Patents

Literature

157results about How to "Reflective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof ultraviolet-resistant high-strength light and thin fabric and preparation method thereof

ActiveCN106480581AIncreased mechanical strength and electromagnetic shielding performanceExcellent UV resistanceUltrasonic/sonic fibre treatmentWoven fabricsSolventPlain weave

The invention provides a method for preparing a waterproof ultraviolet-resistant high-strength light and thin fabric. The method comprises the following steps: blending ceramic fibers and triangular special-shaped polyester fibers to form warp yarns, blending spandex fibers and titanium-nickel alloy fibers to form weft yarns, weaving plain weaves or basket weaves serving as a fabric structure to form base cloth; adding colloidal silica sol and nanometer titania sol into a solvent, fully stirring, adding graphene oxide solution, dripping a polystyrene high polymer, homogenizing and stirring so as to obtain a coating finishing agent; washing and airing the base cloth, performing low-temperature plasma treatment so as to obtain modified base cloth in a nitrogen atmosphere; spraying deionized water on the surface of the modified base cloth, wetting, repeatedly coating the coating finishing agent, drying, roasting, washing, well-pressing, and performing tenter setting, thereby obtaining the product.

Owner:SHAOXING DAFABRIC CLOTH TRADE

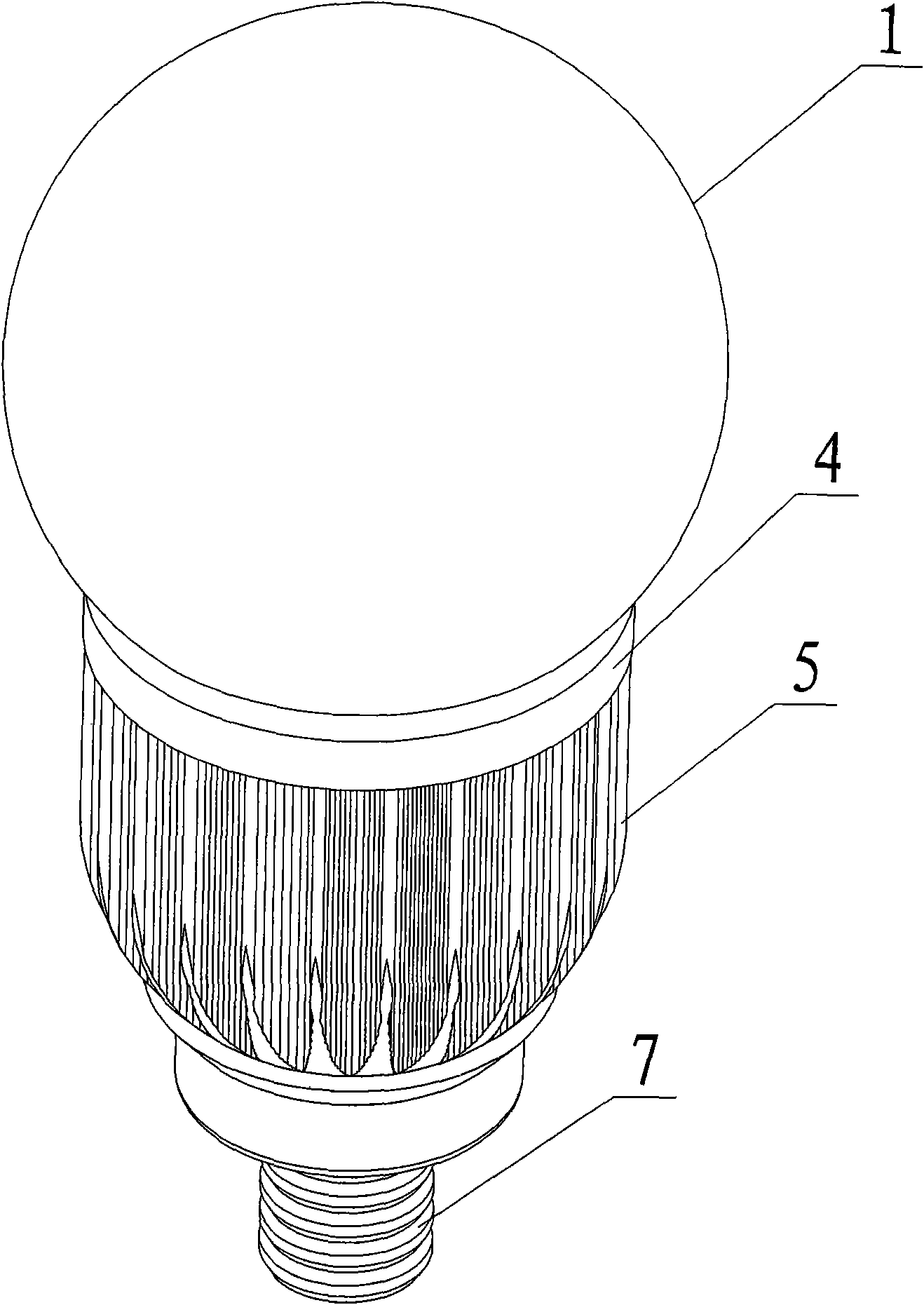

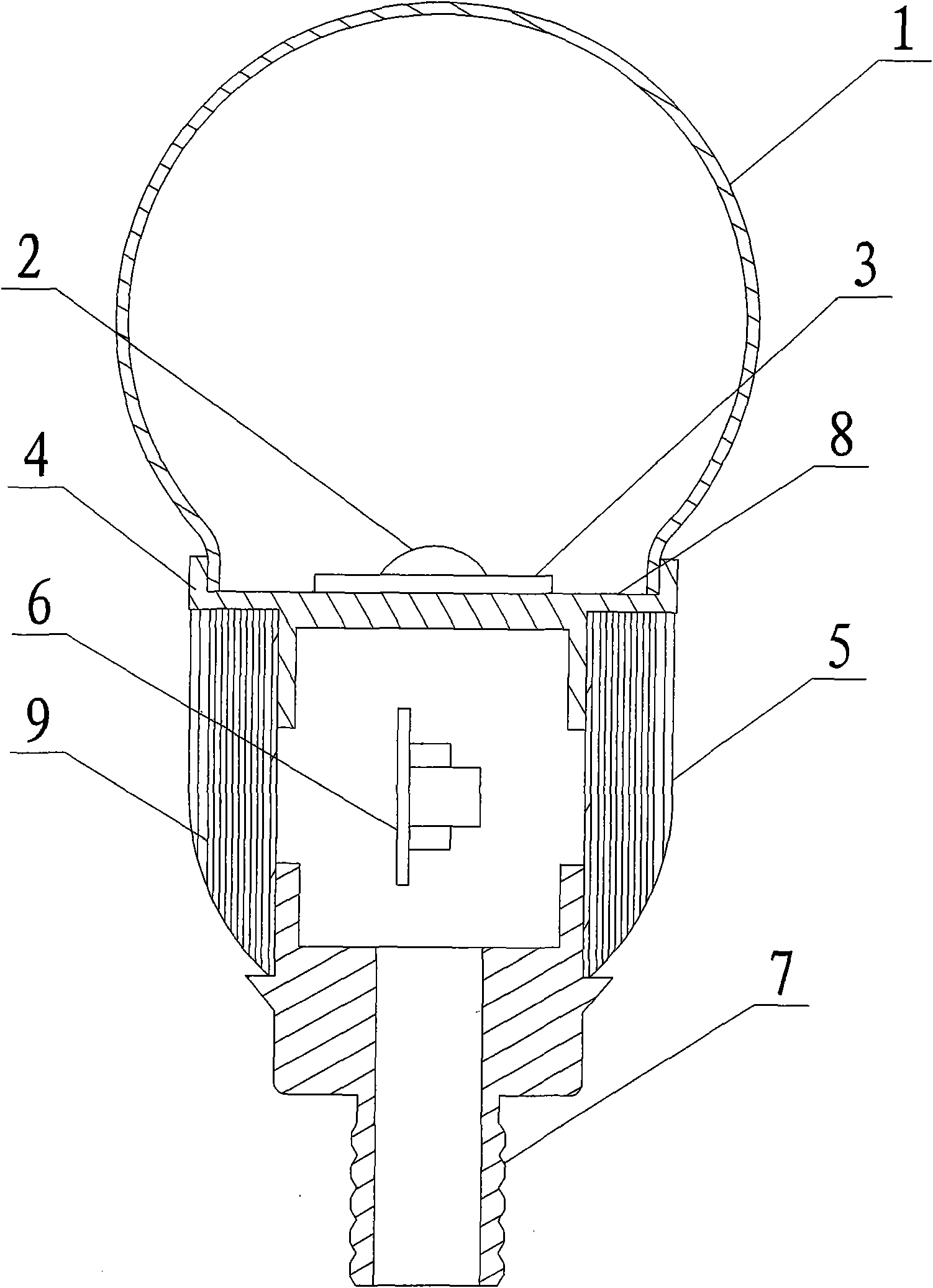

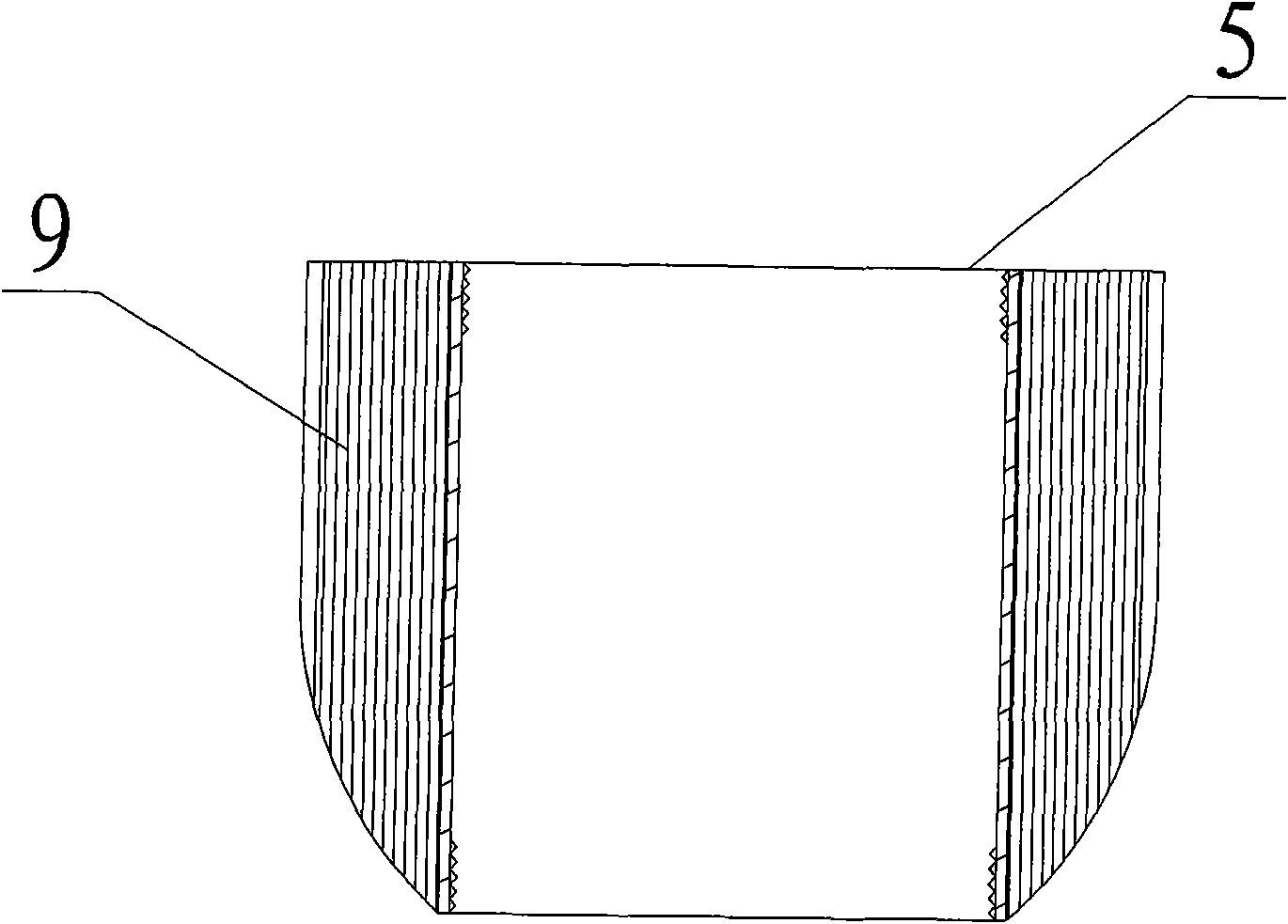

High-power LED energy-saving bulb

InactiveCN101614345AReflectiveHigh light efficiencyPoint-like light sourceElectric circuit arrangementsEngineeringLight source

The invention relates to a high-power LED energy-saving bulb, which comprises an LED light source, a circuit board, a radiator, an LED driving device, a connector for connecting with an interface of an illumination lamp, and a reflecting cup base, wherein the upper part of the reflecting cup base is provided with a flat-bottomed bowl cup which is provided with a reflecting layer, the connector is provided with a cavity, the LED driving device is fixed in the cavity, the radiator is a metal radiator provided with a vertical radiating fin, the upper part of the connector is fixedly connected with the lower part of the radiator, the lower part of the reflecting cup base is fixedly connected with the upper part of the radiator, the LED light source is fixed on the circuit board, the circuit board is fixed on the flat-bottomed bowl cup, a bulb cover is fixed on the flat-bottomed bowl cup, and the vertical radiating fin is provided with at least one radiating rib groove. The high-power LED energy-saving bulb has the advantages of higher light efficiency, better radiating effect, lower cost, and more reliable structural performance, and is more suitable for mass production and widespread use.

Owner:JIANGSU GUOXING ELECTRIC EQUIP

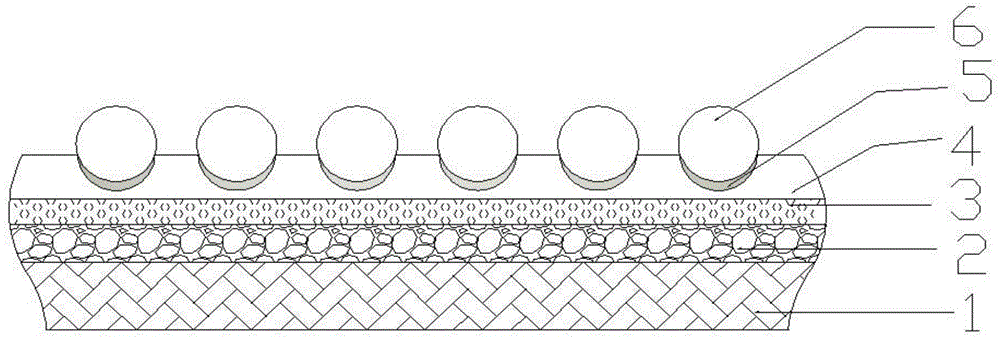

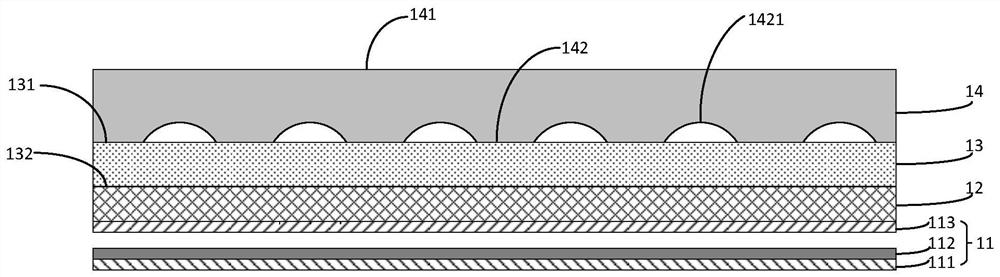

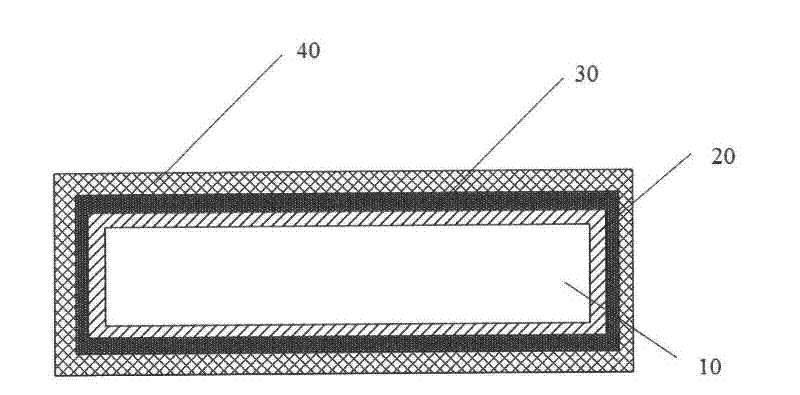

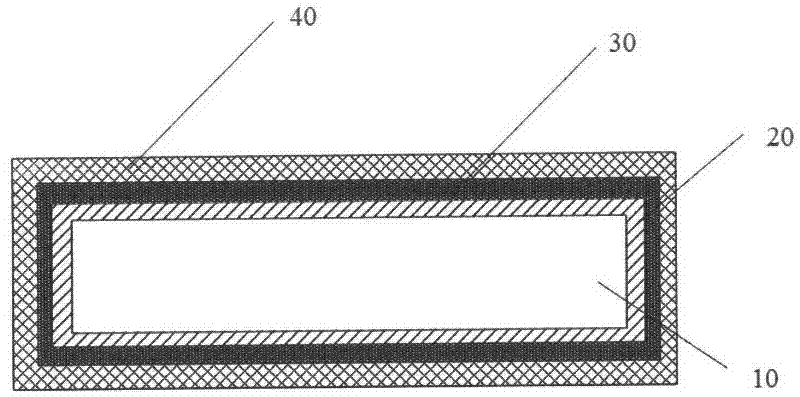

Color printing-type reflecting and light-storing fabric

InactiveCN104635286AGuaranteed reflective effectEasy to useSynthetic resin layered productsGlass/slag layered productsColor printingEngineering

The invention discloses color printing-type reflecting and light-storing fabric, which comprises a fabric layer, an elastic resin layer, a light-storing layer, a color printing layer, a reflecting layer and glass beads, wherein the fabric layer is connected with the elastic resin layer; the elastic resin layer is connected with the light-storing layer; the light-storing layer is connected with the color printing layer; the color printing layer is connected with the reflecting layer; the reflecting layer is connected with the glass beads. According to the color printing-type reflecting and light-storing fabric, the reflecting material has color diversity by adopting a special printing mode under the premise of keeping the reflecting effect of the reflecting material; the reflecting material presents abundant colors; meanwhile, the limitation that the reflecting material only can passively send out light under irradiation of a light source when being used is considered; the material has light storing and light emitting properties, can automatically send out the light in darkness, can be relatively widely applied, and has an all-weather warning function, so that the material has relatively good application space.

