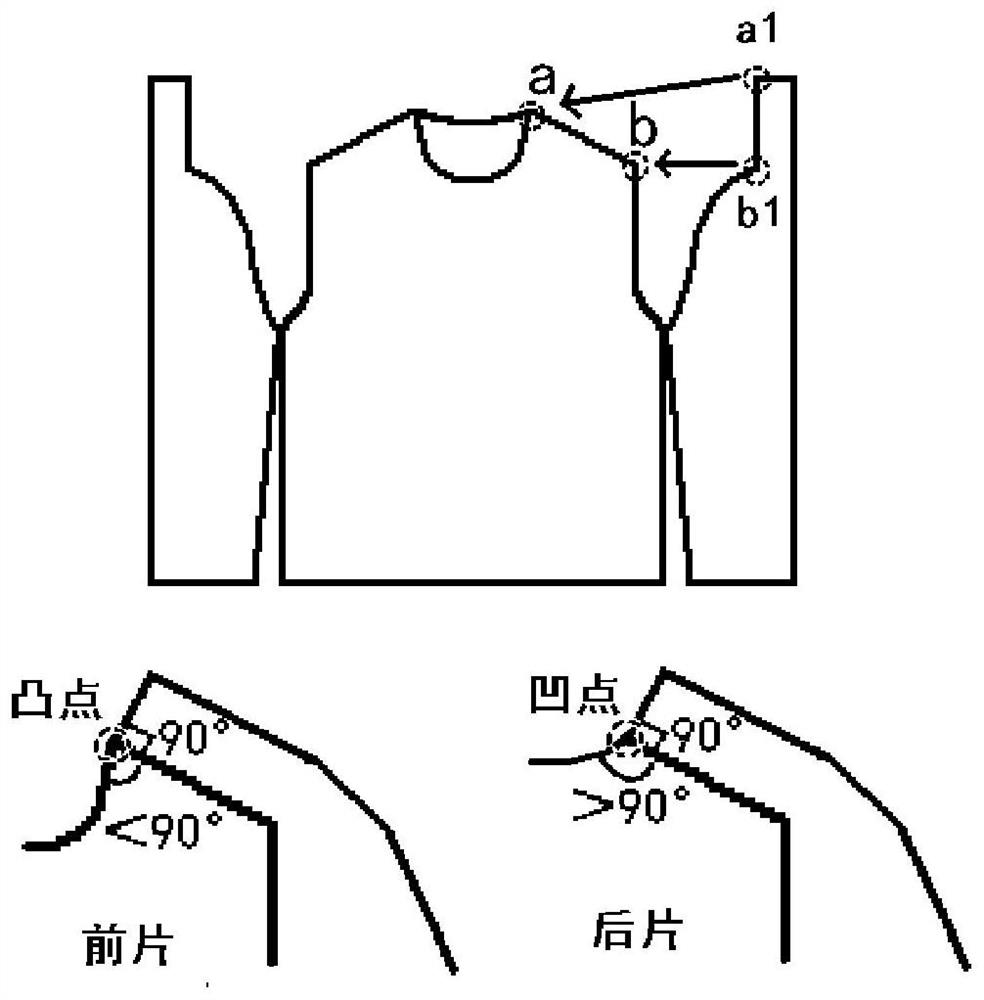

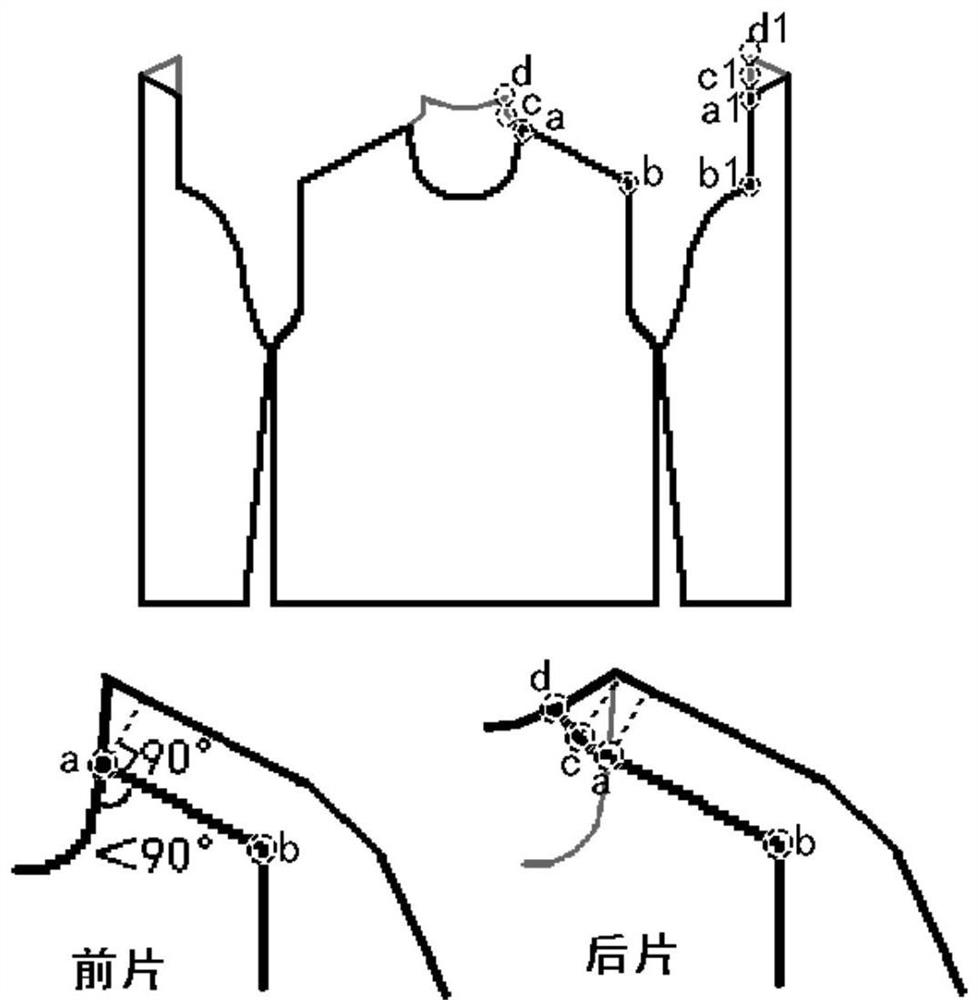

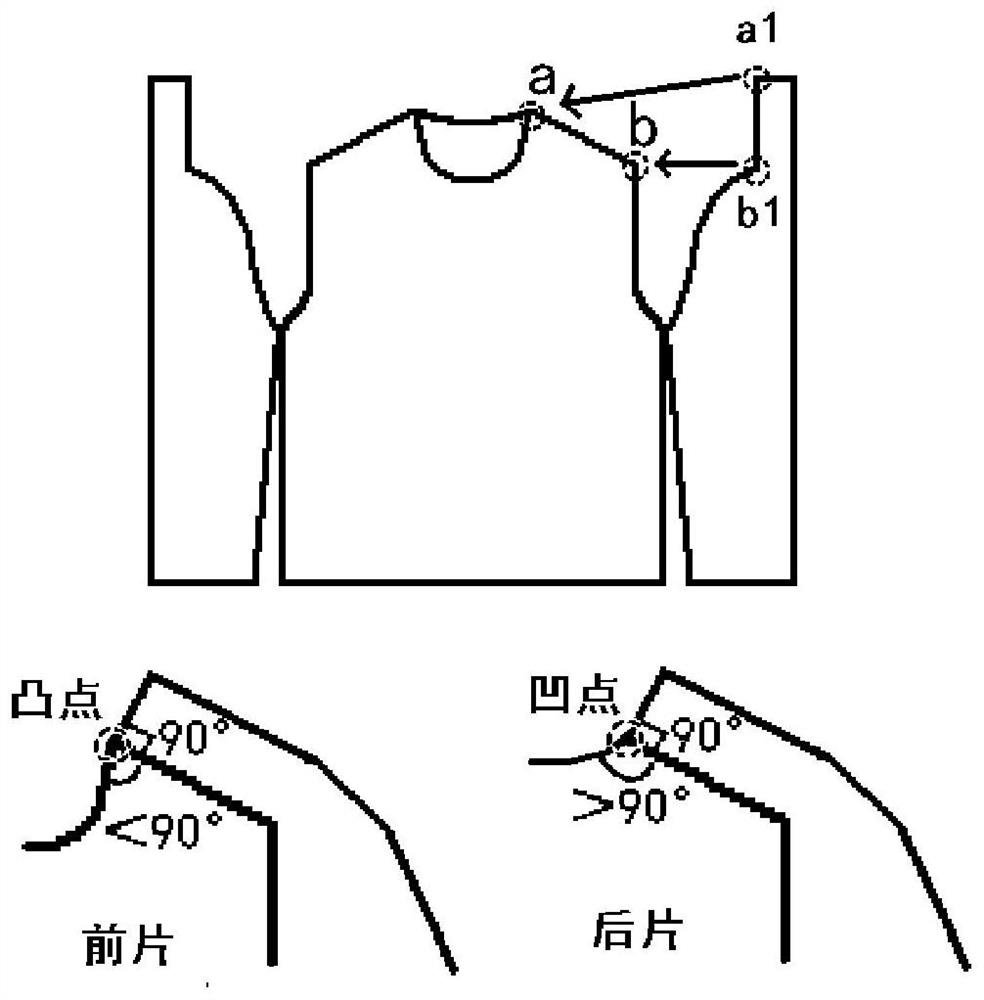

Knitting method and knitted fabric of fully-formed saddle shoulder collar type structure

ActiveCN112593338AMeet needsPromote international influenceWeft knittingNeck collarMechanical engineering

The invention discloses a knitting method and knitted fabric of a fully-formed saddle shoulder collar type structure. According to a fully-formed square shoulder type shoulder line forward-moving knitting method, a front piece and a rear piece achieve the natural difference in the knitting process, and therefore a shoulder line forward-moving effect is naturally shown after style forming. The knitting method of the fully-formed saddle shoulder collar type structure breaks through the limitation of a traditional product process method, and a knitting method combination with front and back differences is set according to the characteristics of the front and back collar types of a saddle shoulder, so that the front and back collars are smoother, the product quality and the wearing comfort areimproved, and the customer requirements can be better met.

Owner:嘉兴市蒂维时装有限公司

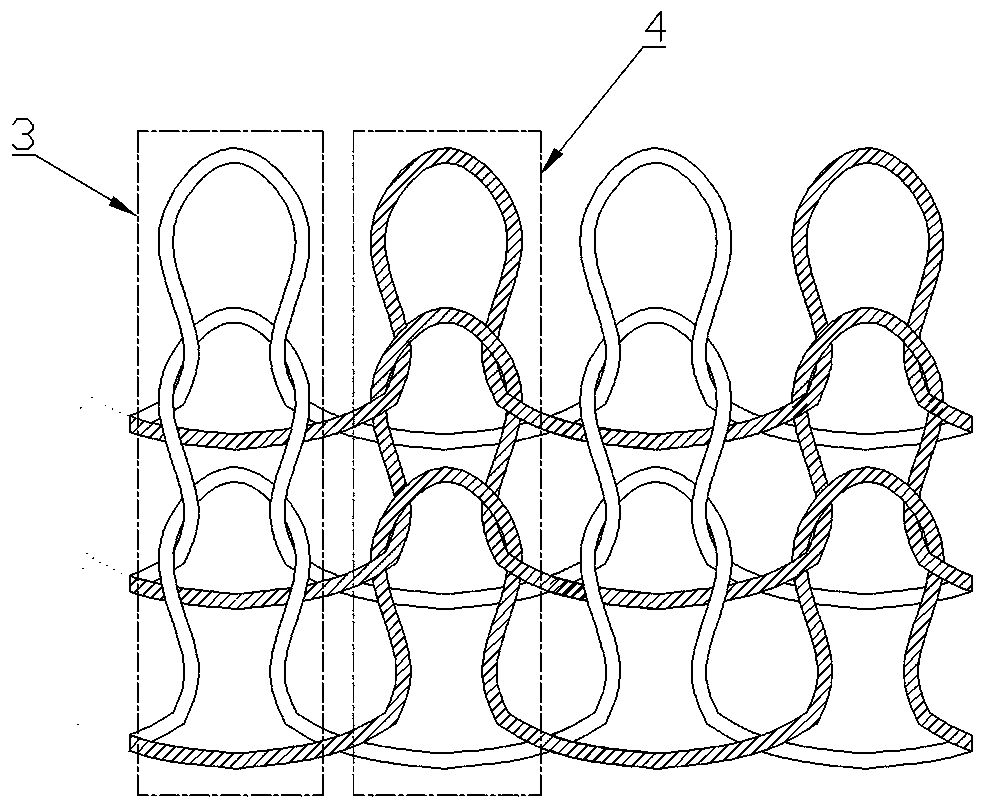

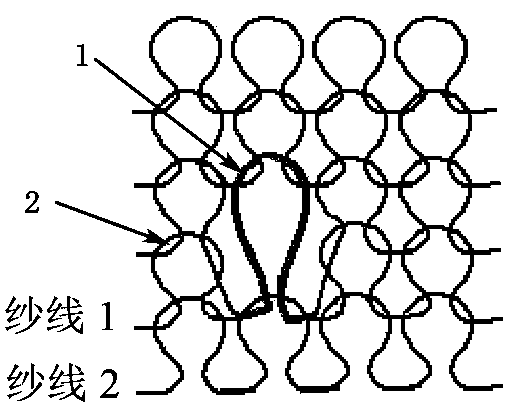

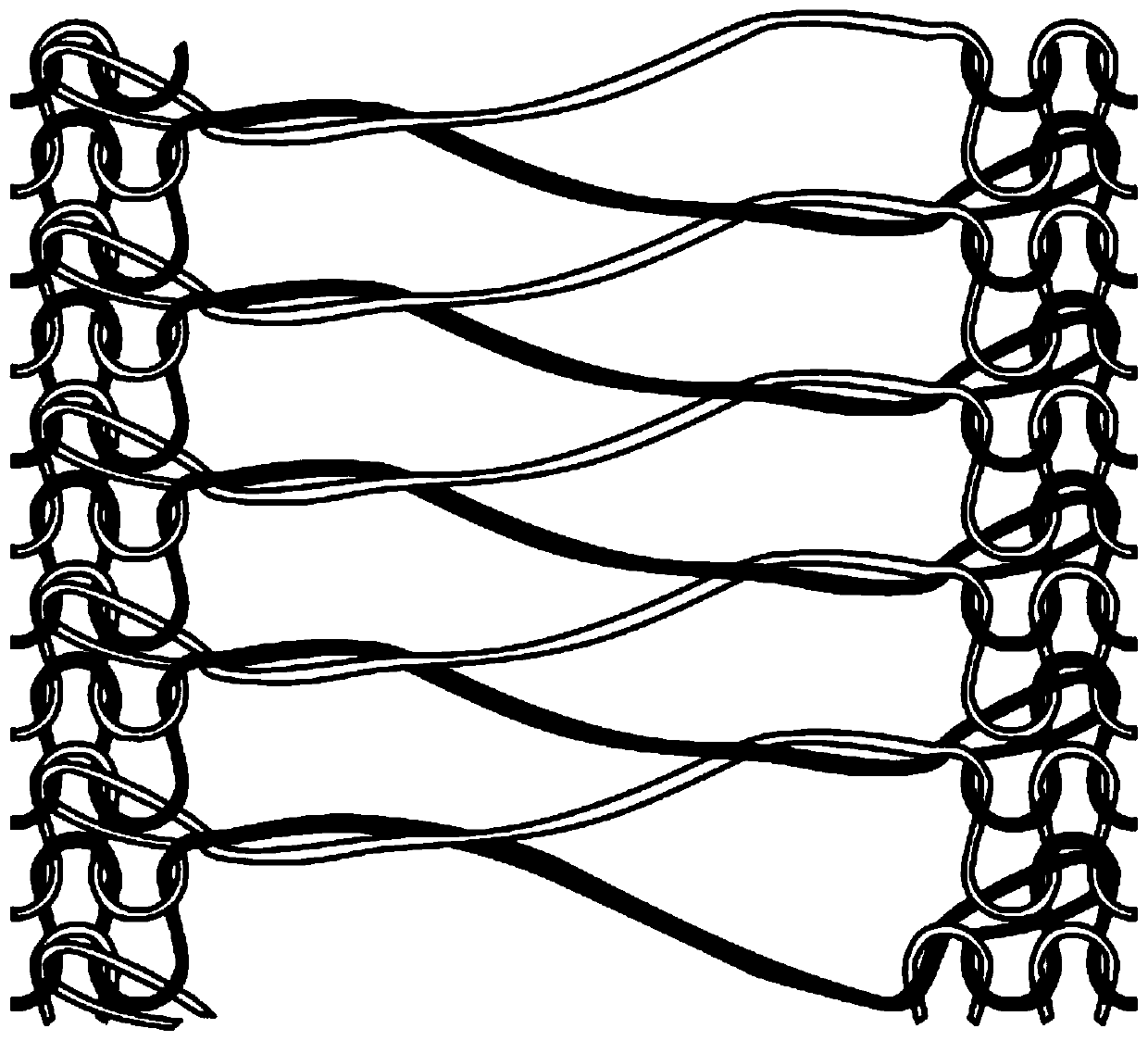

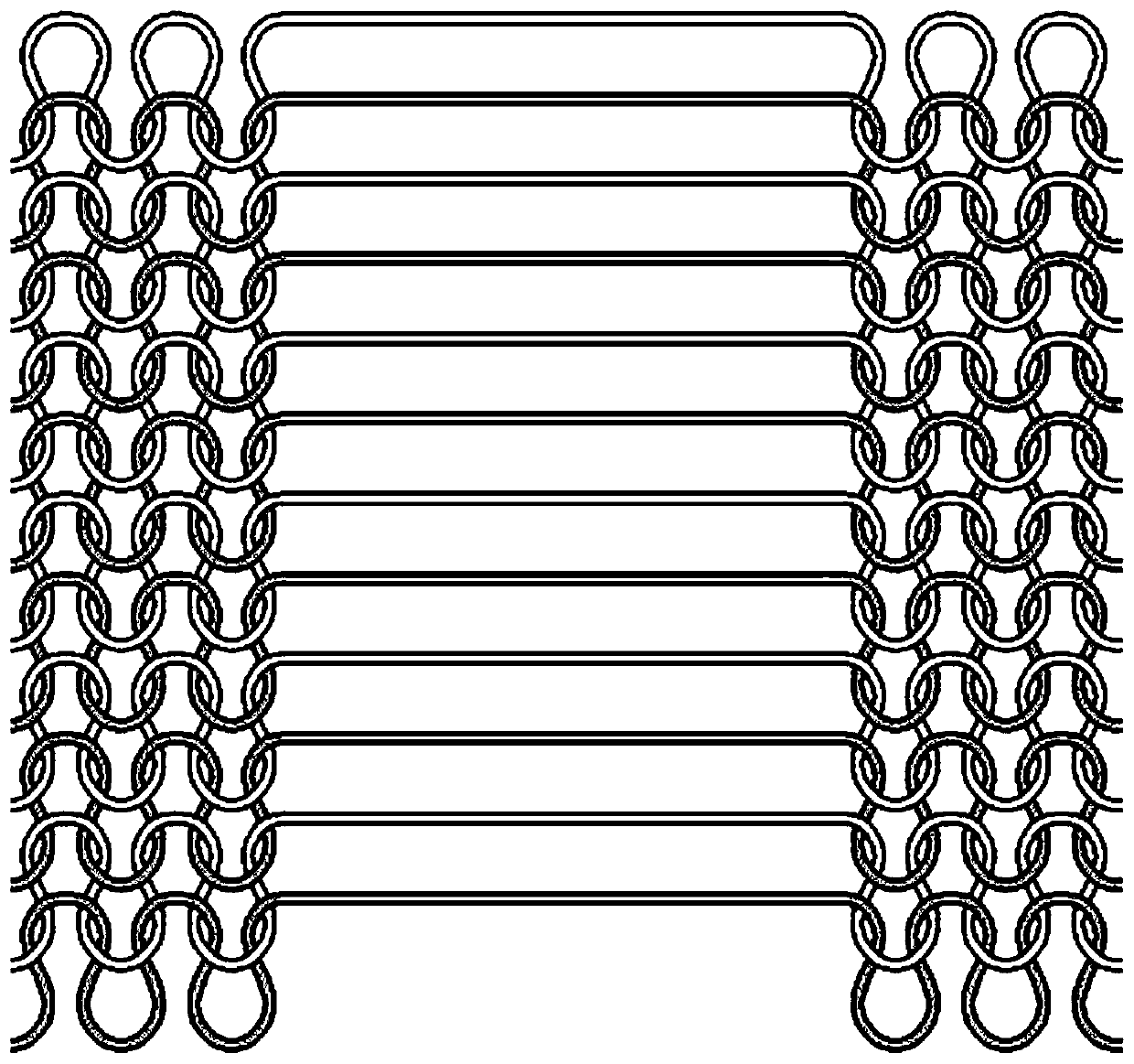

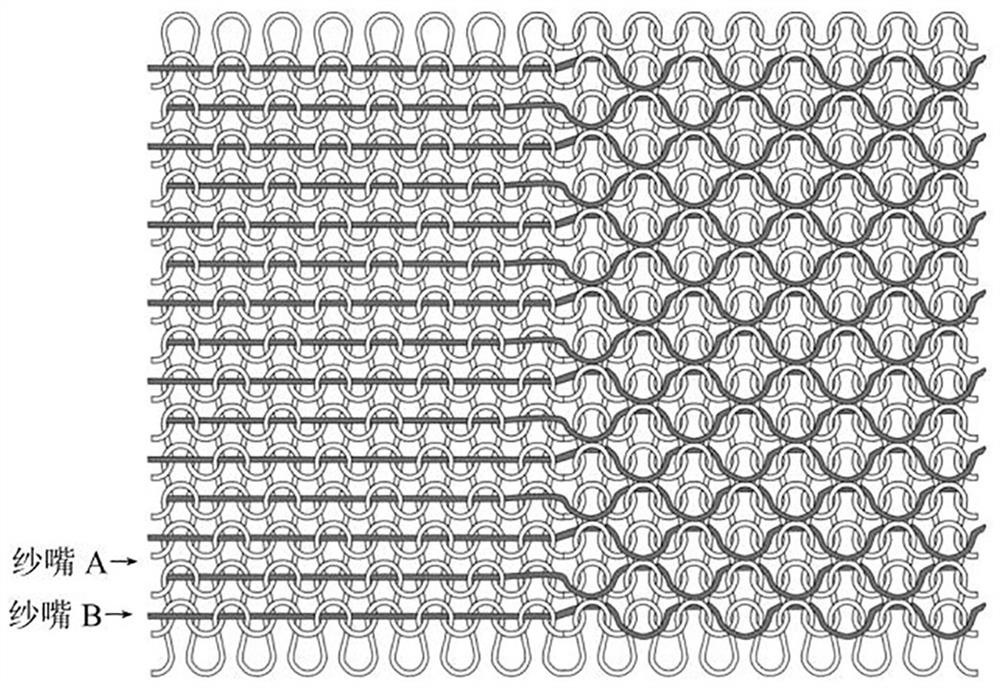

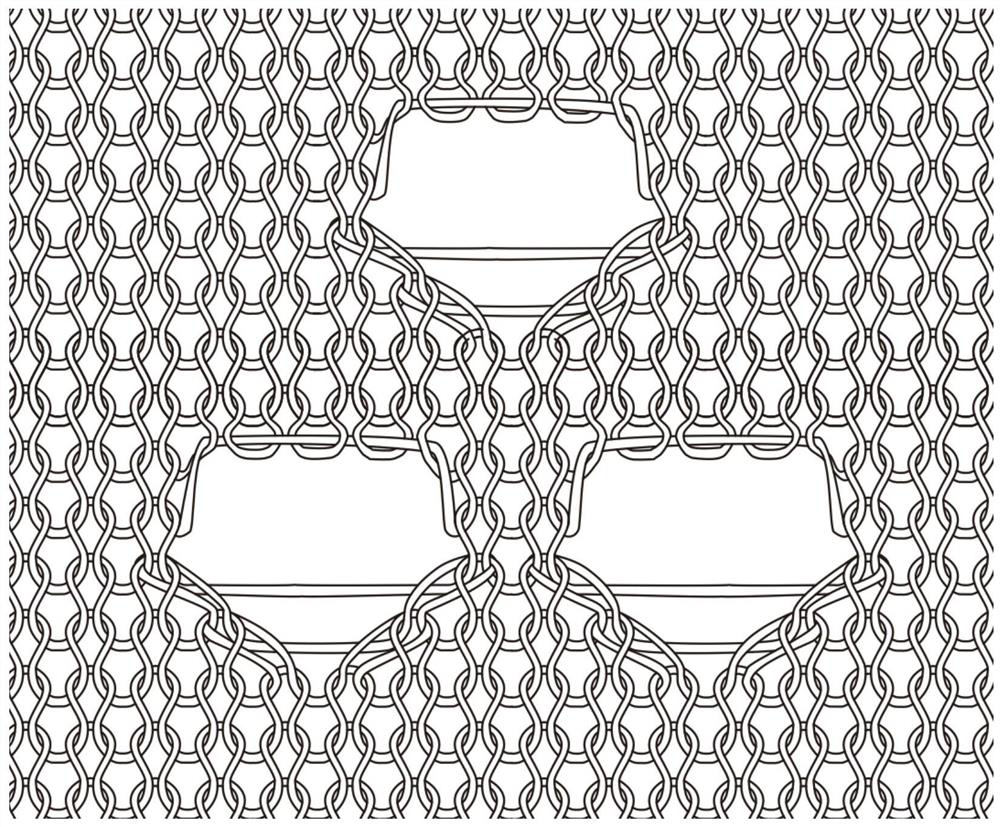

Microstereoscopic relief vertical stripe weave for knitted fabric and knitting method of microstereoscopic relief vertical stripe weave

