A weaving method for improving the weaving efficiency of flat knitting machine fully formed garments

A fully formed and flat knitting technology, which is applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of high time and energy consumption, low efficiency, and non-compliance with production requirements, so as to improve design concepts and maximize efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

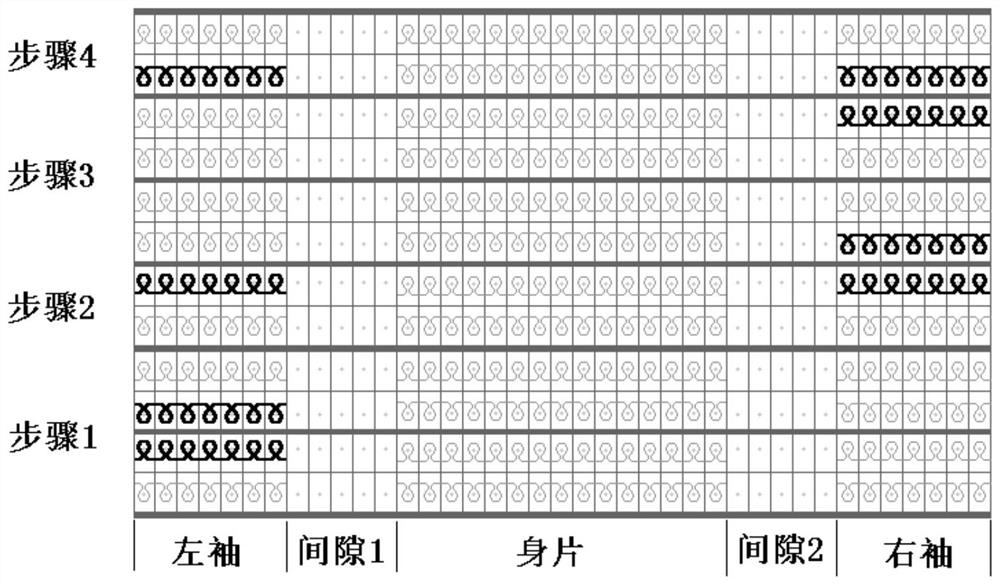

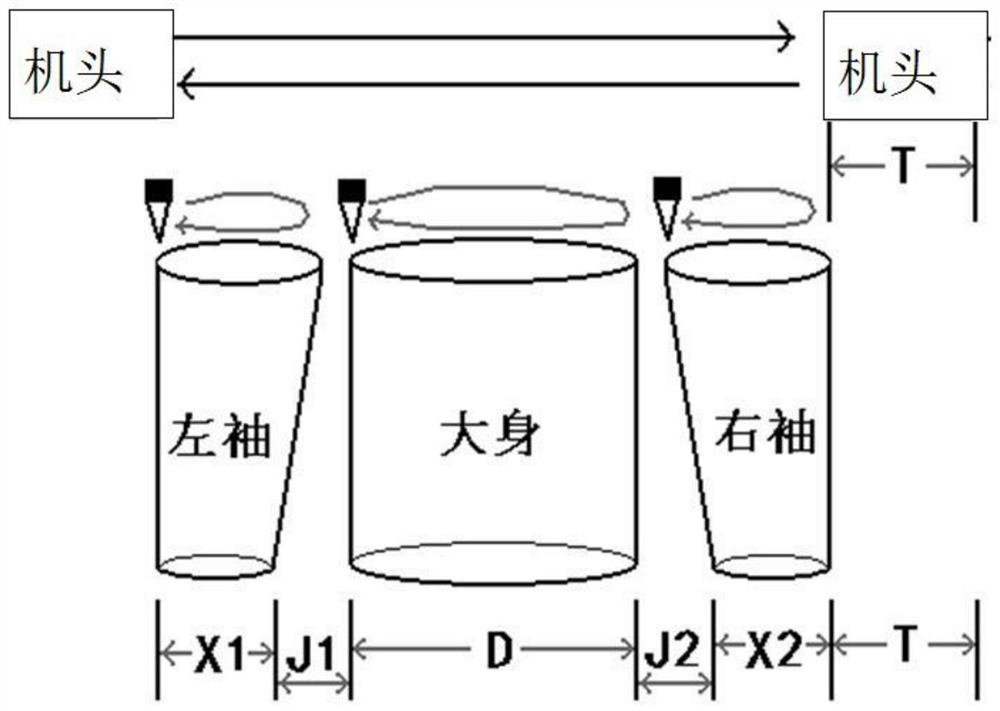

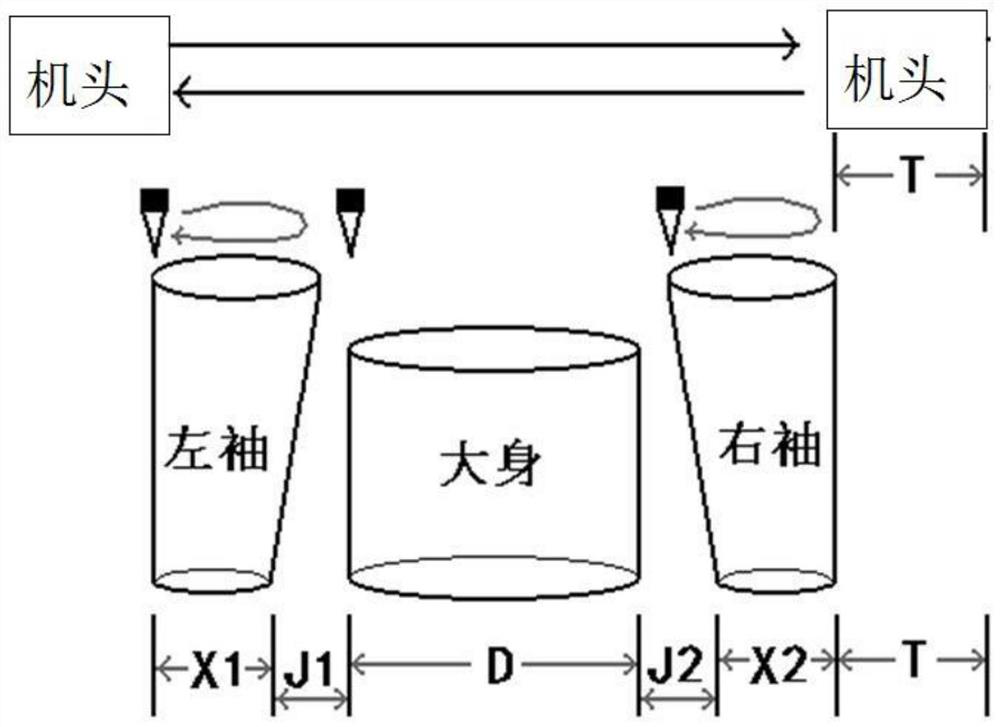

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with regard to specific embodiment:

[0024] Such as Figure 4 As shown, set the left sleeve knitting width to X1, the right sleeve knitting width to X2, the body knitting width to D, the left sleeve and body width to J1, the right sleeve to body width to J2, set the left and right sleeves The interval width is J3, the width of the machine head is T, using a fully formed computerized flat knitting machine with one or more pairs of front and rear needle beds extending in the left and right directions and facing each other in the front and rear directions, under the premise that the value of J3 is greater than the value of T , perform the following operations on the left and right sleeves and the body before closing the sleeves,

[0025] Step 1. The machine head of the flat knitting machine knits the extra revolutions of the left sleeve first, and then stops at the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com