Owner:ZHEJIANG YGM TECH CO LTD

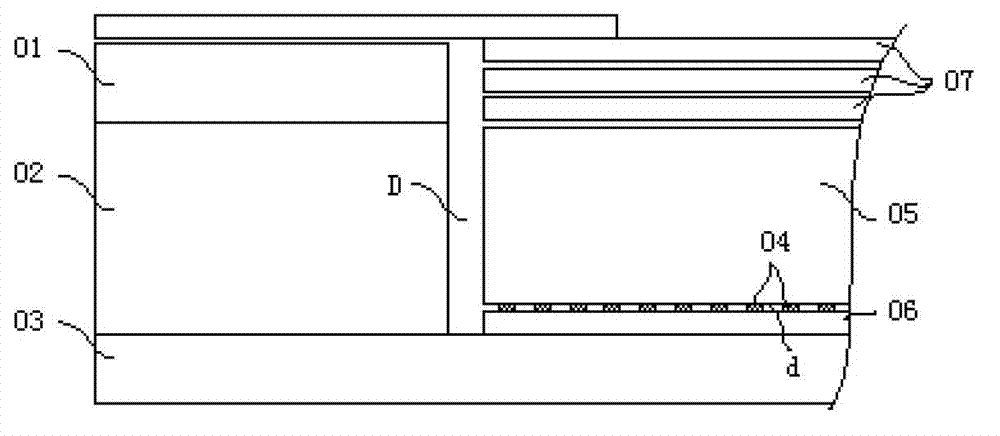

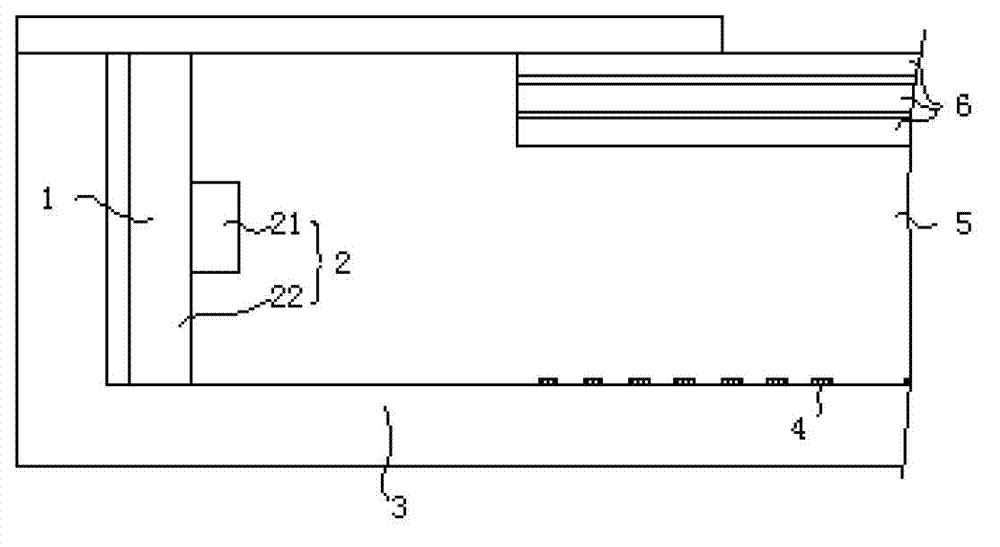

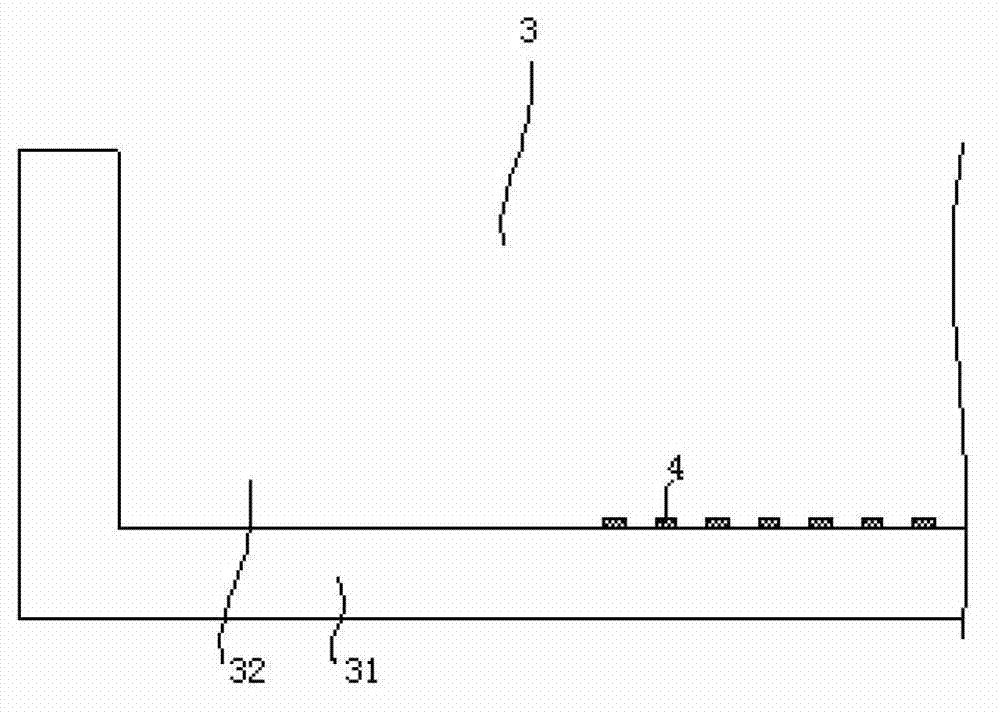

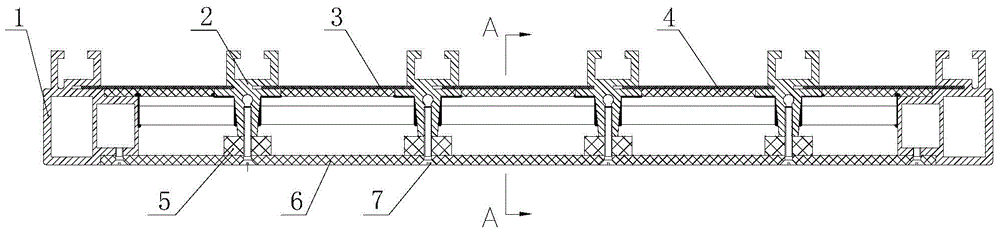

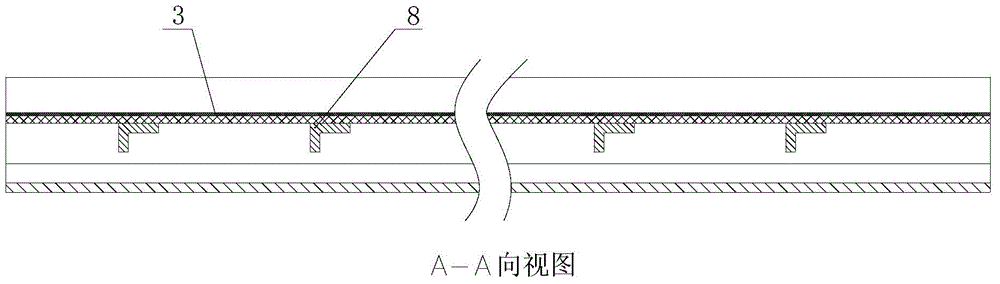

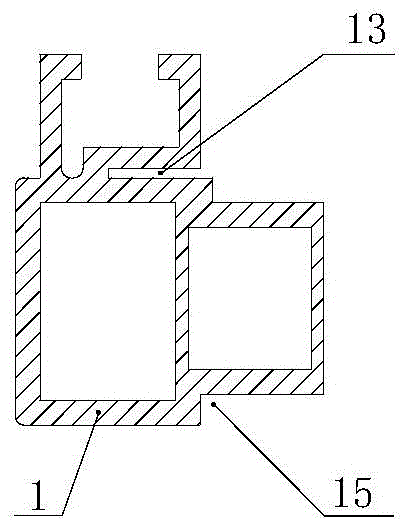

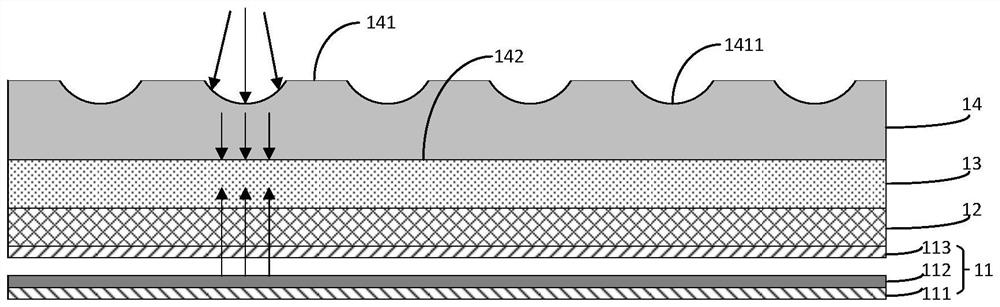

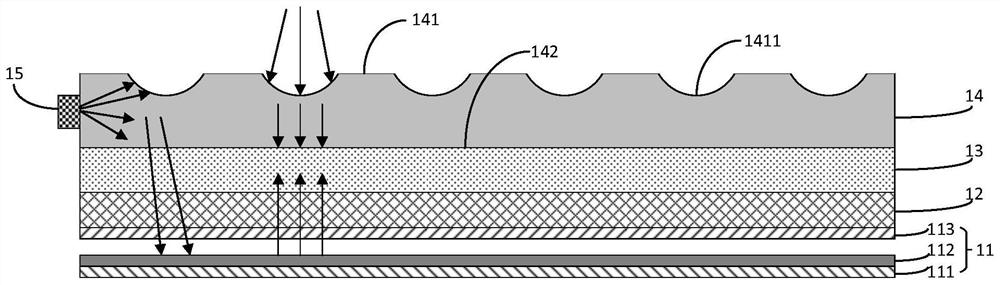

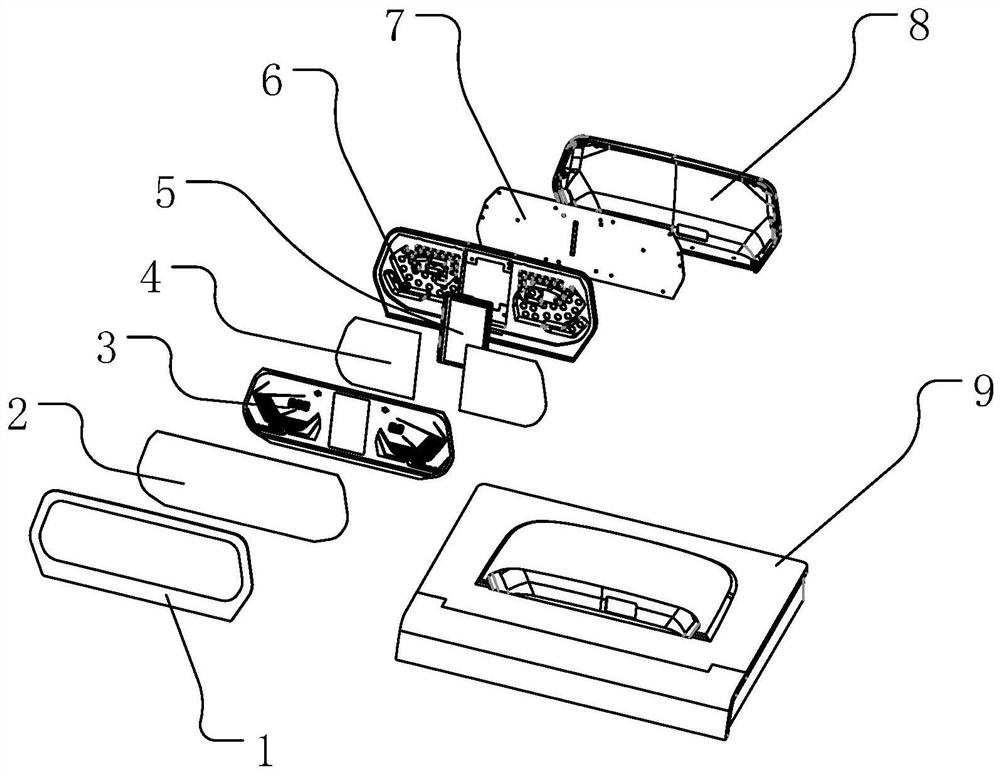

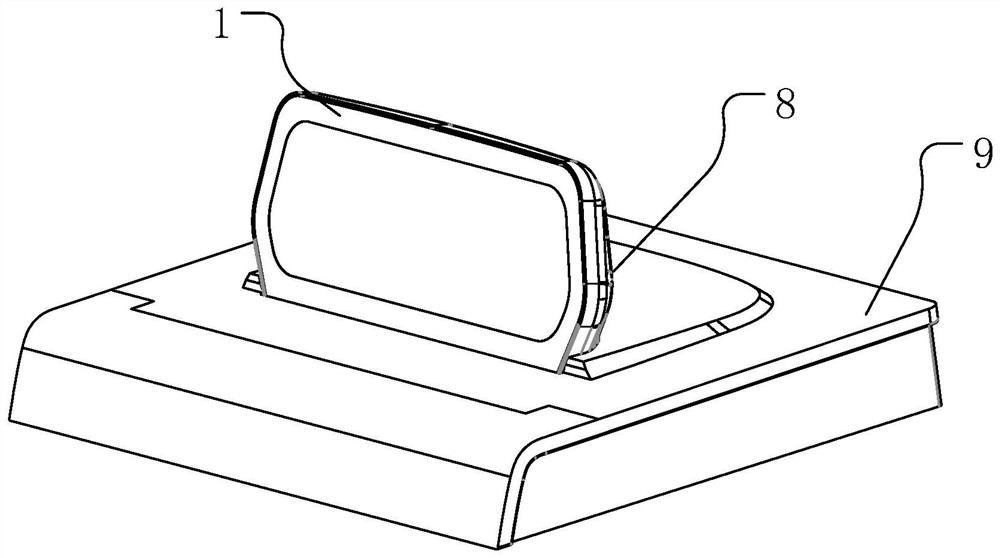

Backlight module, production method thereof and display device

ActiveCN103047584AIncrease profitReflectivePoint-like light sourceLight fasteningsLight guideDisplay device

The invention relates to the technical field of display and discloses a backlight module. The backlight module comprises a back frame with a recessed part, a light emitting diode (LED) light tube group and a light guide plate, wherein the bottom plate of the recessed part is provided with a net point, the bottom plate of the recessed part is made of a plate material with a reflecting layer, the LED light tube group is installed on the side of the recessed part of the back frame, the light guide plate is located in the recessed part of the back frame, and the light guide plate, the back frame and the LED light tube group are integrated through the injection molding. The light guide plate, the back frame and the LED light tube group are integrated through the injection molding, the light emitted by an LED transmits to the light guide plate directly, the light which is reflected by the bottom plate of the recessed part transmits to the light guide plate, when the light emitted by the LED light tube group transmits in the backlight module, the light transmits to few mediums, the loss of the light in the backlight module is reduced, and the light utilization rate is improved. The invention also provides a display device with the backlight module and a preparation method of the backlight module.

