Collective stitch type complex tissue knitted fabric and knitting method thereof

A composite weave and needle-set technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of single needle style and few changes in knitted fabrics, and achieve high artistic value, wide application fields, and good design The effect of ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

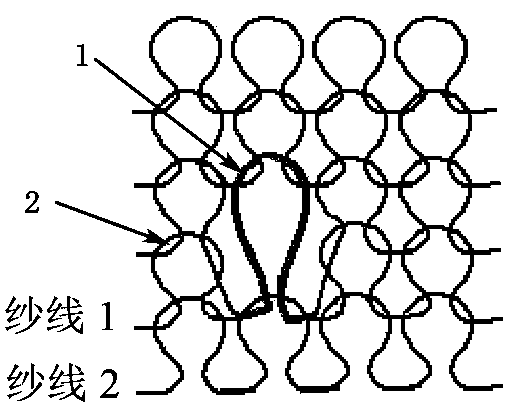

[0020] Such as figure 1 As shown, the needle-collecting composite weave knitted fabric described in this embodiment is a weft-knitted single-jersey fabric, which includes a common weave 2 and a needle-collecting composite weave 1, and the common weave 2 is made of multiple rows of yarns looped together Composition, the needle-collecting composite weave 1 is a structure composed of two yarns and two rows of loops between ordinary weaves 2 .

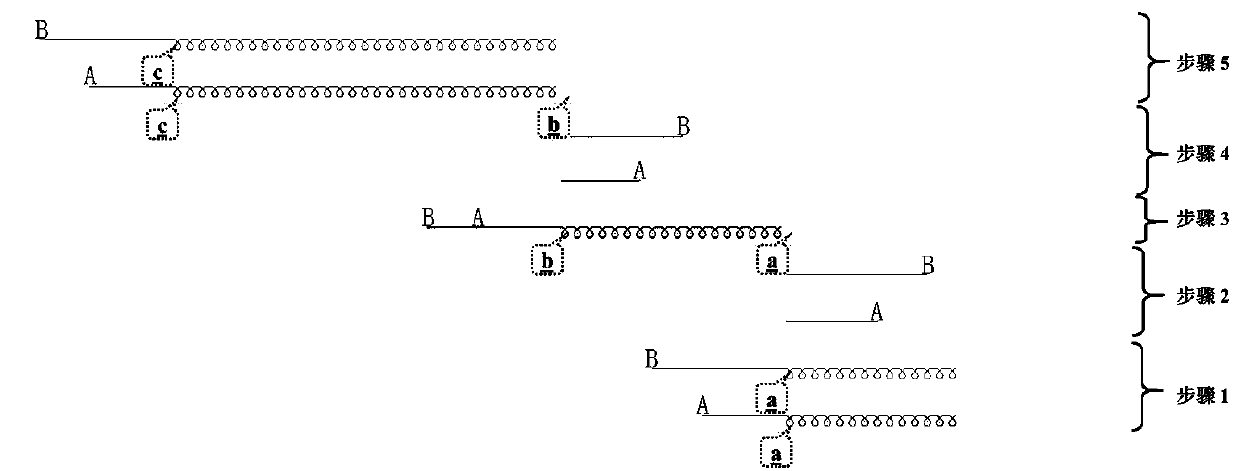

[0021] The knitting method of the above-mentioned needle-collecting composite structure knitted fabric is to use multiple yarn feeders with different widths to move in the left and right direction and move in the front and rear directions to perform free change between multiple yarn feeders sequential weft knitting and multiple yarn feeders simultaneous weft knitting, The common weave is formed when multiple yarn feeders are weft knitting one after another in the vertical direction, and the needle-collecting composite weave is formed when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com