Knitting method for improving appearance effect of single splicing corner under fully-formed clamp and knitted fabric

A fully formed and knitted fabric technology, which is applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems affecting the appearance of clothing, achieve the effect of improving the appearance and broadening the development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention will be further described with regard to specific embodiment:

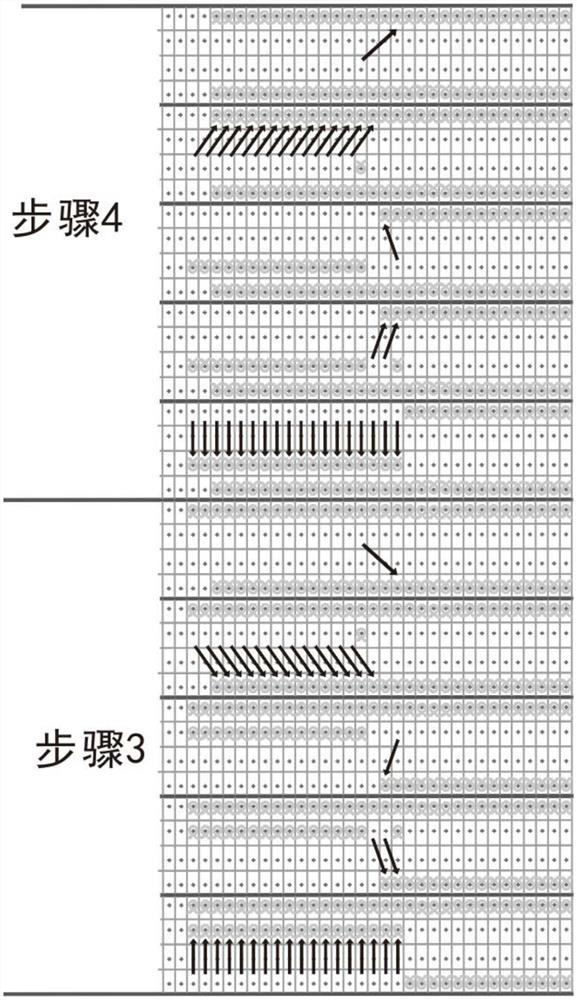

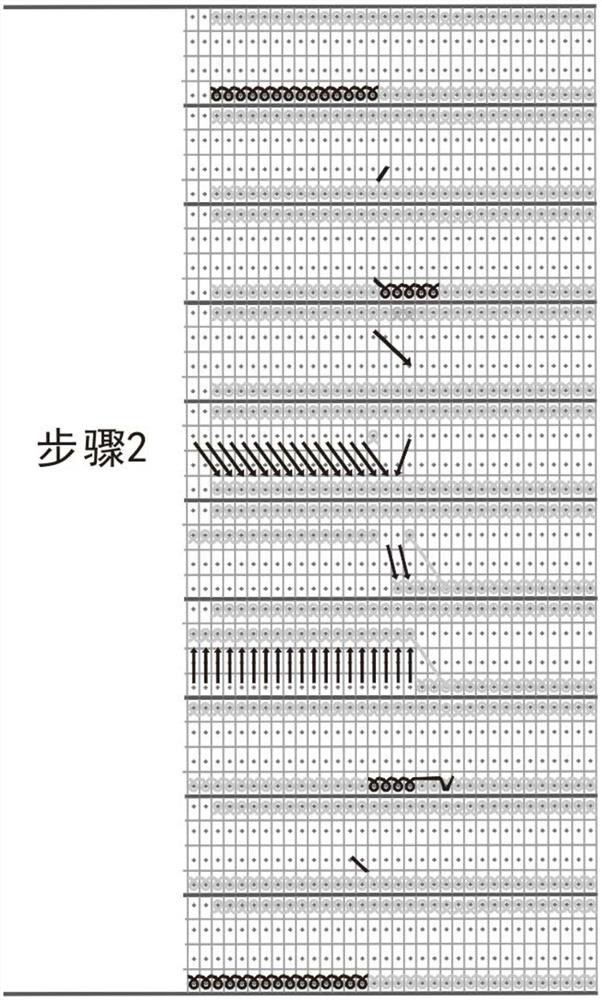

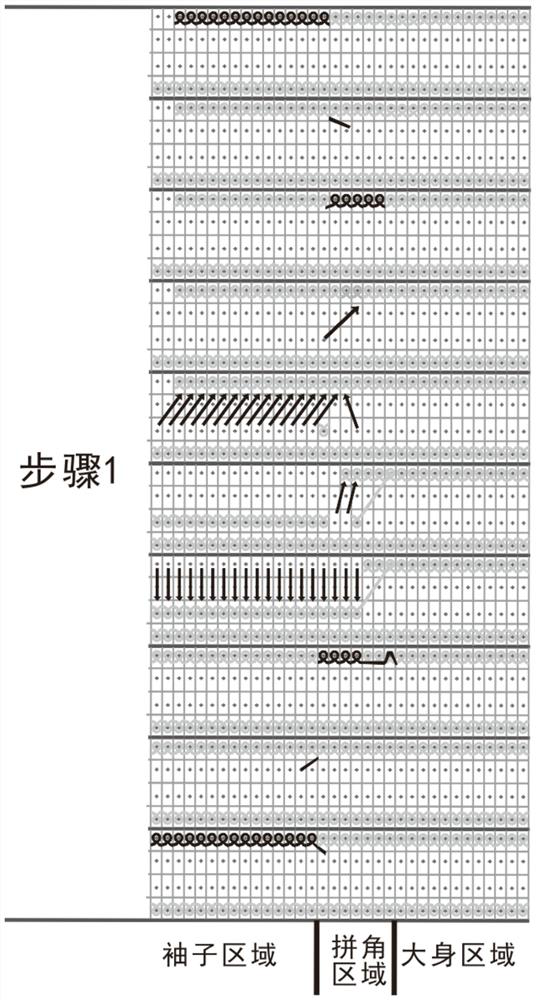

[0013] In order to better express and understand, such as figure 1 As shown, taking the corner structure on the left side with a corner width of 7 needles as an example, the knitting method for improving the appearance of a single corner under a fully formed clip uses a pair of front and rear pairs extending in the left and right directions and facing each other in the front and rear directions. The flat knitting machine with the above needle bed performs the following knitting,

[0014] Step 1: Knit the sleeve area with the yarn feeder in the right row, then lower the stitches on the needle bed, kick the yarn feeder in the left row, knit the corner area in the right row, and then lower the stitches at the 1st, 2nd, 3rd, and 4th needles on the needle bed. Tuck at the 7th needle position on the rear lower needle bed in the corner stitchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com