Microstereoscopic relief vertical stripe weave for knitted fabric and knitting method of microstereoscopic relief vertical stripe weave

A three-dimensional embossing, knitted fabric technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of not fully meeting the needs of product design and development, lack of technical development breadth and depth, etc., and achieve good design concepts and high aesthetics. Value, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

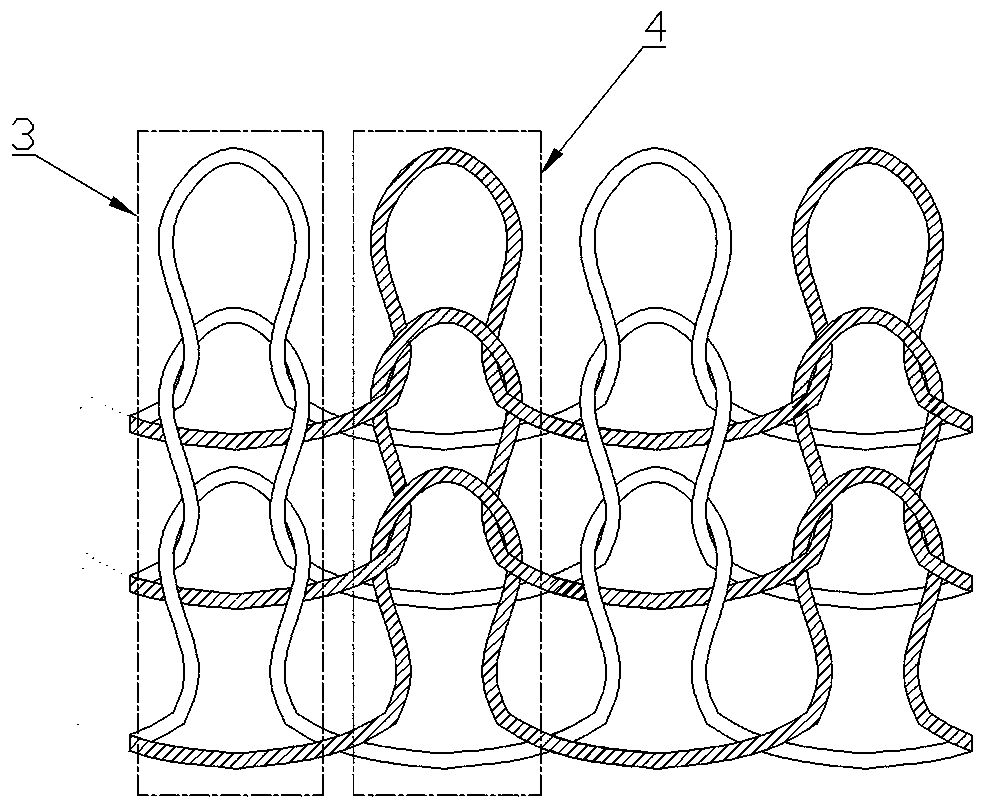

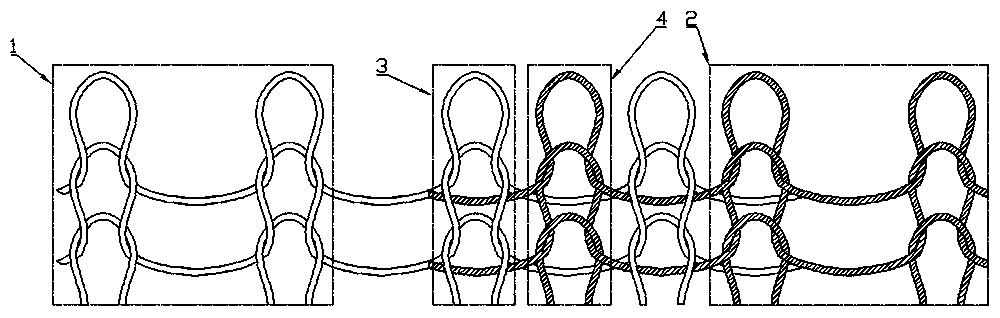

[0027] The micro-stereo-relief vertical texture of the knitted fabric described in this embodiment, such as figure 1 , figure 2 As shown, it includes a plain stitch 1 and an anti-flat stitch 2, the flat stitch 1 is composed of the front stitch 3 of the spacer, the anti-flat stitch 2 is composed of the reverse stitch 4 of the spacer, and the front of the spacer The stitches 3 and the spacer back stitches 4 are alternately arranged on the wale.

