Knitted garment mesh structure and knitting method thereof

A technology of mesh structure and clothing, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems affecting product quality, the edge of holes is not smooth enough, and does not conform to marketing, so as to improve the quality of finished products and improve the design concept Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

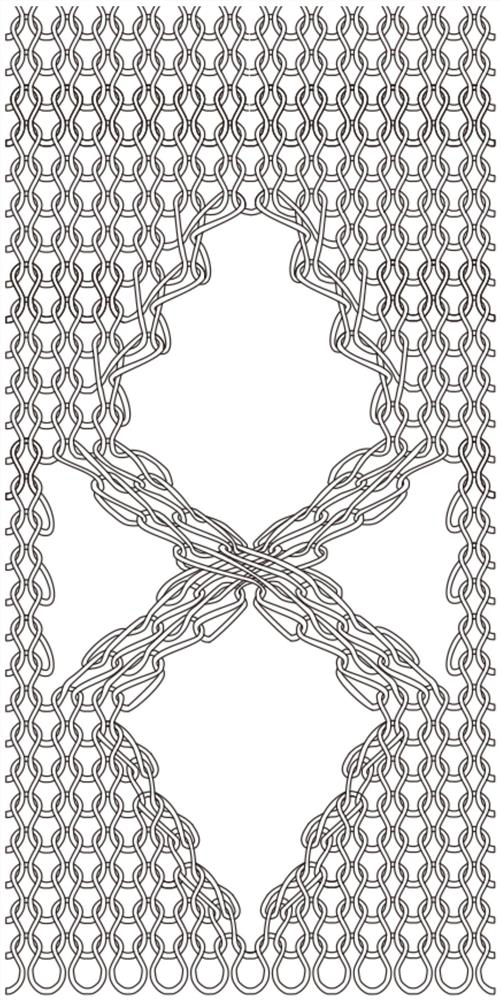

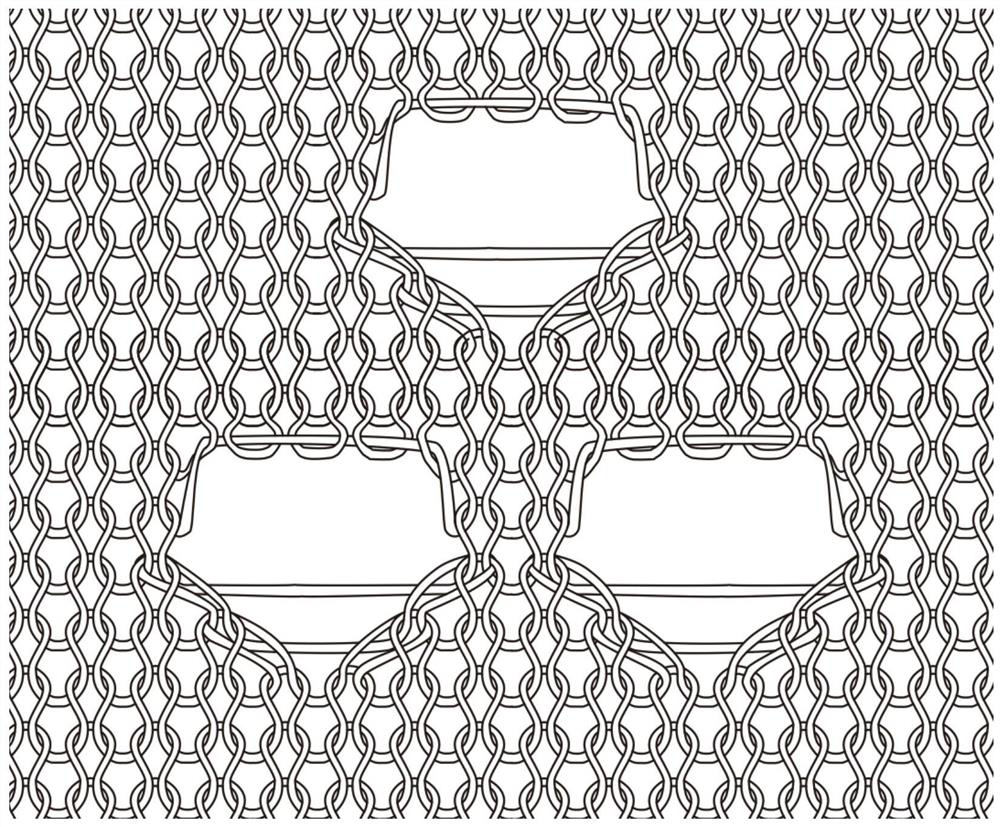

[0020] The weaving of the mesh structure of knitted garments as mentioned above can be realized by changing the operation mode of the yarn feeder and moving the needle at the same time, so that it can produce a new and beautiful hole effect, greatly improve the quality of the finished product, and change the traditional monotonous mesh structure. Organize the form so that its edges are rounded.

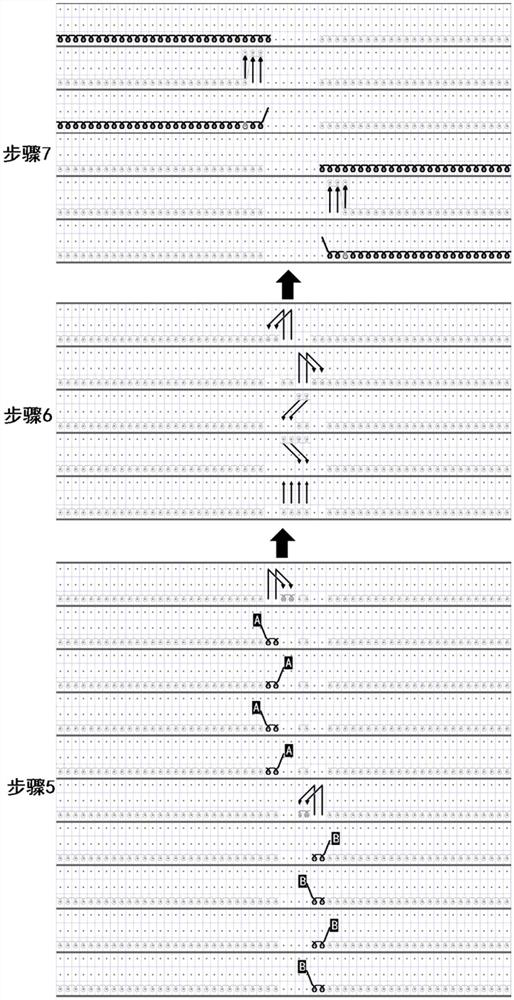

[0021] In order to better express and understand, the weaving method of knitted garment mesh structure is as follows: image 3 As shown, using a flat knitting machine with a pair or more than one pair of needle beds extending in the left-right direction and facing each other in the front-rear direction, the two connecting loops are knitted separately with the yarn feeder A and the yarn feeder B respectively, including the following steps,

[0022] Step 1: After knitting 2 rows on the left and right, move the stitches on the right edge of the left knitting area to the left, and at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com