Whole-garment moire pattern stitch structure and knitting method thereof

A kind of weave structure, full molding technology, applied in the direction of knitting, weft knitting, textiles and papermaking, etc., can solve the problem of inability to meet the realization of the full molding process structure, and achieve the effect of improving the sense of quality and widening the development space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

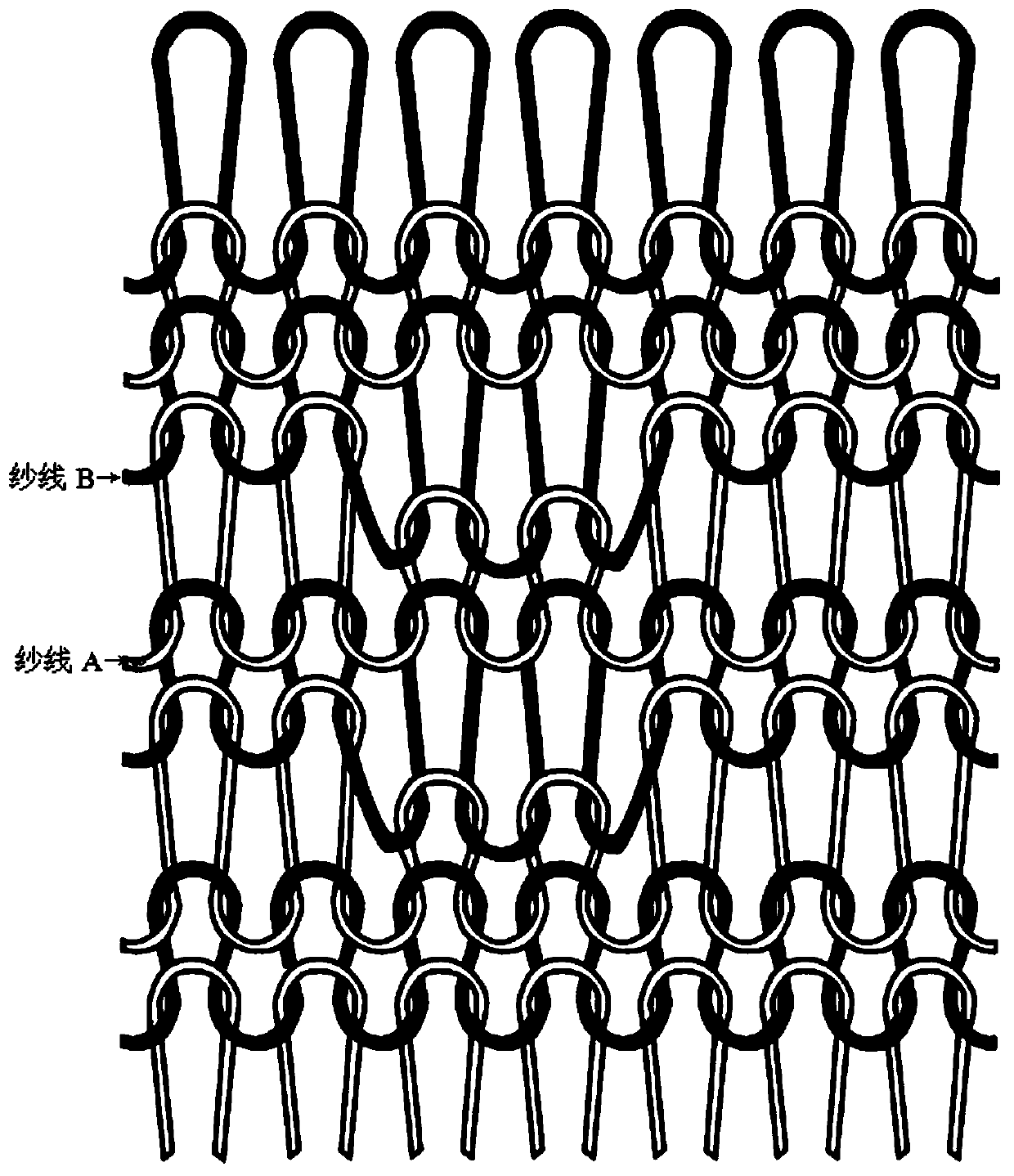

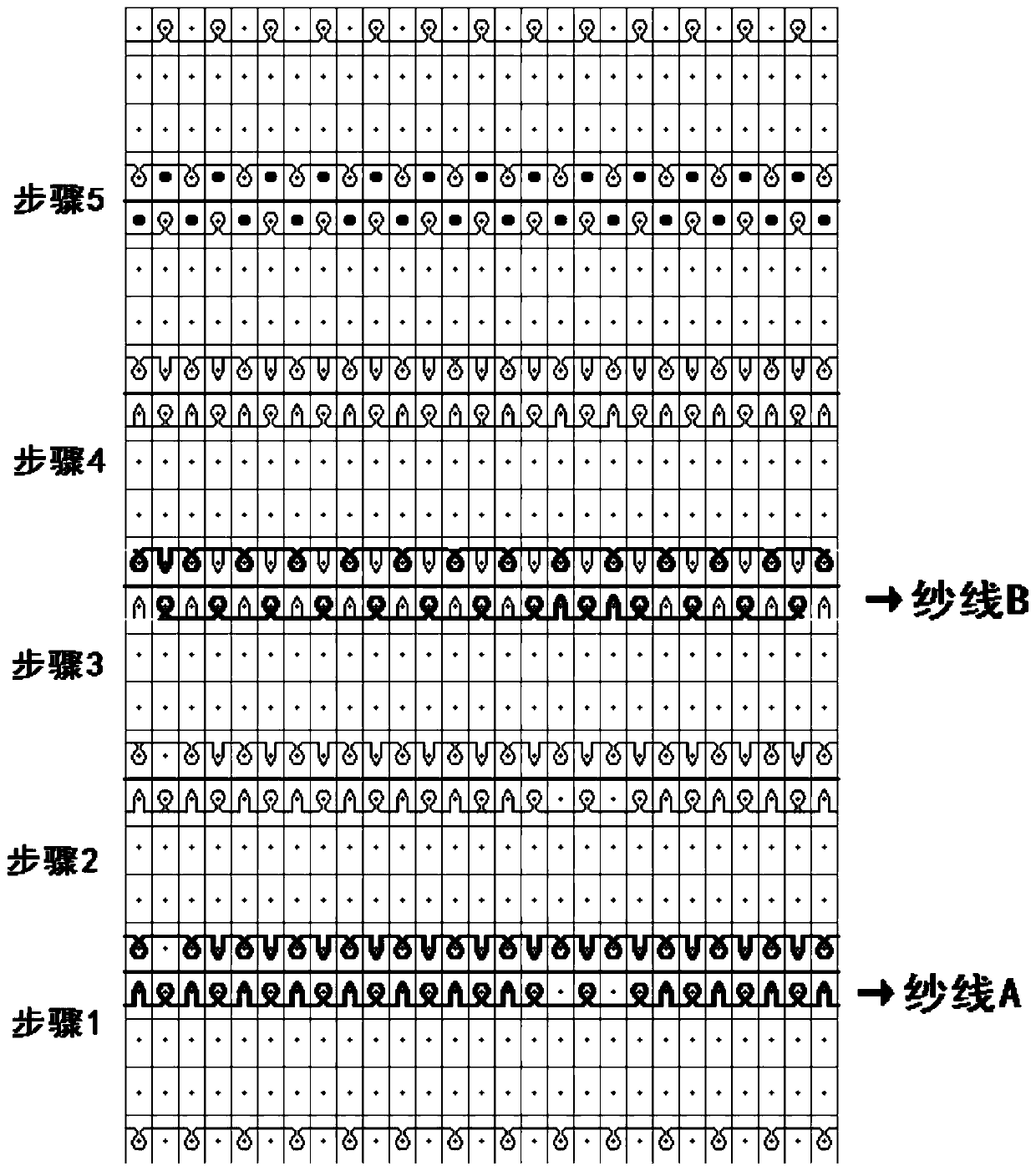

[0018] A fully formed moiré pattern weave structure such as figure 1 As shown, including the fabric body, the fabric body is integrally formed with a single-sided pattern pattern on the fabric body through a fully formed computerized flat knitting machine, and the pattern pattern has no dotted line part. It can not only meet the realization requirements of all fully formed process structures, but also not be restricted by the organization on the reverse side of the pattern design. Moreover, the woven fabric presents a richer texture and color contrast, and the pattern pattern is a combination of knitting yarns with different properties. Different knitting yarns such as color, shape, elasticity, etc. The knitting method is as follows, using a flat knitting machine having a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-rear direction, yarn A and yarn B are knit in one color at a time, and the stitches of the empty ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com