Owner:BOE TECH GRP CO LTD +1

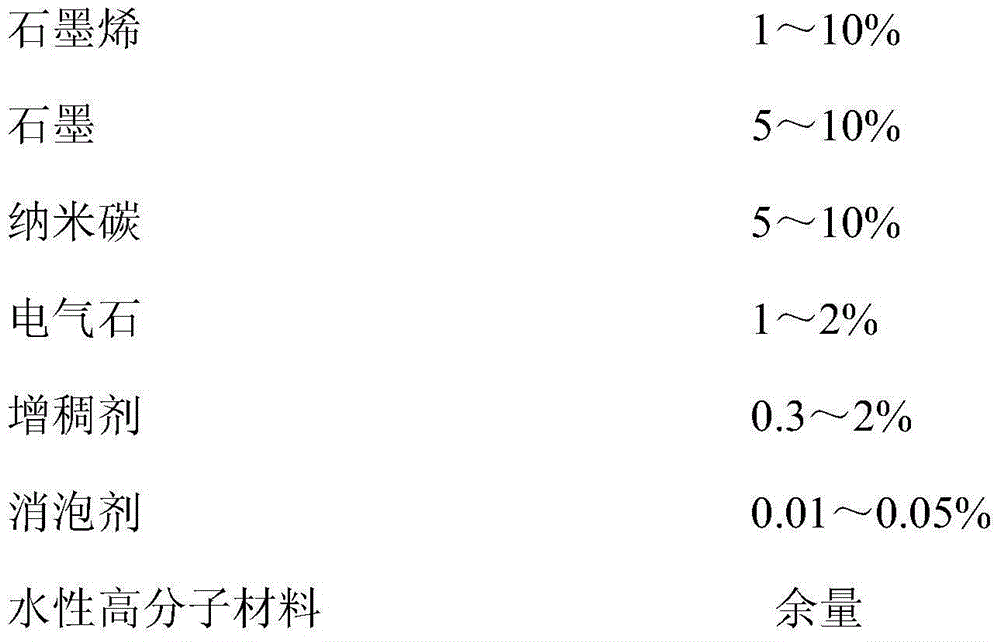

High-efficiency and high-strength composite material with far infrared radiation heating and preparation method thereof

InactiveCN106317728AMetabolism and HealthEfficient and high-strength far-infrared radiant heating energyEnvironmental resistanceElectric heating

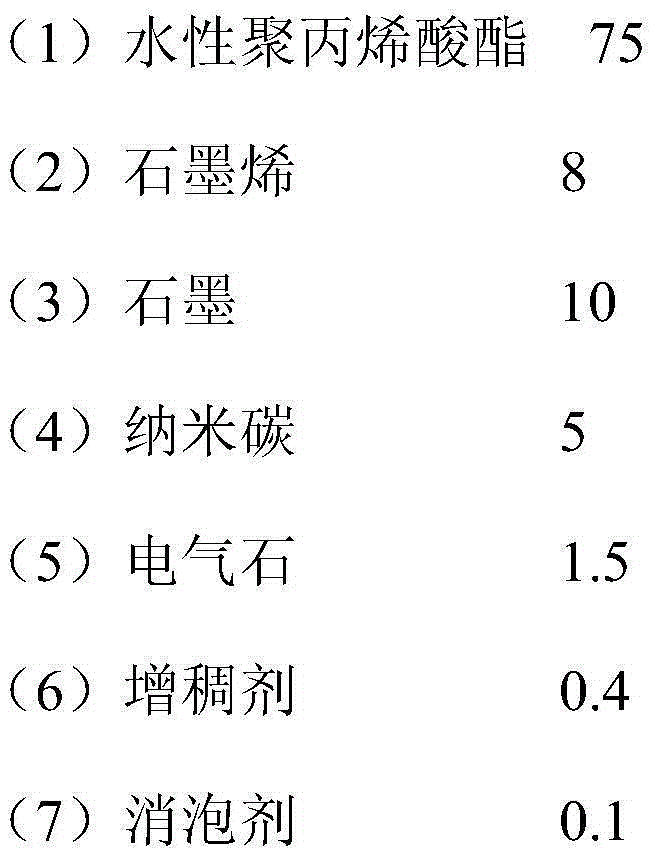

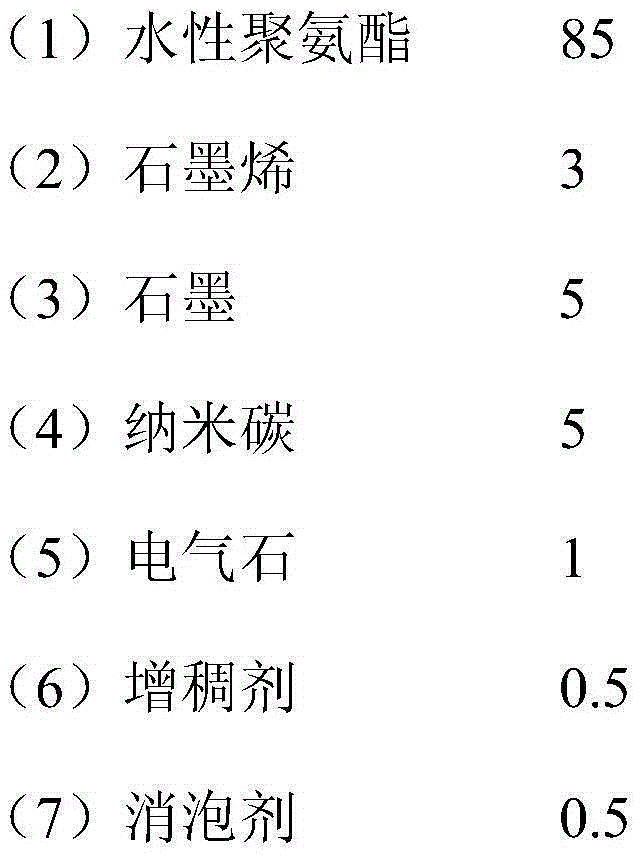

The invention relates to a high-efficiency and high-strength composite material with far infrared radiation heating. The material is characterized in that the material comprises the following raw materials in percentages by mass: 1-10% of graphene, 5-10% of graphite, 5-10% of nanocarbon, 1-2% of tourmalinite, 0.3-2% of a thickening agent, 0.01-0.05% of an antifoaming agent, and the balance being an aqueous high-molecular material. The far infrared composite material comprises graphene, graphite, nanocarbon, tourmalinite, and other powder materials with the far infrared radiation heating function. The material can be widely applied to electric heating, electric heating drying, health care, antibiosis, and other aspects. In addition, the composite material comprises the special tourmalinite material, in order to release a certain concentration of negative oxygen ions, and realize the purpose of air purification and environmental protection.

Owner:SHANGHAI WEIXING NOVEL BUILDING MATERIAL

Method of spraying and coating electric automobile coating piece surface and enabling painting surface to have reflective effect at night

InactiveCN103286052ASolve the poor adhesion between layersSave painting time and energyPretreated surfacesCoatingsMaterials scienceCoating

The invention discloses a method of spraying and coating an electric automobile coating piece surface and enabling a painting surface to have a reflective effect at night. The production method includes the steps of conducting preprocessing, conducting primer spraying and baking, conducting floating coating, conducting naturally leveling and surface drying, conducting finishing coat spraying, conducting baking and the like. The phenomenon that lifting occurs to a sprayed finishing coat when primer is not dried is eliminated, the problem that interlayer adhesion is poor due to excessive baking is solved, meanwhile, spraying time and energy are saved, the finishing coat of a coating piece plays a role in reflecting light, and safety is improved when an electric automobile conducts safe operation at night.

Owner:HEFEI HUAXIN ELECTRIC VEHICLE TECH DEV

Environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and preparation method thereof

The invention provides an environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and a preparation method thereof. The environment-friendly PVC foaming ceiling panel comprises the following components in parts by weight: 90-110 parts of PVC resin, 5-10 parts of polylactic acid, 7-12 parts of polycaprolactone, 10-20 parts of polyester fiber, 50-70 parts of barium sulfate, 3-7 parts of plasticizer, 5-11 parts of stabilizer, 1.7-5 parts of titanium dioxide, 0.6-2 parts of PE (Poly Ethylene) wax, 2-5.5 of processing modifier, 1.4-3.2 parts of anti-impact modifier, 0.7-1.5 parts of composite foaming agent and 20-30 parts of sepiolite. The environment-friendly PVC foaming ceiling panel provided by the invention has the characteristics of environmental friendliness, good weather fastness, high fire resistance, strong scratch resistance, sound insulation, thermal insulation, dust prevention, noise absorption, insect prevention and light reflection and is very suitable for serving as an indoor ceiling.

Owner:安徽济峰节能材料有限公司

Waterborne fireproof heat-insulation paint for wooden building and preparation method thereof

The invention belongs to the technical field of functional coatings, and in particular relates to a water-based fireproof and heat-insulating coating for wooden buildings and a preparation method thereof. The water-based fireproof and heat-insulating paint for wooden buildings mainly includes the following raw materials in parts by weight: 25-30 parts of silicon acrylic emulsion, 10-15 parts of ammonium polyphosphate, 6-8 parts of melamine, 3-6 parts of pentaerythritol, and rutile titanium dioxide 10-15 parts, 3-6 parts of hollow glass microspheres, 2-5 parts of sericite, 2.5-6 parts of hollow ceramic microspheres, 2-4 parts of nano far-infrared ceramic powder, 4-7 parts of diatomaceous earth, water-based enhancer 0.5-1 part of thickener, 0.2-0.4 part of water-based defoamer, 0.4-0.8 part of water-based wetting and dispersing agent, 0.1-0.3 part of water-based antifungal agent, 1-2 parts of film-forming aid, 20-30 parts of deionized water share. The method of the invention is simple, and the prepared coating is fireproof, heat-insulating, mildew-proof, high in adhesion, good in aging resistance, widely used and environmentally friendly, and can be used in wooden buildings for flame-retardant, reducing the temperature rise caused by strong sunlight radiation, and preventing indoor The heat is lost to the outside and other aspects have achieved beneficial effects, effectively protecting the building and saving energy.

Owner:江苏绿能环保集成木屋有限公司

PET anti-grass cloth and production method thereof

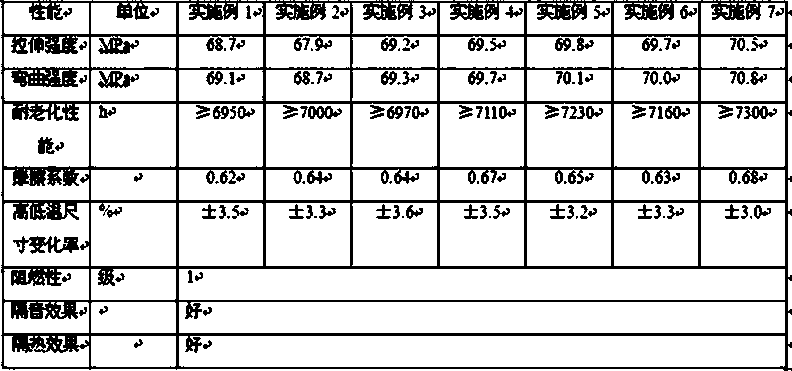

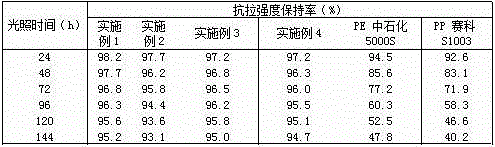

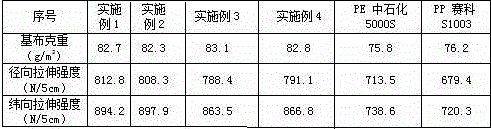

ActiveCN105542401AHigh tensile strengthGood weather resistanceFilament/thread formingWoven fabricsMasterbatchOxygen

The invention relates to a piece of PET anti-grass cloth. The PET anti-grass cloth comprises a PET raw material, auxiliary agents and nano-silver. The auxiliary agents include an anti-oxidant, a filler, an adhesion agent, a flexibilizer and a color masterbatch or include an anti-oxidant, a filler, a flexibilizer and a color masterbatch, wherein the weight ratio of PET raw material to anti-oxidant to filler to adhesion agent to flexibilizer to color masterbatch to nano-ilver is 88-89: 2: 3: 1: 3: 3: 0.1. The tensile strength of the PET anti-grass cloth is improved by 30 to 50%; the PET anti-grass cloth is free of damage after outdoor usage for 2 to 3 years; the PET anti-grass cloth is capable of increasing earth temperature by 1 to 3 DEG C and increasing output by 20 to 40%; and the PET anti-grass cloth has an oxygen index of more than 26 and glossiness of no less than 110%.

Owner:SHANDONG LONGXING PLASTIC FILM TECH CO LTD

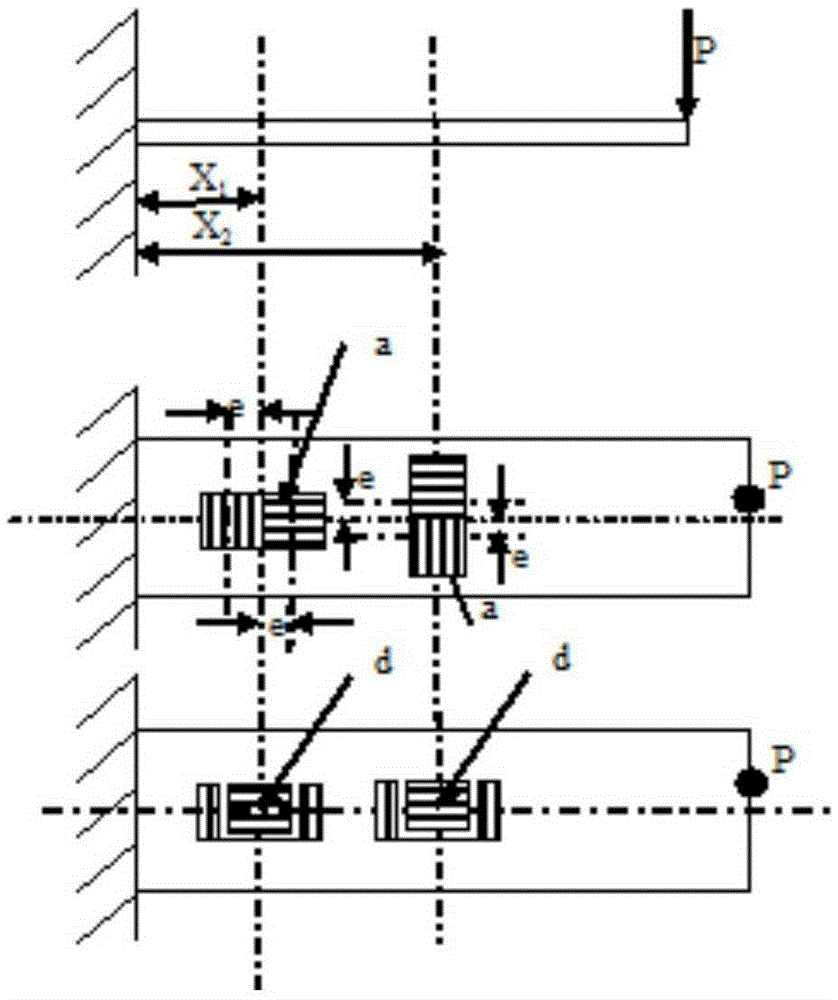

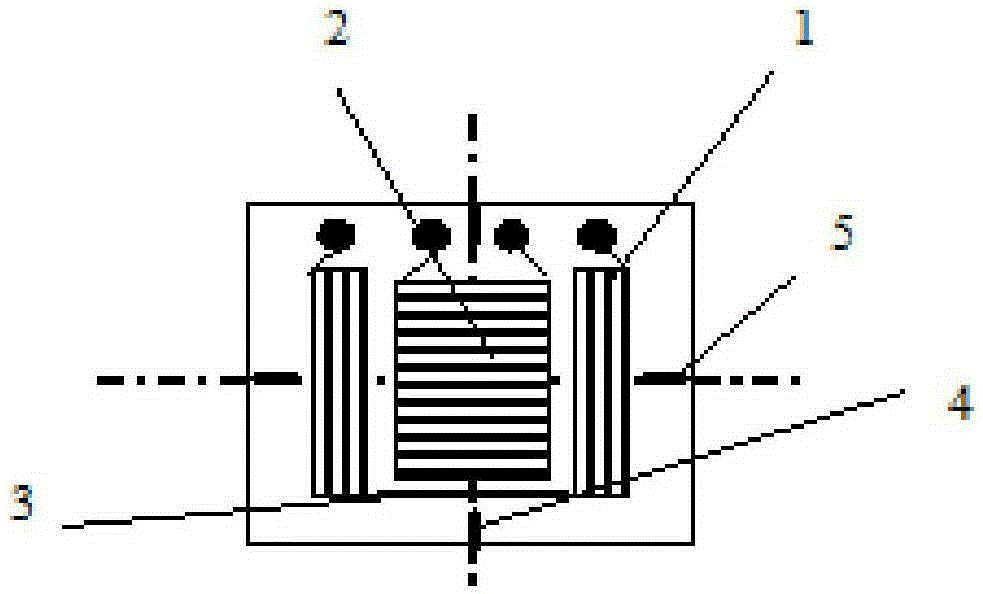

Resistance strain gauge

InactiveCN105241371ASame effectReduce areaForce measurementElectrical/magnetic solid deformation measurementElectrical resistance and conductanceObservational error

The invention relates to a resistance strain gauge. A longitudinal sensitive grid and a horizontal sensitive grid are structurally symmetrical in longitudinal and transverse coordinates, and are used for eliminating measurement error under the effect of non-simple load. The longitudinal sensitive grid is divided into two units, and the two units are connected through a short circuit wire; the short circuit wire and a strain gauge substrate are in non-curing connection; the short circuit wire does not participate in deformation; and the horizontal sensitive grid is embedded in the longitudinal sensitive grid area without overlapping and causing interference, and convenient production is achieved. The longitudinal and transverse coordinates are coordinates having light-reflection performance, so that paste of the resistance strain gauge can be done conveniently under the condition of non-ideal illumination condition. Due to reasonable structural characteristics, the center of the longitudinal sensitive grid and the center of the horizontal sensitive grid are symmetrical with a paste center X1, so that longitudinal and horizontal strain values are same with actual strain values under the action of the bending force P; and the longitudinal and transverse coordinates both have light-reflection performance, so that the paste of the resistance strain gauge can be done conveniently under the condition of non-ideal illumination condition.

