Knitted fabric with burnt-out effect and knitting method thereof

A knitted fabric and burnt-out technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of inaccurate pattern processing, cumbersome process links, and high post-finishing losses, so as to achieve rich design methods and broad development space. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

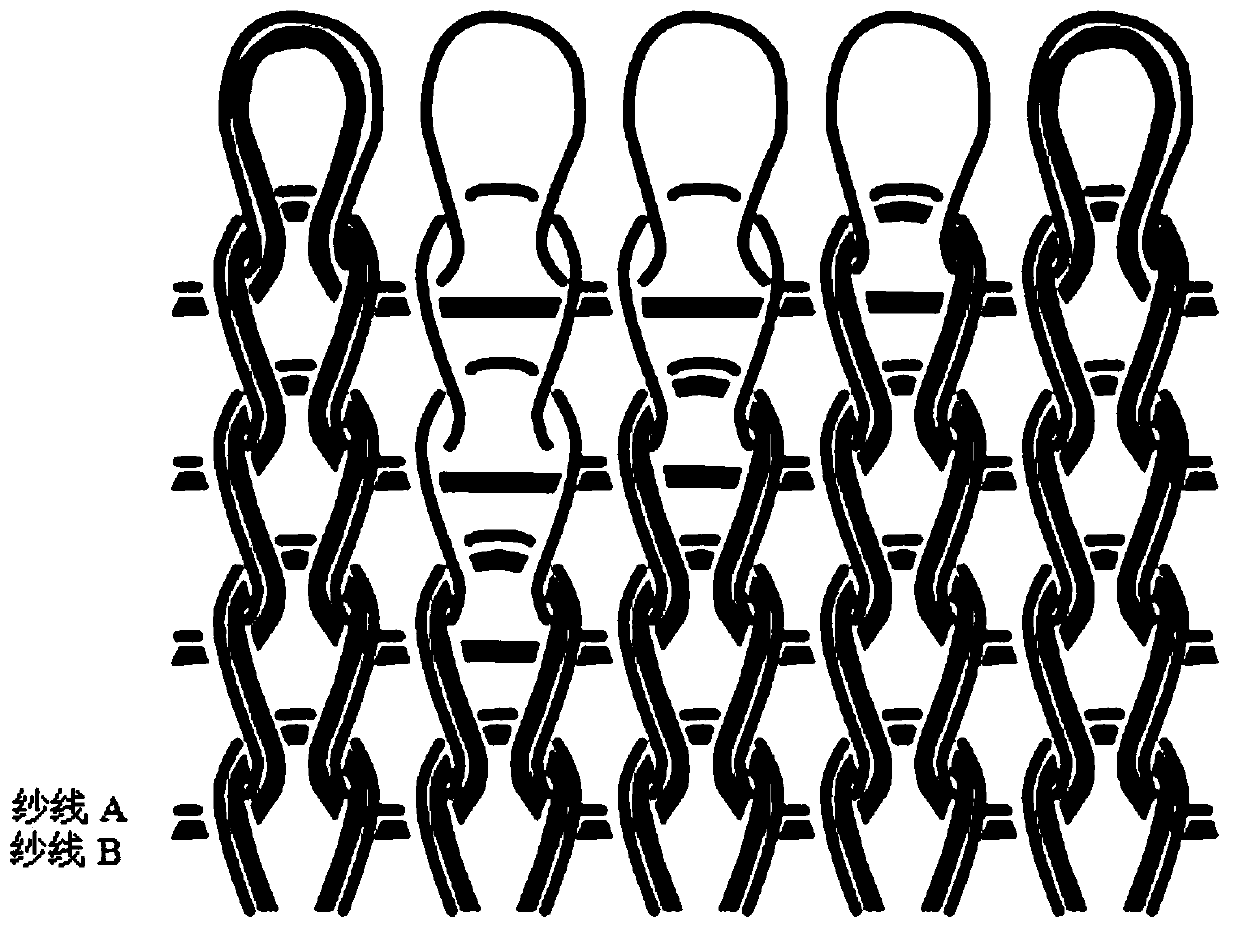

[0021] Such as figure 1 As shown, the present invention relates to a knitting method that uses different width yarn feeders on computerized flat knitting machines of the same specification to freely switch between different coil effects, wherein yarn A is made of transparent yarn, and the main part is yarn A and yarn B Knit together, the semi-transparent pattern part is woven with transparent yarn A, and yarn B is not woven with the float action, so that a burnt-out knitted fabric can be produced.