The invention discloses microstereoscopic relief vertical stripe weave for knitted fabric. The microstereoscopic relief vertical stripe weave comprises front plain stitch and reverse plain stitch, wherein the front plain stitch is formed by spaced front stitch wales, the reverse plain stitch is formed by spaced reverse stitch wales, and the spaced front stitch wales and the spaced reverse stitch wales are arranged in a staggered manner. The invention further discloses a knitting method of the microstereoscopic relief vertical stripe weave for the knitted fabric. According to the method, the front plain stitch and the reverse plain stitch in staggered arrangement are knitted in by alternate plain knitting and reverse stacking on a front needle bed and a back needle bed. According to the microstereoscopic relief vertical stripe weave for the knitted fabric and the knitting method of the microstereoscopic relief vertical stripe weave, the microstereoscopic relief vertical stripe effect can be shown on the fabric surface, higher aesthetic value is obtained, the weave structure can only ravel in the inverse knitting direction, is low in raveling property, has longer service life, huge market potential and high adaptability, can meet multiple pattern demands and pushes international influence of the knitting industry of China.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

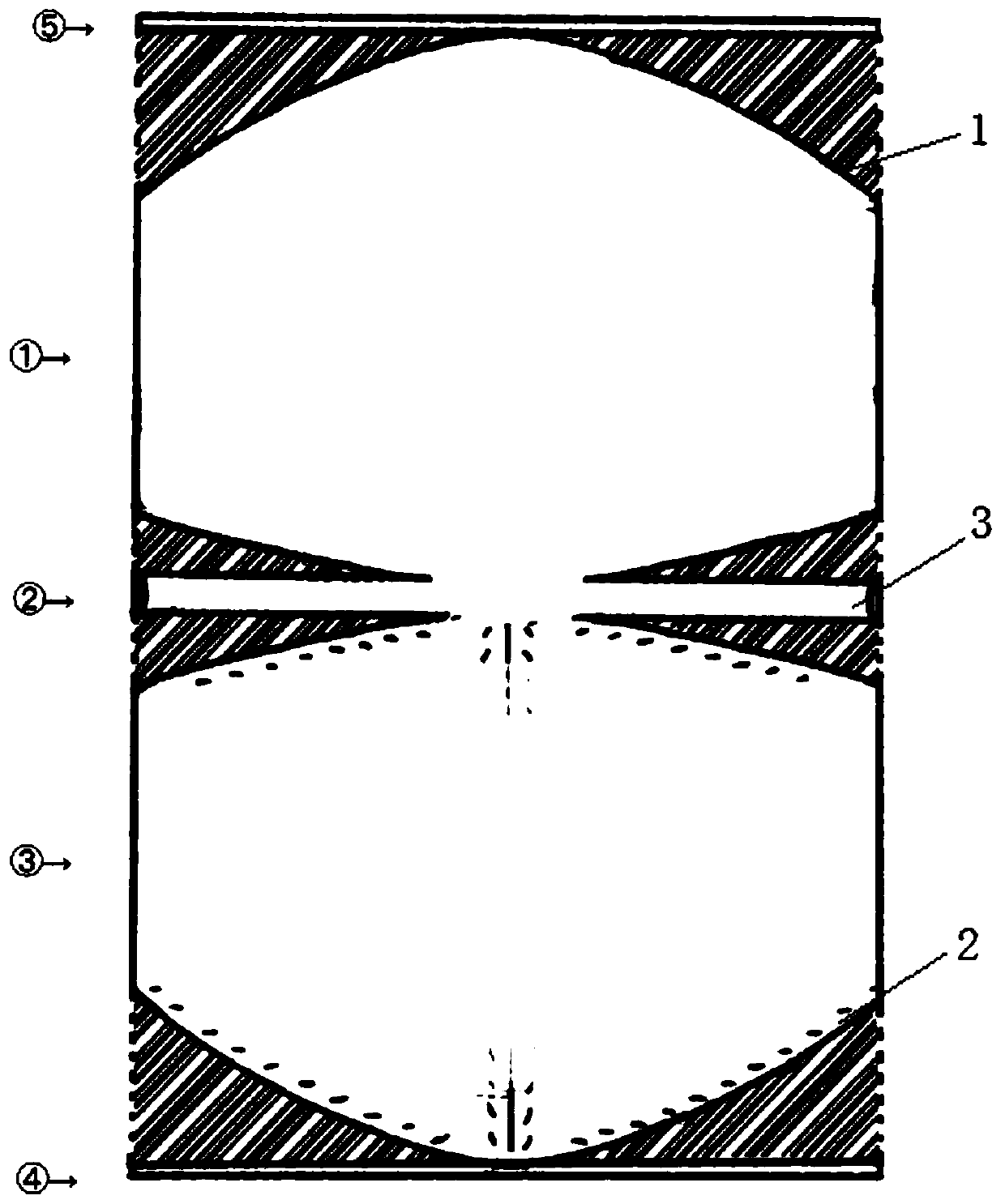

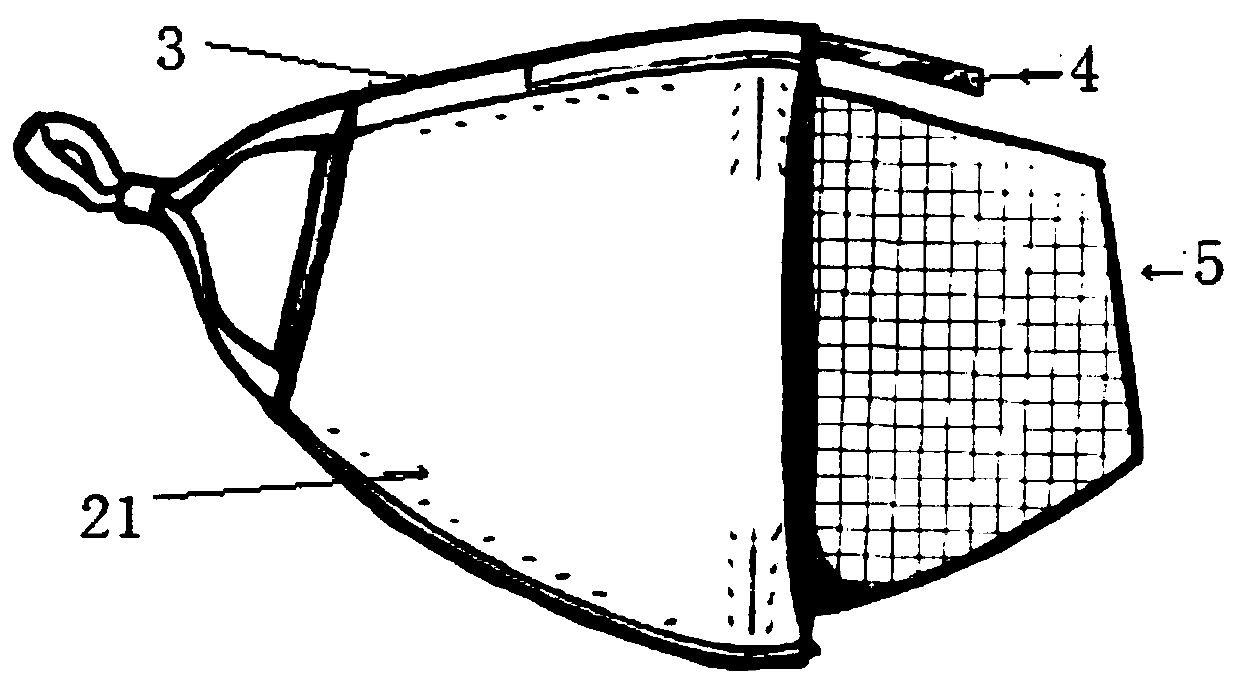

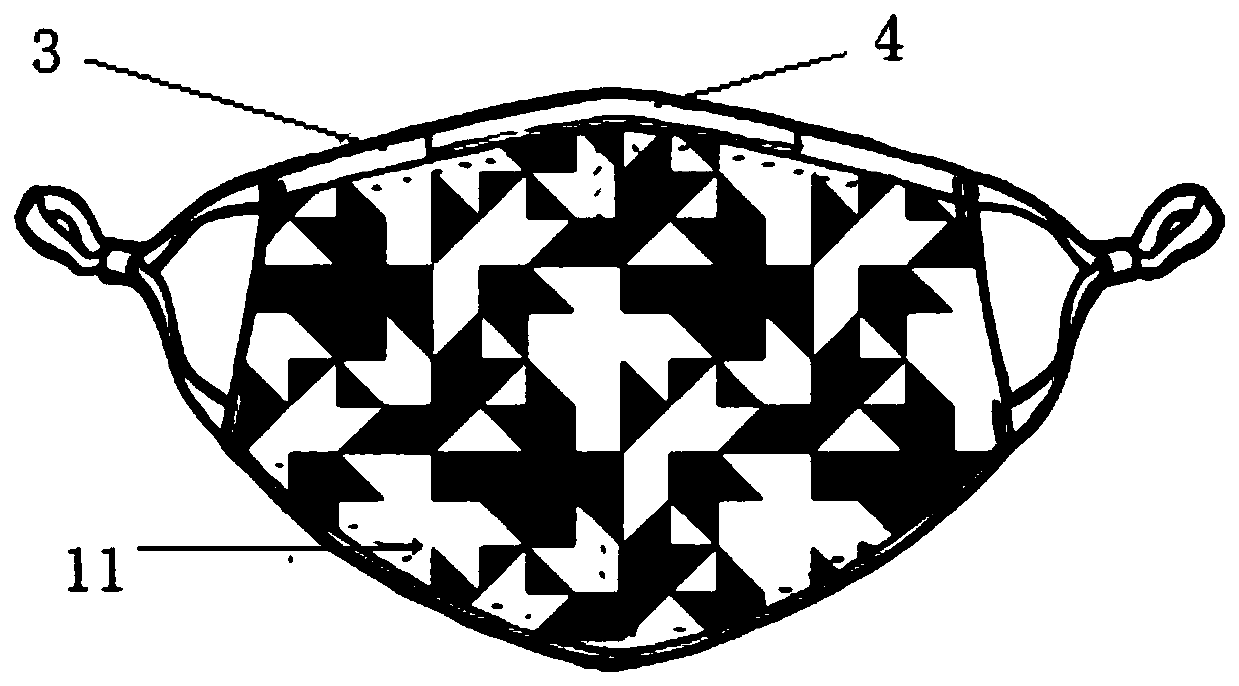

Antibacterial knitted mask with replaceable filter element and knitting method thereof

PendingCN111134395AImprove breathabilityBreak through limitationsWeft knittingProtective garmentEngineeringAnti bacteria

The invention discloses an antibacterial knitted mask with a replaceable filter element and a knitting method thereof. The antibacterial knitted mask with a replaceable filter element comprises a maskbody; the mask body comprises an antibacterial layer on the outer side and a breathable skin-friendly layer on the inner side; the upper portion of the antibacterial layer and the upper portion of the breathable skin-friendly layer are integrally knitted through an air layer structure, shaping strips are further inserted into the air layer structure, the lower portion of the antibacterial layer and the lower portion of the breathable skin-friendly layer are attached and then connected in a sewn mode, an interlayer is formed between the antibacterial layer and the breathable skin-friendly layer, and the interlayer is filled with a filter element. The antibacterial knitted mask with the replaceable filter element is long in service life, breathable and comfortable to wear, the limitation ofa traditional mask is broken through, and a new path is opened up for a knitted mask.

Owner:桐越针织科技浙江有限公司

Collective stitch type complex tissue knitted fabric and knitting method thereof

The invention relates to a collective stitch type complex tissue knitted fabric and a knitting method thereof. Yarn carriers with different widths are utilized to realize free changes between a singleyarn carrier and a plurality of yarn carriers, so as to simultaneously knit yarns fed by the plurality of yarn carriers to realize a purpose of freely switching coil sizes and thicknesses, thereby realizing one-time knitting on computerized flat knitting machines with a same specification to obtain a collective stitch type complex tissue knitted fabric with a three-dimensional effect. Compared with the prior art, the invention breaks through the above limitation of a conventional knitting method and opens up a new path for knitted products to realize a texture effect of different stitch typecoils on the computerized flat knitting machines with a same specification. Therefore, a design method of a knitted fabric pattern structure is enriched, a design concept is better interpreted at lower cost, the artistic value and aesthetic value of a product are improved, and a wider development space is provided for knitted product development and market.