Owner:SHANGHAI INST OF TECH

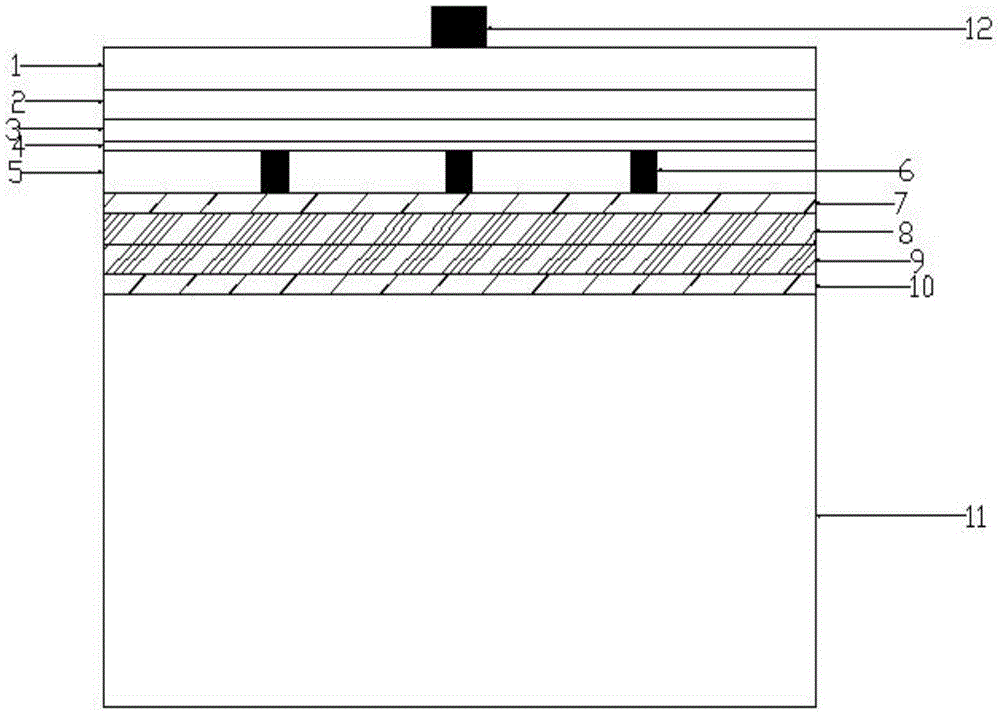

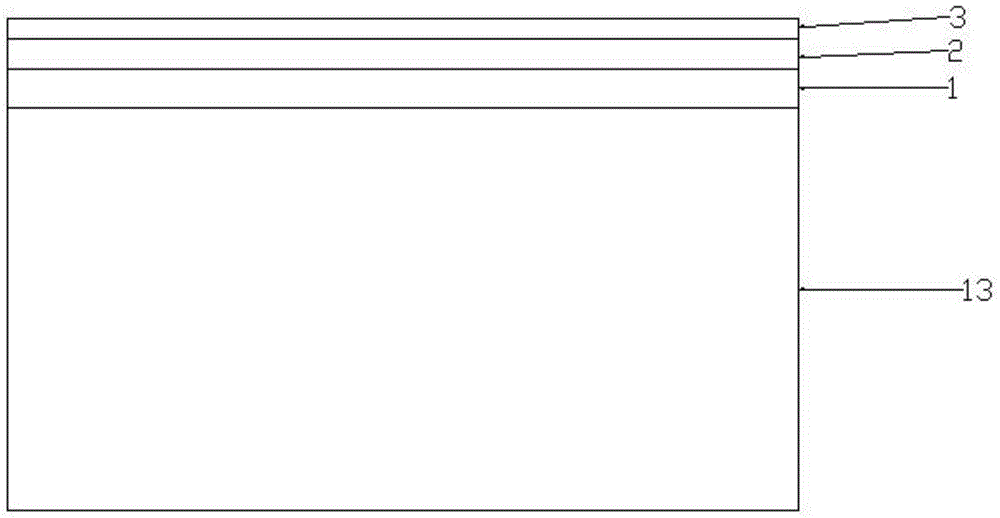

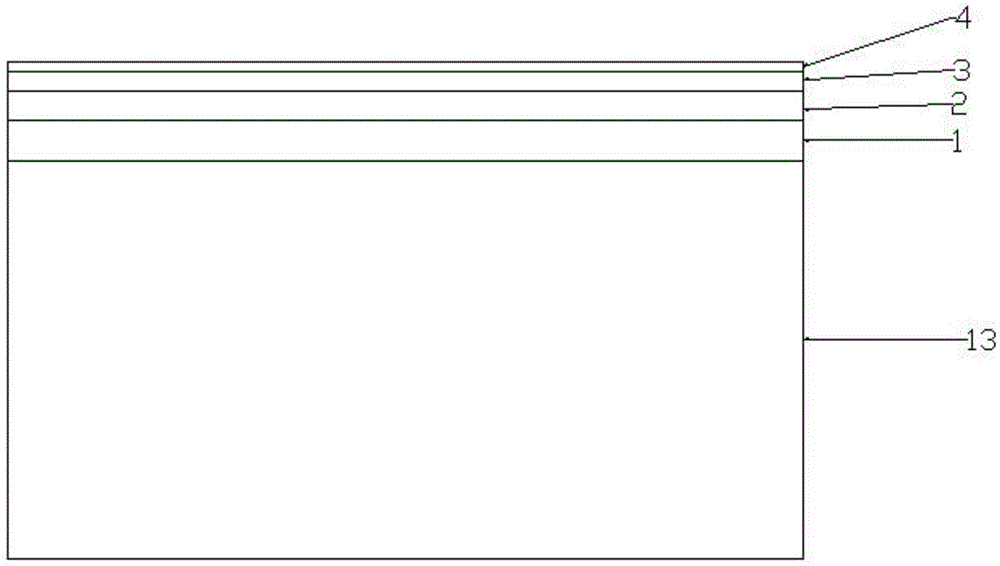

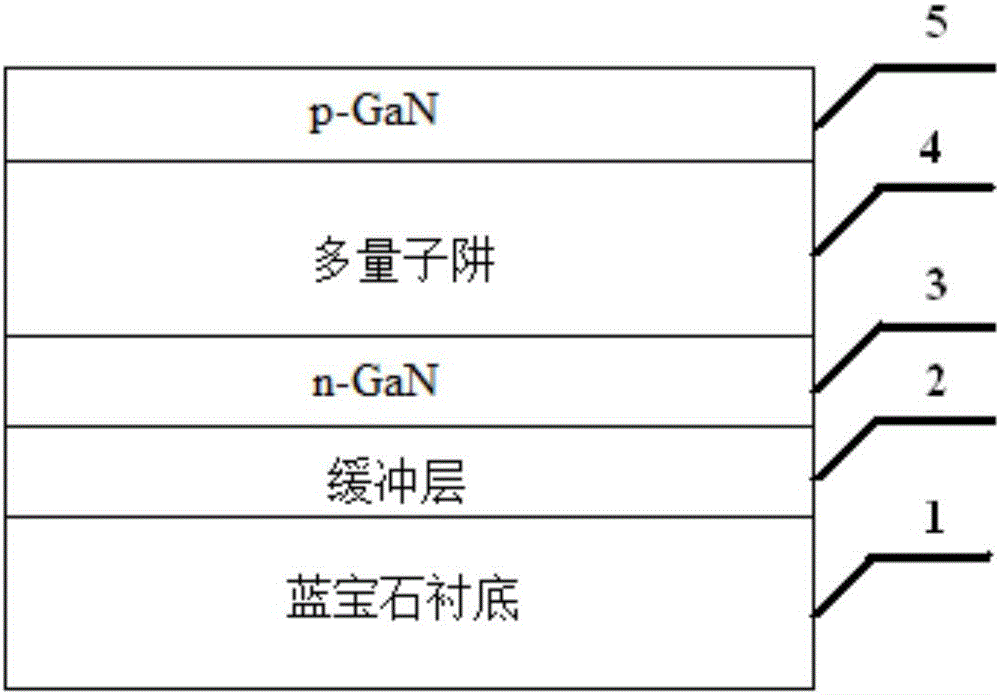

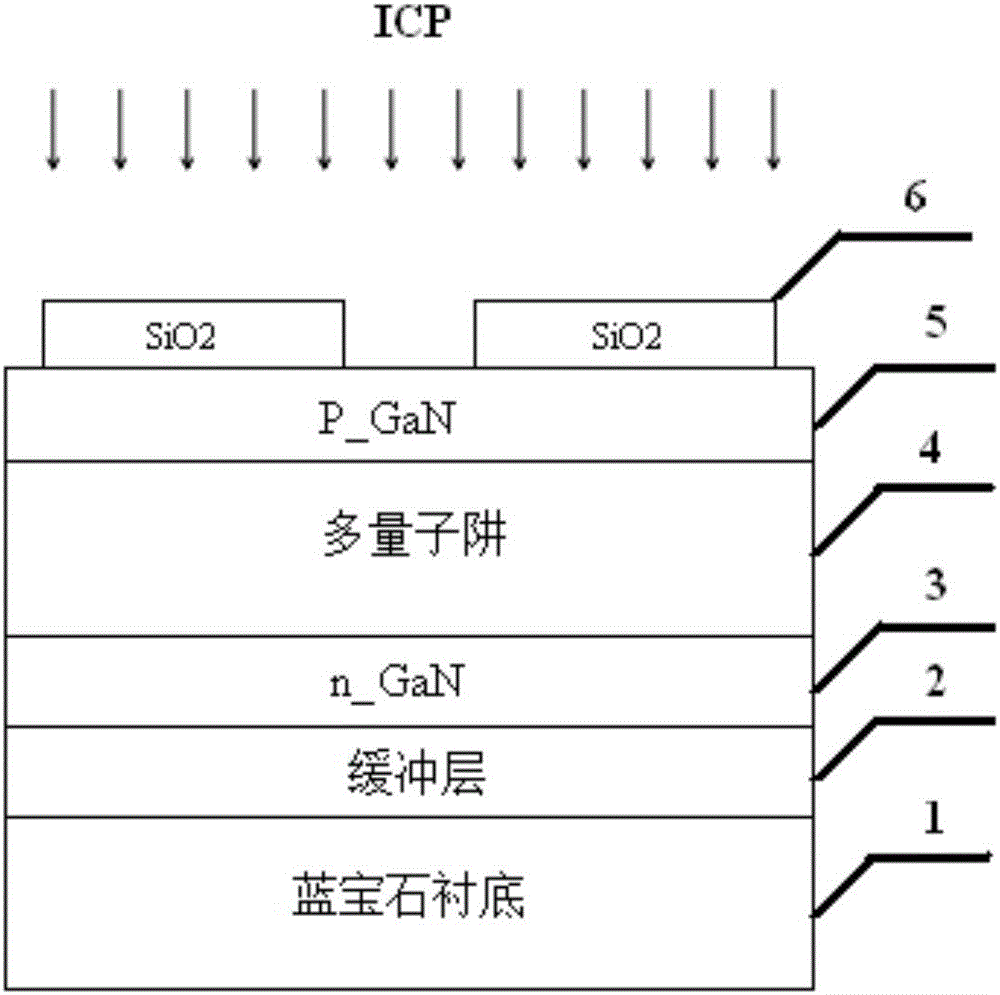

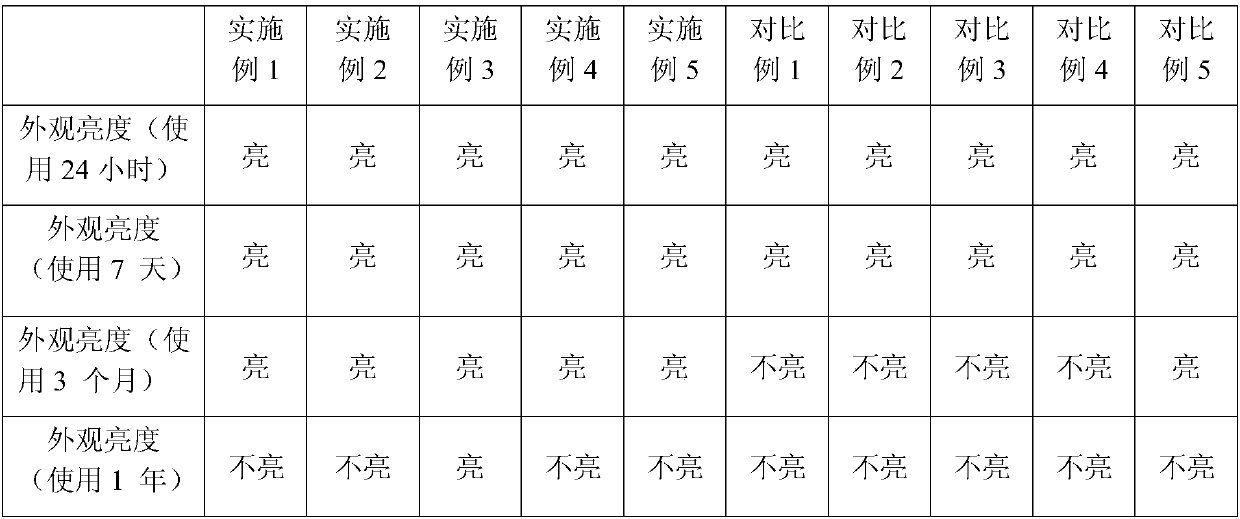

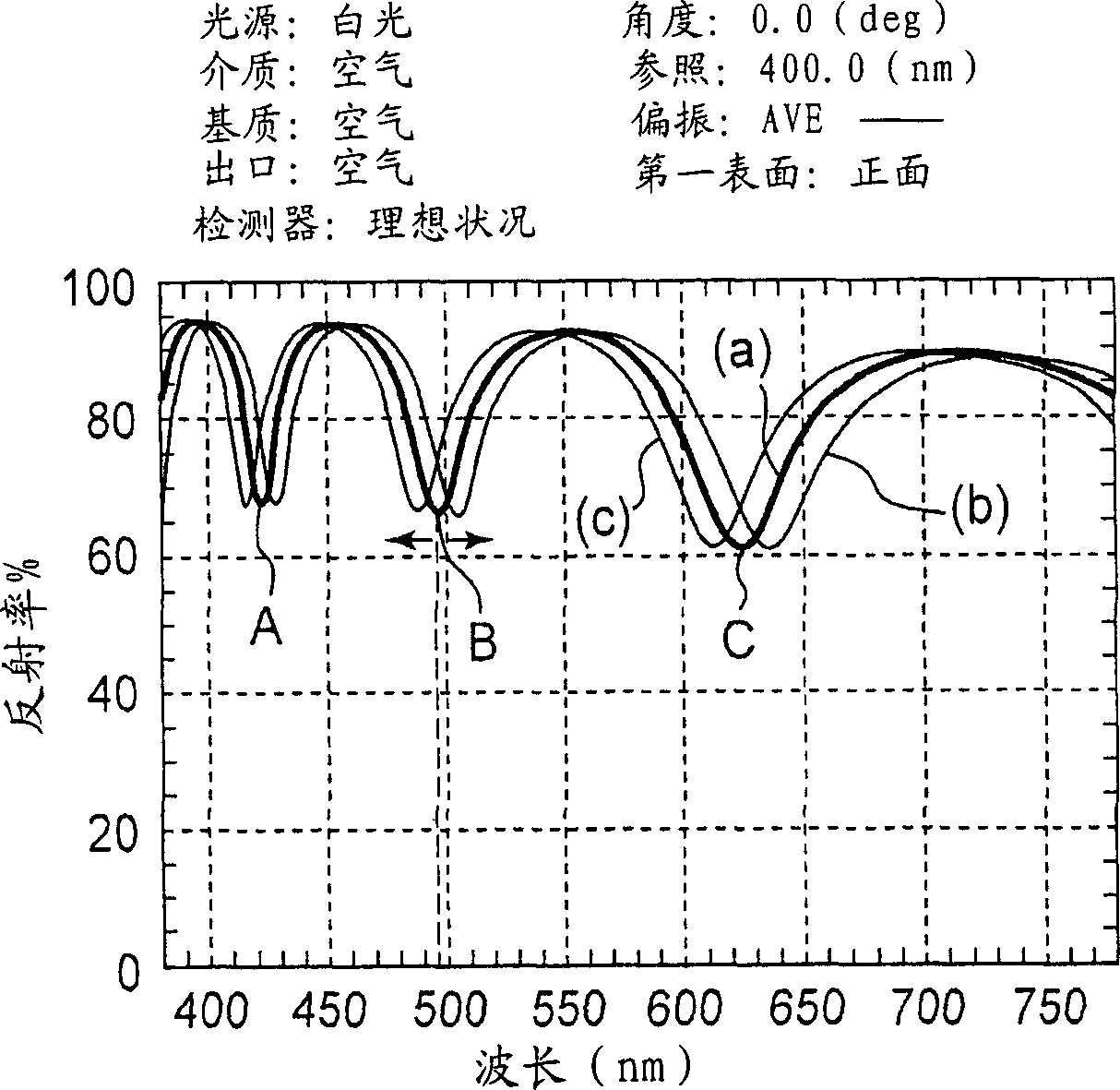

Preparation method of vertical ultraviolet LED chip

InactiveCN105679895AOutstanding FeaturesHighlight significant progressSemiconductor devicesEvaporationUltraviolet

The invention discloses a preparation method of a vertical ultraviolet LED chip, in particular, a method applicable for manufacturing a semiconductor device which is provided with at least one potential jump barrier and is suitable for light emission. A metal current spreading layer Ni / Ag and a DBR are adopted to replace a metal reflective layer of the vertical ultraviolet LED chip, the thickness of Ni in the metal current spreading layer Ni / Ag being controlled in the range of 5 to 10 Angstroms, and the thickness of Ag in the metal current spreading layer Ni / Ag being controlled in the range of 10 to 40 Angstroms. According to the DBR, at first, a SiO2 layer of which the thickness ranges from 4200 to 4400 Angstroms is formed through electron beam evaporation; and TiO2 and SiO2 are evaporated alternately, and evaporation is performed for 4 to 20 cycles, and the thickness of the TiO2 in each evaporation cycle ranges from 278 to 348 Angstroms, and the thickness of the SiO2 in each evaporation cycle ranges from 477 to 596 Angstroms. With the preparation method of the invention adopted, problems caused by the absorption of light by a metal reflective layer in the prior art can be improved, and the illumination brightness of the vertical ultraviolet LED chip can be improved.

Owner:HEBEI UNIV OF TECH +1

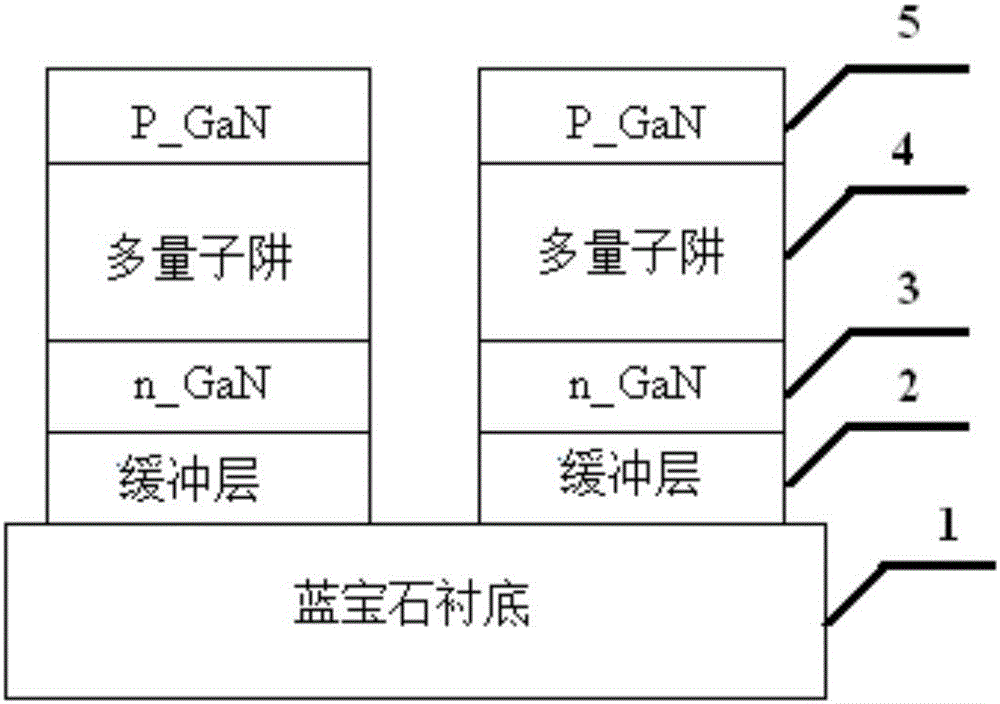

Diamond heat sink GaN-based different-side electrode LED manufacturing method

ActiveCN106784276APerformance impactThe heat dissipation advantage is obviousSemiconductor devicesSputteringEtching

The present invention discloses a diamond heat sink GaN-based different-side electrode LED manufacturing method. The method comprises: performing MOCVD growth of GaN-based LED epitaxial materials on a sapphire substrate; performing ICP etching of the GaN-based LED epitaxial materials of the sapphire substrate, and performing device isolation; performing magnetron sputtering of p-type contact metal, reflective metal and bonding metal on the surfaces of the GaN-based LED epitaxial materials on the sapphire substrate; performing magnetron sputtering of the bonding metal on the surface of a diamond heat sink substrate; performing metal bonding of the GaN-based LED epitaxial materials of the sapphire substrate and the diamond heat sink substrate; performing stripping of the sapphire substrate through adoption of the laser stripping technology; and finally performing magnetron sputtering of n-type contact metal. The diamond heat sink GaN-based different-side electrode LED manufacturing method employs diamond with high heat conductivity to take as a heat sink, LED anodic metal is in metal bonding contact with the diamond, and the heat radiation advantage is obvious; the LED anodic metal is in metal bonding with the diamond in a low temperature to effectively avoid the influence of traditional high-temperature bonding on the LED performance; and the technology is simple in the sapphire substrate leaser stripping process.

Owner:SHAANXI UNIV OF SCI & TECH

TPU thin film with light reflection and thermal insulation functions and preparation method thereof

The invention relates to a TPU thin film with light reflection and thermal insulation functions and a preparation method thereof. The TPU thin film is prepared from, by weight, 50-100 parts of polyester glycol, 15-30 parts of diisocyanate, 5-35 parts of a chain extender, 1-5 parts of molybdenum disulfide micro powder, 1-5 parts of white carbon black, 2-5 parts of metal oxide-modified diatomaceous earth powder, 2-5 parts of dibutyl phthalate, 0.5-1 parts of a titanate coupling agent, 1-5 parts of talcum powder and 1-5 parts of sepiolite. The TPU thin film has the excellent light reflection and thermal insulation functions.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

