A kind of multi-layer windproof fabric and its application

A fabric and fabric layer technology, applied in applications, protective clothing, layered products, etc., can solve the problems of poor air permeability, water pressure resistance, lack of wind resistance, poor thermal insulation, etc., to achieve rough appearance and delicate hand feel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

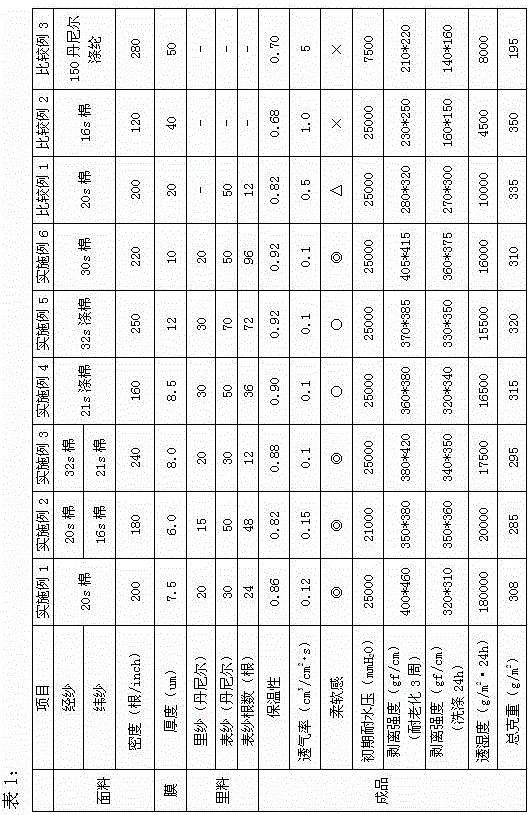

Examples

Embodiment 1

[0046] Fabric layer: both warp and weft yarns are made of 20s cotton yarn, woven on an air-jet loom, and then processed as follows: gray fabric singeing (80m / min)→cold stacking→boiling→stentering (room temperature)→mercerizing (70m / min)→surface Sanding (15m / min) → continuous dyeing → finished product setting (180°C) → pre-shrinking (140°C), to produce a pure cotton raised woven fabric with a total density of 200 threads / inch;

[0047]Lining layer: the inner yarn is 20 denier polyester single yarn, the outer yarn is 30 denier, 24 polyester multifilament yarns, and the plain weave is used to weave on the warp knitting machine, and then processed as follows: scouring→intermediate setting (190 ℃)→raising processing→dyeing (125℃)→wet resin setting to make pure polyester raising warp knitted fabric;

[0048] Lamination: Use a non-porous hydrophilic polyurethane film with a thickness of 7.5um as the middle layer. First, the fabric layer and the waterproof and moisture-permeable film ...

Embodiment 2

[0050] The fabric layer is a pure cotton raised woven fabric with a finished density of 180 threads / inch formed by 20s cotton spun yarn as the warp yarn and 16s cotton spun yarn as the weft yarn; the middle layer is a non-porous hydrophilic polyurethane film with a thickness of 6.0um; the lining The layer is a pure polyester raised warp knitted fabric formed by 15 denier polyester single yarn as the inner yarn, and 50 denier and 48 polyester multifilament yarns as the surface yarn. The rest of the process is the same as in Example 1. The performance is shown in Table 1.

Embodiment 3

[0052] The fabric layer is made of 32s cotton spun yarn as the warp yarn and 21s cotton spun yarn as the weft yarn, and the finished product density is 240 / inch pure cotton raised woven fabric; the middle layer is a non-porous hydrophilic polyurethane film with a thickness of 8.0um; the lining The layer is a pure polyester raised warp knitted fabric formed by 20 denier polyester single yarn as the inner yarn, and 30 denier and 12 polyester multifilament yarns as the surface yarn. The rest of the process is the same as in Example 1. The performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com