Owner:嘉兴市蒂维时装有限公司

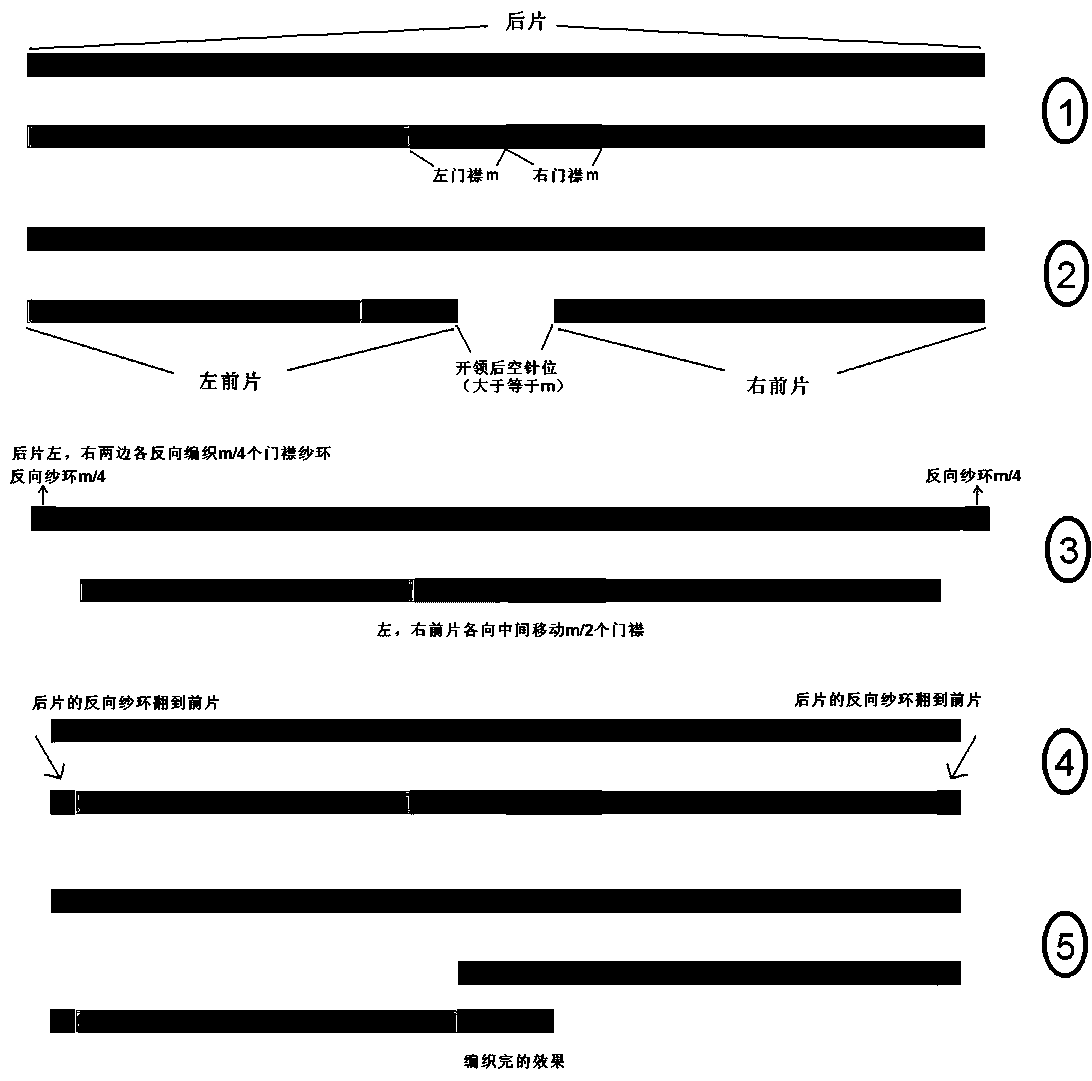

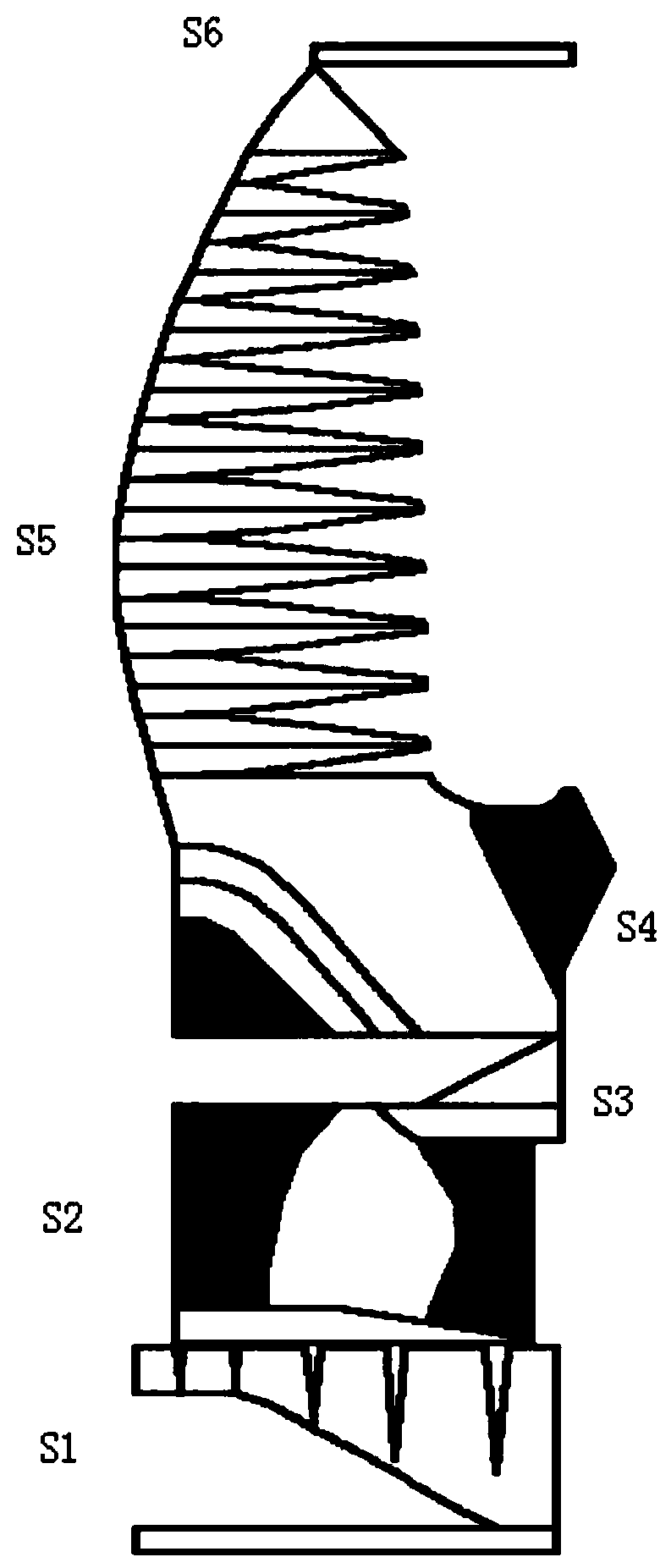

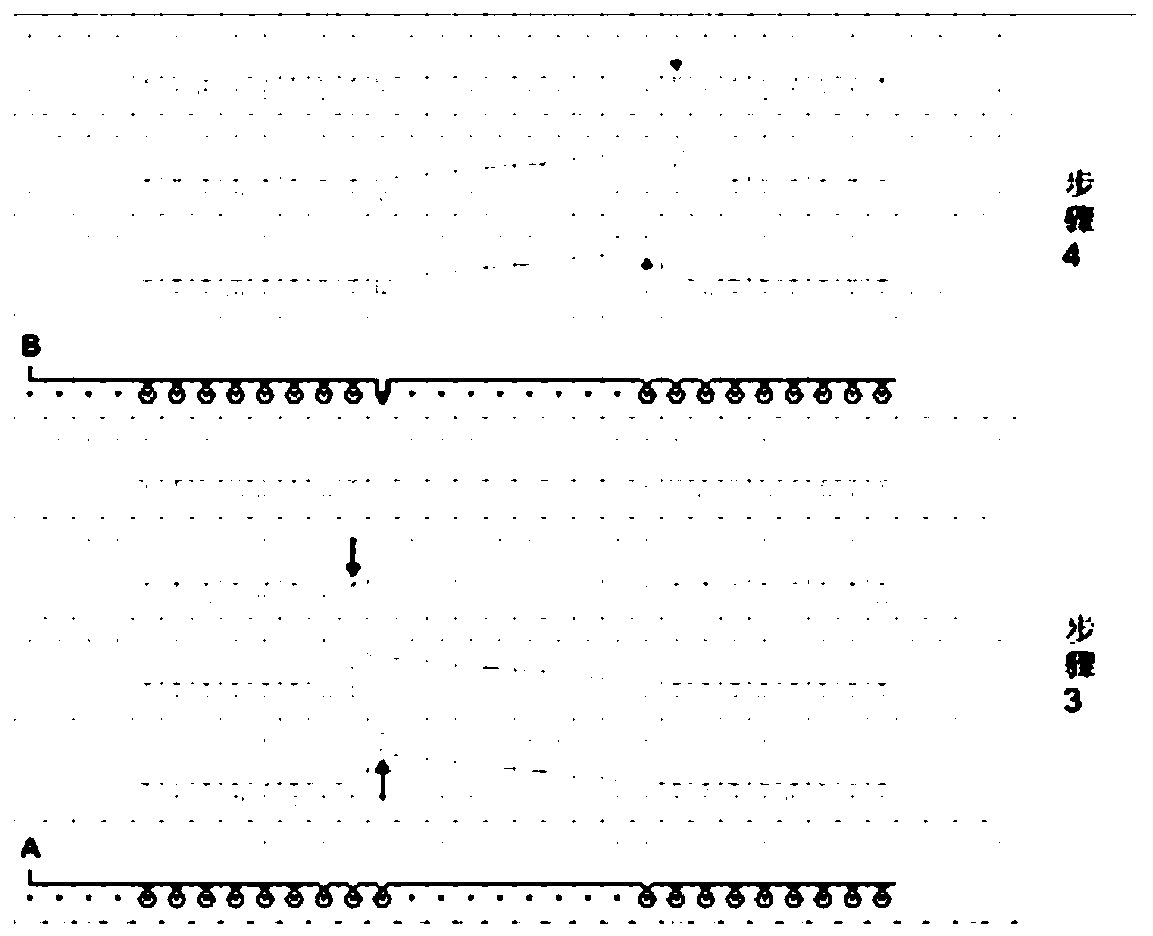

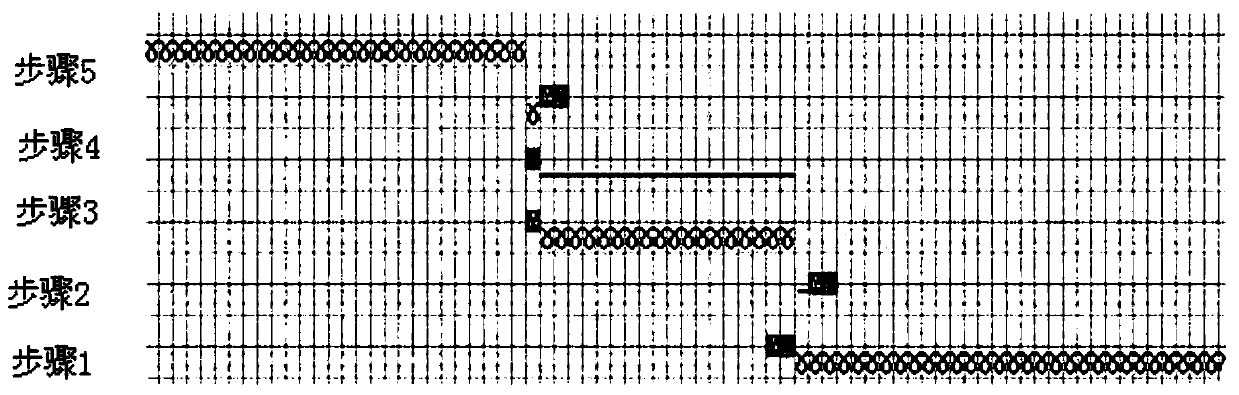

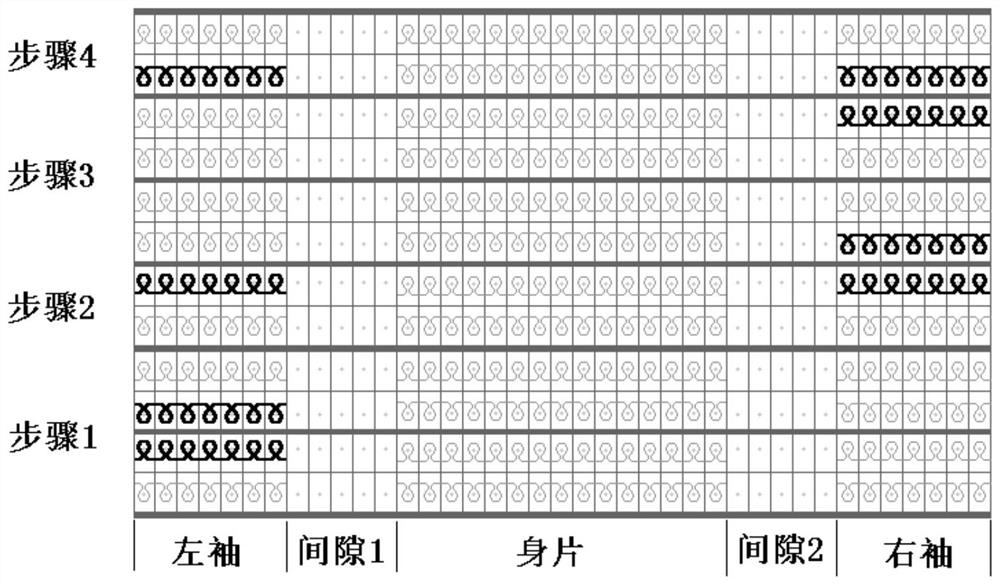

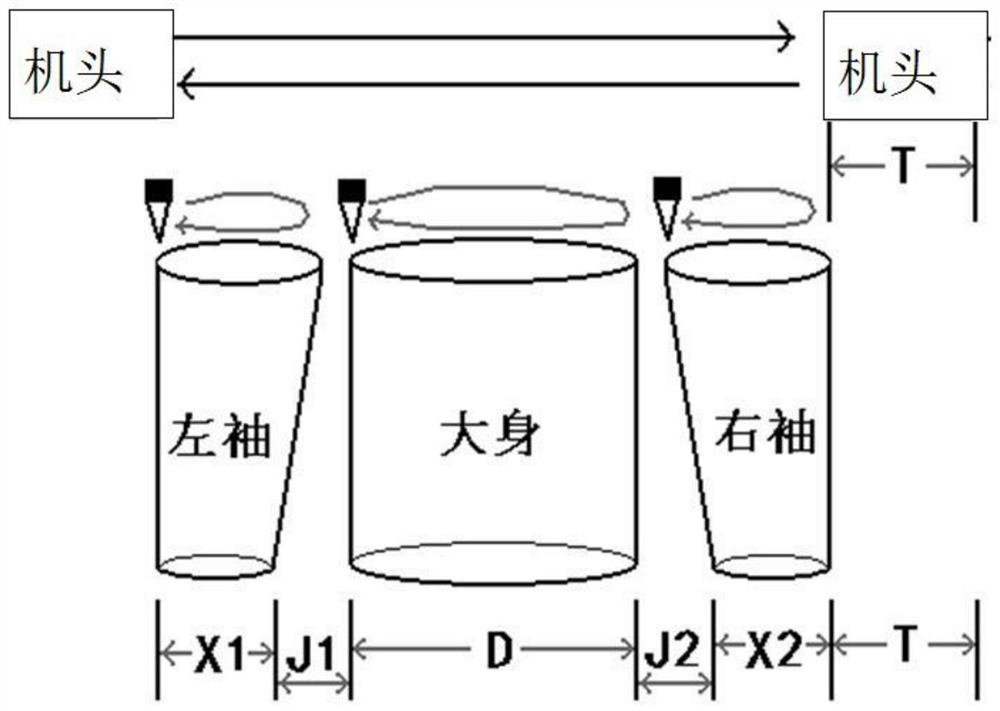

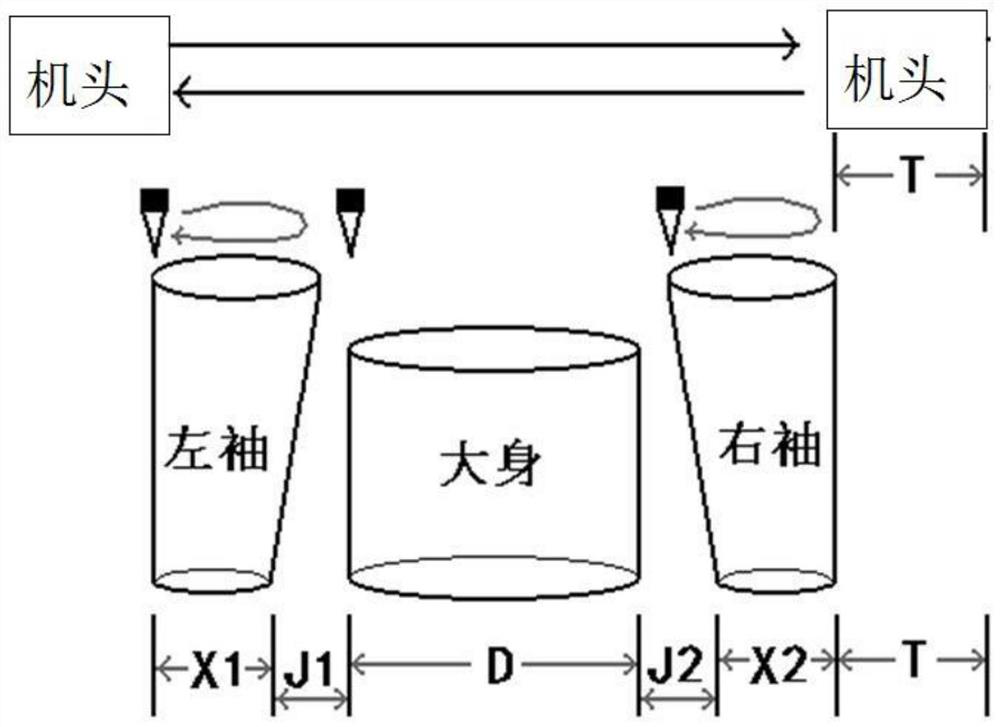

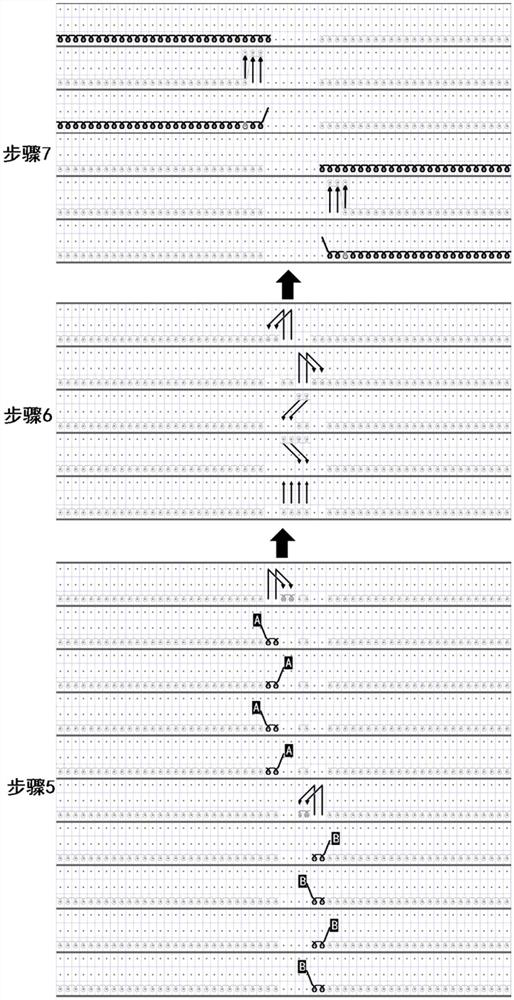

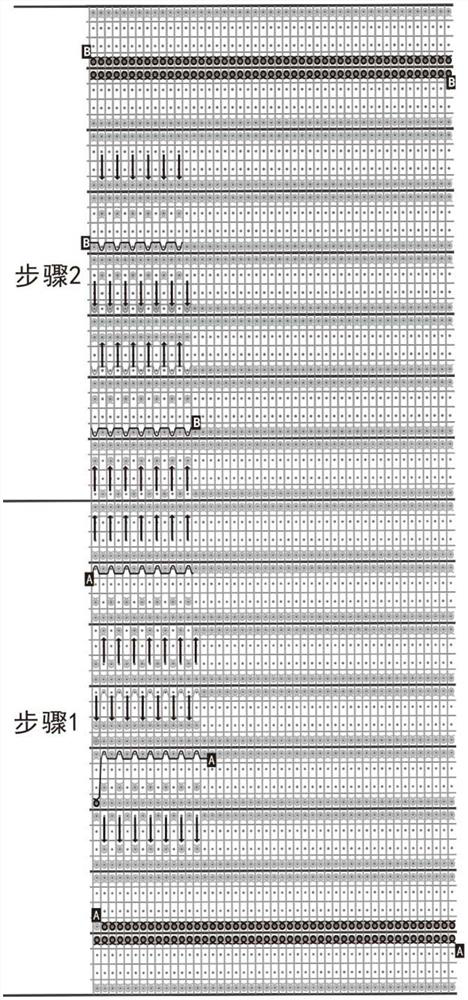

Knitting method for improving knitting efficiency of full-forming clothes of flat knitting machine

ActiveCN112176517APromote international influenceImprove the sense of qualityWeft knittingMechanical engineeringIndustrial engineering

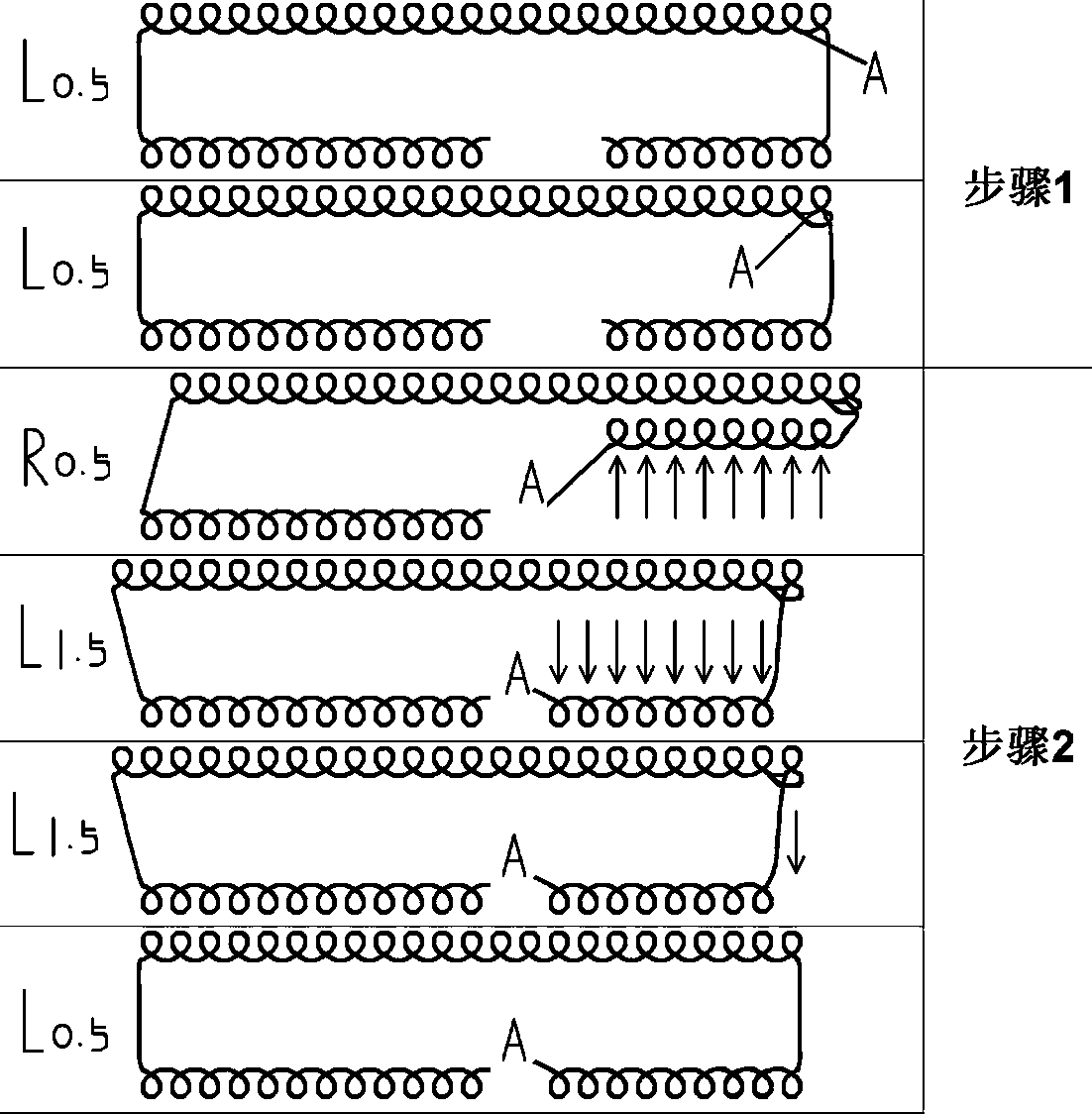

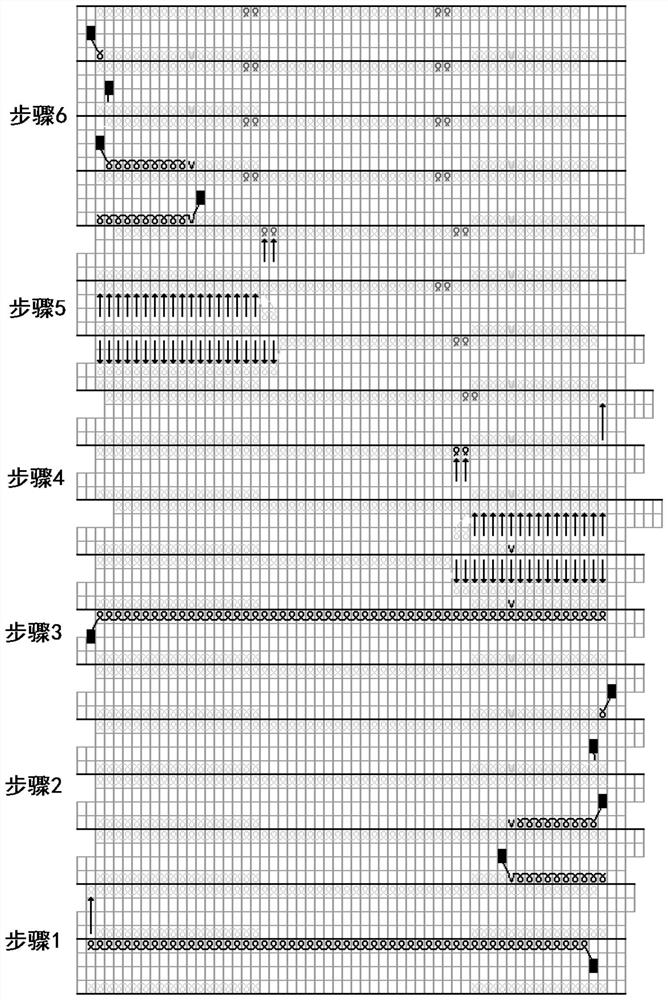

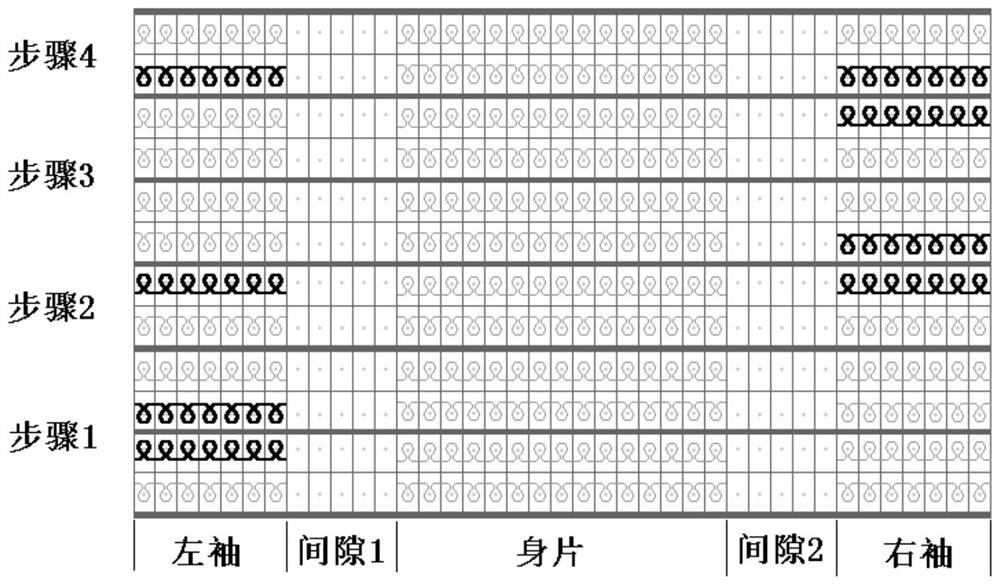

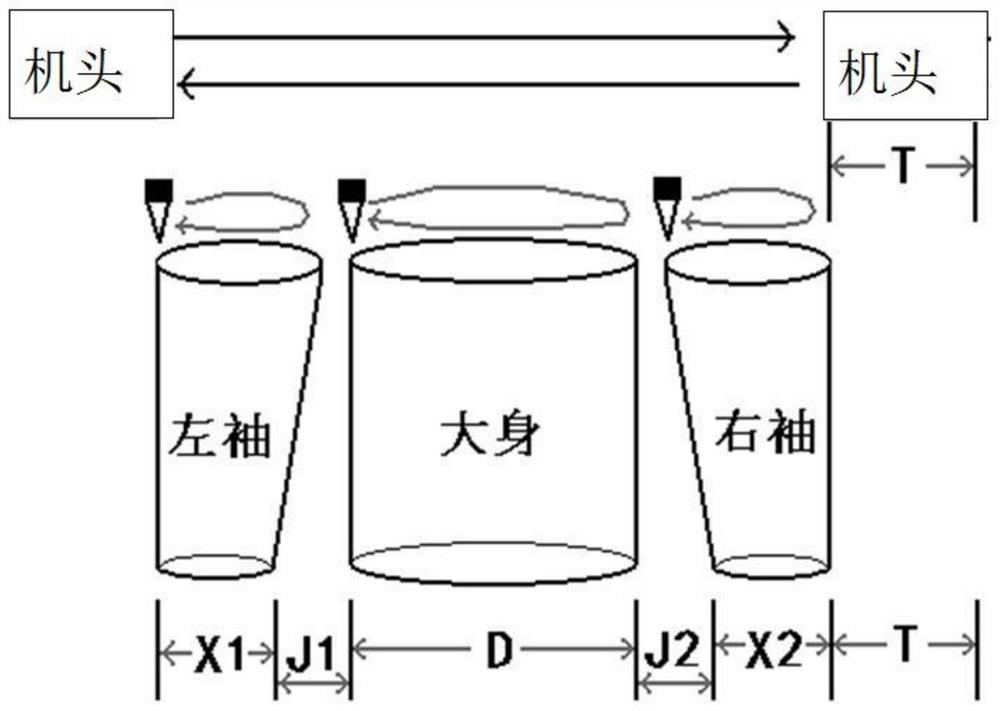

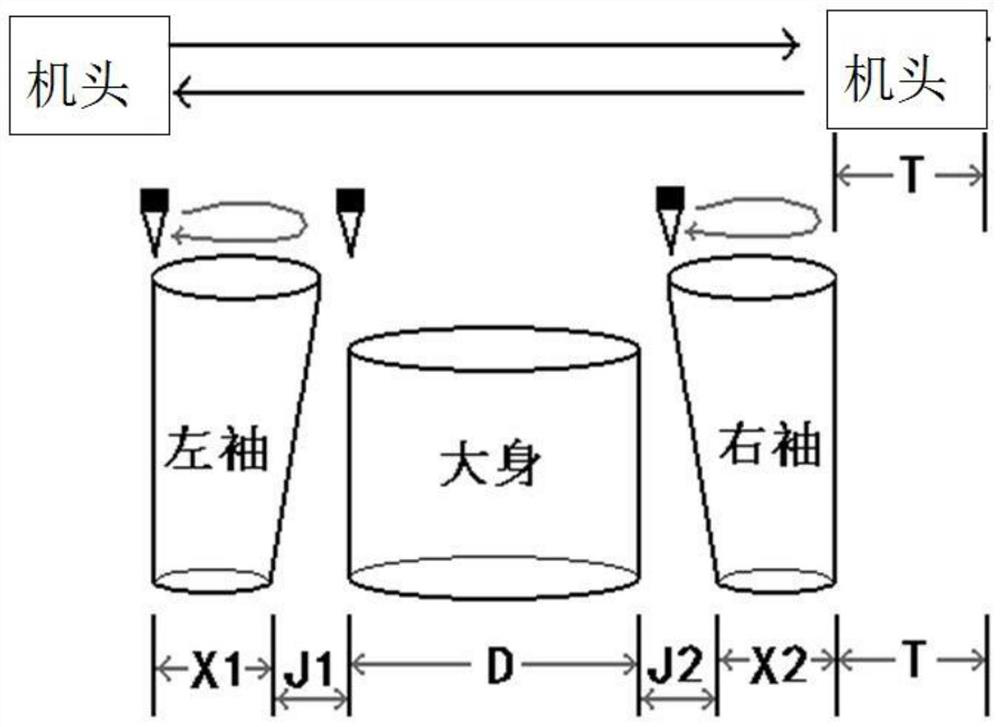

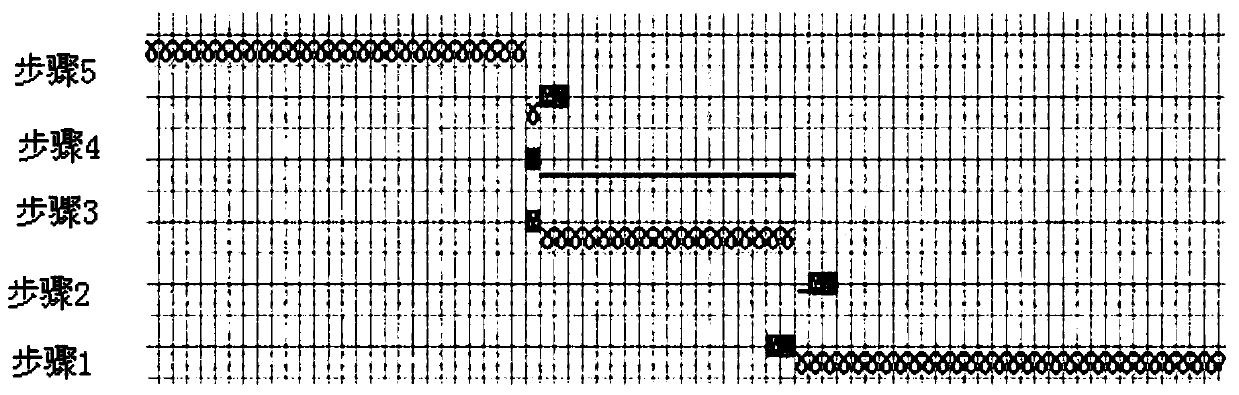

The invention discloses a knitting method for improving the knitting efficiency of full-forming clothes of a flat knitting machine. The knitting method comprises the following steps that the flat knitting machine with one or more pairs of front and rear needle beds extending in left-right direction and facing each other in front-rear direction is used, the spacing width of left and right sleeves is set as J3, the width of a machine head is set as T, and on the premise that J3 is greater than T, knitting is carried out in the following mode, S1, the machine head of the flat knitting machine firstly knits the excessive revolution of the left sleeve and then stops on the right side of the knitting width of the left sleeve. According to the knitting method for improving the knitting efficiencyof the full-forming clothes of the flat knitting machine, the limitation of a traditional knitting method is broken through, the knitting method can be adjusted for the full-forming clothes with thelarge length difference between the body piece and the sleeves on full-forming computerized flat knitting machine equipment, therefore efficiency maximization is achieved, and the requirements for energy conservation, emission reduction and efficient production at present are met.