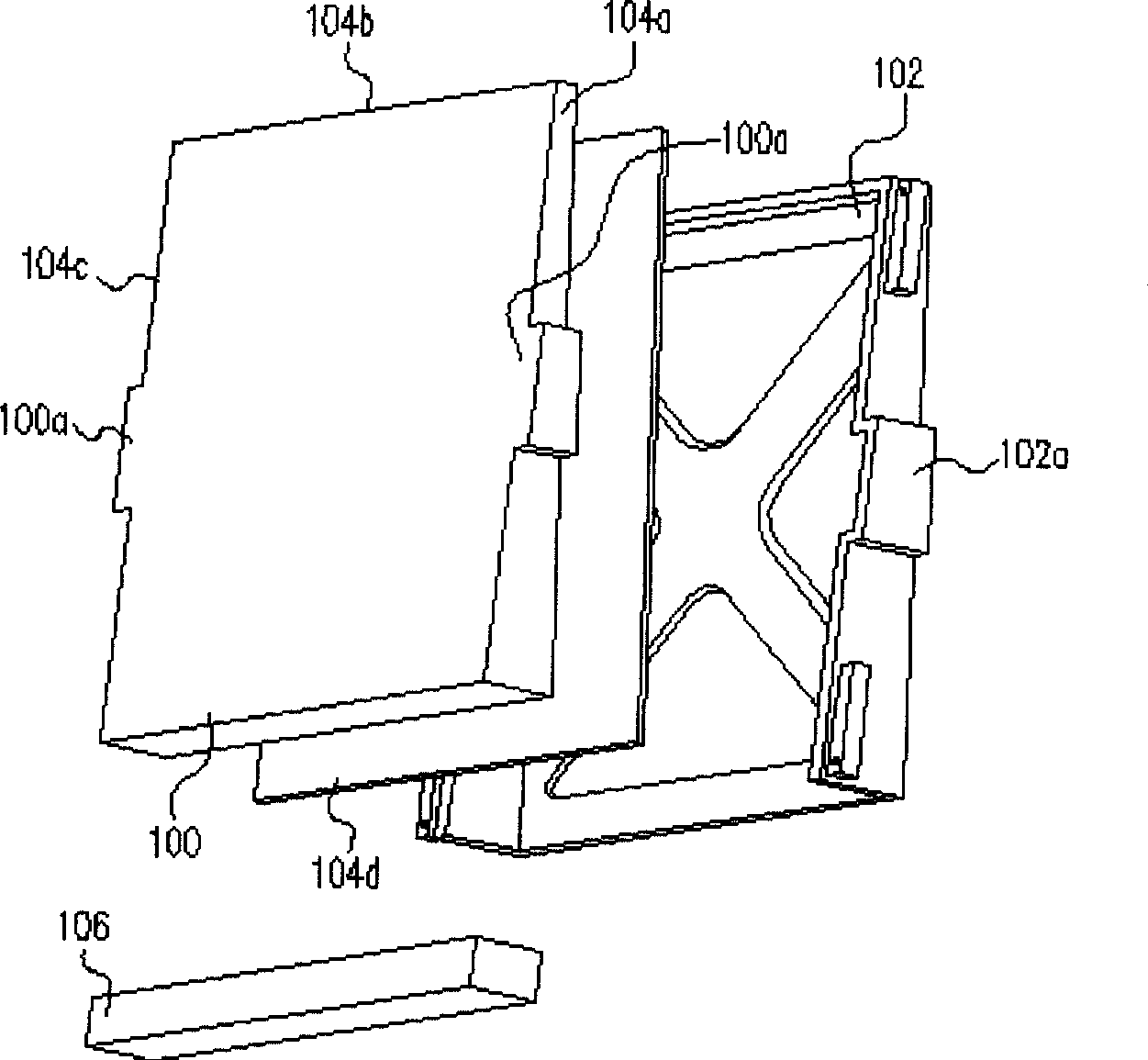

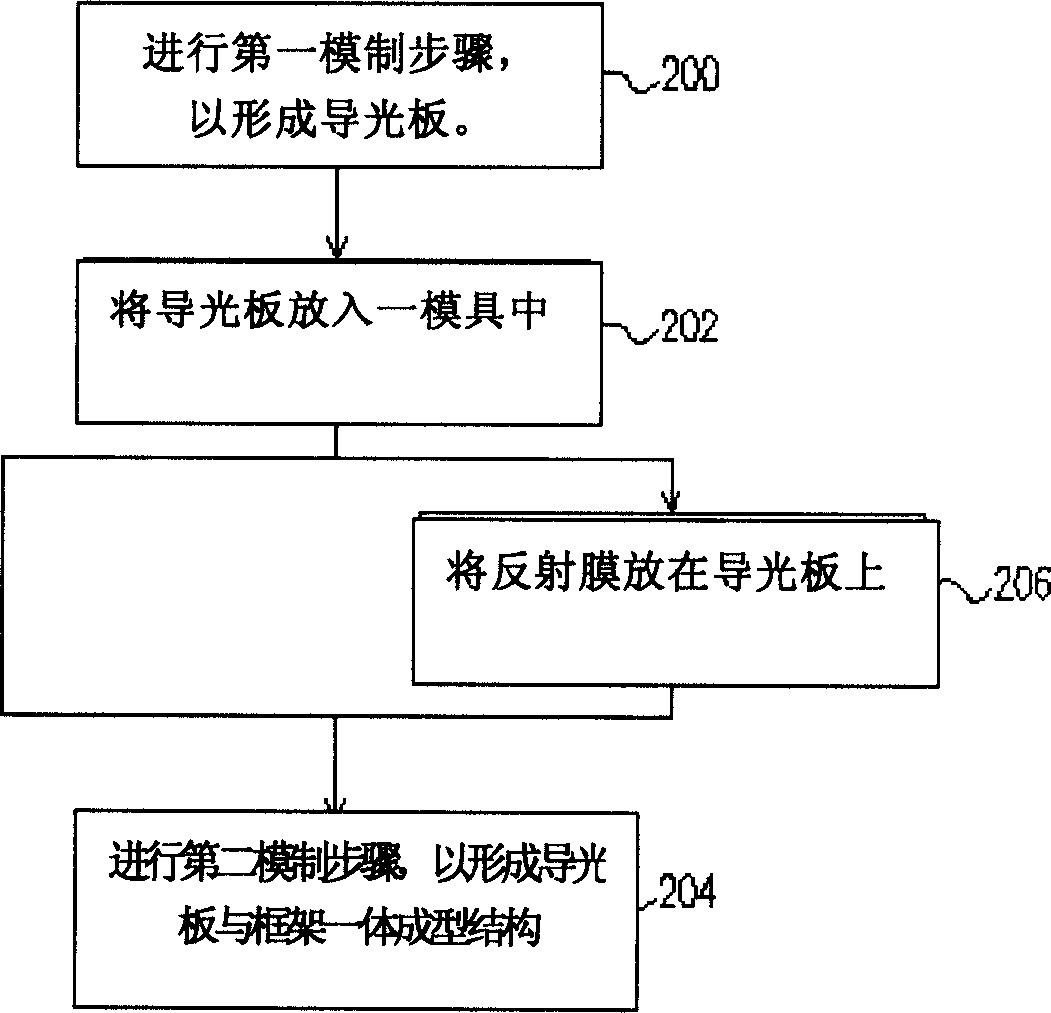

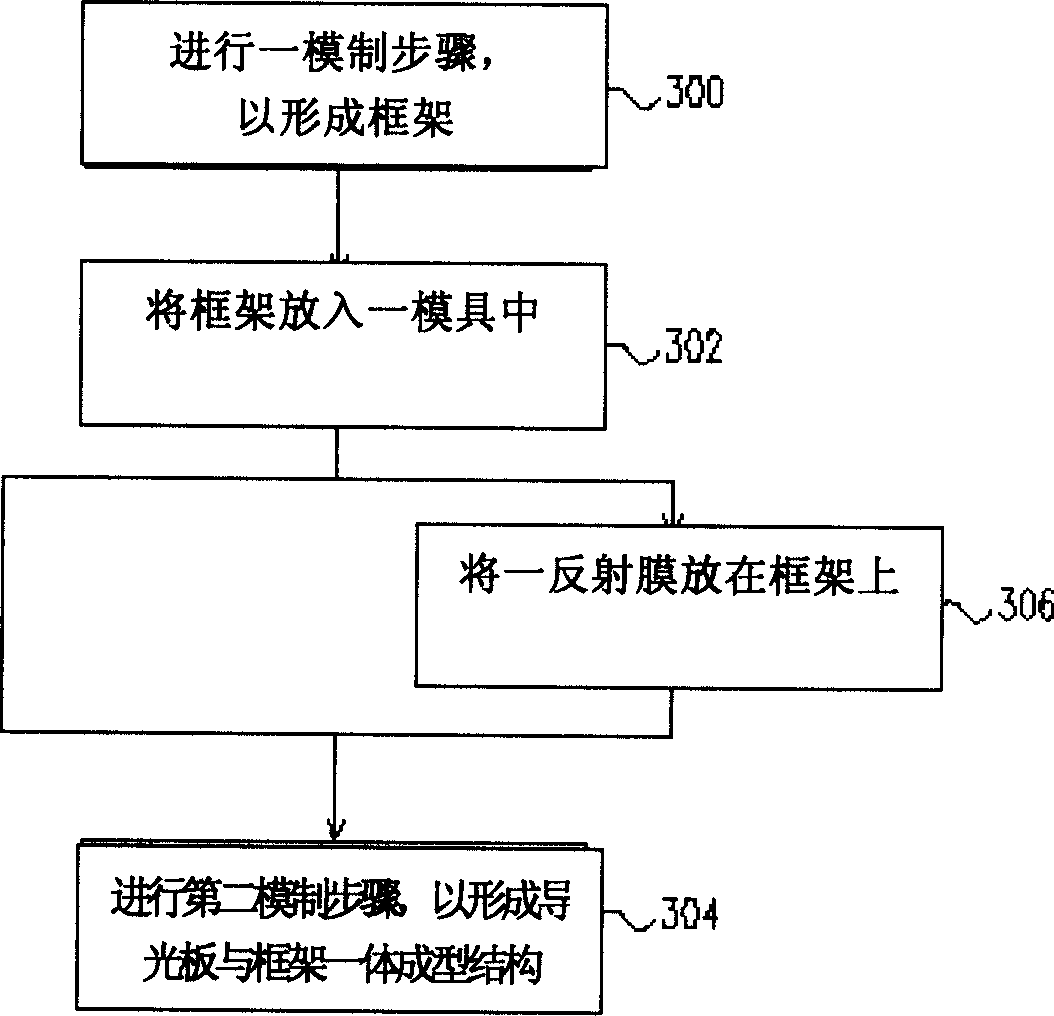

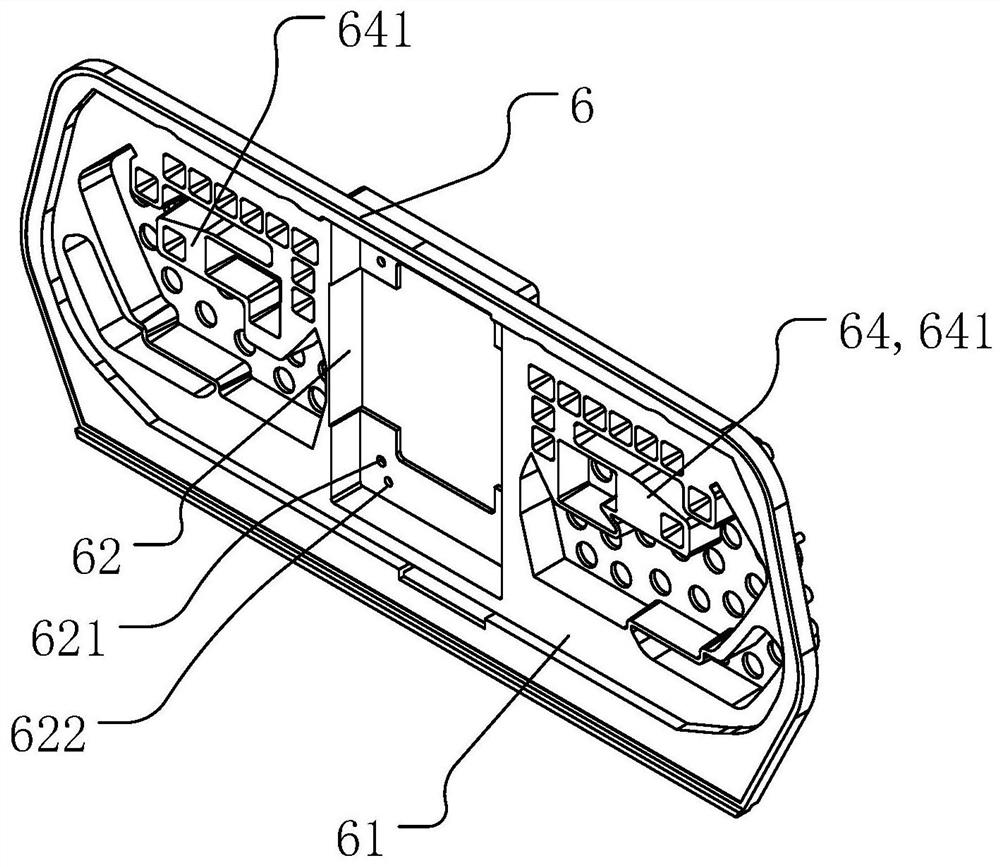

Method for fabricating guiding light plate frame

InactiveCN1696783AImprove bindingSolve the problem of reduced assembly strengthNon-linear opticsLight guideEngineering

A method for preparing light guide plate and frame includes moulding light guide plate and then integrating moulded light guide plate with frame to form one body structure or moulding frame and then integrating moulded frame with light guide plate to form one body structure. The frame is prepared to be light reflecting type.

Owner:TPO DISPLAY

Laminate film

ActiveCN101218098AReflectiveStable film formationMirrorsDiffusing elementsLiquid-crystal displayCarboxylic acid

A white laminated film which has practically sufficient reflectivity at a visible range, can be formed stably, is free from deterioration (yellowing) by ultraviolet radiation, rarely deforms by heat and can be advantageously used as a reflector substrate for liquid crystal displays and internal illumination type electrically spectacular signs, is provided. The laminated film comprises a first layer of a composition which comprises 31 to 60 wt% of inert particles having an average particle diameter of 0.3 to 3.0 µm and 40 to 69 wt% of a polyester consisting of 1 to 100 mol% of naphthalenedicarboxylic acid and 0 to 99 mol% of terephthalic acid as a dicarboxylic acid component and ethylene glycol as a diol component, and a layer B of a composition which comprises 0 to 30 wt% of inert particles having an average particle diameter of 0.3 to 3.0 µm and 70 to 100 wt% of a polyester consisting of 3 to 20 mol% of naphthalenedicarboxylic acid and 80 to 97 mol% of terephthalic acid as a dicarboxylic acid component and ethylene glycol as a diol component and which is in direct contact with the first layer.

Owner:TEIJIN DUPONT FILMS JAPAN

Water-based thermal insulation coating and preparation method thereof

InactiveCN102337062AAvoid heating upEnergy savingReflecting/signal paintsEmulsionWorking environment

The invention discloses a water-based thermal insulation coating, which is characterized by mainly comprising the following components in percentage by weight: 13 to 20 percent of rutile type titanium dioxide, 7 to 12 percent of hollow glass bead, 5 to 10 percent of mica powder, 28 to 36 percent of crylic acid emulsion, 0.1 to 0.2 percent of water-based preservative, 0.2 to 0.6 percent of water-based thickener, 0.1 to 0.3 percent of water-based wetting agent, 0.3 to 0.6 percent of water-based dispersant, 0.1 to 0.5 percent of water-based defoaming agent, 0.1 to 0.3 percent of water-based mildew preventive, 0.2 to 0.3 percent of water-based levelling agent, 4 to 8 percent of water-based aluminum paste and the balance of clear water. The water-based thermal insulation coating integrates three functions, namely blocking, reflecting and radiating functions, can reduce or prevent temperature rise caused by intense radiation of sunlight, and can effectively reduce the temperature in a building on the waterproof basis so as to save energy and improve living and working environments.

Owner:叶氏化工研发(上海)有限公司 +1

Polypropylene modified sound insulation composite material and preparation method thereof

ActiveCN107793637AImprove sound absorptionImprove sound insulationBulk chemical productionAntioxidantAcoustic wave

The invention discloses a polypropylene modified sound insulation composite material and a preparation method thereof. The polypropylene modified sound insulation composite material comprises, in weight percent, 33.8%-88.8% of polypropylene, 10%-60% of modified talcum powder, 0.2% -2% of antioxidants and 1%-6% of additives. The composite material mainly takes the modified talcum powder as a raw material, the modified talcum powder after intercalation modification in a supercritical carbon dioxide state is of a laminated structure in a polypropylene substrate, polymer macromolecules easily enter in the production process of the modified talcum powder, the stripping degree of the modified talcum powder in polypropylene is greatly improved, the reflection frequency of the same weight parts oftalcum powder for sound waves is increased, the composite material has excellent sound insulation effects and better stiffness increasing effects, and sound absorption and sound insulation performances of the composite material are improved.

