Knitting method of two-needle-plate flat knitting machine jacquard cable weave and knitted fabric

A jacquard weave and weave technology, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problem of inability to twist weave in two-needle flat knitting machines, and achieve the effect of improving the design concept and widening development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with the accompanying drawings, the present invention will be further described with respect to specific embodiments:

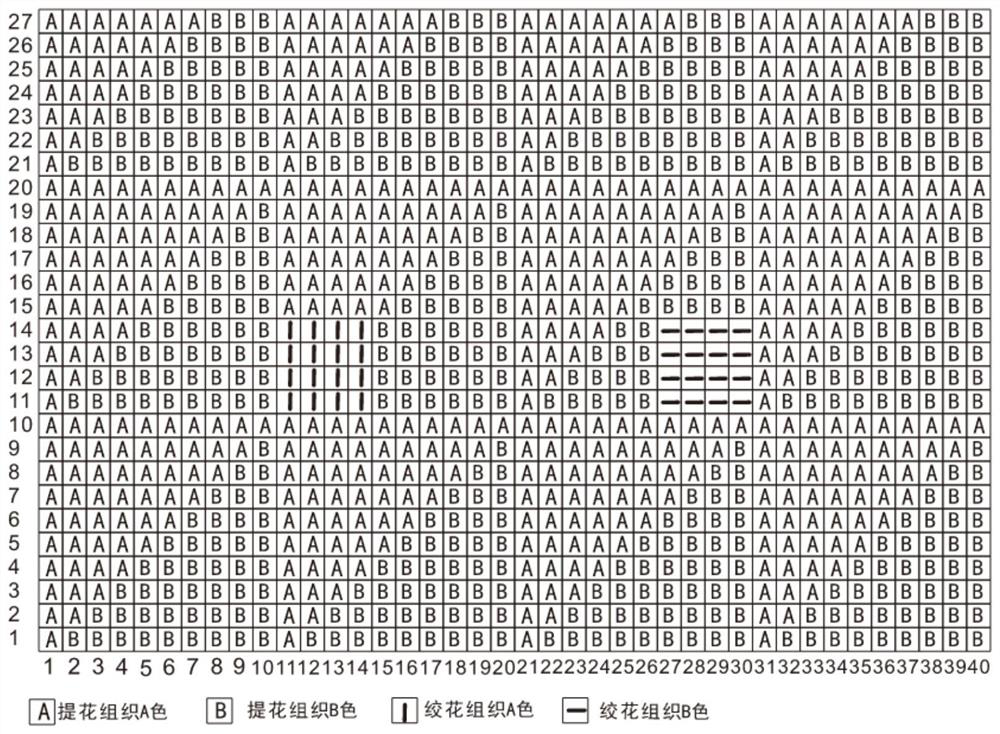

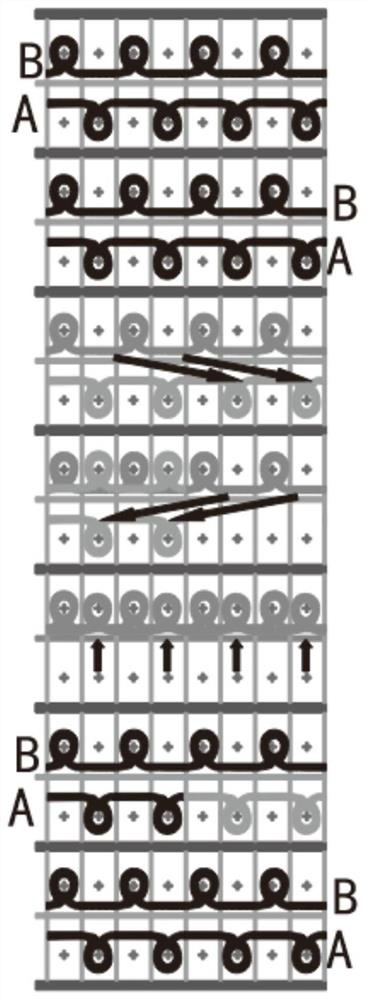

[0014] Structurally, as figure 1 As shown, the present invention sets the jacquard weave A color and the jacquard weave B color area according to the pattern requirements, and uses the rear needle bed and the front needle bed to knit the traditional air layer jacquard in the jacquard weave A color and the jacquard weave B color area. Weave, that is, in the area of jacquard area A, color A is knitted with even needles on the front needle bed, and color B is knitted at odd needle positions on the rear needle bed; otherwise, in the color B area of jacquard area, color B is knitted with even needles on the front needle bed, and odd needles on the rear needle bed are knitted for color B. Bit weave A color. In the area that needs to be twisted on the traditional jacquard weave, the vacant needle positions of the even-numbered needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com