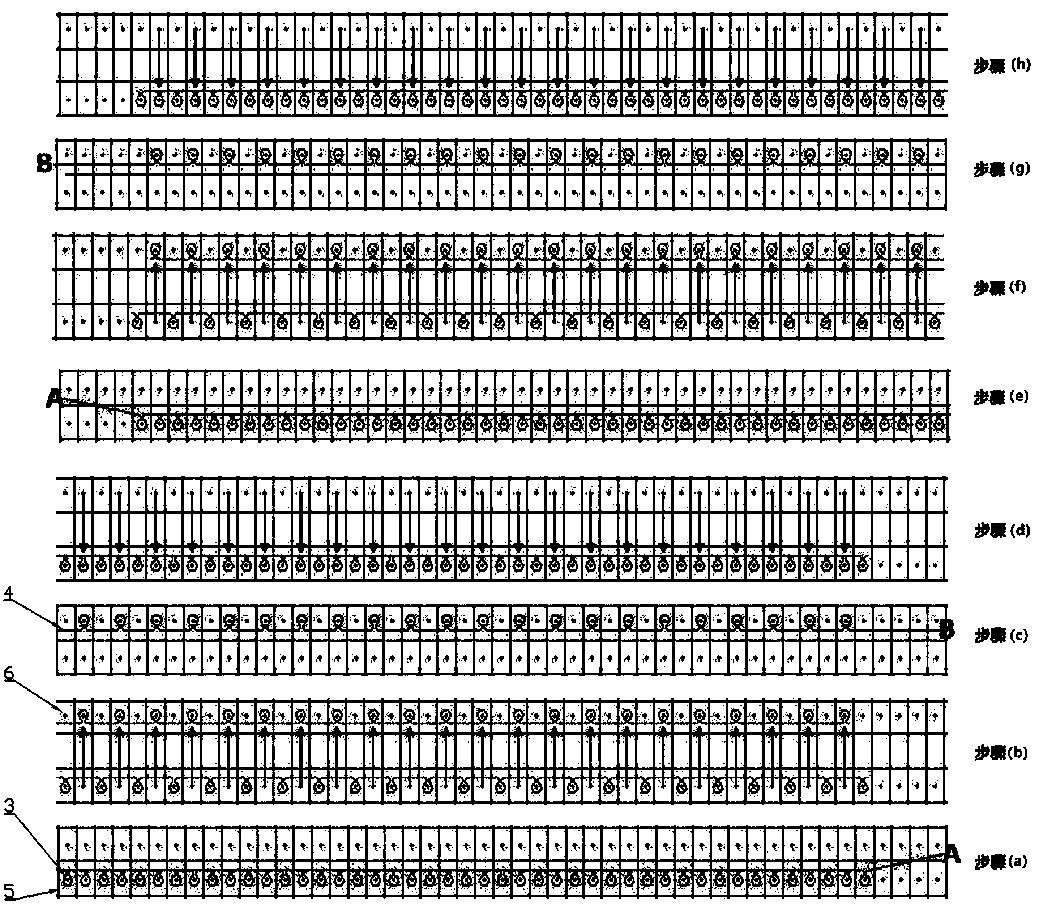

[0028] The weaving method of the micro-stereo-relief vertical weave of the knitted fabric described in this embodiment, such as image 3 As shown, a kind of flat knitting machine is used, and the flat knitting machine includes a front needle bed 5 and a rear needle bed 6. The front needle bed 5 and the rear needle bed 6 are opposite to each other and extend parallel to both sides. There are yarn feeder A and yarn feeder B; the knitting method, such as image 3 shown, including the following steps:

[0029] (a) Yarn feeder A moves f...

Embodiment 2

[0041] The micro-stereo-relief vertical texture of the knitted fabric described in this embodiment, such as Figure 4 As shown, in addition to the features described in Embodiment 1, in order to realize the weaving of various patterns and patterns through this weave, the plain stitch 1 and the reverse jersey 2 can use yarns 7 of different thicknesses.

[0042] In this embodiment, thick yarn 71 is used for plain stitch 1, and fine yarn 72 is used for reverse flat stitch 2, which can form stripes of different shades on the surface of the fabric to achieve an aesthetic effect.

[0043] In the weaving method of the micro three-dimensional relief vertical texture of the knitted fabric described in this embodiment, during the weaving process, the yarn feeder A uses thick yarn 71 when feeding yarn, and the yarn feeder B uses thin solid yarn 72 when feeding yarn .

[0044] The thick yarn 71 and the thin yarn 72 mentioned in this embodiment only refer to the comparison between the two...

Embodiment 3

[0046] The micro three-dimensional embossed vertical weave of the knitted fabric described in this embodiment, in addition to the characteristics described in Embodiment 1, in order to realize the weaving of various patterns and patterns through this weave, the normal flat stitch 1 and the reverse flat stitch 2 Yarns 7 of different thicknesses can be used.

[0047] In this embodiment, the plain stitch 1 uses thin yarns 72, and the reverse flat stitch 2 uses thick yarns 71, which can form stripes of different shades on the surface of the fabric to achieve an aesthetic effect.

[0048] In the weaving method of the micro three-dimensional relief vertical texture of the knitted fabric described in this embodiment, during the weaving process, the yarn feeder A uses the fine yarn 72 when feeding the yarn, and the yarn feeder B uses the thick yarn 71 when feeding the yarn .

[0049] The thick yarn 71 and the thin yarn 72 mentioned in this embodiment only refer to the comparison betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com