Owner:嘉兴市蒂维时装有限公司

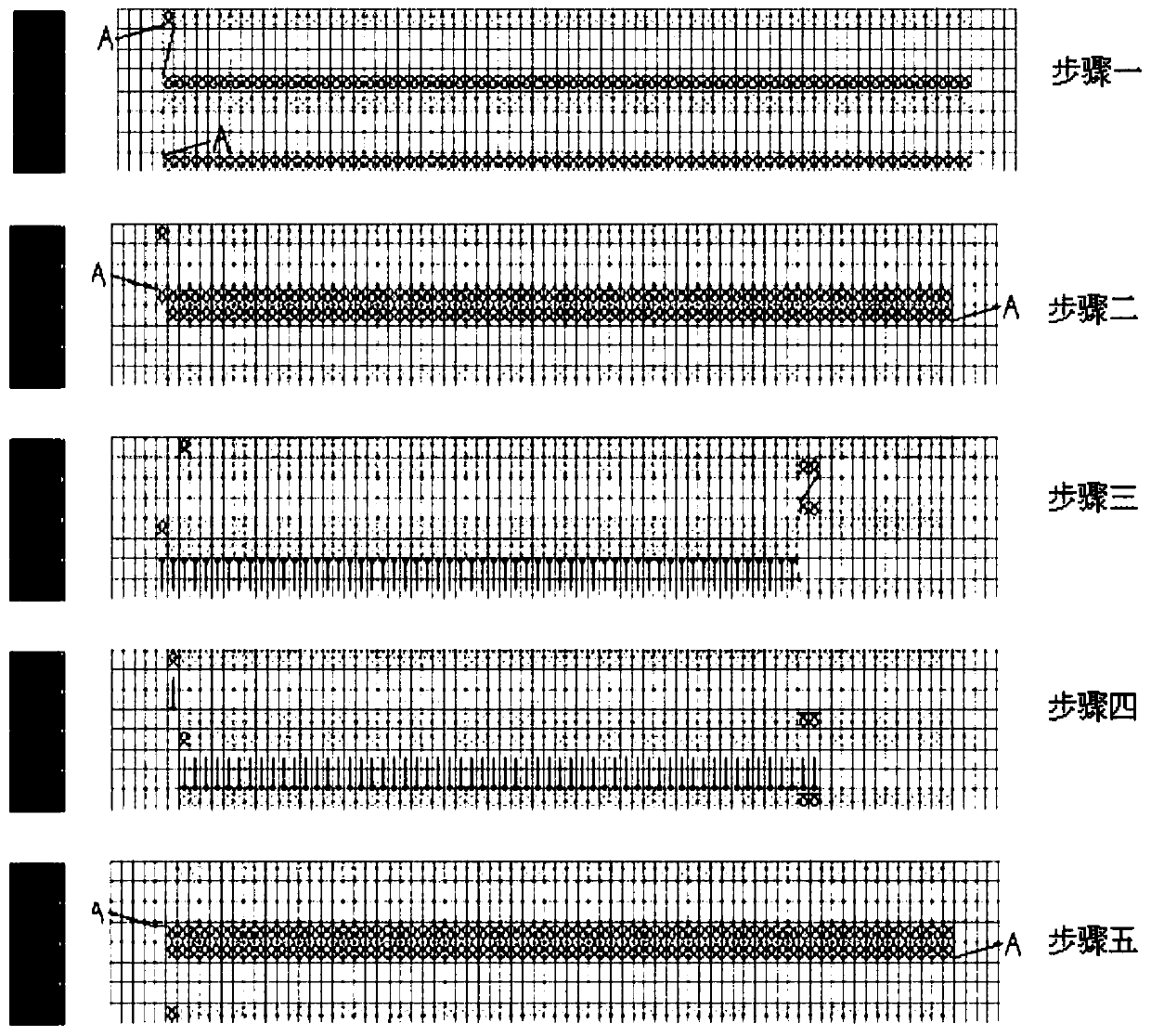

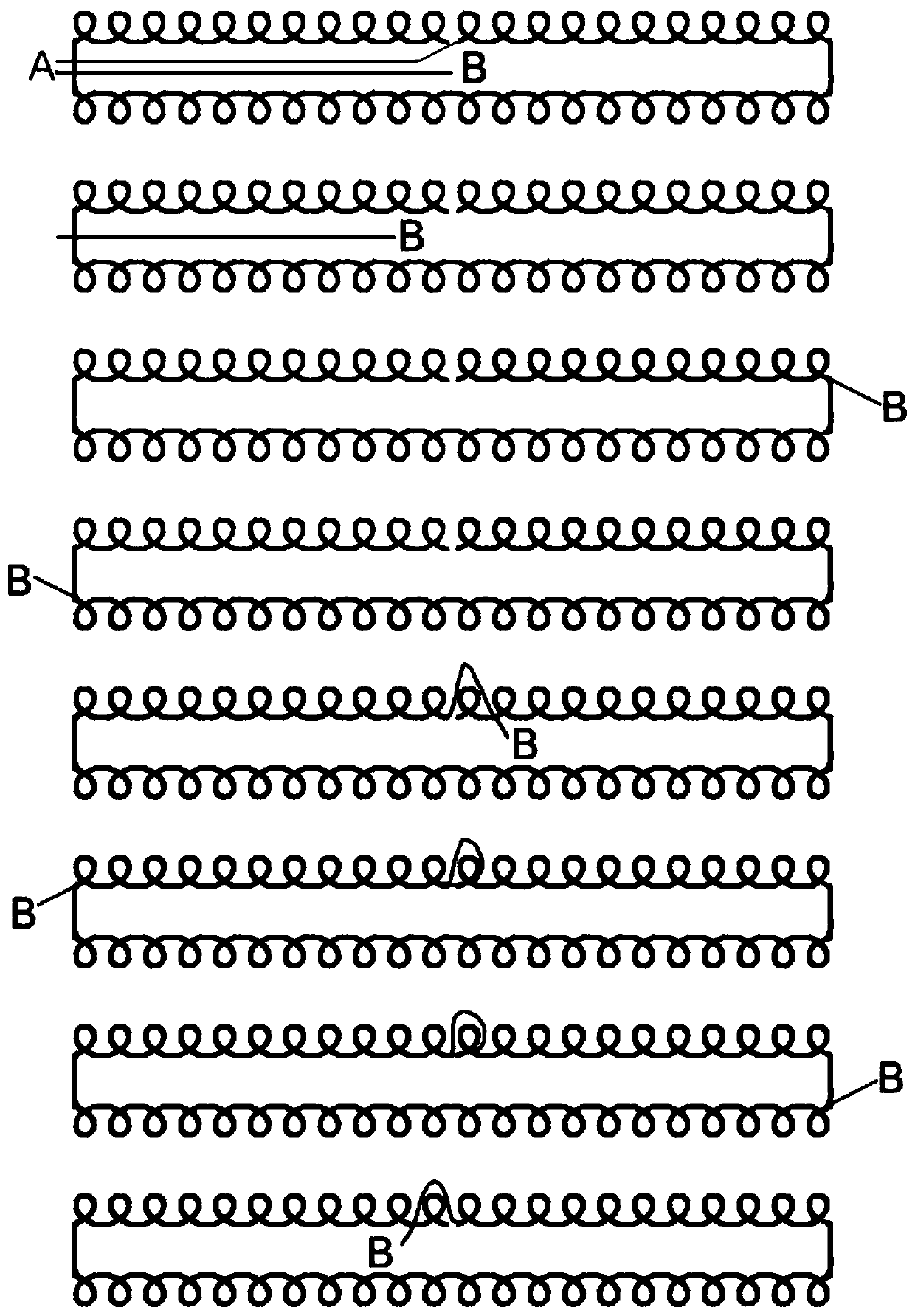

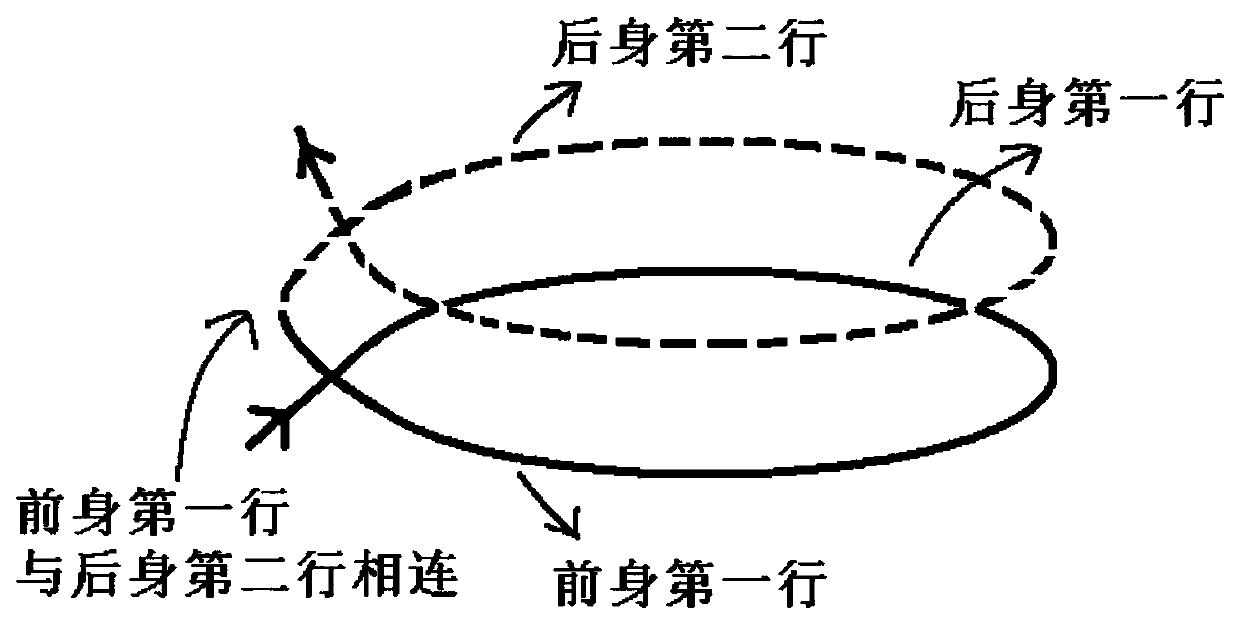

Kitting method for preventing dislocation of fully fashion stripe pattern

ActiveCN110644121ASolve the problem that the color will be misalignedHuge market potentialWeft knittingYarnStructural engineering

The invention discloses a knitting method for preventing dislocation of fully fashion stripe pattern. In the knitting method, a flat knitting machine with needle beds extending left to right and opposite front to back relatively is adopted; on the basis of cylindrical knitting, yarn feeders for last yarn feeding are driven to move to edges of cloth pieces while yarn feeders for next yarn feeding are driven to move to middles of cloth pieces. The knitting method for preventing dislocation of fully fashion stripe pattern can prevent color dislocation, at alternations of left, right, front and back pieces, of each stripe color, of the fully fashion stripe pattern.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