[0022] Specifically, using a flat knitting machine with a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-back direction, the flat knitting machine has at least two yarn feeders of different widths, so as to realize different loop texture patterns with yarn feeders of different widths,

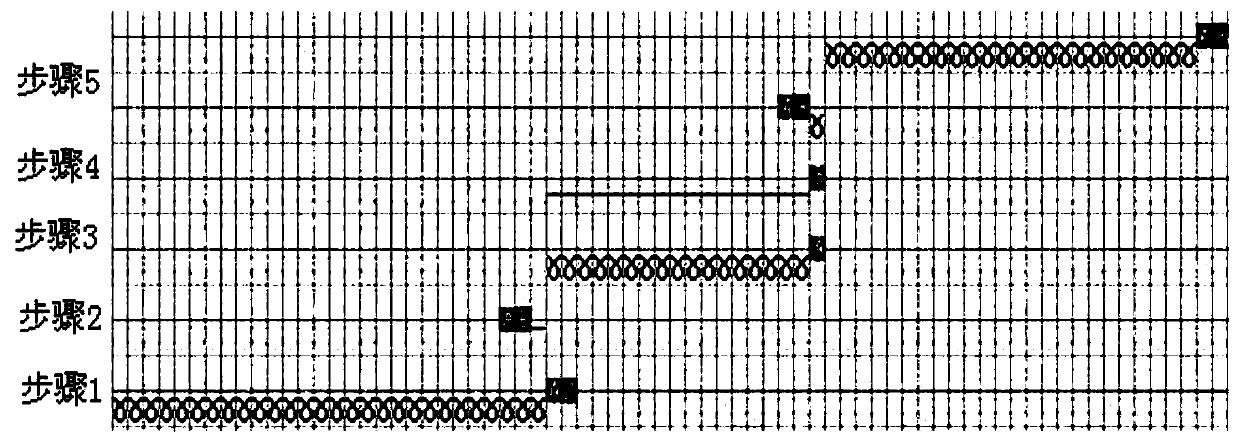

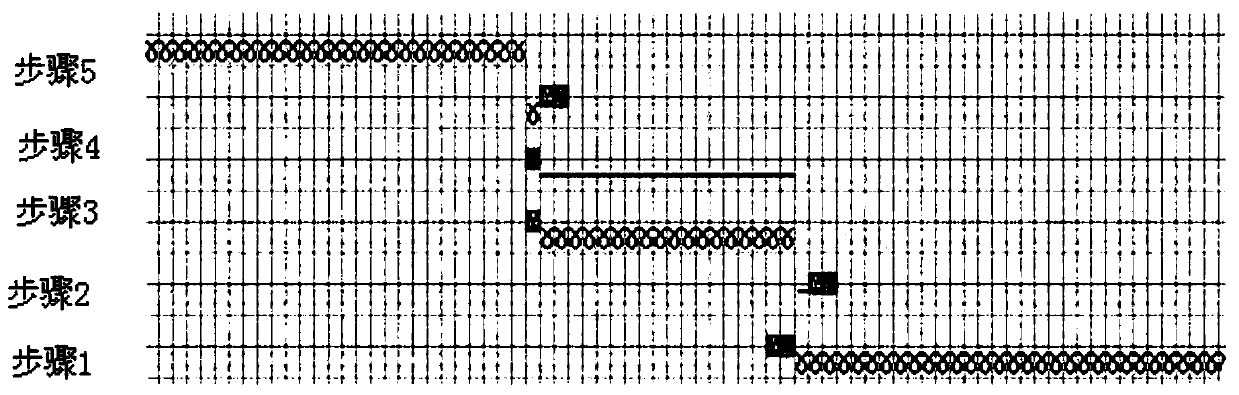

[0023] Such as figure 2 As shown, when the yarn feeder moves to the right, follow the steps below, step 1, yarn A and yarn B pass yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com