Knitting method for improving fully-formed stripe weave and knitted fabric

A fully formed, knitted fabric technology, applied in weft knitting, knitting, textile and papermaking, etc., can solve the problems of loose loops, affecting the quality of garments, easy to be pulled by force, etc., to achieve firm edge loops, improved design concepts, and guaranteed The effect of garment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

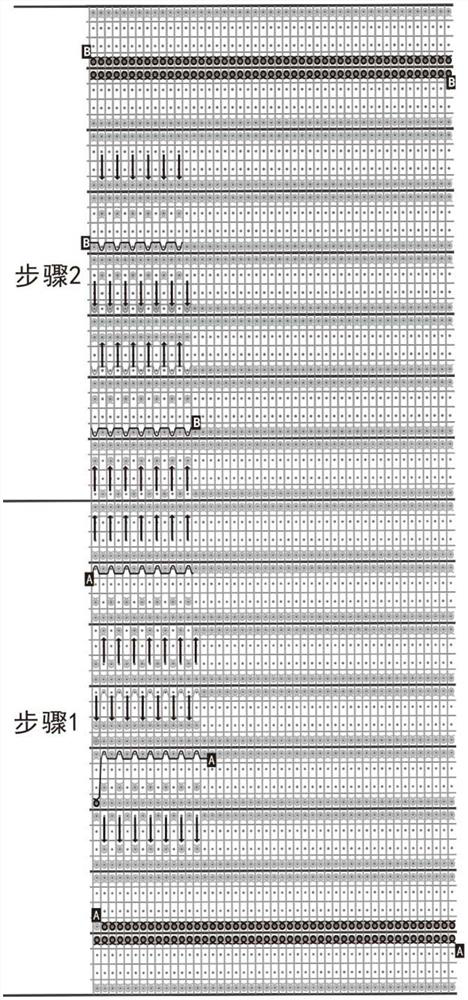

[0011] Below in conjunction with the accompanying drawings, the present invention will be further described with respect to specific embodiments:

[0012] A knitting method for improving the fully formed stripe structure. During the knitting process, when the yarn feeder A and the yarn feeder B are switched, the yarn feeder A carries out the reverse knitting when the last stitch is taken out, so as to achieve the effect of crossing so that the loops are not knitted. It will be loosened by force, thereby improving the effect of edge loosening in traditional methods.

[0013] For better expression and ease of understanding, such as figure 1 As shown, using a flat knitting machine having a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-rear direction, the following knitting is performed,

[0014] Step 1: Yarn feeder A knits the stitches on the needle bed after knitting in the right row; yarn feeder A knits the stitches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com