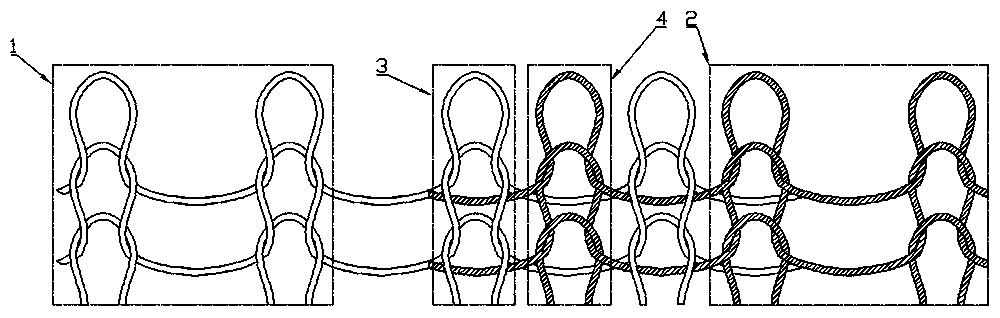

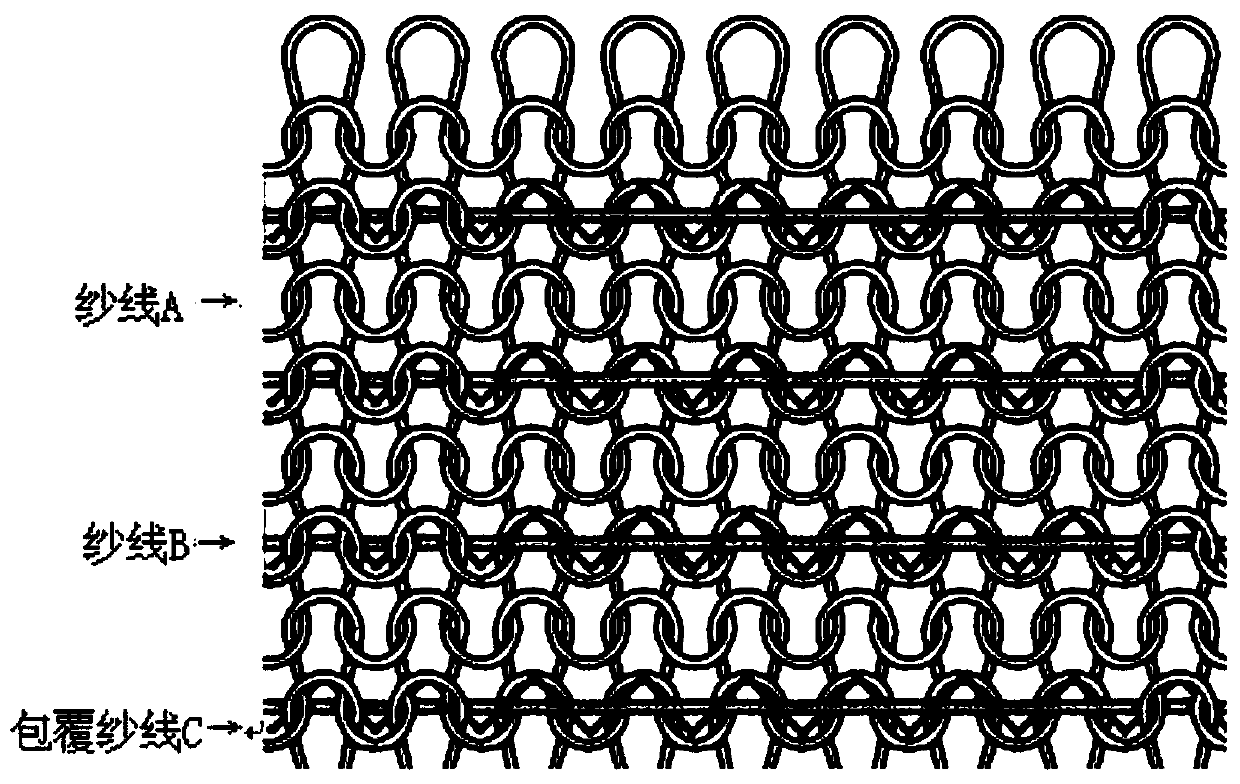

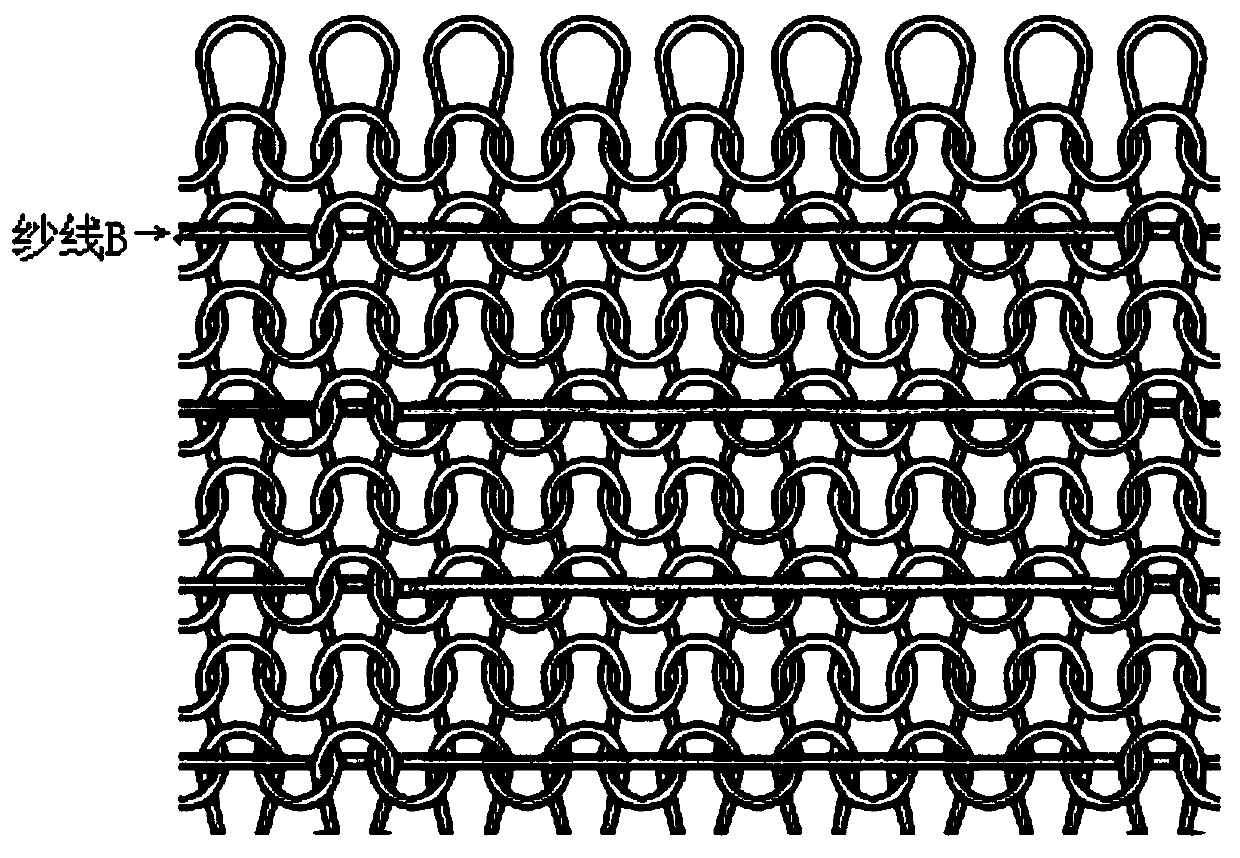

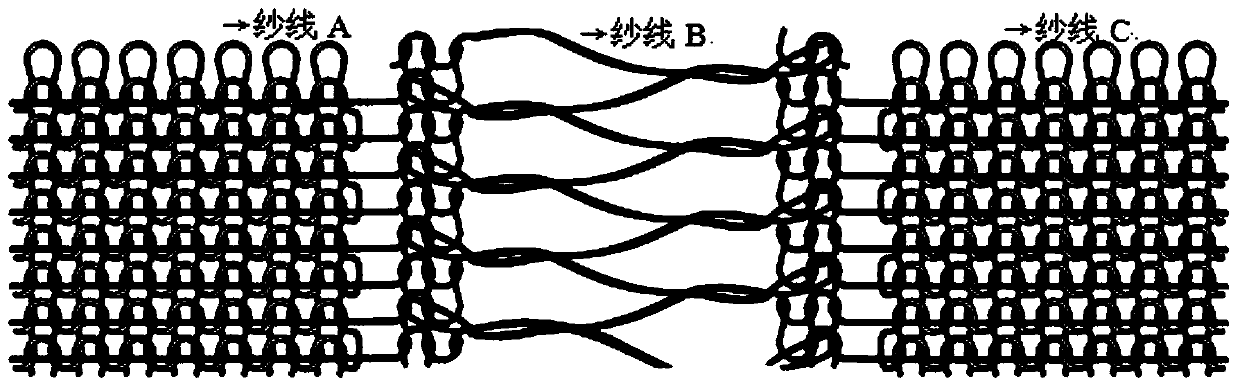

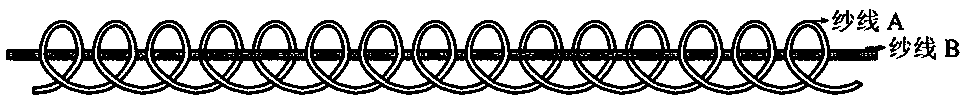

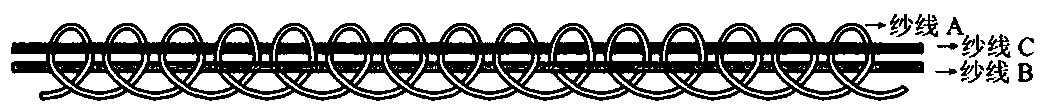

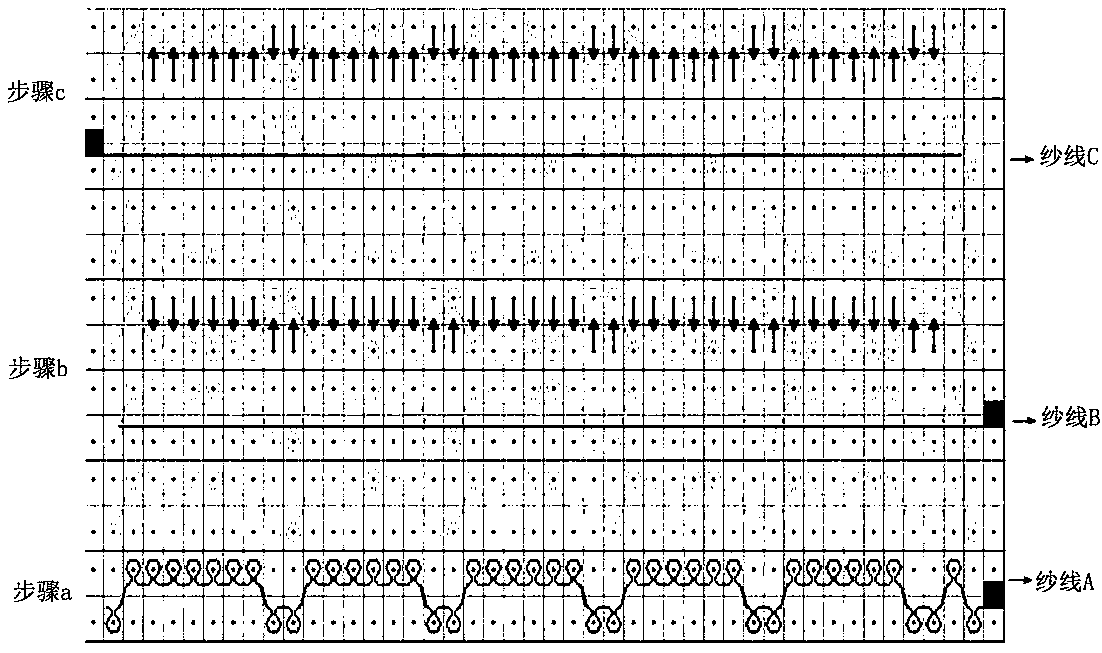

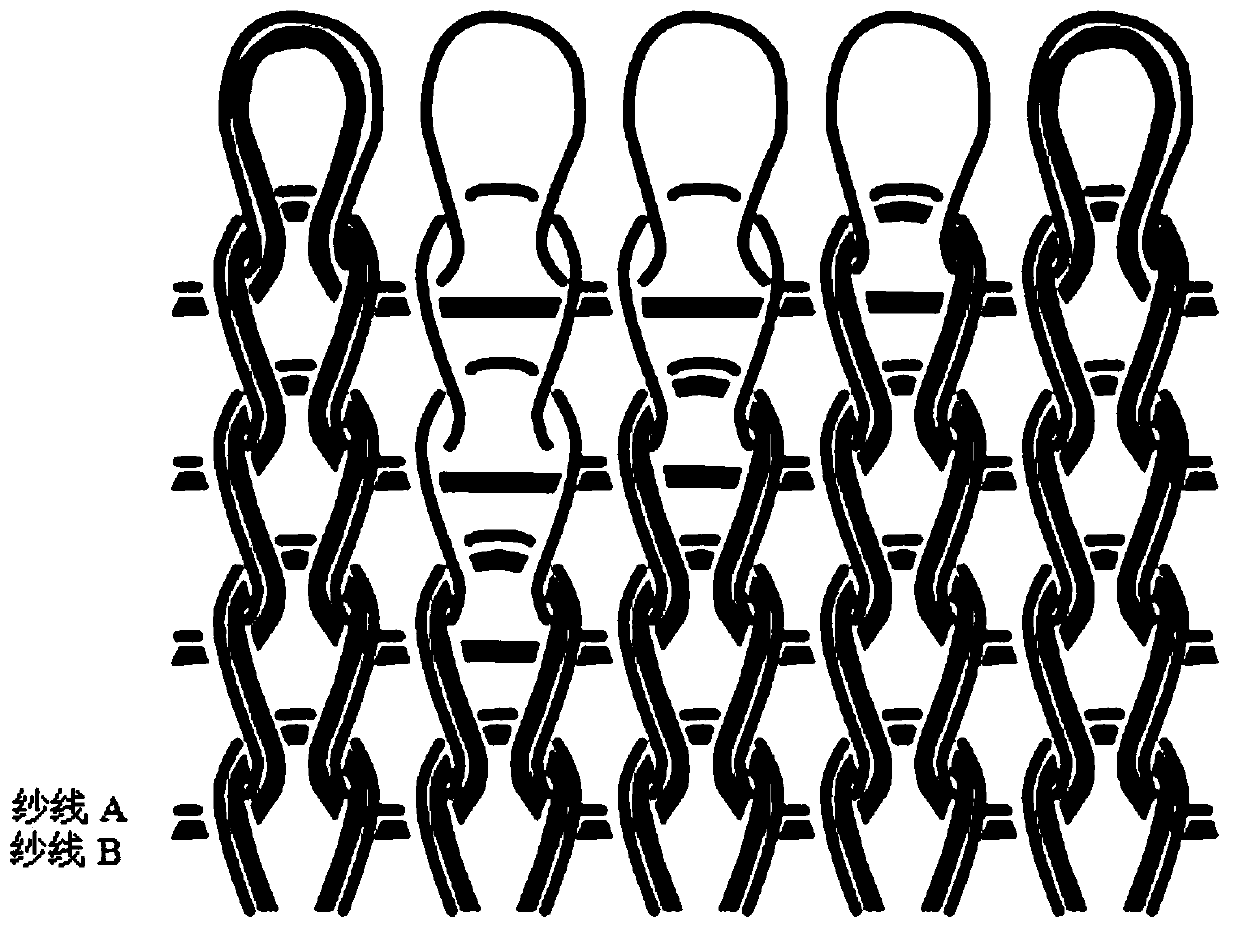

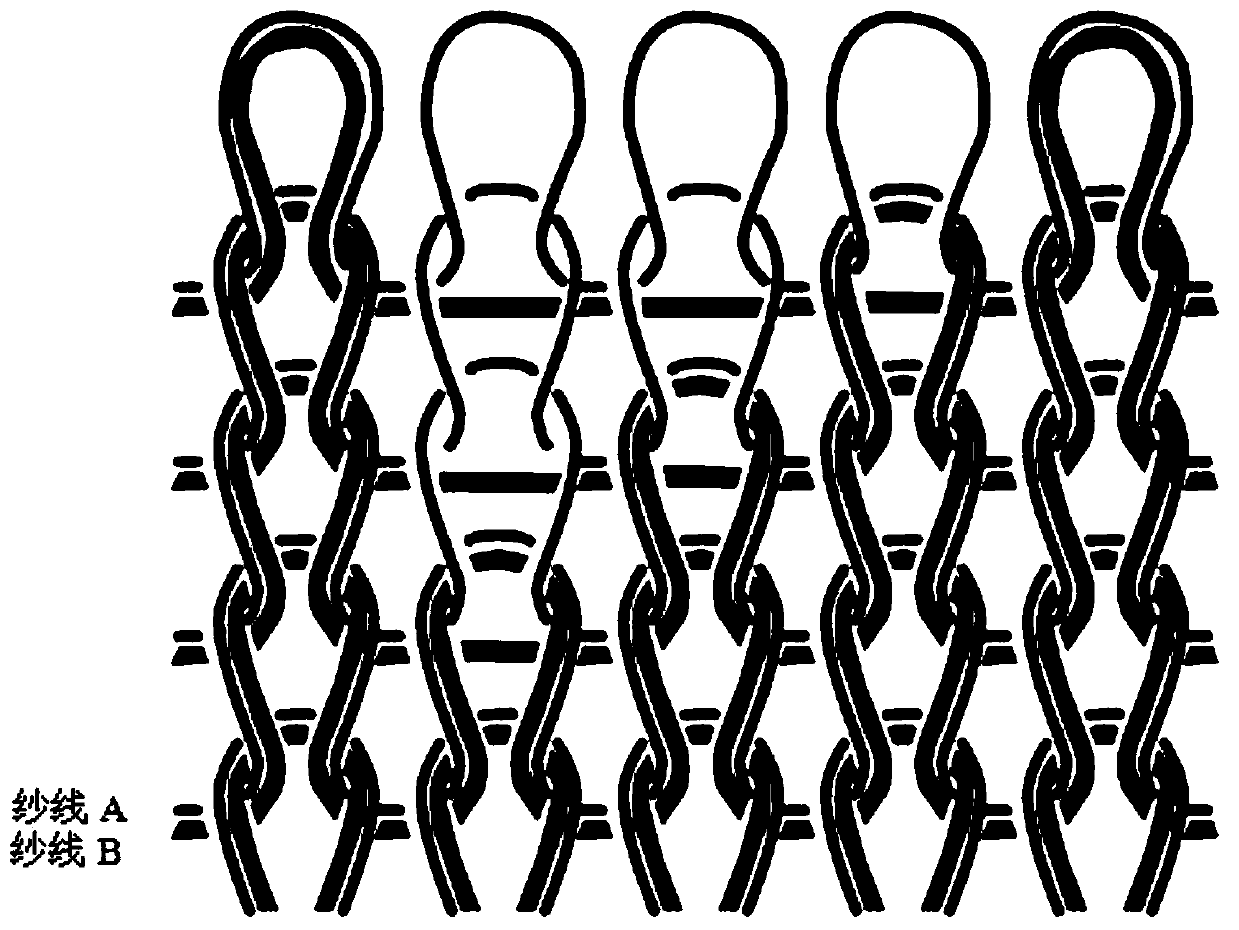

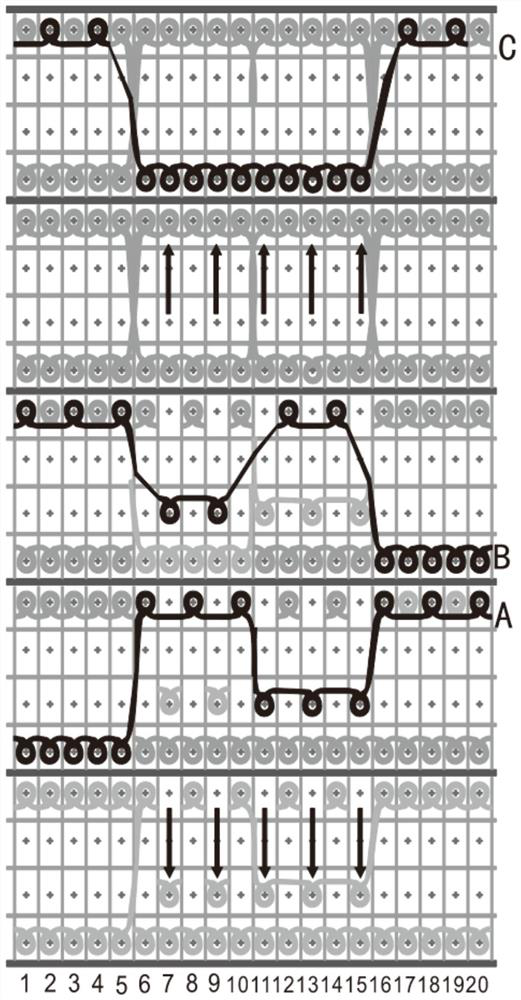

Single weft laid-in covered stitch structure and knitting method thereof

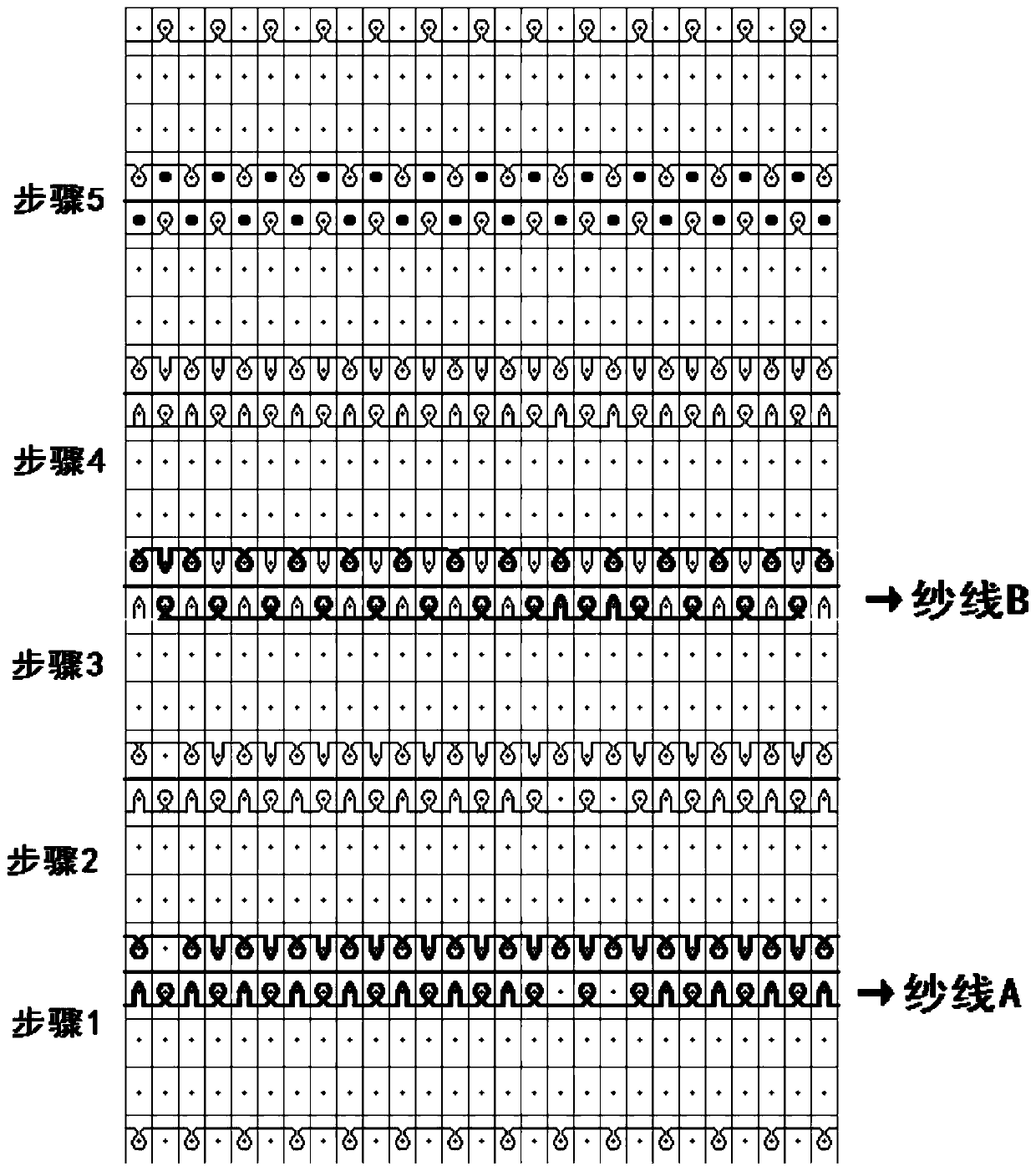

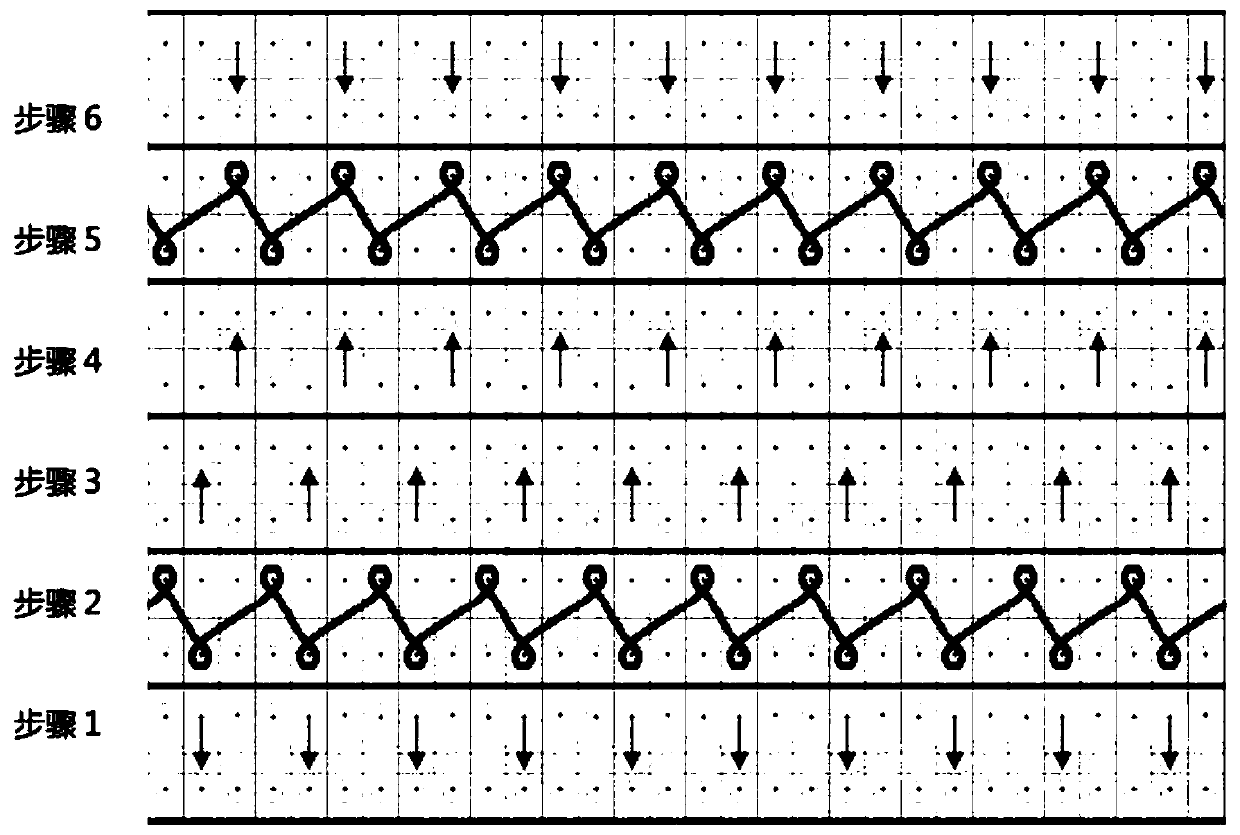

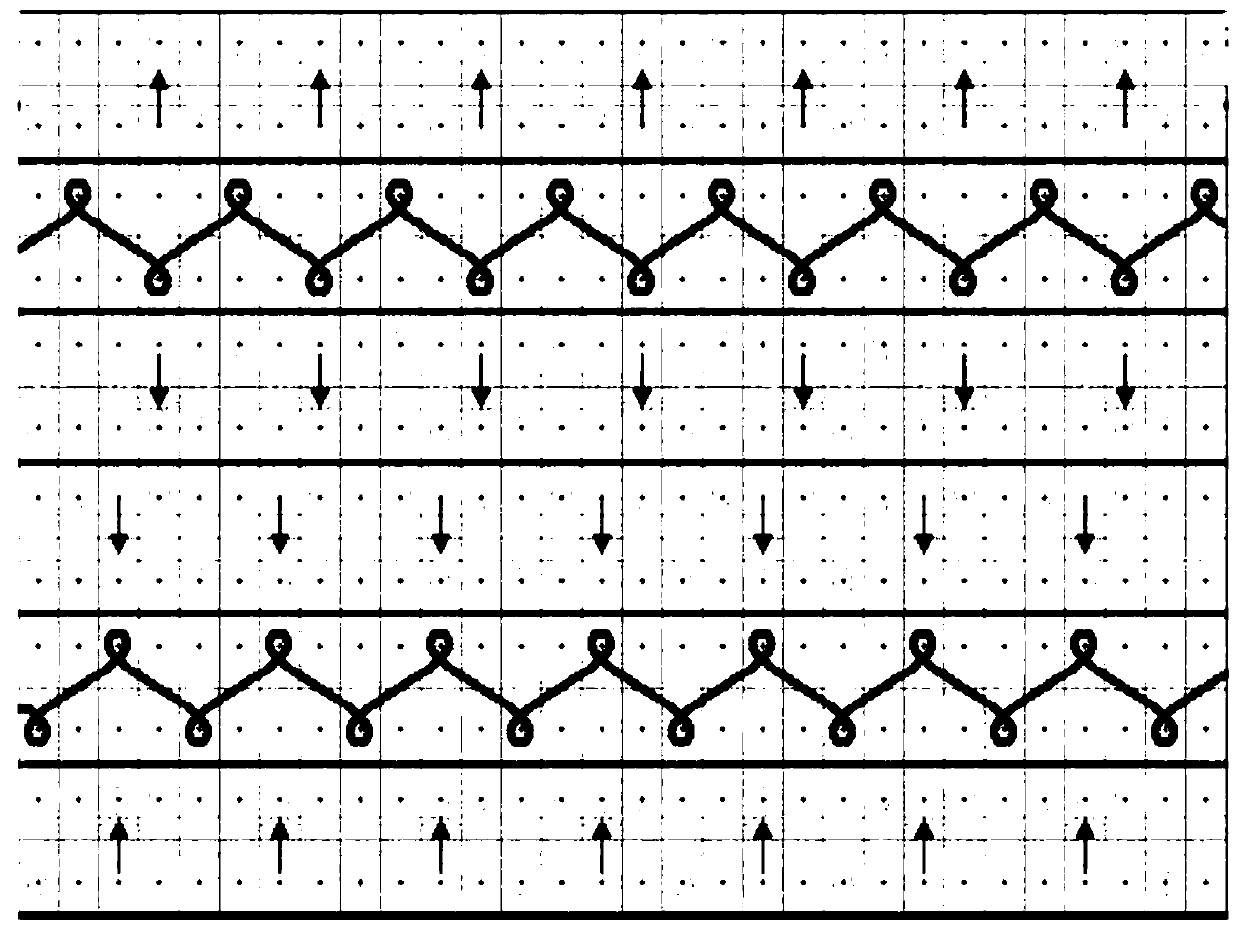

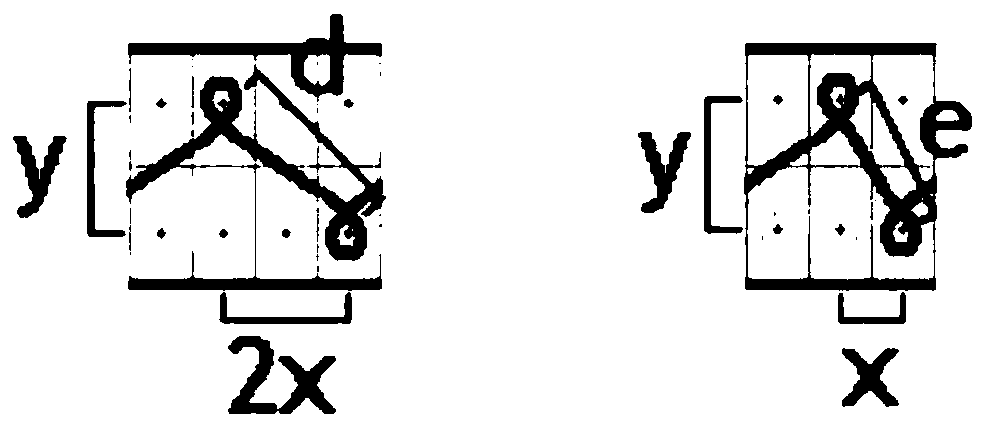

ActiveCN111101267APromote international influenceGuaranteed nudityWeft knittingEngineeringMaterials science

The invention discloses a single weft laid-in covered stitch structure and a knitting method thereof. The single weft laid-in covered stitch structure is formed by knitting yarns A, yarns B and covered yarns C; and according to pattern demands, yarn A knitted loops are overturned to a corresponding needle bed, the covered yarns C are uniformly knitted in a tuck mode, and after the yarns B are laidin a weft non-knitting form, the covered yarns C cover the yarns B by needle overturning. The knitting method of the single weft laid-in covered stitch structure breaks through the limitation of a conventional knitting method, and not only can ensure that weft yarns are exposed out of the surface according to the pattern demands, but also can enable the weft yarns to be fixed by covering.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

