The knitting structure and knitting method of the shoulder version of the improved full-molded raglan sleeve

A fully-formed, raglan sleeve technology, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of insufficient rows of fully-formed raglan sleeves, unbalanced body structure, and inadequate layout. To achieve the effect of optimizing the shoulder craft version, huge market potential, and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

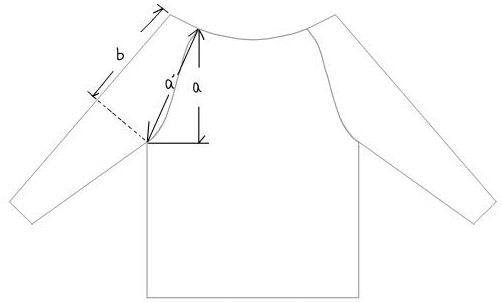

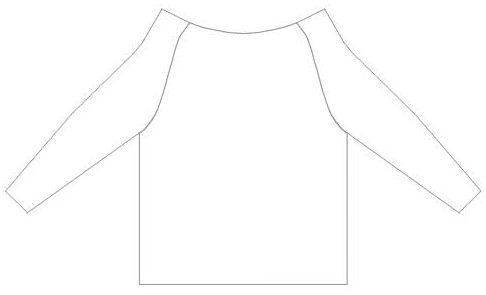

[0016] Such as image 3 As shown, the braided structure for improving the shape of the shoulders of the fully-molded raglan sleeves described in this embodiment includes fully-molded woven garment parts and sleeve panels, wherein the sleeve height of the sleeve panels is greater than or equal to the hang of the garment panels. shoulder height. Wherein the change of this length is realized by the number of knitting rows of the sleeve mountain being greater than the number of knitting rows at the shoulder part of the clothes.

[0017] The knitting method of the knitting structure of the above-mentioned improved fully-molded raglan sleeve shoulder pattern is: using the combined knitting method of return and tuck, on the basis of cylindrical knitting, the sleeve hills of the front and rear panels need to be increased. Knit at least two rows of each left row and right row to form a multi-knit part, and knit a tuck at least one stitch at the edge of the multi-knit part.

[0018] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com