Owner:中广核俊尔(上海)新材料有限公司

Technique of producing one-component waterproof coating material with polymer copolymerization emulsions as base material

PendingCN101153176AInhibitionIncreased durabilityAntifouling/underwater paintsPaints with biocidesPolymer scienceCarvacryl acetate

The present invention discloses a process technics of a single-component waterproof dope taking macromolecule copolymer latex as the base material; 35 portion of polypropylene acid ester latex and 30 portion of polythene-acetic acid ethylene ester latex are added into a separating machine for mixing evenly in the high speed function mode; 4 portion of dibutyl phthalate, 0.4 portion of dispersant, 0.4 portion of organic silicon defoamer, 3.5 portion of glycol are added to be separated for 10 minutes; and then 15 portion of talcum powder, 15 portion of titanium powder and 15 portion of kaolin are added into a kettle for separated and milled so as to obtain the present invention. The present invention has the advantages of cool construction, stronger weather resisting property, waterproof, seepy, heat resisting and cold resisting, glistening, heat insulated, heat preservation, acid-resisting and alkali-resisting and much higher adhesion intension.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

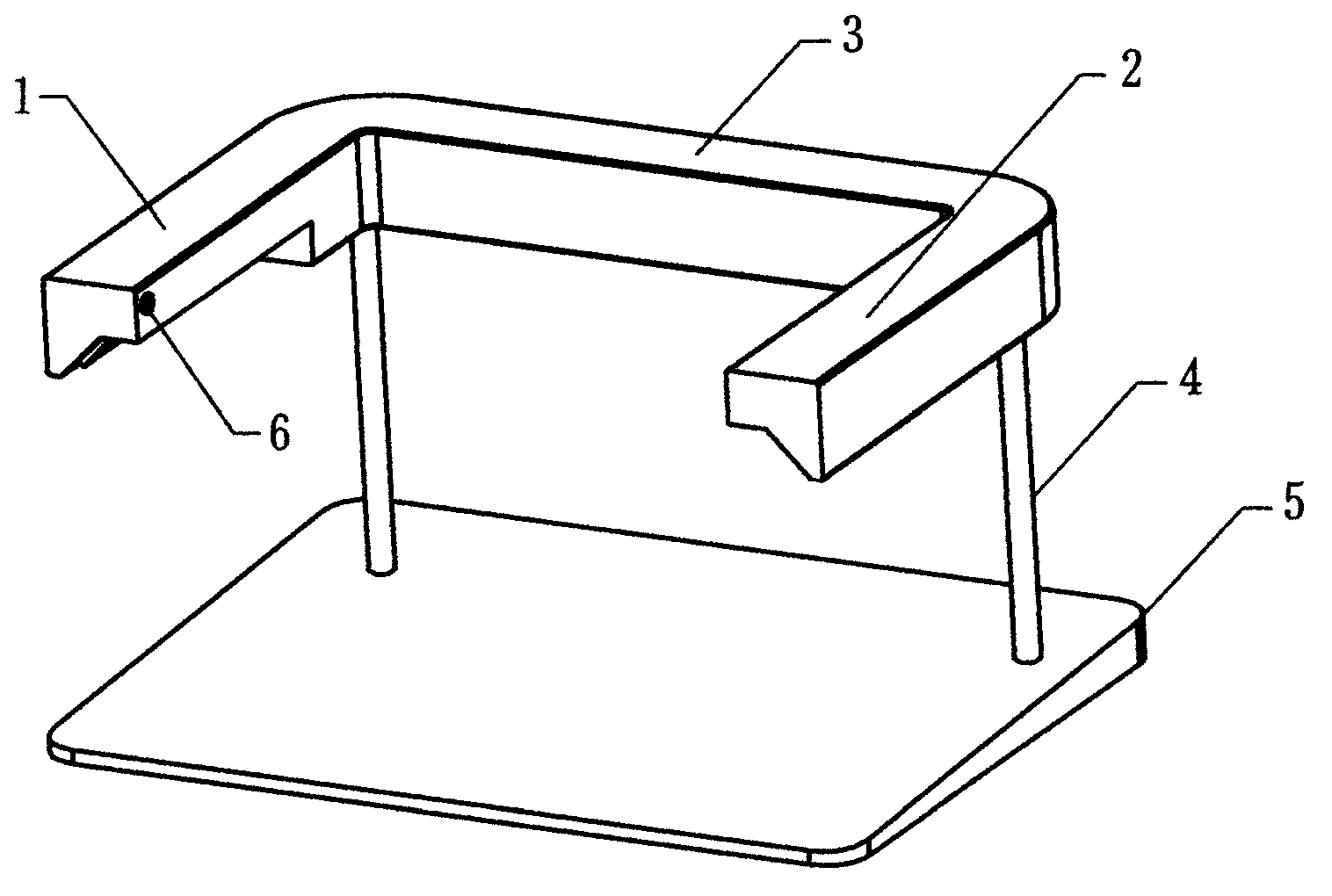

All-transparent type luminous road sign

The invention relates to the field of rod traffic sign manufacturing, in particular to an all-transparent type luminous road sign. The all-transparent type luminous road sign comprises a box body and a bottom plate for the box body which are composed of frame profiles and skeleton profiles. The all-transparent type luminous road sign is characterized in that the skeleton profiles are horizontally arranged in the box body, vertically installed angle aluminums are connected between the frame profiles and the skeleton profiles, a panel of the box body is transparent panel, the ends of the skeleton profiles are fixedly connected with transparent strengthening ribs, and the transparent strengthening ribs are fixed to the inner side of the transparent panel. A reflecting film is stuck on the outer side of the transparent panel. The all-transparent type luminous road sign has the advantages that a sign panel is luminous entirely, and the visual range of the sign is improved; transparent PC alloy is bonded to the pane through the reflecting film, the structural strength is higher through the adoption of the transparent strengthening ribs, the full transparence is realized, and light reflecting function of a common sign is possessed at the same time.

Owner:NANJING SKY TRAFFIC IND

Manufacturing process of signboard

The invention discloses a manufacturing process of a signboard. The manufacturing process is characterized in that the reflective signboard is manufactured by virtue of such processes as conducting surface treatment on the signboard, cutting the signboard, wiping the signboard with alcohol, grinding the signboard, wiping the signboard with alcohol, etching the signboard, printing the signboard, conducting drying treatment, covering the signboard with a film, inspecting the signboard, packaging the signboard and the like. According to the manufacturing process provided by the invention, by wiping the signboard with the alcohol twice, the surface smoothness of the signboard can be improved; by grinding the signboard with reflecting powder on the surface thereof, the reflecting powder can be mixed in the signboard, so that the reflecting performance of the signboard is improved; and by covering the reflecting film on the signboard which is printed and dried, the reflecting performance of the signboard is further enhanced, so that the display effect of the signboard is improved and the service life of the signboard is prolonged.