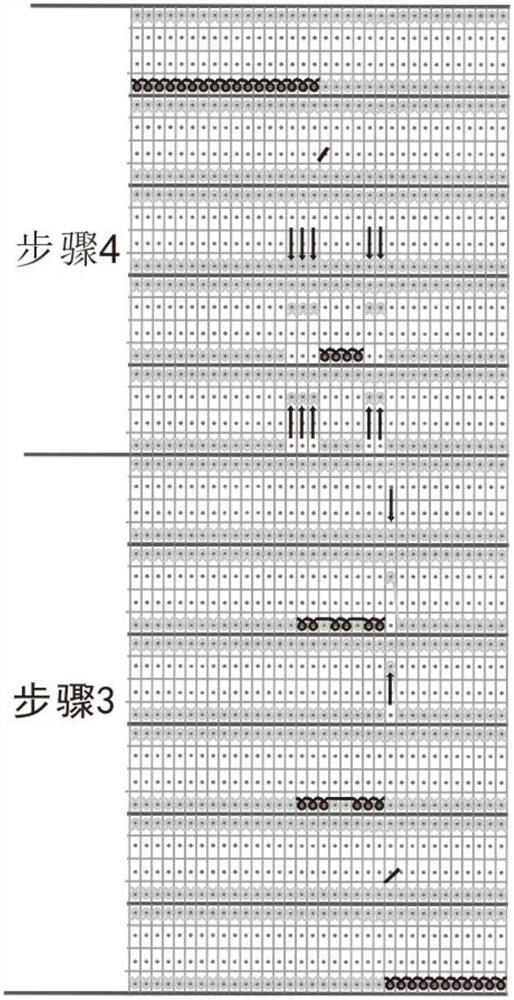

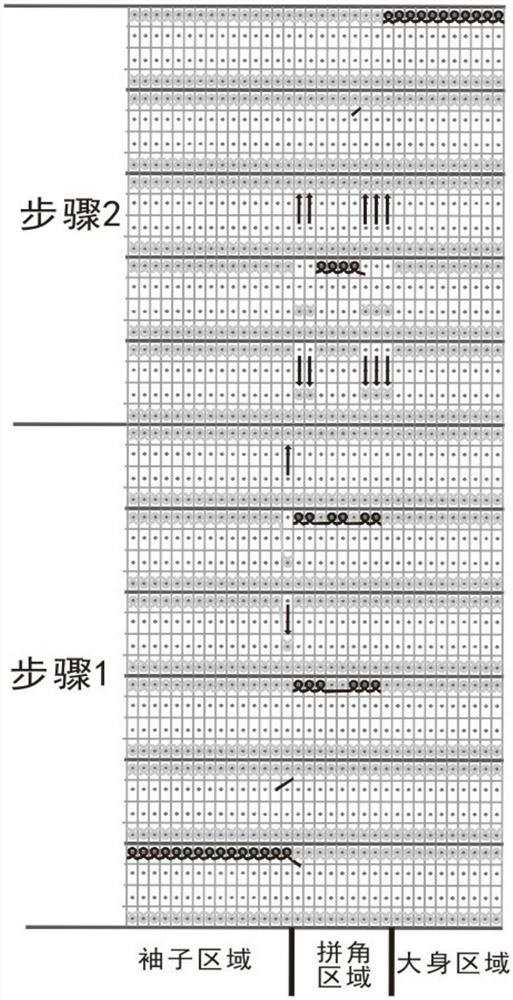

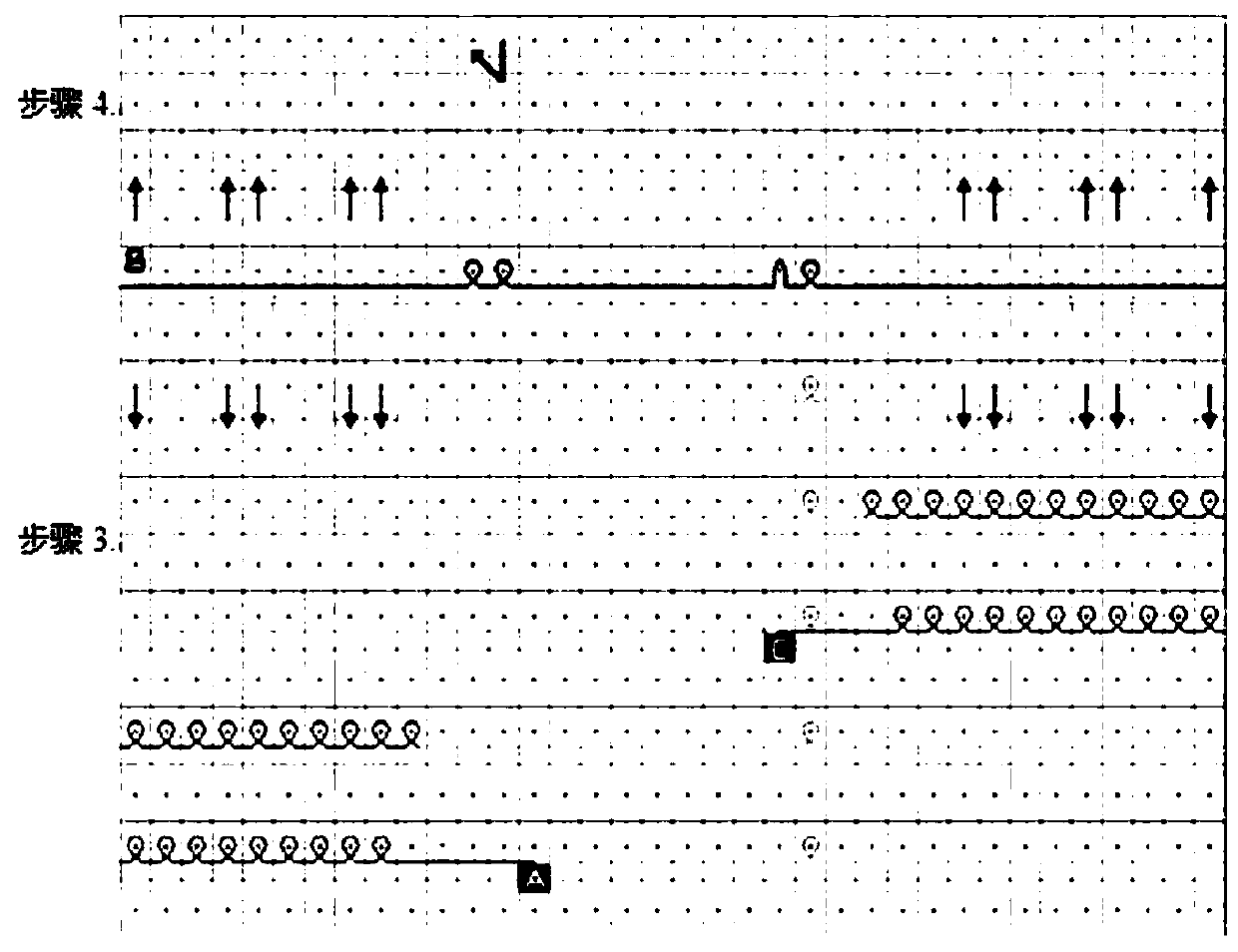

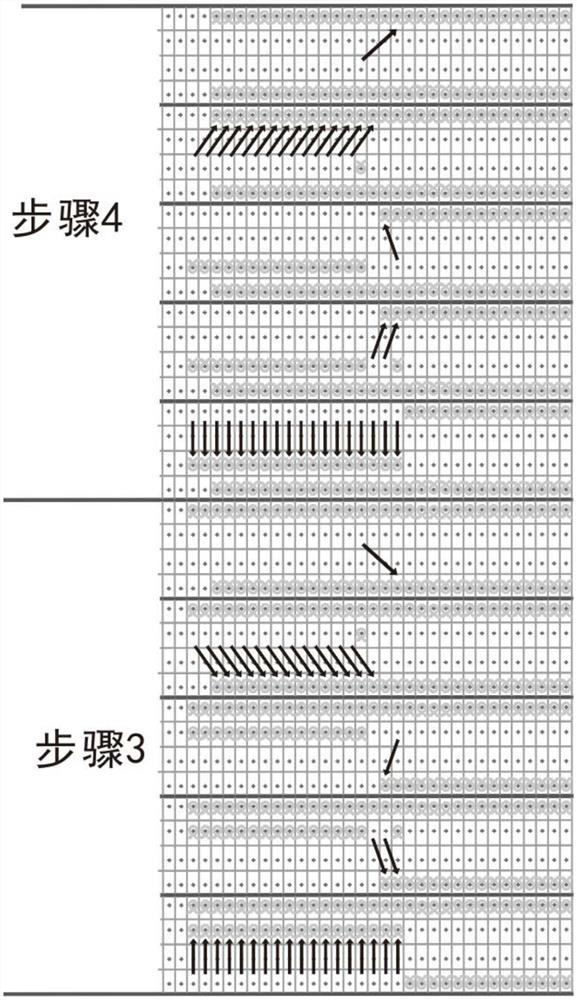

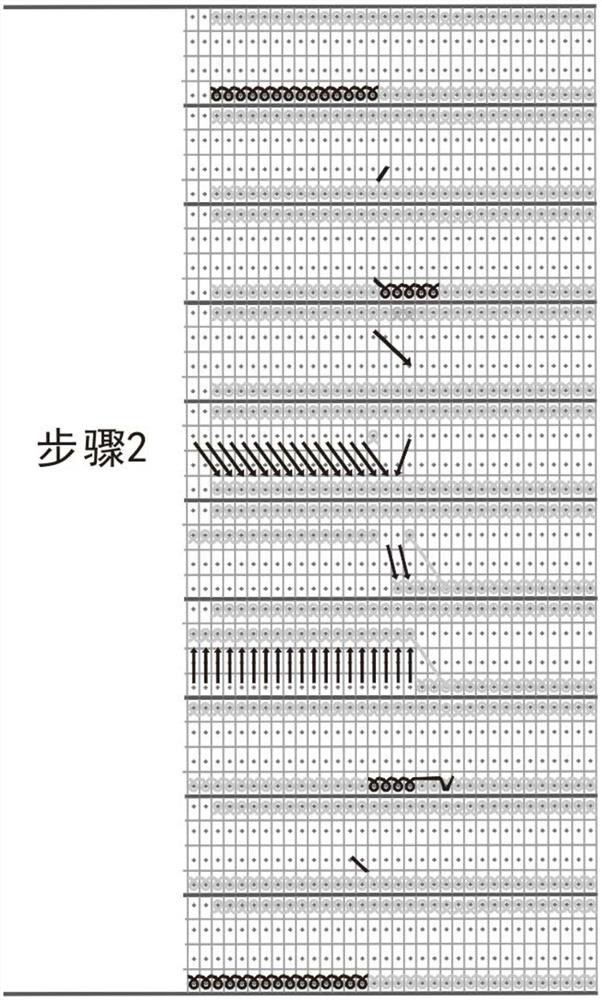

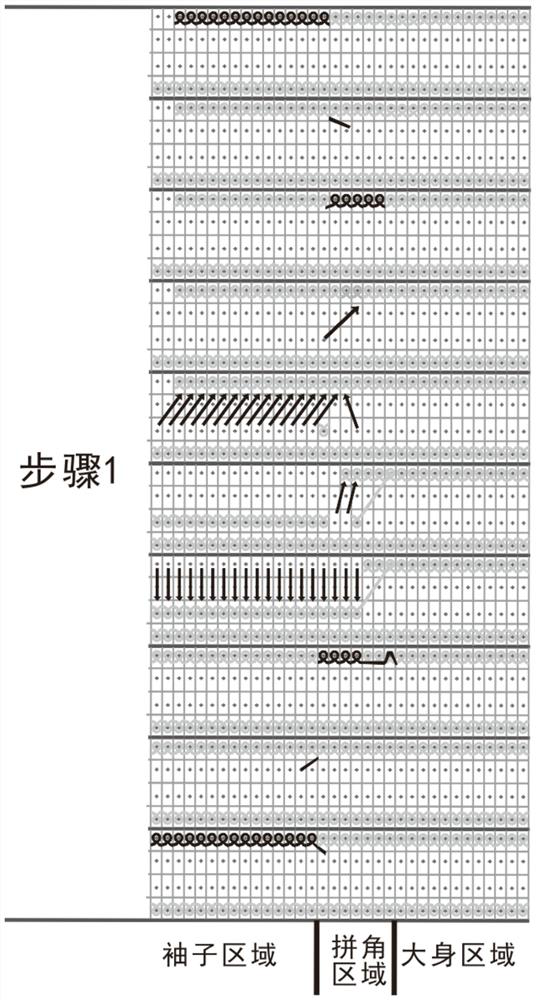

Knitting method for improving appearance effect of double splicing corners under fully-formed clamp and knitted fabric

ActiveCN114164550ABreak through limitationsPromote international influenceWeft knittingYarnStructural engineering

The invention discloses a knitting method for improving the appearance effect of double splicing corners under a fully-formed clamp, which uses a flat knitting machine with more than one pair of front and back needle beds which extend along the left-right direction and are opposite to each other in the front-back direction, and comprises the following knitting steps of: 1, knitting a needle position coil of the back needle bed after a sleeve area by a yarn nozzle in the right row, kicking the yarn nozzle back in the left row, knitting the first, second, third, sixth, seventh and eighth needle position coils of the back lower needle bed in the corner splicing area in the right row; turning the rightmost needle position coil of the rear lower needle bed in the sleeve area to the front upper needle bed; and knitting the first, second, fourth, fifth, seventh and eighth needle position loops of the rear lower needle bed in the corner splicing area on the left line of the yarn nozzle, and turning the rightmost needle position loop of the front upper needle bed in the sleeve area to the rear lower needle bed. According to the knitting method, by means of a staggered knitting mode and staggered needle stacking positions, the structures located at the same needle position are prevented from being connected, so that gaps disappear, the quality of finished products is improved, and a new knitting method is provided for a fully-formed clamping lower double-splicing-corner structure.

Owner:嘉兴市蒂维时装有限公司

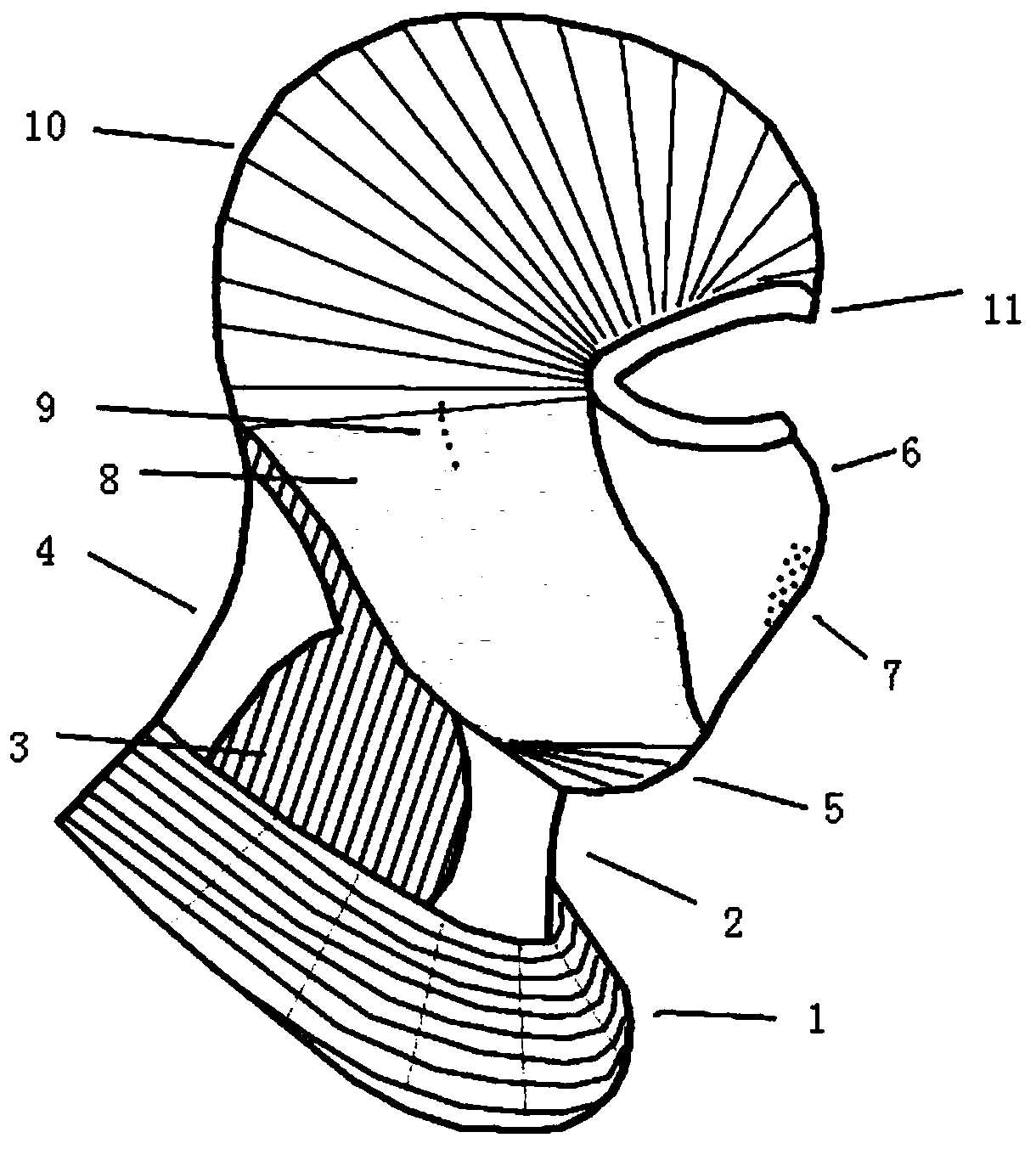

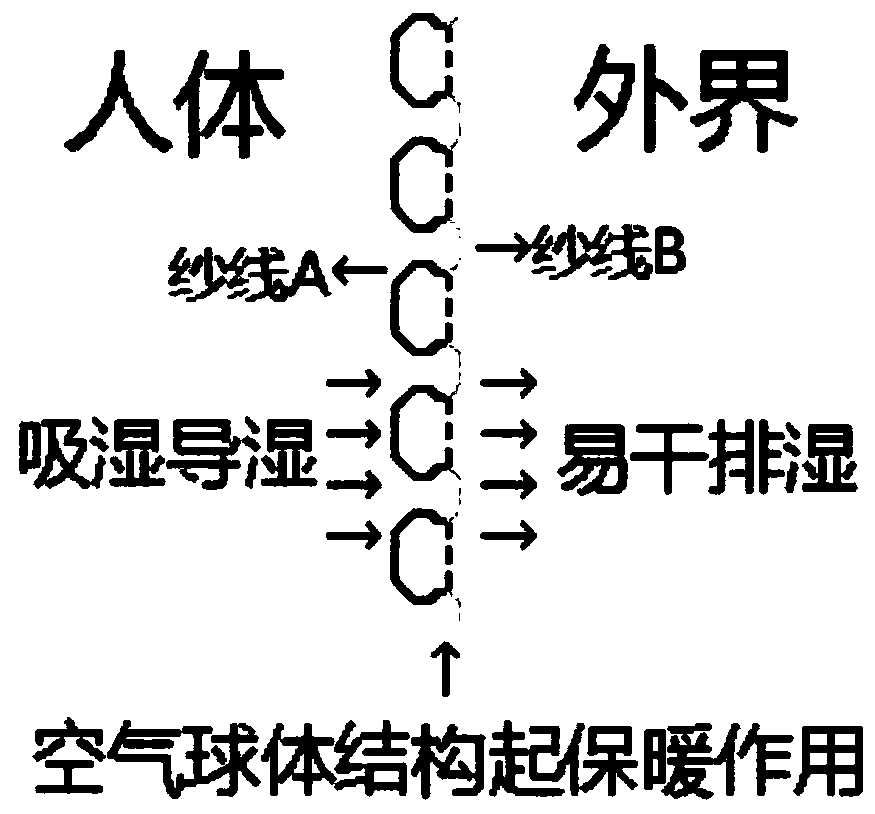

Fully-formed knitted sports face guard and knitting method thereof

ActiveCN111358070ARich texture colorHuge market potentialWeft knittingHeadwearYarnStructural engineering

The invention discloses a fully-formed knitted sports face guard and a knitting method thereof. The face guard comprises a helmet type face guard cover body, wherein the face guard cover body is integrally formed by knitting wet-permeable and easy-to-dry yarns; the front neck, the rear neck and the front face of the face guard cover body are woven to form a spherical knitted structure with moisture-conducting and warm-keeping functions; a head cover part is formed at the head part of the face guard cover body according to a wet-conducting and warm-keeping function spherical knitted structure formed and knitted according to the head structure; two eyes of the face guard cover body are fitted with the eyes in an idling knitting manner, and the mouth and nose parts of the face guard cover body are subjected to needle moving and hole picking knitting on the basis of the spherical knitted structure with the wet-conducting and warm-keeping functions to enhance the air permeability. The fully-formed knitted sports face guard can be woven into a face guard structure which is fitter and comfortable according to the head structure of a human body, the defects of a traditional process are overcome, the face guard is more fit and comfortable to wear, and meanwhile the functional requirements of all areas are met.

Owner:嘉兴市蒂维时装有限公司

Weft yarn cross mesh knitted structure and knitting method thereof

The invention discloses a weft yarn cross mesh knitted structure and a knitting method thereof. The structure is formed by weaving yarns A, yarns B and yarns C, wherein the yarns B in a non-woven yarnclipping form on the two sides of a weave area and the yarns A and the yarns C form any weft laid-in stitch, the yarns B form a mesh unit area through non-weaving, and reverse stitching is conductedon the edge, so that the yarns are staggered to form the mesh structure. According to the knitting method of the weft yarn cross mesh knitted structure, not only is the diversity of the weft laid-in stitch enriched, but also the mesh size can be adjusted through the weft yarn spacing distance in the knitting process, the limitation of a traditional knitting method is broken through, and a new pathis opened for the weft laid-in stitch.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

Knitting method for improving appearance effect of single splicing corner under fully-formed clamp and knitted fabric

ActiveCN114164549AImprove appearanceBroad room for developmentWeft knittingYarnStructural engineering

The invention discloses a knitting method for improving the appearance effect of a fully-formed single splicing corner under a clamping condition, which uses a flat knitting machine with more than one pair of front and back needle beds which extend in the left-right direction and are opposite to each other in the front-back direction, and comprises the following knitting steps of: 1, knitting a needle position coil of the back lower needle bed after a sleeve area by a yarn nozzle in the right row, kicking the yarn nozzle back in the left row, knitting the first, second, third and fourth needle position loops of the lower needle bed behind the corner splicing area in the right row, and doubling stitch at the seventh needle position of the lower needle bed behind the corner splicing area; needle position loops of the rear lower needle bed in the sleeve area and first, second, third and fourth needle position loops of the rear lower needle bed in the corner splicing area are turned to the front upper needle bed, and second and third needle position loops of the front upper needle bed in the corner splicing area are turned to the rear lower needle bed towards a right needle position. According to the knitting method, by means of a staggered knitting mode and staggered needle stacking positions, the structures located at the same needle position are prevented from being connected, so that gaps disappear, the quality of finished products is improved, and a new knitting method is provided for a full-forming clamping single splicing corner structure.

Owner:嘉兴市蒂维时装有限公司

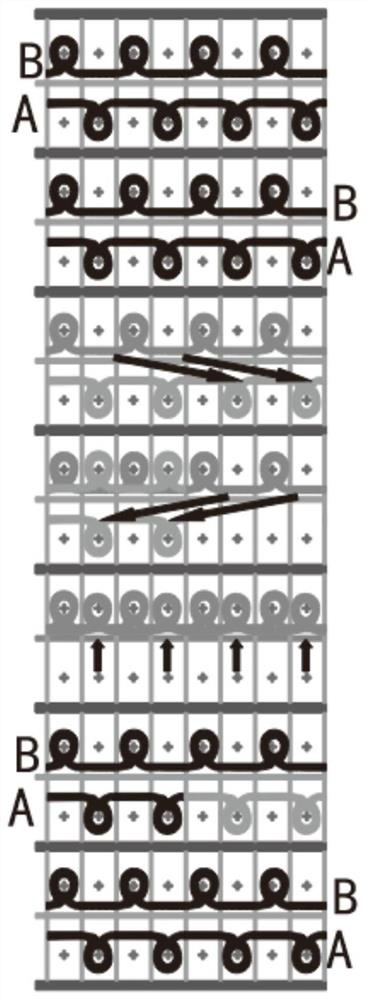

Double-sided yarn braiding method

The invention discloses a double-sided yarn braiding method. In the method, a flat knitting machine having a pair of front and rear needle beds that extend in the left-right direction and which are opposed to each other in the front-to-rear direction is used, the flat knitting machine braids with yarn A, yarn B and yarn C through a yarn nozzle, the yarn B and the yarn C are located on the oppositeand negative sides of a braided coil by turning the coil before and after selectively during braiding, and the braiding direction includes the right direction of a gauze nozzle and the left directionof the gauze nozzle. Through the combination of flexible pattern designs and knitted yarns with different properties (such as different knitted yarns like color, shape, elasticity), knitted fabric can show more abundant texture color contract, and fabric products have a wide range of applicable fields and great market potential.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

Whole-garment moire pattern stitch structure and knitting method thereof

ActiveCN110791863ARealize requirementsPromote international influenceWeft knittingStructural engineeringMechanical engineering

The invention discloses a whole-garment moire pattern stitch structure and a knitting method thereof. The whole-garment moire pattern stitch structure comprises a fabric body which is provided with the single-face pattern stitch formed by a whole-garment computerized knitting machine integrally, and the pattern stitch is free of dotted lines. The knitting method of the whole-garment moire patternstitch structure cannot only meet requirements on all whole-garment processing structures, but break the limit of the pattern stitch in terms of pattern design.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

