All-forming front-back varying narrowing knitting method and fabric formed through method

A fully-molded, front-to-rear direction technology, applied in the field of knitting, can solve the problems of human wearing comfort and the lack of breadth and depth in the development of garment technology pattern technology, and can not fully meet the needs of product design and development, so as to optimize the garment technology pattern, Abundant design methods and effects in a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

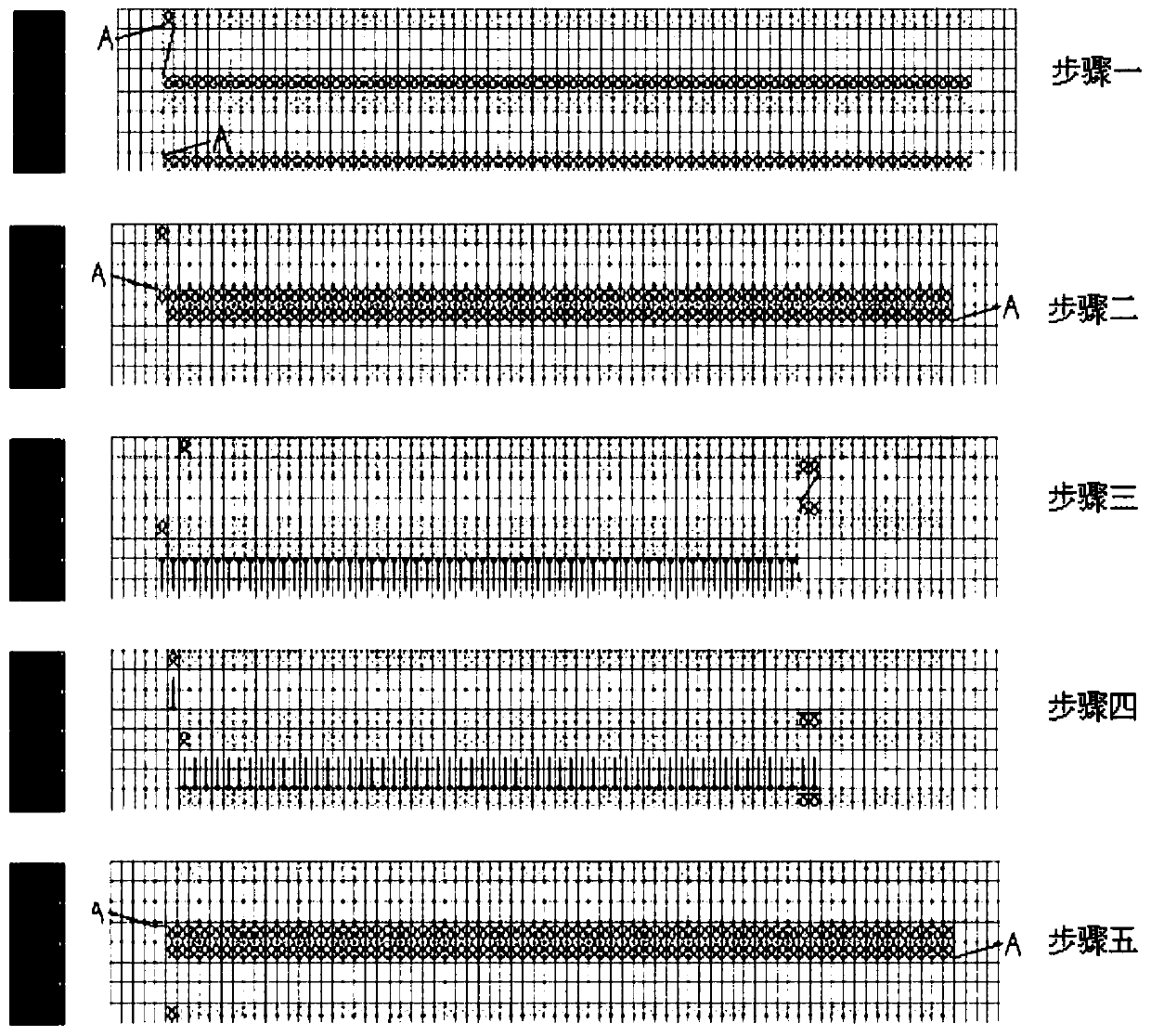

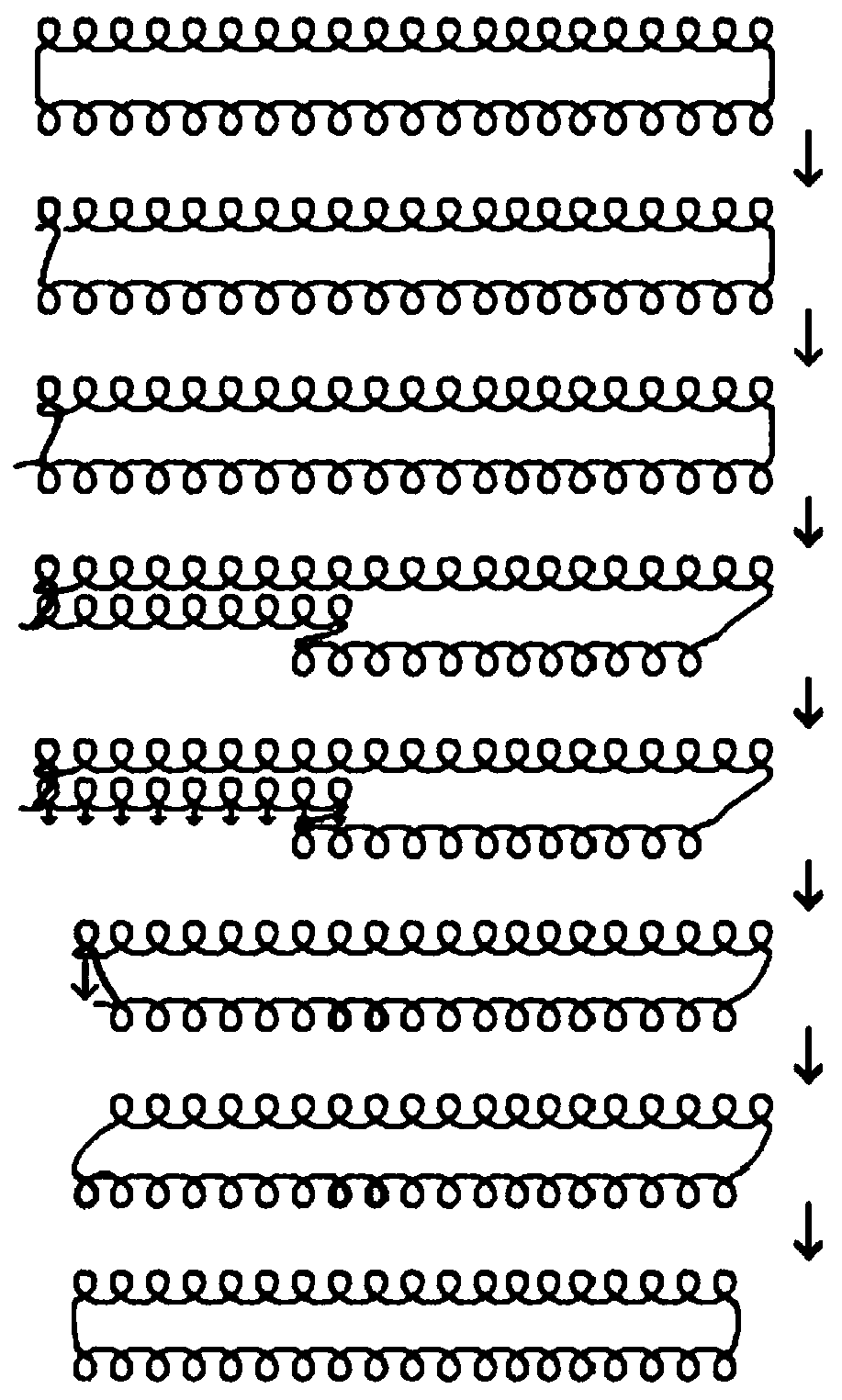

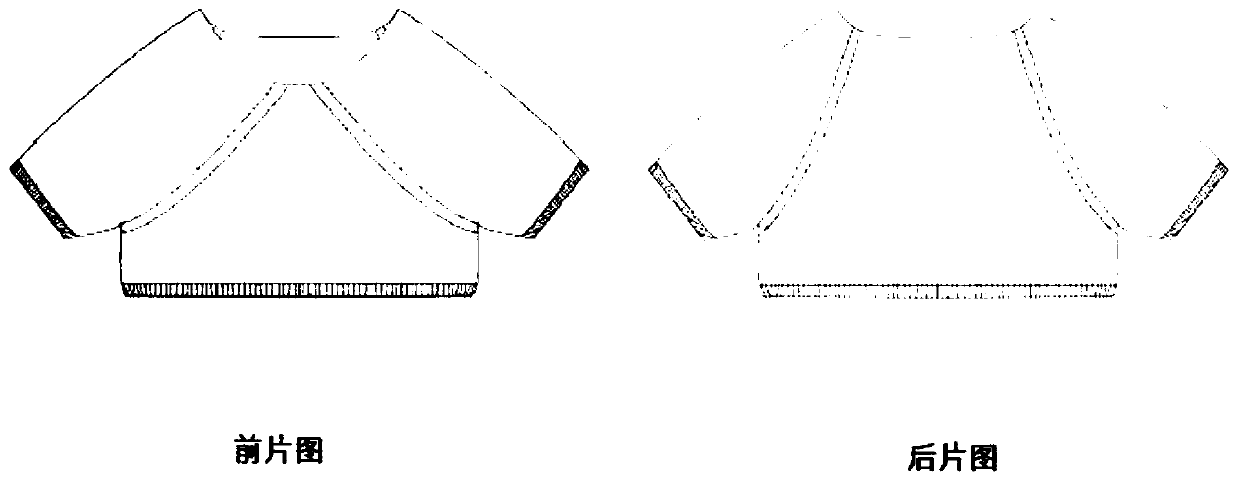

[0032] Such as Figure 1-2 As shown, the present invention relates to a combination design utilizing a shaker to transfer needles on a full-form machine. The whole-form machine selects the whole garment flat knitting machine of Shima Seiki Corporation of Japan, the model MACH2-153XS, and on this basis, through The improvement of the knitting method can realize the knitting method that the front and rear panels of the fabric have different narrowing numbers, and can also maintain the same width of the front and back. The organizational structure is based on cylindrical knitting, transfer the loops that need to be narrowed on the needle boards that need to be narrowed to the corresponding needle boards for shaker narrowing, and then place more needles on the corresponding needle boards than required. The extra loops on the narrowed needle board are reverse knitted and then transferred to the narrowed needle board.

[0033] Hereinafter, specific embodiments of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com