Two-needle-plate cylindrical 2x1 tight rib knitting structure and knitting method thereof

A tight rib knitting, cylindrical technology, applied to the two-needle plate cylindrical 2X1 tight rib knitting structure and its knitting field, can solve the problems affecting the quality of finished products, loose rib density, etc., to improve the quality of finished products and broaden the development space , The effect of improving the design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

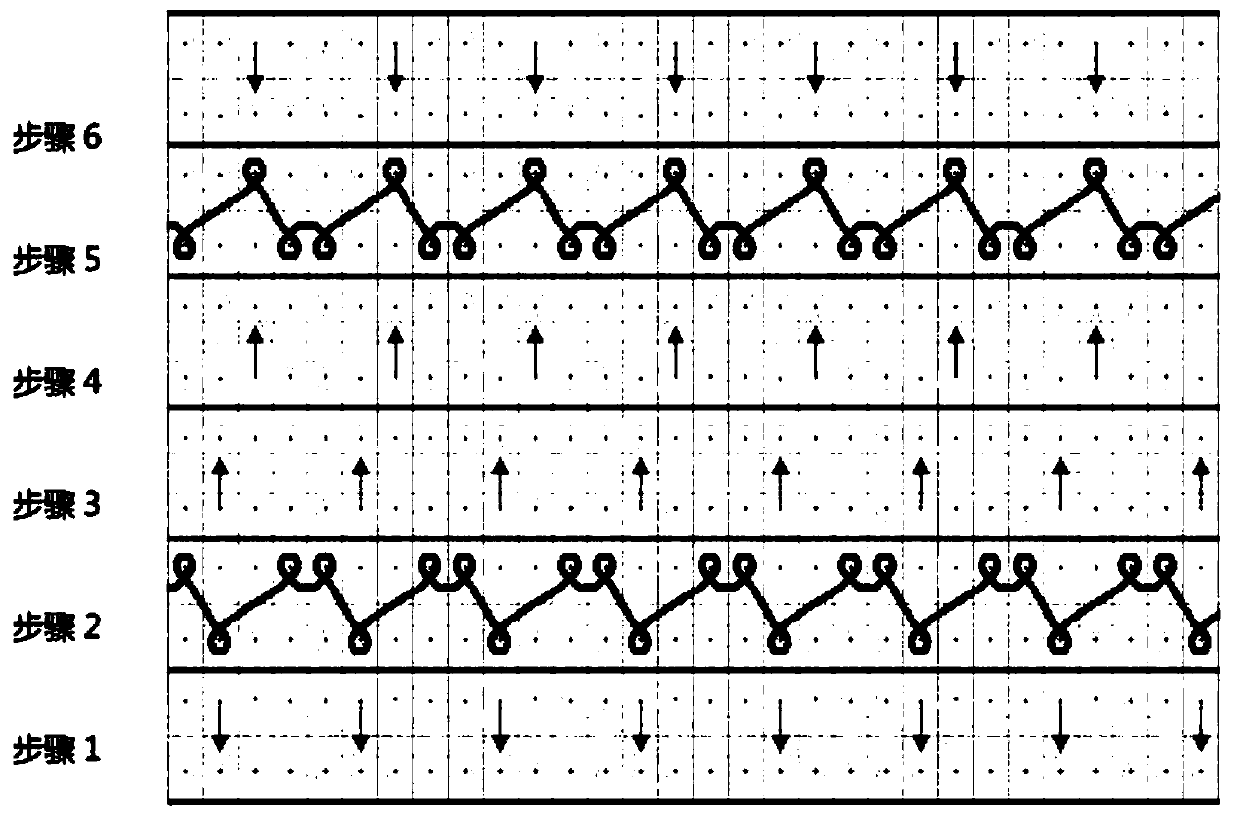

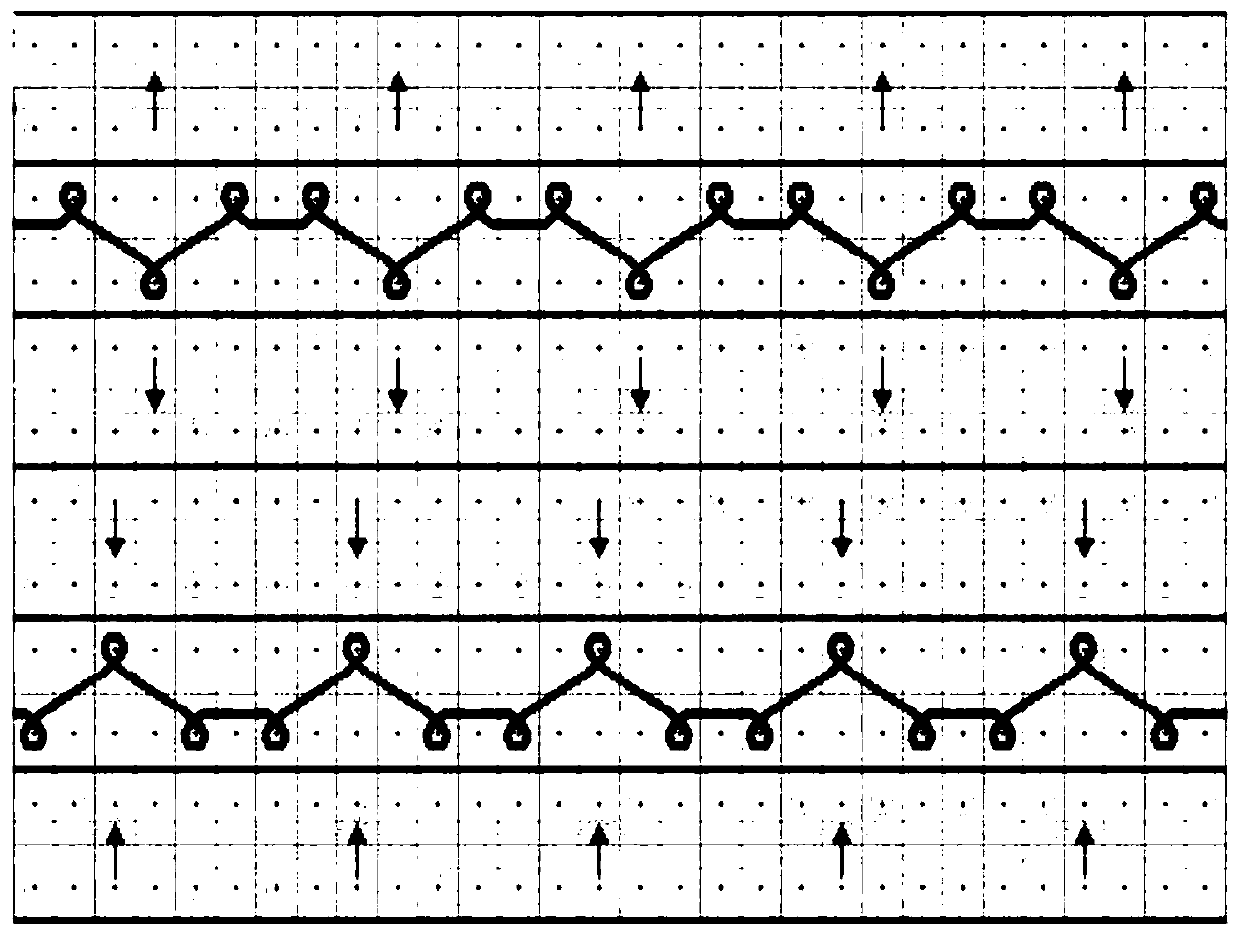

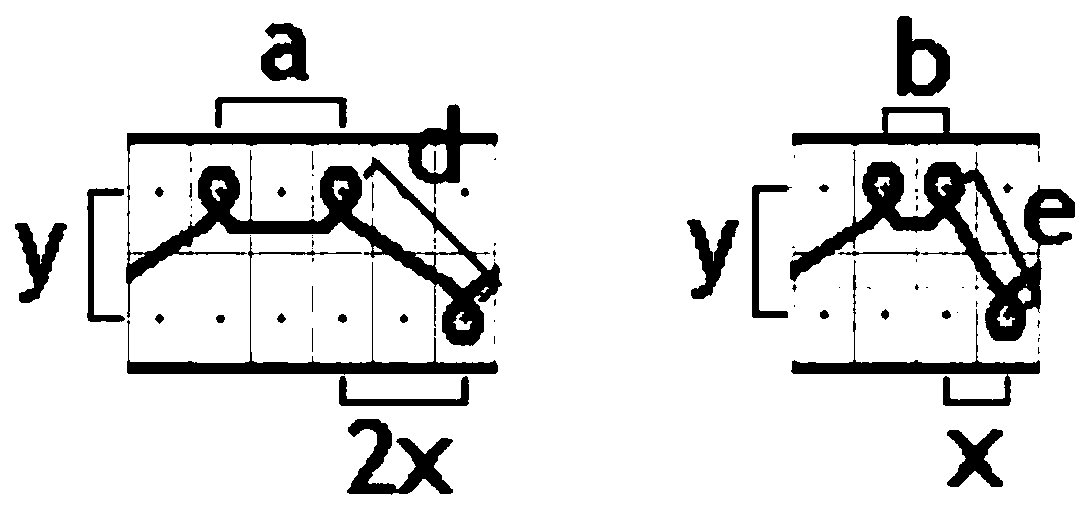

[0019] like figure 1 As shown, a cylindrical 2X1 tight rib knitting structure with two needle plates is knitted on a flat knitting machine. When knitting, the 1+4N needle positions and 4N needle positions from left to right are the common needle positions. The front and rear needle beds Knit the front stitch of the front rib and the front stitch of the back rib respectively, knit the back stitch of the front rib at the 3+4N needle position, and knit the back rib stitch at the 2+4N needle position, where N is a natural number. In other words, when weaving the front rib, the rear rib loops are all located on the rear needle bed of the corresponding needle position, and the front rib is transferred according to the requirements of the positive and negative loops of the corresponding needle position and located on the front and rear needle beds, and then knit; when weaving the rear rib, the front rib loop They are all located on the front needle bed of the corresponding needle po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com