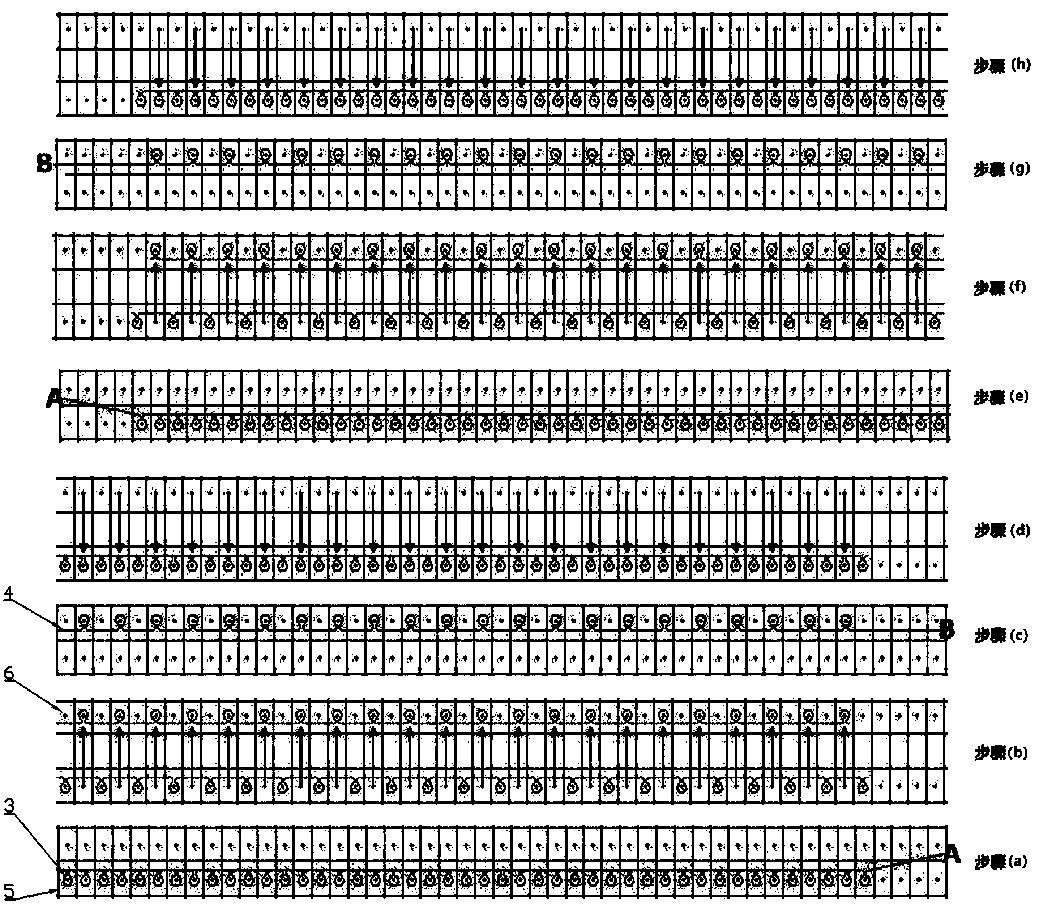

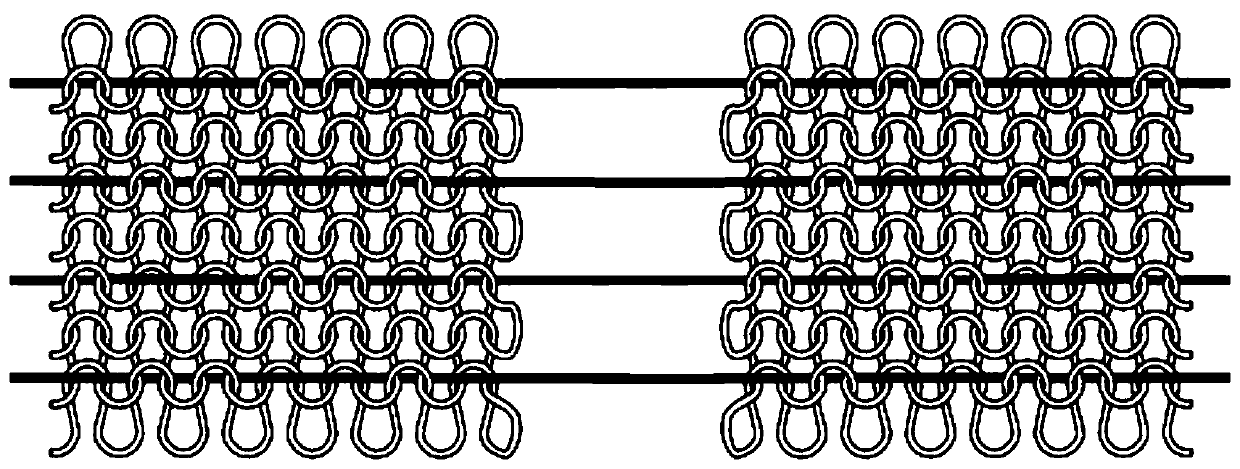

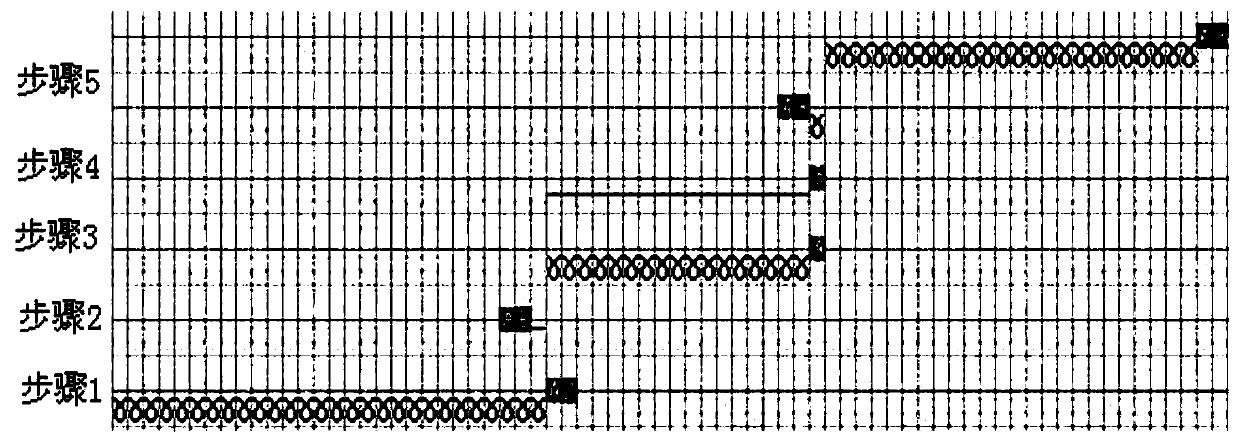

Two-needle-plate cylindrical 1x1 tight rib knitting structure and knitting method thereof

ActiveCN111304807AImprove finished product qualityImprovement of design conceptWeft knittingStructural engineeringMechanical engineering

The invention discloses a two-needle-plate cylindrical 1x1 tight rib knitting structure and a knitting method thereof. During knitting, the 1+3N needle position counted from left to right is used as acommon needle position, a front needle bed and a rear needle bed are used for knitting a front face coil of a front rib and a front face coil of a rear rib respectively, the 3N needle position is used for knitting a front rib reverse face coil, and the 2+3N needle position is used for knitting a rear rib reverse face coil, wherein N is a natural number. According to the two-needle-plate cylindrical 1x1 tight rib knitting structure, according to the arrangement of the needle positions, within the same needle number width, the knitting number of the front plate rib and the rear plate rib is twothirds of the total needle number N, no empty needle position exists on one side of the joint of the rib front needle and the rib rear needle, the density is higher than that of a traditional process, the quality of a finished product is greatly improved, and the structure can play an important role in the application aspect of two-needle-plate fully-formed garment starting ribs.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

Two-needle-plate cylindrical 2x1 tight rib knitting structure and knitting method thereof

ActiveCN111304808AImprove qualityRich texture and color contrastWeft knittingStructural engineeringMechanical engineering

The invention discloses a two-needle-plate cylindrical 2x1 tight rib knitting structure and a knitting method thereof. The two-needle-plate cylindrical 2x1 tight rib knitting structure is knitted on aflat knitting machine, the 1+4N needle position and the 4N needle position counted from left to right serve as common needle positions during knitting, a front needle bed and a rear needle bed are used for knitting a front face coil of a front rib and a front face coil of a rear rib respectively, the 3+4N needle position is used for knitting a front rib reverse face coil, and the 2+4N needle position is used for knitting a rear rib reverse face coil, wherein N is a natural number. According to the two-needle-plate cylindrical 2x1 tight rib knitting structure, according to the arrangement of the needle positions, within the same needle number width, the knitting number of the front plate rib and the rear plate rib is three fourths of the total needle number N and larger than that of a traditional technology, no empty needle position exists on one side of the joint of the rib front needle and the rib rear needle, and therefore the density is higher than that of the traditional technology, the quality of a finished product is greatly improved, and the two-needle-plate cylindrical 2x1 tight rib knitting structure plays an important role in the application aspect of two-needle-plate fully-formed garment starting ribs.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

Float interlaced texture of knitted fabrics and knitting method of float interlaced texture of knitted fabrics

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

Knitted fabric with burnt-out effect and knitting method thereof

The invention discloses a knitted fabric with a burnt-out effect and a knitting method thereof. According to the method, a flat knitting machine with a pair of front and rear needle beds extending inthe transverse direction and facing each other in the front-rear direction is used and provided with at least two yarn nozzles different in width, and different loop texture patterns are formed through the yarn nozzles different in width. The knitted fabric, knitted by means of the knitting method, with the burnt-out effect breaks through the limitation of traditional knitting methods and createsa new way for realizing different loop effects of knitted products. The design means of patterned structures of the knitted fabric can be enriched, a certain effect is achieved on better explanation of the design concept and further increase of the artistic value and aesthetic value of the products, and a wider development space is provided for the development of the knitted products and the market.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

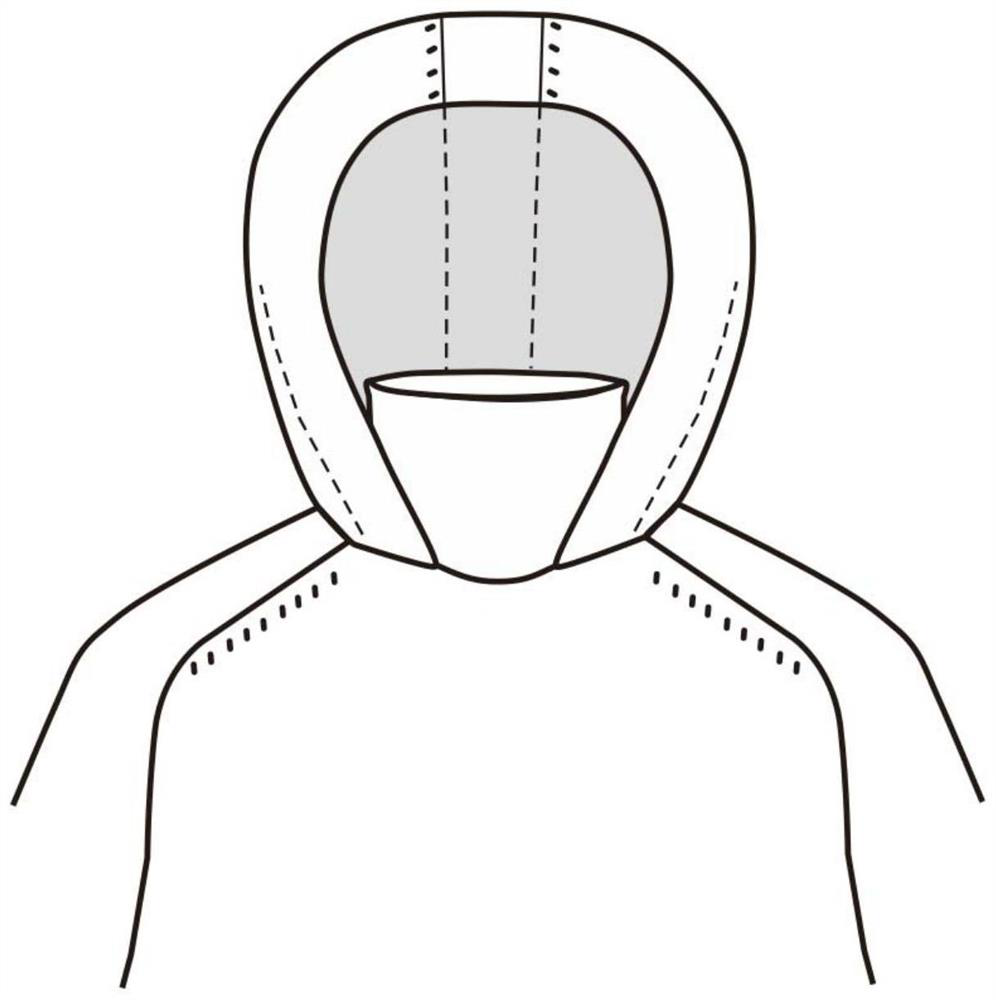

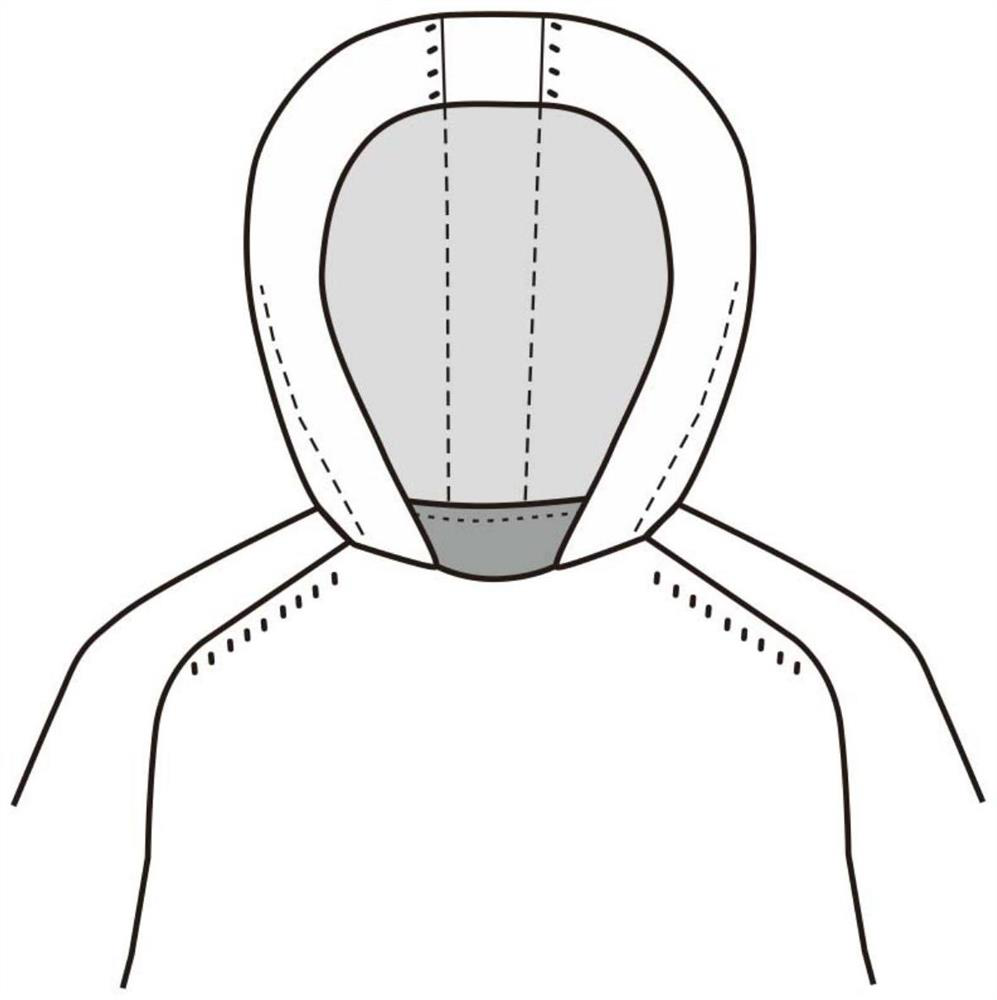

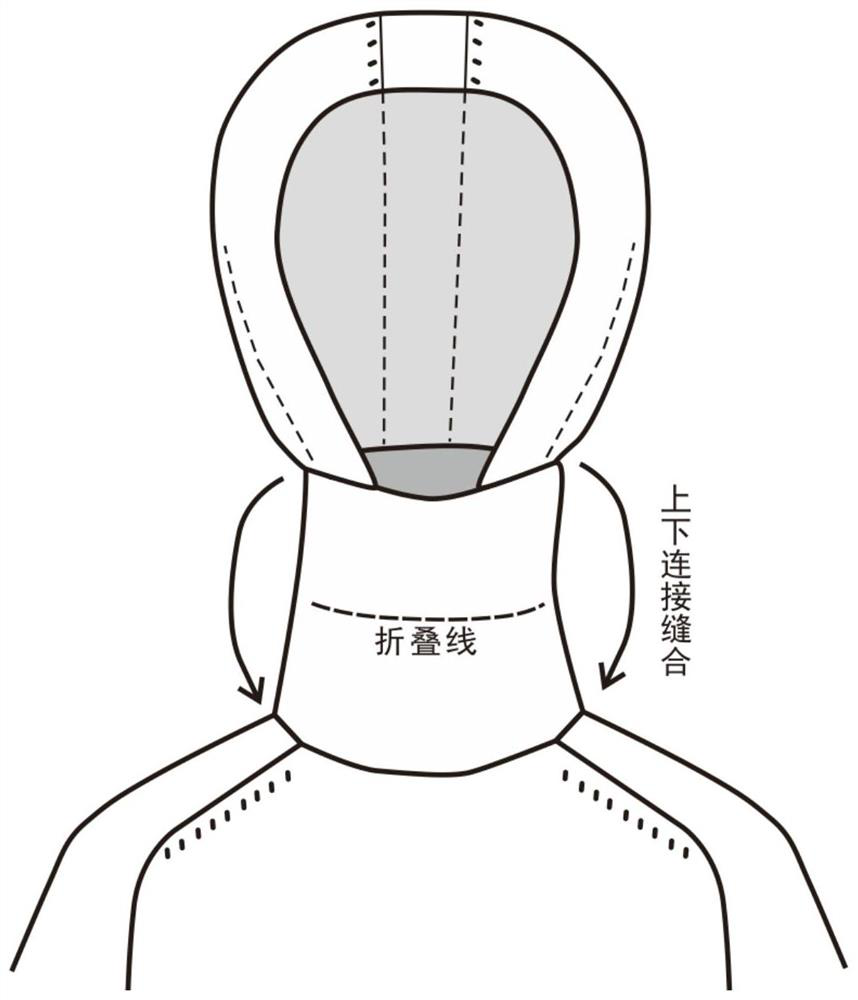

Weaving method for integrally forming fully-formed high-collar hoody and application thereof

ActiveCN114541022AImprove appearance detail qualityPromote international influenceWeft knittingTextile/flexible product manufactureStructural engineeringMechanical engineering

Owner:嘉兴市蒂维时装有限公司

A kind of knitting method and knitted fabric of fully formed saddle shoulder collar structure

The invention discloses a weaving method and knitted fabric of a fully formed saddle shoulder collar structure. The knitting method of the fully formed flat shoulder style shoulder line forward makes the front and rear panels achieve a natural difference in the knitting process, so that the effect of the shoulder line forward naturally appears after the style is formed. The knitting method of the fully formed saddle shoulder collar structure breaks through the above-mentioned limitations of the traditional product process method. According to the characteristics of the saddle shoulder front and back collar, a combination of knitting methods with front and rear differences is set to make the front and rear collar more smooth and improve the quality of the product. And wearing comfort, more able to meet customer needs.

Owner:嘉兴市蒂维时装有限公司

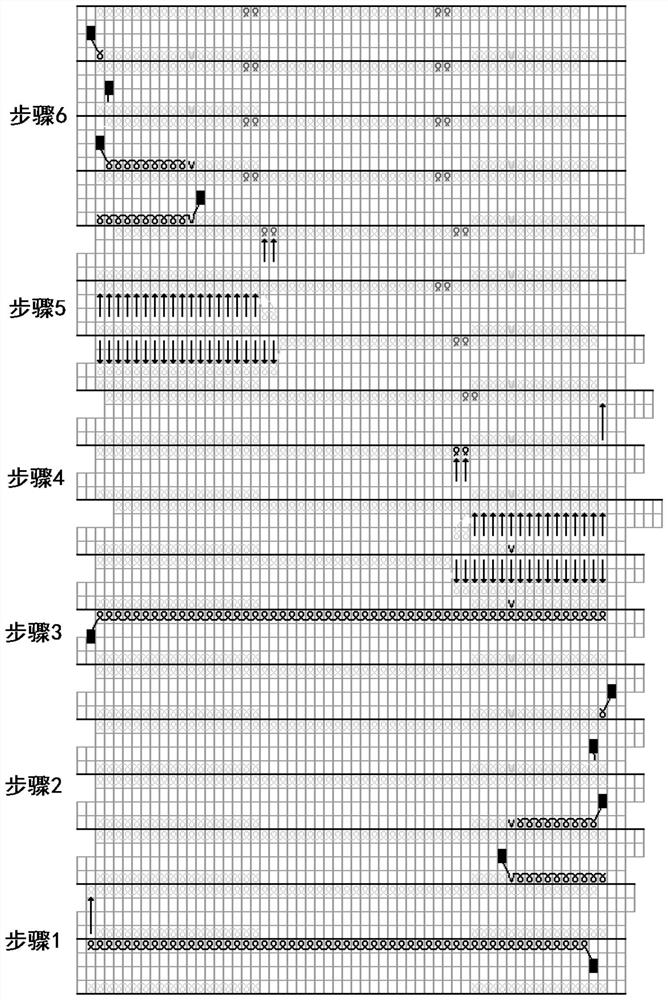

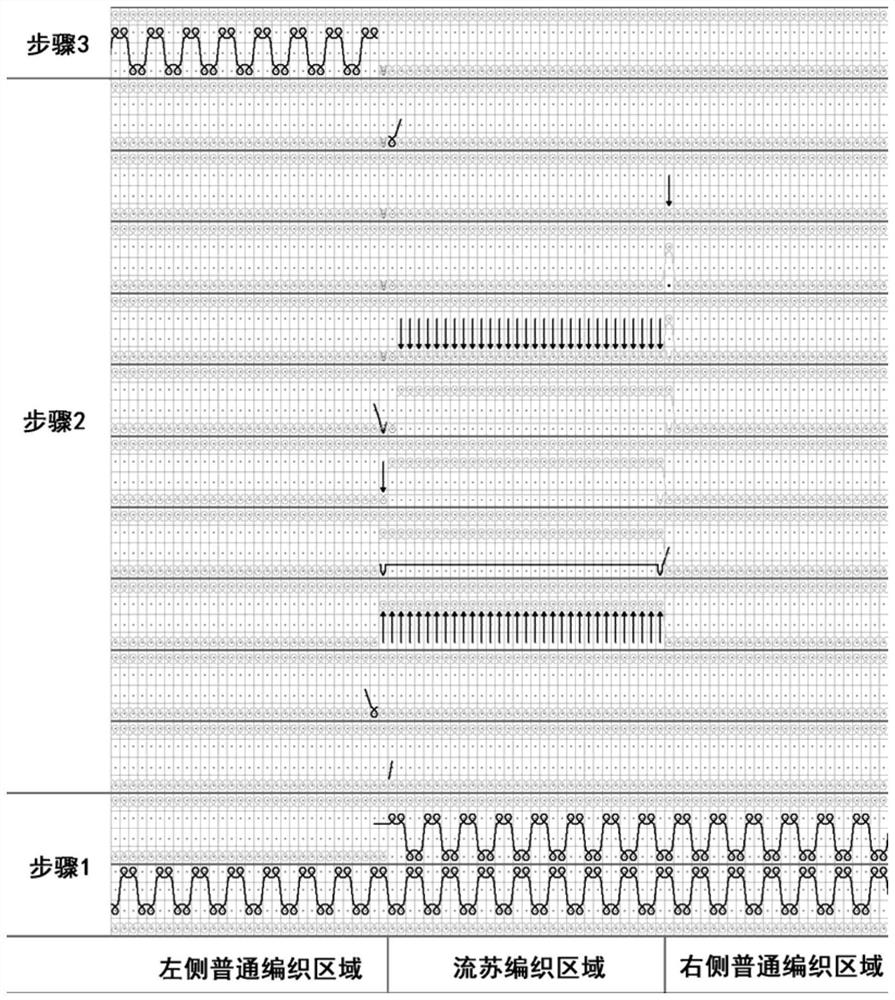

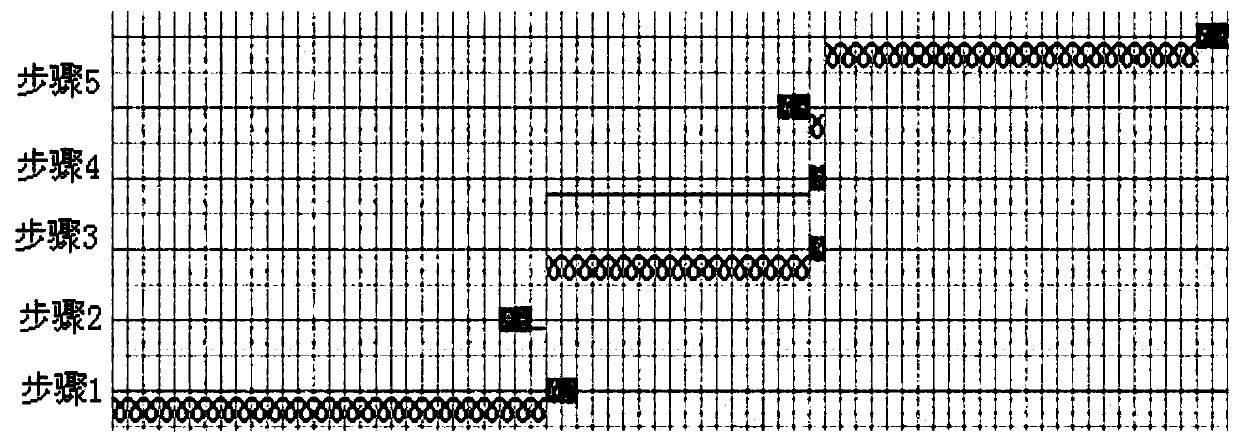

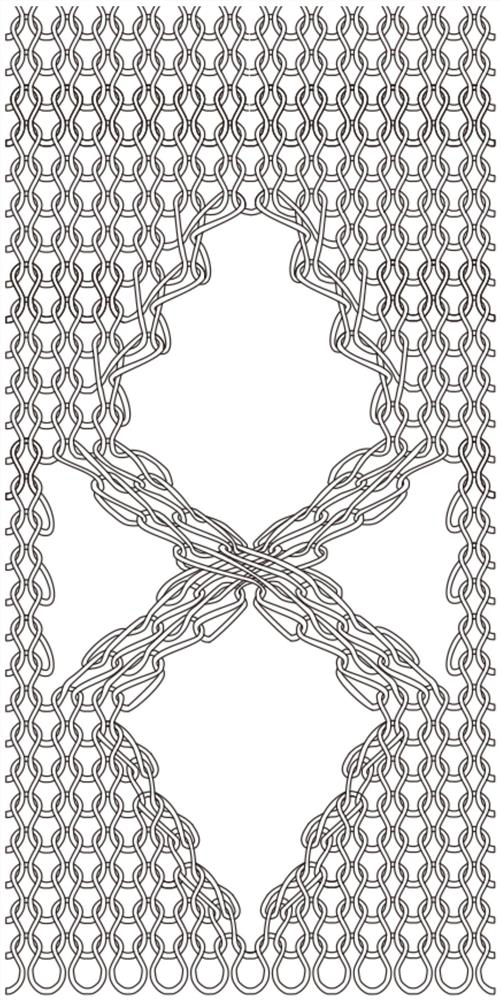

Fully-formed vertical tassel weave structure and weaving method thereof

ActiveCN114232188APromote international influenceEasy to interpretWeft knittingTextile/flexible product manufactureEngineeringStructural engineering

The invention discloses a fully-formed vertical tassel weave structure and a weaving method thereof.A tassel weaving area is arranged on a fully-formed cylinder weave structure according to the tassel position requirement, the left side of the tassel weaving area is connected with the fully-formed cylinder weave structure, and the right side of the tassel weaving area is connected with the fully-formed cylinder weave structure; and after tucking is performed on the rear side of the tassel knitting area to form the length required by tassels, knocking-over is performed, so that a tassel structure is formed, and then a vertical tassel tissue structure is obtained through circulation of each row. According to the fully-formed vertical tassel weave structure woven by the weaving method, the diversity of fully-formed weave is enriched, and the quality of ready-made clothes is guaranteed.

