Double-sided yarn braiding method

A double-sided, yarn technology, used in weft knitting, knitting, textiles and papermaking, etc., can solve problems such as inability to meet design requirements, achieve rich texture and color contrast, huge market potential, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

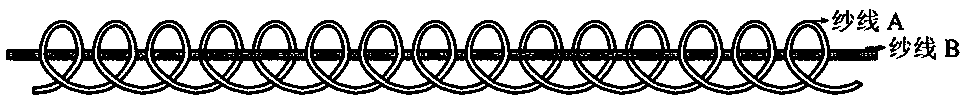

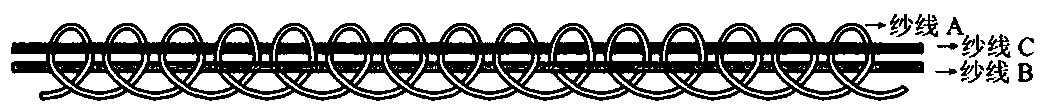

[0016] This embodiment describes the double-sided sandwich knitting method.

[0017] Such as figure 2 As shown, a double-sided clamping knitting method uses a flat knitting machine with a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-back direction. , Yarn C for weaving. During weaving, the yarn B and yarn C are respectively located on the front and back sides of the knitting coil through the selection of the coils. When running, the concrete steps of this weaving method are:

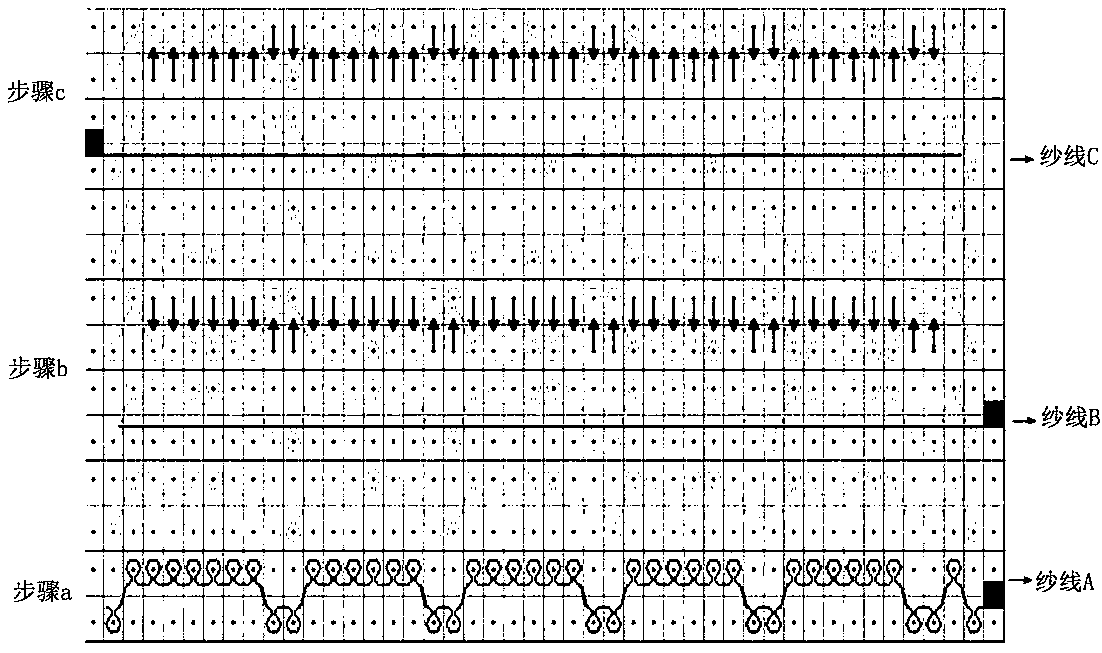

[0018] Such as image 3 As shown, (1) when going right on the Shazui

[0019] (a) Yarn A knits forward and reverse stitches on the right according to the pattern requirements of clamped yarn B;

[0020] (b) The yarn feeder is equipped with yarn B for non-woven yarn clamping in the weft direction. At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com