Owner:ANHUI STARLIGHT LOGO SYST CO LTD

Display panel and display apparatus

InactiveCN112255829AIncrease brightnessTo achieve the spotlight effectNon-linear opticsInput/output processes for data processingDisplay deviceEngineering

Owner:TCL COMM (NINGBO) CO LTD

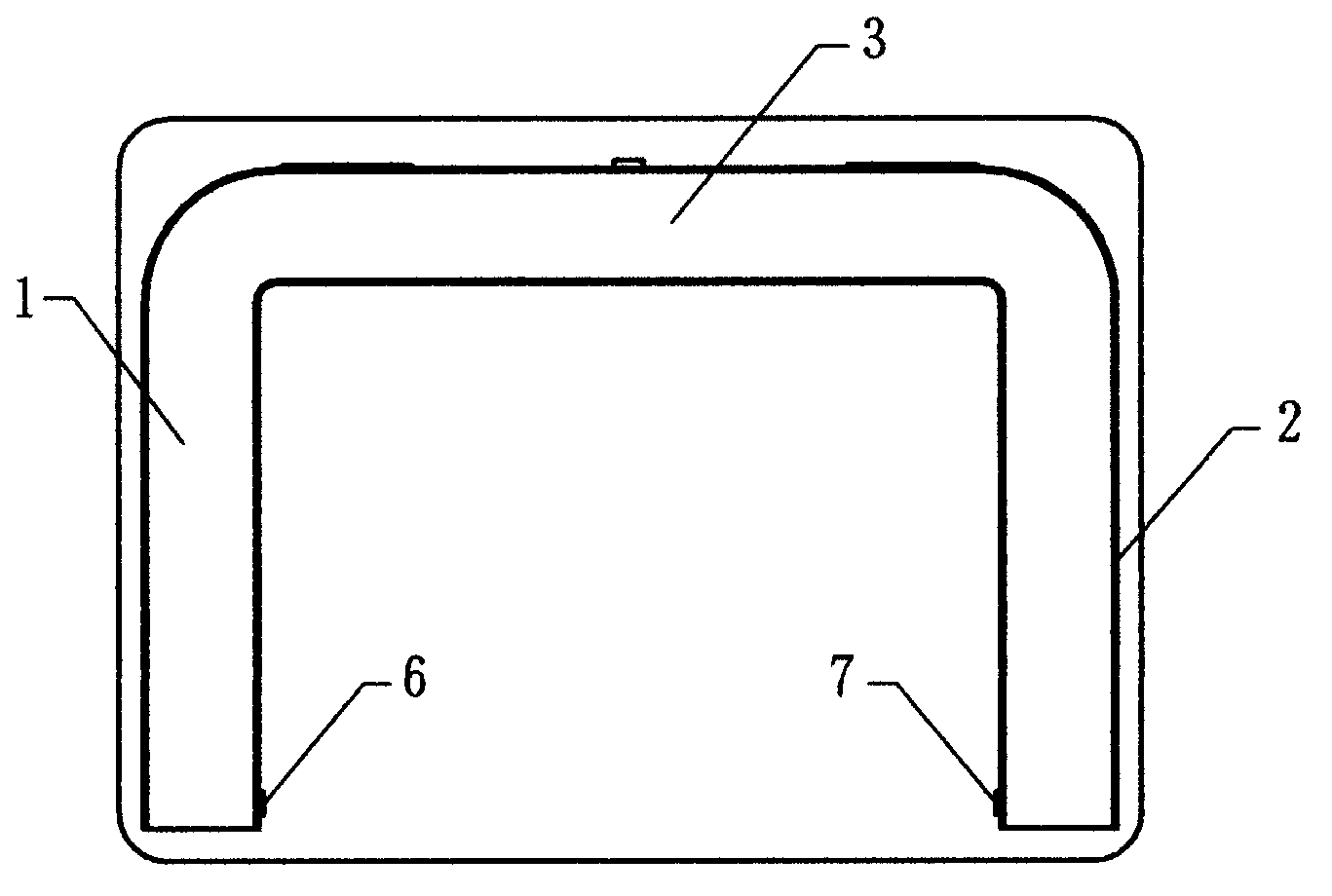

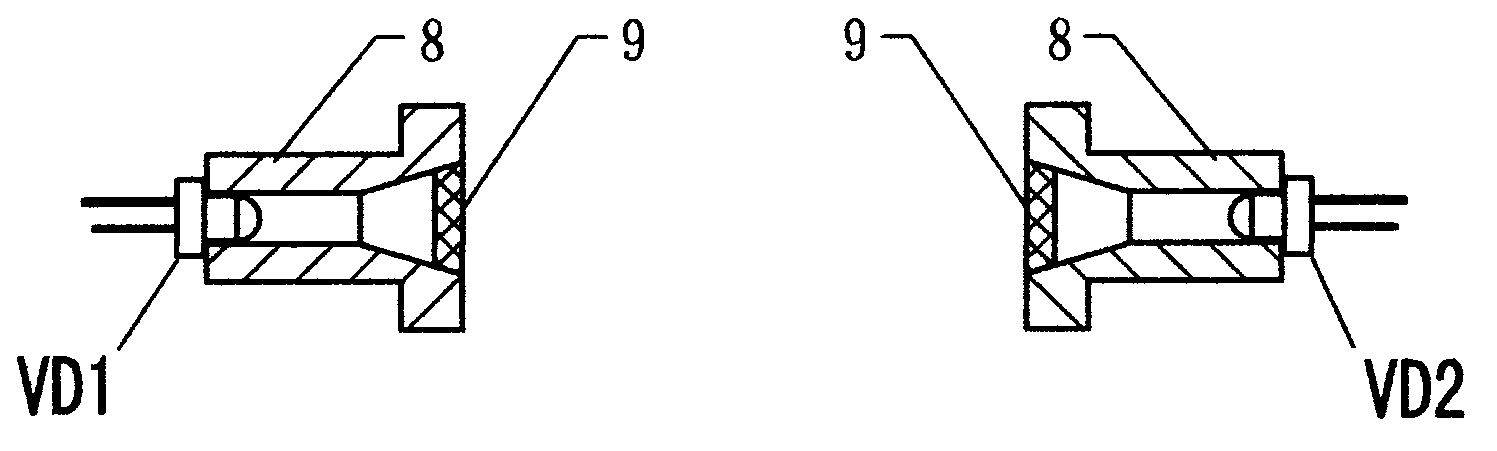

Shadowless table lamp with sitting posture monitoring function

InactiveCN103899969ALow contrast between light and darkMonitor writing distanceLighting support devicesPoint-like light sourceInfraredLight beam

The invention relates to a shadowless table lamp with a sitting posture monitoring function. The shadowless table lamp comprises a U-shaped lamp body and a supporting body, wherein a left lamp cap and a right lamp cap are arranged on the U-shaped lamp body, and an LED light source is arranged in each lamp cap; the two lamp caps are arranged above the two sides of a writing area, and the rear ends of the lamp caps (the ends away from a writer) are connected with the two ends of a common connecting body respectively to form the U-shaped lamp body seeing from an overlook viewing angle. The two sides or the rear of the U-shaped lamp body is provided with an environment light filling lamp. An infrared ray emitting diode and an infrared ray receiving diode are arranged at the opposite positions, close to the front ends, of the two lamp caps, the infrared ray emitting diode and the infrared ray receiving diode correspond in position to form an invisible infrared monitoring light beam, when the head of the user is lower than a specified height, the infrared monitoring light beam is cut off, and an infrared ray monitoring alarm circuit will make a sound for reminding. A lamp rod and a writing board serving as a base are used as the supporting body of the U-shaped lamp body, the surface of the writing board does not reflect light, and the writing board tilts forward slightly to facilitate writing.

Owner:王傲立

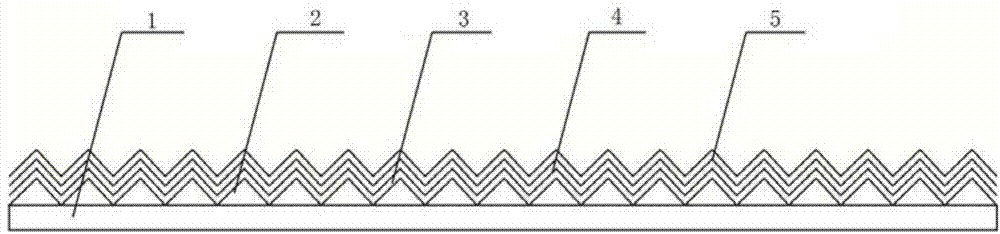

Tunnel reflecting material and preparation method thereof

ActiveCN104847376ASimple processing technologyReduce manufacturing costCovering/liningsUnderground chambersProtection layerEnergy conservation

The invention discloses a tunnel reflecting material and a preparation method thereof. The tunnel reflecting material comprises a baseplate, triangular pyramid, hexagonal pyramid or octagonal pyramid protrusions are arranged on one side face of the baseplate, the side face of the baseplate and the surfaces of the protrusions are sprayed with a color layer, the surface of the color layer is sprayed with a reflecting layer, and the surface of the reflecting layer is sprayed with a transparent protection layer. The tunnel reflecting material is simple in processing process, low in manufacture cost, long in service life and energy saving and mainly applied to tunnels, roads and places with the requirement on improvement of reflecting effect and illumination brightness.

Owner:SICHUAN JIEBANG SCI & TECH CO LTD

TPU film and preparation method thereof

The invention discloses a TPU film. The TPU film comprises, by weight, 90-110 parts of TPU, 0.5-2.0 parts of an antioxidant, 0.5-3.0 parts of special effect powder and 0.5-1.0 part of a processing aid. The special effect powder comprises one of metal powder, pearl powder, organic powder and inorganic powder. The special effect powder and TPU are molten and mixed to form a film. The film does not fade.

Owner:东莞兴正程环保材料科技有限公司

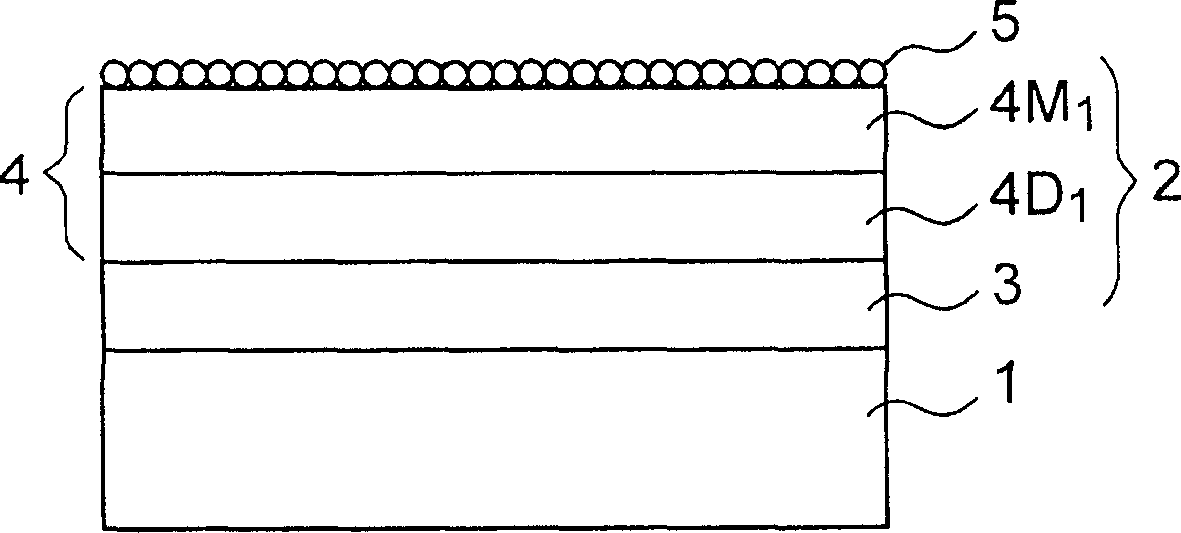

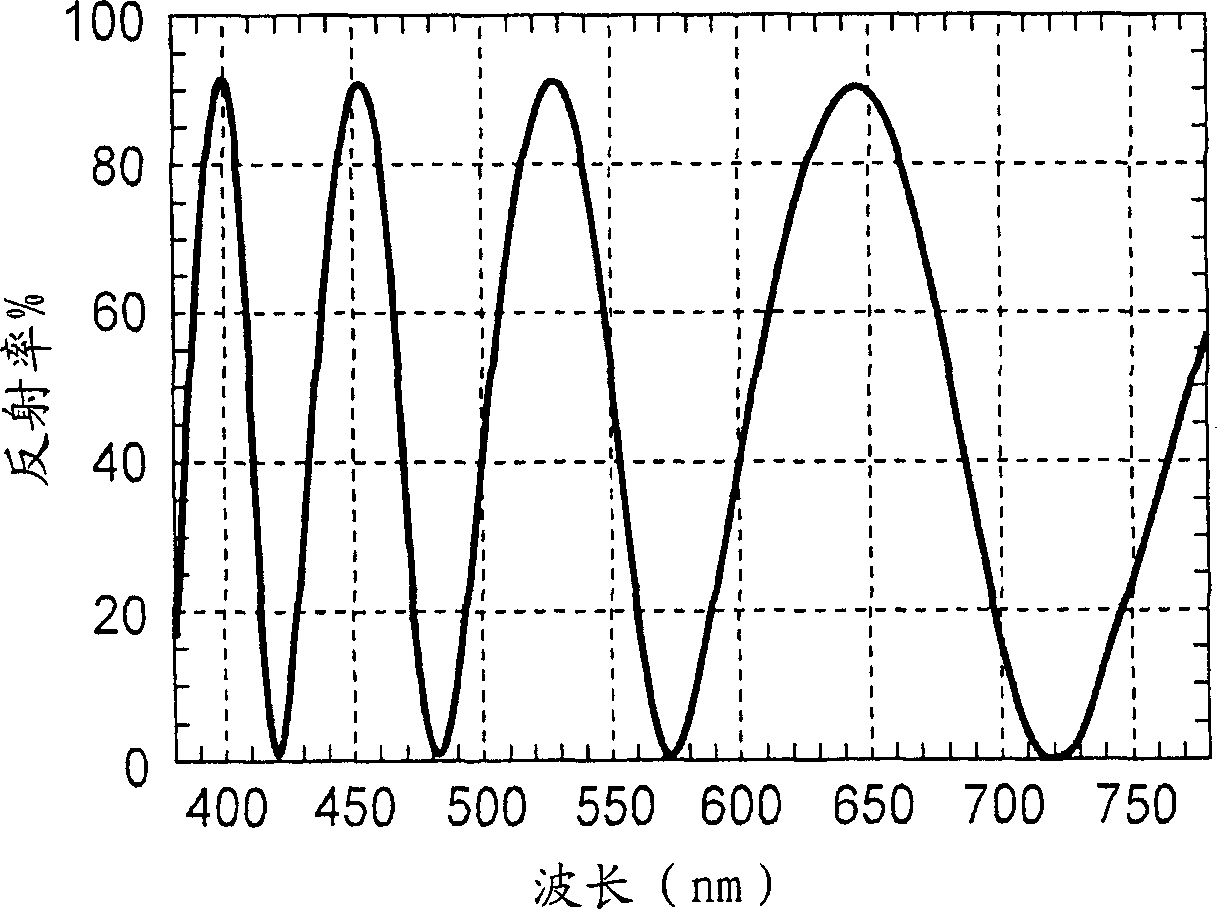

Screen and method for manufacturing the same

InactiveCN1737679AIncrease brightnessIncrease contrastProjectorsSelective reflectionReflective layer

A screen for displaying an image by projection light includes: a selectively reflective layer having reflection properties with respect to light in a specific wavelength region corresponding to the projection light, and having absorption properties with respect to light in a wavelength region other than the specific wavelength region. And the selectively reflective layer includes an optical multilayer film having a dielectric film and a light-absorbing thin film having transmission properties, and a reflective layer for reflecting light which has passed through the optical multilayer film.