Owner:嘉兴市蒂维时装有限公司

A weaving method for improving the weaving efficiency of flat knitting machine fully formed garments

ActiveCN112176517BPromote international influenceImprove the sense of qualityWeft knittingMechanical engineeringIndustrial engineering

The invention discloses a knitting method for improving the knitting efficiency of fully formed garments on a flat knitting machine. A flat knitting machine with a pair of front and rear needle beds or more than one pair of needle beds extending in the left and right directions and facing each other in the front and rear directions is used to set the interval width of the left and right sleeves. is J3, and the width of the head is T. On the premise that the value of J3 is greater than the value of T, knitting is carried out as follows. Step 1. The head of the flat knitting machine knits the excess rotation of the left sleeve first, and then the head stops at the left sleeve. Sleeve knit width right side. The knitting method for improving the knitting efficiency of fully-formed garments on flat knitting machines breaks through the limitations of traditional weaving methods. On the fully-formed computerized flat knitting machine, the weaving method is adjusted for fully-formed garments with a large difference in body length and sleeve length, thereby achieving high efficiency. Maximization, in line with the current demand for energy saving, emission reduction, and efficient production.

Owner:嘉兴市蒂维时装有限公司

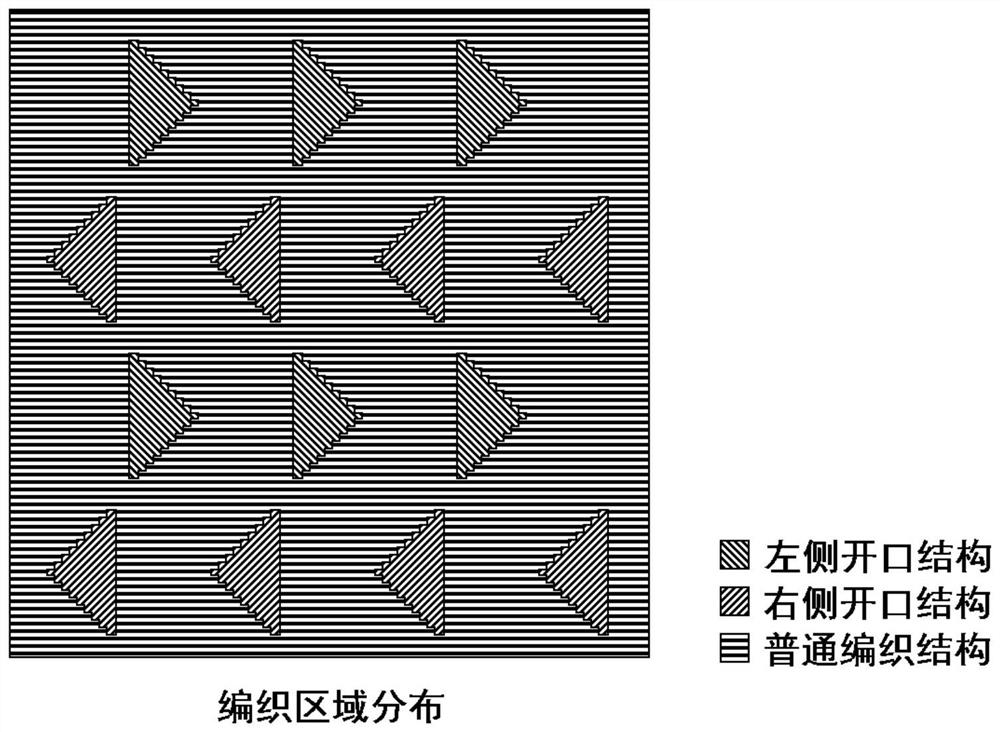

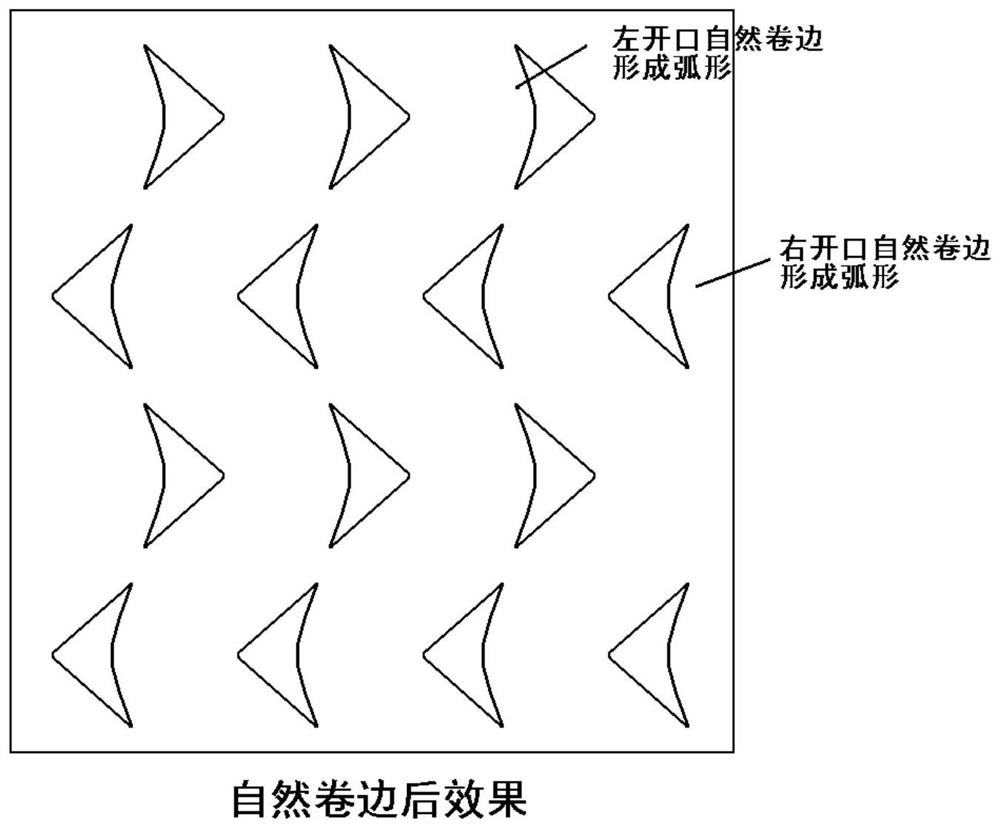

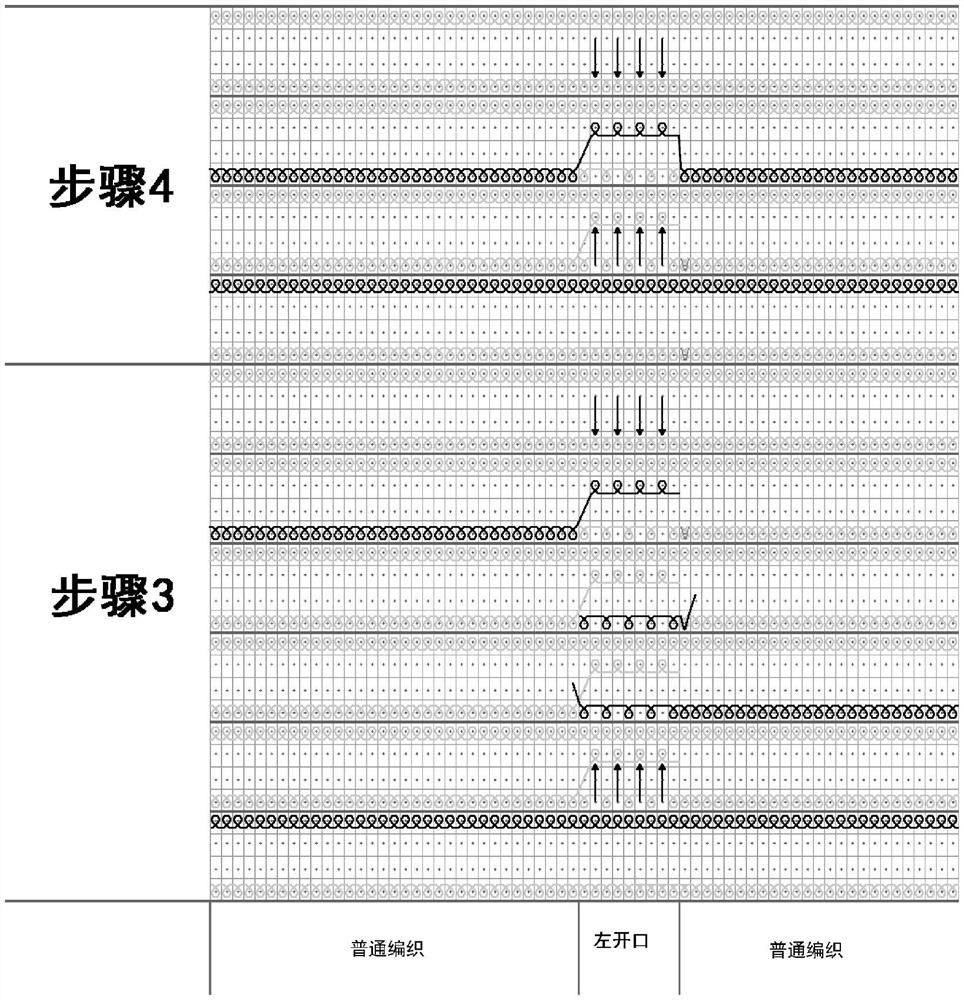

Fully-formed bag-shaped weave structure and weaving method thereof

ActiveCN113957594APromote international influenceEasy to interpretWeft knittingStructural engineeringMechanical engineering

The invention discloses a fully-formed bag-shaped weave structure and a weaving method thereof. A left opening structure and a right opening structure are arranged on a common woven structure according to design requirements, and the bag-shaped weave structure is formed by combining and matching arcs formed by naturally curling the opening sides of the left opening structure and the right opening structure. According to the fully-formed bag-shaped weave structure woven by the weaving method, the weave effect that one side of the fully-formed bag-shaped weave structure is opened and naturally curled is formed through weaving of the bag-shaped weave structure, so that a novel fully-formed weave is formed through permutation and combination, and the diversity of the fully-formed weave is enriched.

Owner:嘉兴市蒂维时装有限公司

A kind of knitted fabric with burnt-out effect and its weaving method

ActiveCN110184728BHuge market potentialPromote international influenceWeft knittingStructural engineeringMechanical engineering

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

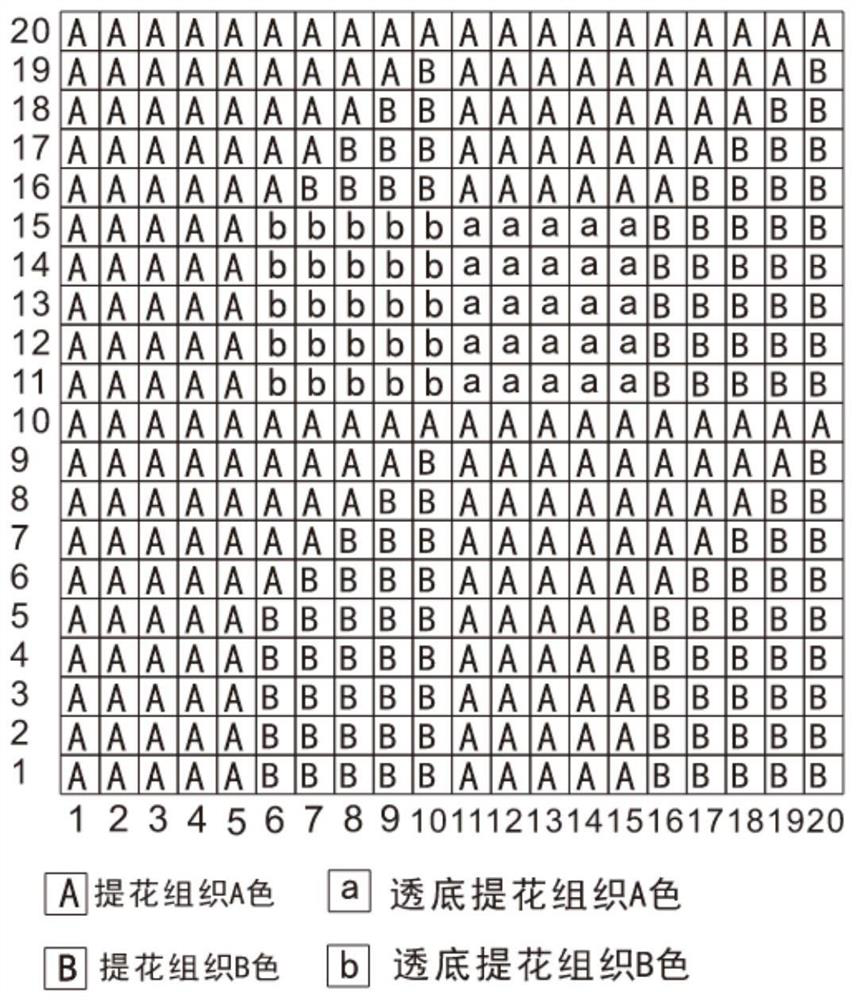

Knitting method of air layer through-bottom jacquard weave of four-needle-plate flat knitting machine and knitted fabric

PendingCN114855342APromote international influenceBreak through limitationsWeft knittingTextile/flexible product manufactureYarnStructural engineering

The invention discloses a knitting method of an air layer through-bottom jacquard weave of a four-needle-plate flat knitting machine, which comprises the following steps: using the four-needle-plate flat knitting machine with more than one pair of front and back needle beds which extend in the left-right direction and are opposite to each other in the front-back direction, setting a jacquard weave color A area and a jacquard weave color B area according to pattern requirements, and utilizing a back lower needle bed and a front upper needle bed to weave the air layer through-bottom jacquard weave. And weaving a one-interval-one air layer jacquard weave, and weaving transparent yarns by using a front lower needle bed to cover the A-color area of the jacquard weave, so as to realize the bottom-penetrating jacquard weave effect. The transparent yarns capable of seeing the patterns on the bottom layer are woven on the surface of the jacquard weave, so that the effect of covering another layer of yarns on the jacquard weave surface is realized, the transparent jacquard weave capable of seeing the patterns on the bottom layer is further provided, the structure of the jacquard weave is enriched, and more design requirements are met.

Owner:嘉兴市蒂维时装有限公司

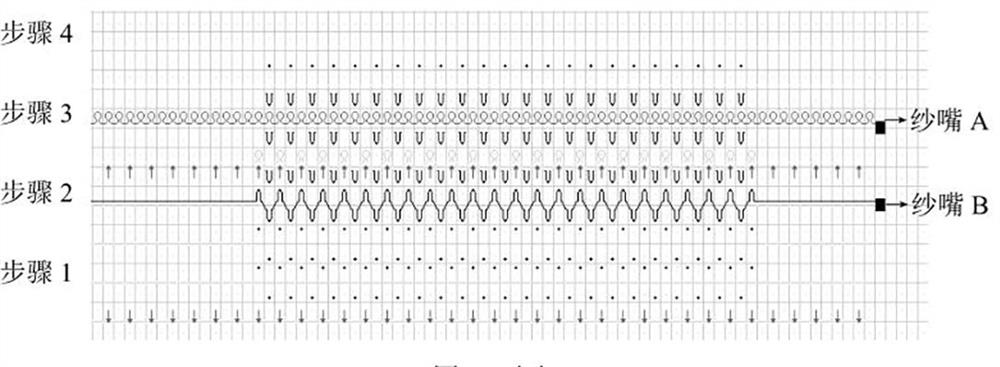

Terry weaving method for single weft-inserted knitted fabric

ActiveCN110055669BRich texture and color contrastHuge market potentialFlat-bed knitting machinesYarnIndustrial engineering

The invention relates to a terry stitch weaving method of a single-side weft-inlaid knit fabric. A yarn ring presser is utilized at the premise of a single-side fabric to form a special weft-inlaid terry weave, and novel terry texture is achieved. The terry stitch weaving method can be combined with an INLAY technique with no weftwise yarn sandwich for a flat knitting machine so that terry structure is formed at the special portion; the design means of knit pattern structures can be enriched; the terry stitch weaving method plays a good role of better interpreting the design concept and improving quality, artistic value and aesthetic value of products, and helps provide a broader development space for knit product development and market. In addition, in terms of industrial practicality, the terry stitch weaving method is widely applicable to computerized flat knitting machines with a weft inlaying function. The terry stitch weaving method can satisfy and attract more consumers and helps promote international influence of the knitting industry of China.

Owner:桐越针织科技浙江有限公司

Knitting method of two-needle-plate flat knitting machine jacquard cable weave and knitted fabric

PendingCN114855344AImprovement of design conceptBroad room for developmentWeft knittingTextile/flexible product manufactureStructural engineeringMechanical engineering

The knitting method comprises the following steps: using the two-needle-plate flat knitting machine which is provided with a pair of front and back needle beds which extend in the left-right direction and are opposite to each other in the front-back direction, and knitting the jacquard weave at intervals by using the back needle bed and the front needle bed in a jacquard weave color A region and a jacquard weave color B region, and in the area where the jacquard weave needs to be provided with the cable weave, the jacquard and cable weave is realized by utilizing empty needle positions of even-numbered needle positions of the rear needle bed on the needle bed after needle separation to carry out needle turning. The double-layer jacquard weave is knitted on the two-needle-plate flat knitting machine equipment in a needle separation mode, the needle turning and stranding structure is carried out through the unoccupied needle position after needle separation, and therefore knitting of the jacquard and stranding weave is achieved.

Owner:嘉兴市蒂维时装有限公司

Knitted garment mesh structure and knitting method thereof

The invention discloses a knitted garment mesh structure and a knitting method thereof. The knitted garment mesh structure comprises meshes in a fabric. The meshes are knitted in the following mode that a left-right separated knitting mode is adopted, and needle moving and hole picking are conducted in sequence according to the sizes of holes; a new yarn nozzle independent knitting connection area is added to each of the left edge and the right edge of each hole; mutual crossing is performed in a knitting and needle moving manner until the edges of the holes are reached; and yarn nozzles of knitting connection parts are brought out, finally edge loops are subjected to needle moving towards the middle in sequence, and meanwhile, needle digging and hole filling are carried out on empty needle positions generated by needle moving till the middles are combined. The mesh structure woven by the knitting method has a novel and attractive mesh effect, and the quality of a finished product is greatly improved.

Owner:嘉兴市蒂维时装有限公司

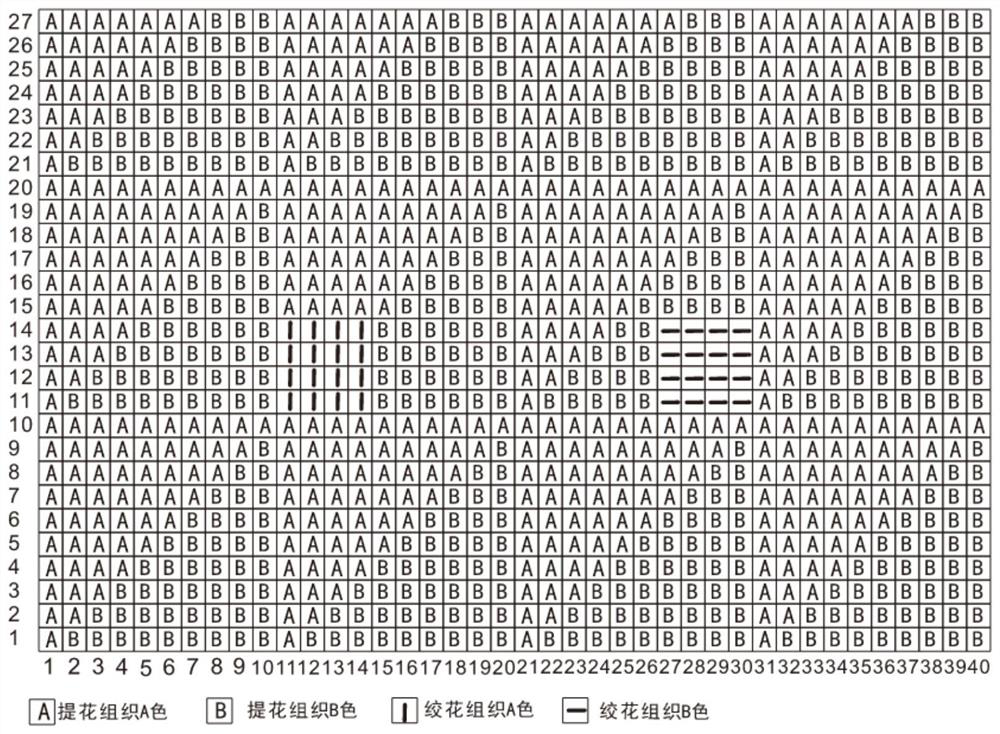

Knitting method for improving fully-formed stripe weave and knitted fabric

PendingCN114836884AThe edge coil is firmGuarantee the quality of garmentsWeft knittingYarnStructural engineering

A flat knitting machine with more than one pair of front and back needle beds extending in the left-right direction and opposite to each other in the front-back direction is used, in the knitting process, when a yarn nozzle A and a yarn nozzle B are switched, the yarn nozzle A carries out reverse knitting when the last needle is taken out, and the yarn nozzle B carries out reverse knitting when the last needle is taken out. And a coil of the yarn nozzle A and a coil of the yarn nozzle B are crossed. According to the invention, a thread end take-out and take-in mode when a fully-formed stripe weave switches a yarn nozzle is improved, so that edge coils are firmer after being stressed and pulled, the effect of loosening of the coils is avoided, and the quality of ready-made clothes is ensured.

Owner:嘉兴市蒂维时装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com