Single weft laid-in covered stitch structure and knitting method thereof

A technology of weaving structure and weft insertion, which is applied in the direction of weft knitting, knitting, textiles and papermaking, can solve the problems such as unsatisfactory weaving structure, and achieve the effect of improving practicability, broad development space, and improving design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

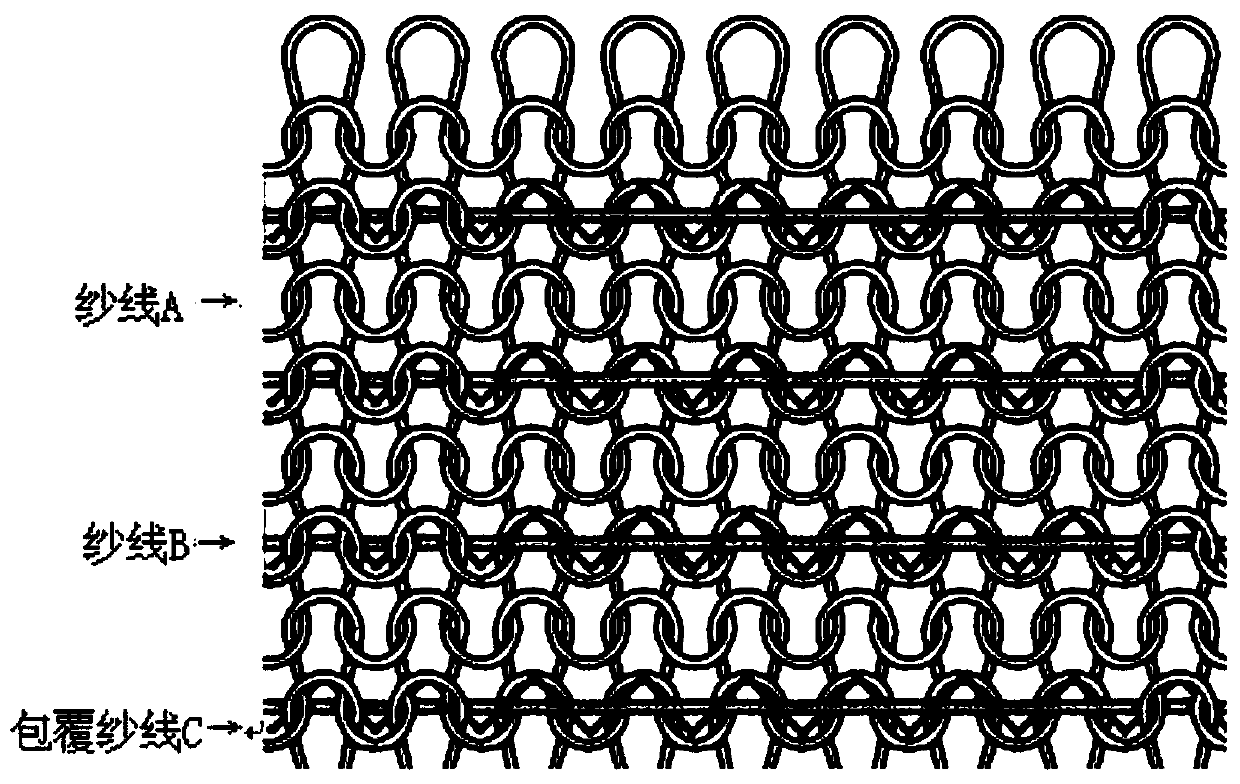

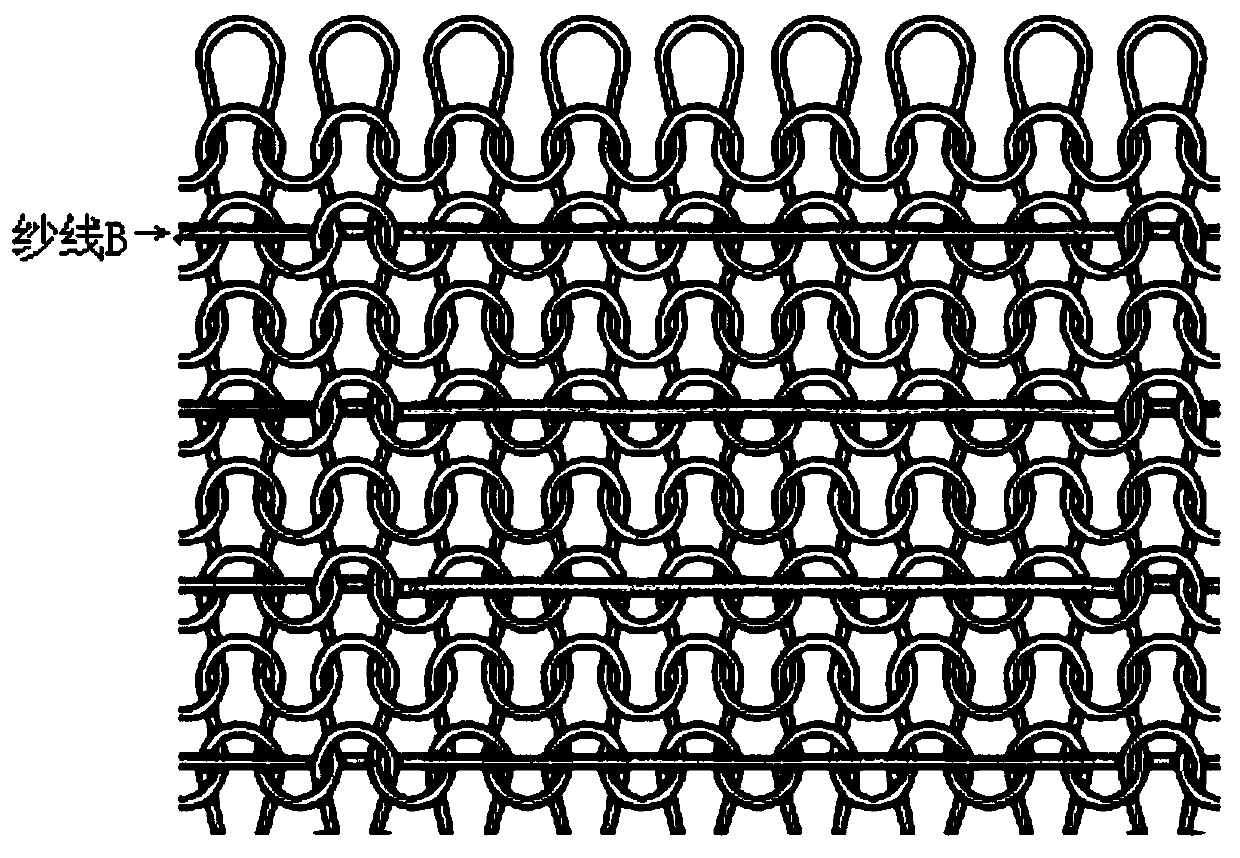

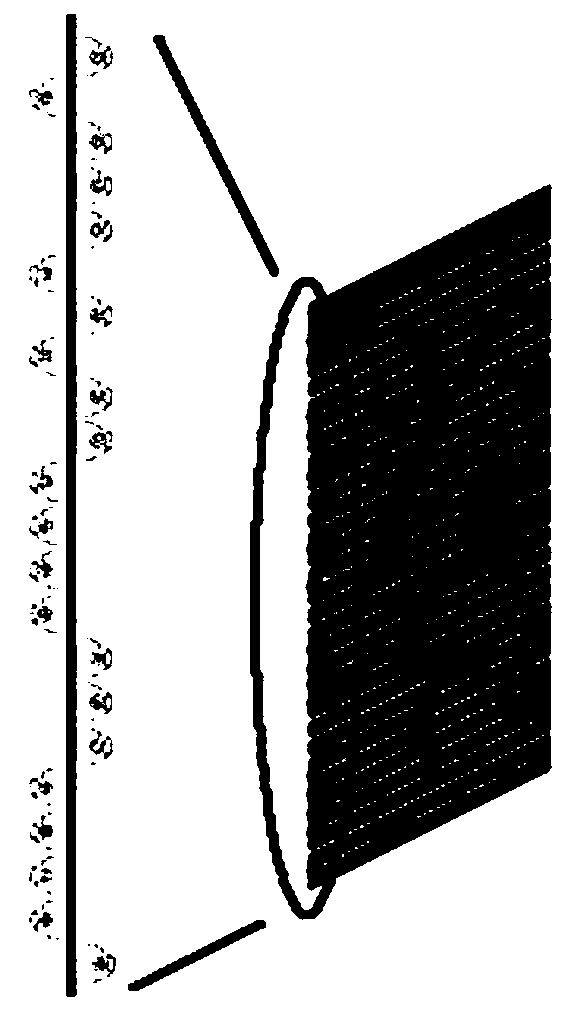

[0025] Such as figure 1 , 3 The one-side weft-inserted covered weave structure shown is woven from yarn A, yarn B and covered yarn C. According to the pattern requirements, the knitting loop of yarn A is turned to the corresponding needle bed, and the covered yarn Thread C is evenly woven in a tucked manner, and yarn B is inserted in the weft non-woven form and passed through transfer, so that the covered yarn C wraps the yarn B, thereby playing a fixed role. The single-sided weft-inserted weave structure breaks through the limitations of traditional weaving methods and opens up a new path for weft-inserted weave. Moreover, in order to present a richer texture and color contrast in the woven fabric, yarn A, yarn B and yarn C are knitting yarns with different properties. Different knitting yarns such as color, shape, elasticity, etc. The woven knitted fabric can present a richer texture and color contrast, and its fabric products have a wide range of applications and a huge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com