Owner:SONY CORP

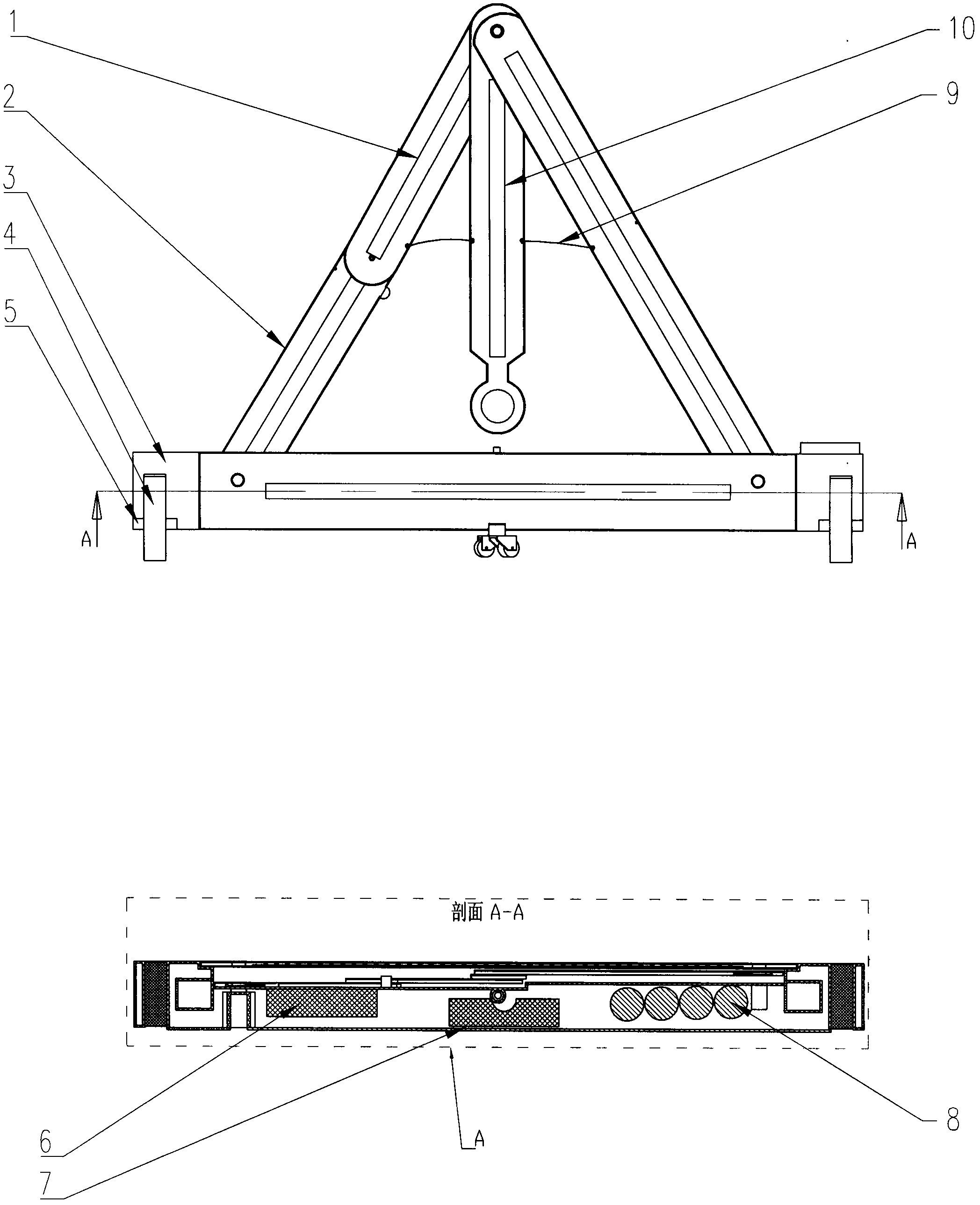

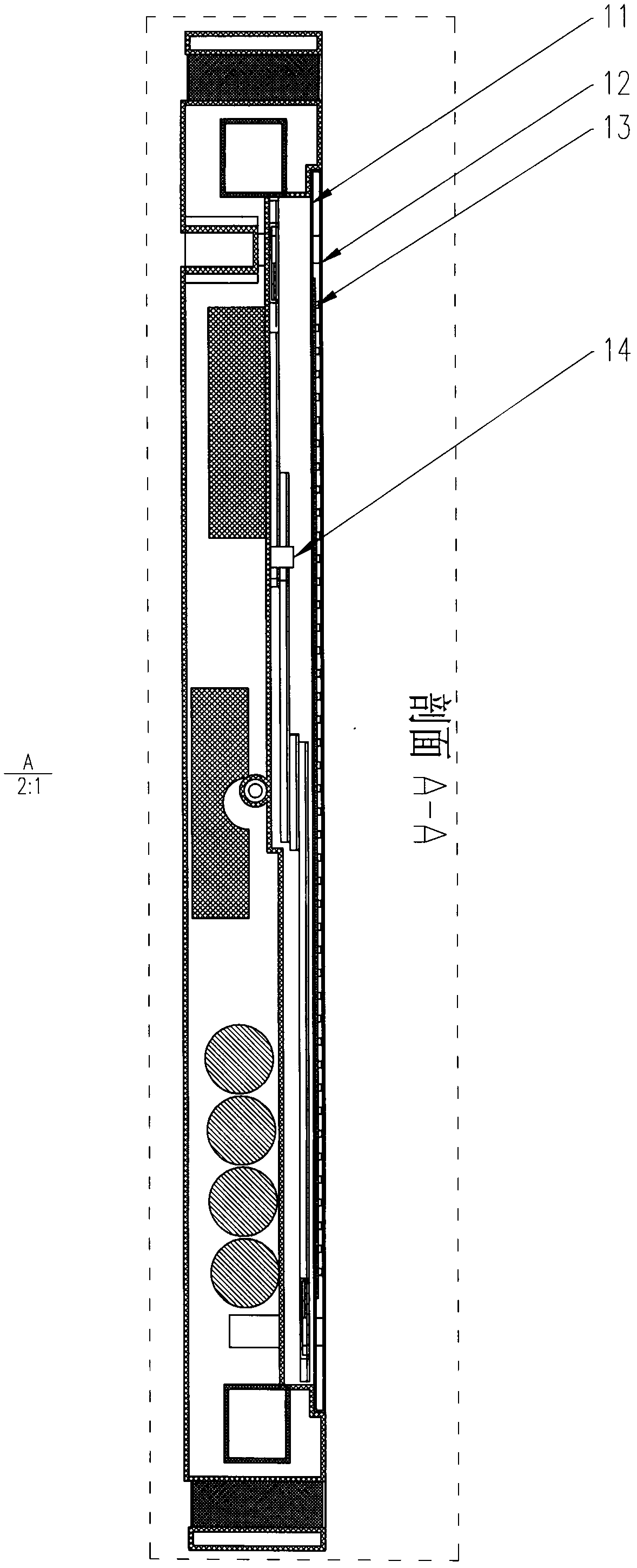

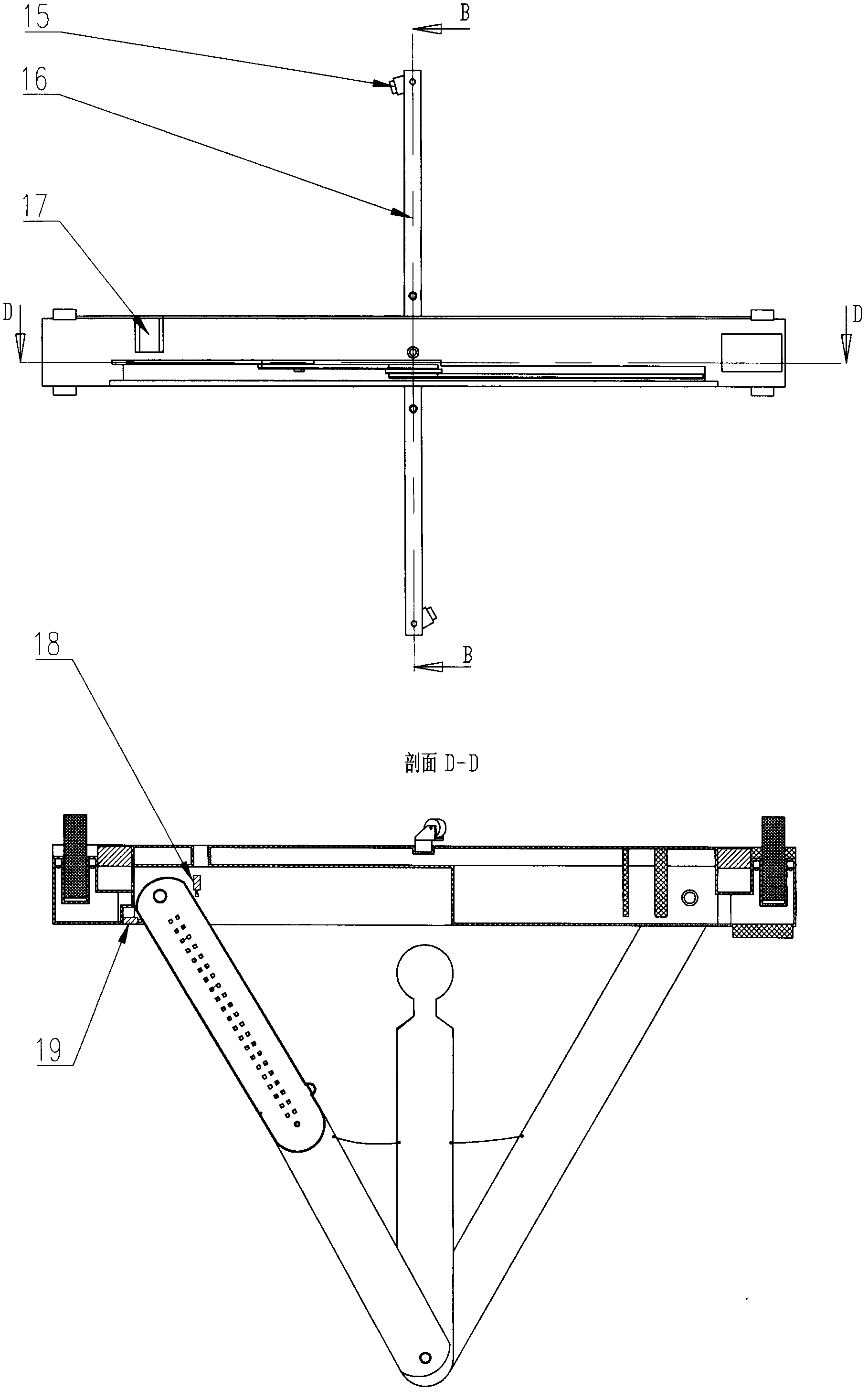

Alarming machine for intelligent automobile

The invention discloses an alarming machine for an intelligent automobile. The alarming machine comprises a lighting slab main body, an electrical appliance control body and a movement mechanism, and is characterized in that: I, the lighting slab main body consists of a lamp bank plate fixing body, a driving axle fixing boring mill, a lamp bank plate LED (Light-Emitting Diode) group, a soft wire and a back cover; II, the movement mechanism comprises a driving wheel, a driving axle, a driving motor, a guide wheel, a guide wheel fixing rod, a guide wheel fixing rod fixing pin, a spring and a spring cover; and III, the electrical appliance control body consists of a remote controller, a main receiving controller, a control board, a position detection switch, a motor, an LED lamp bank group and a power supply; the position detection switch comprises an ascending position detection switch and a descending position detection switch; and the motor comprises an elevating motor and a driving motor.

Owner:太仓鸿羽智能科技有限公司

Method for manufacturing composite coating on base material and section bar obtained therethrough

InactiveCN102501434AHigh hardnessReflectiveLaminationLamination apparatusAdhesion forceMetal clusters

The invention provides a method for manufacturing a composite coating on a base material. The method comprises the following steps: 1, coating at least one bonding layer on the surface of the base material to obtain the base material with the bonding layer; 2, coating at least one metal layer on the base material with the bonding layer to obtain the base material with the metal layer; and 3, coating at least one anticorrosion layer on the base material with the metal layer. According to the composite coating in the embodiment of the invention, the bonding layer is a bottom layer, the metal layer is an intermediate layer, and the anticorrosion layer is a surface layer, so the coating can be attached to the base material without polishing; adhesion force between the coating and the base material is strong, and the surface layer hardness which is high can reach 4H; the surface layer which has a metal cluster has a reflective property, so the anticorrosion effect same as anticorrosion effects of common electroplating effects can be reached; and no electroplating is needed, so no discharge pollution, low energy consumption and low cost are realized in the production process.

Owner:徐为尔

Automobile instrument panel and automobile

ActiveCN111660810AReflectiveImprove stabilityDashboard fitting arrangementsDashboard lighting devicesDashboardLight guide

The invention provides an automobile instrument panel and an automobile. In the automobile instrument panel, a segment code screen and a color film are bonded to form a segment code screen assembly. Aback surface of a cover plate is fully laminated with a front surface of electrostatic glass through a third adhesive film to form a cover plate glass assembly; the back surface of the cover plate glass assembly is fully attached to the front surface of the segment code screen assembly through a first adhesive film; the back surface of the segment code screen assembly is fully attached to a colorliquid crystal display screen through a second adhesive film; and a screen cover part is adhered to a light guide cover, a first backlight source and a circuit board are fixedly connected with the light guide cover through the same fastener, a back shell is fixedly connected with the light guide cover to form an outer shell of the automobile instrument panel, and a first mounting structure connected with a deck plate of an automobile instrument table is only arranged at a lower part of the outer shell. According to the automobile instrument panel, through a structural design, technical problems of light leakage and inconvenience in mounting, dismounting and maintenance in the prior art can be solved.

Owner:HEILONGJIANG TIANYOUWEI ELECTRONICS CO LTD

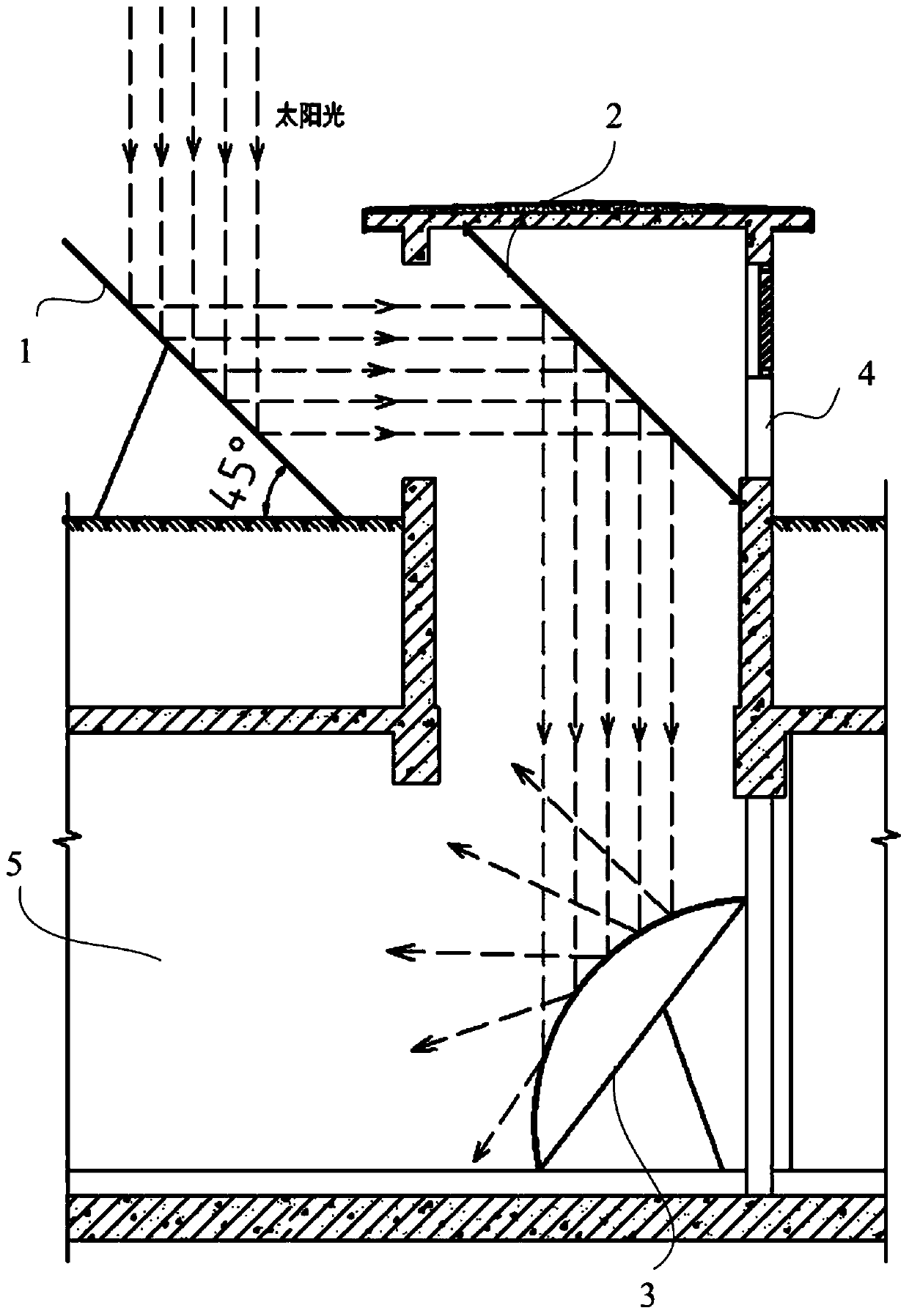

Lighting compensation device for basement construction, and construction method

The invention relates to the technical field of building construction tool equipment, in particular to a lighting compensation device for basement construction, and a construction method. The problemsthat existing basement lighting adopts a lamp lighting mode, as for construction lighting of special places such as civil air defense engineering and humid environments, a safety voltage or an even lower voltage needs to be adopted, and consequently the lighting brightness may be insufficient are solved. The lighting compensation device is composed of two plane mirrors and a convex mirror; lightrays are reflected through the glass mirrors, and the light rays are utilized through the reflective characteristics of the plane mirrors and the convex mirror; and as for a basement part with openings such as ventilating shafts, the plane mirrors and the convex mirror are combined into a device similar to a periscope, outdoor sunlight is reflected to a basement through the plane mirrors, and thestrong parallel light rays are reflected into emitting light rays through the convex mirror to complement light for the basement.

Owner:SHANGHAI NO 7 CONSTR

Hollow capsule containing SiO2 and preparation method therefor

InactiveCN105412044AReflectiveImprove toughnessInorganic non-active ingredientsCapsule deliveryCellulosePolymer science

The invention relates to the hollow capsule technology field, and concretely relates to a hollow capsule containing SiO2 and a preparation method therefor. The hollow capsule is composed of the following raw materials, by weight, 45-60 parts of main material, 2-10 parts of plasticizer, 2-10 parts of Tween, 15-25 parts of titanium dioxide, 3-8 parts of pigment, 2-10 parts of nano SiO2 and 30-40 parts of water. The main material is one or two of gelatin and hydroxypropyl methyl cellulose. The plasticizer is one or two of glycerin and polyethylene glycol. The preparation method for the hollow capsule has a simple technology, the hollow capsule moisture content is controlled between 10% and 20%, the prepared hollow capsule has good ultraviolet shield anti-tarnishing performance, has high tensile strength, and is not easy to change color.

Owner:GUANGDONG GUOFANG MEDICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com