Method for fabricating guiding light plate frame

A manufacturing method and technology for a light guide plate, applied in optics, nonlinear optics, instruments, etc., can solve the problems of light gathering and insufficient assembly strength, and achieve the effect of strong bonding force and solving the reduction of assembly strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

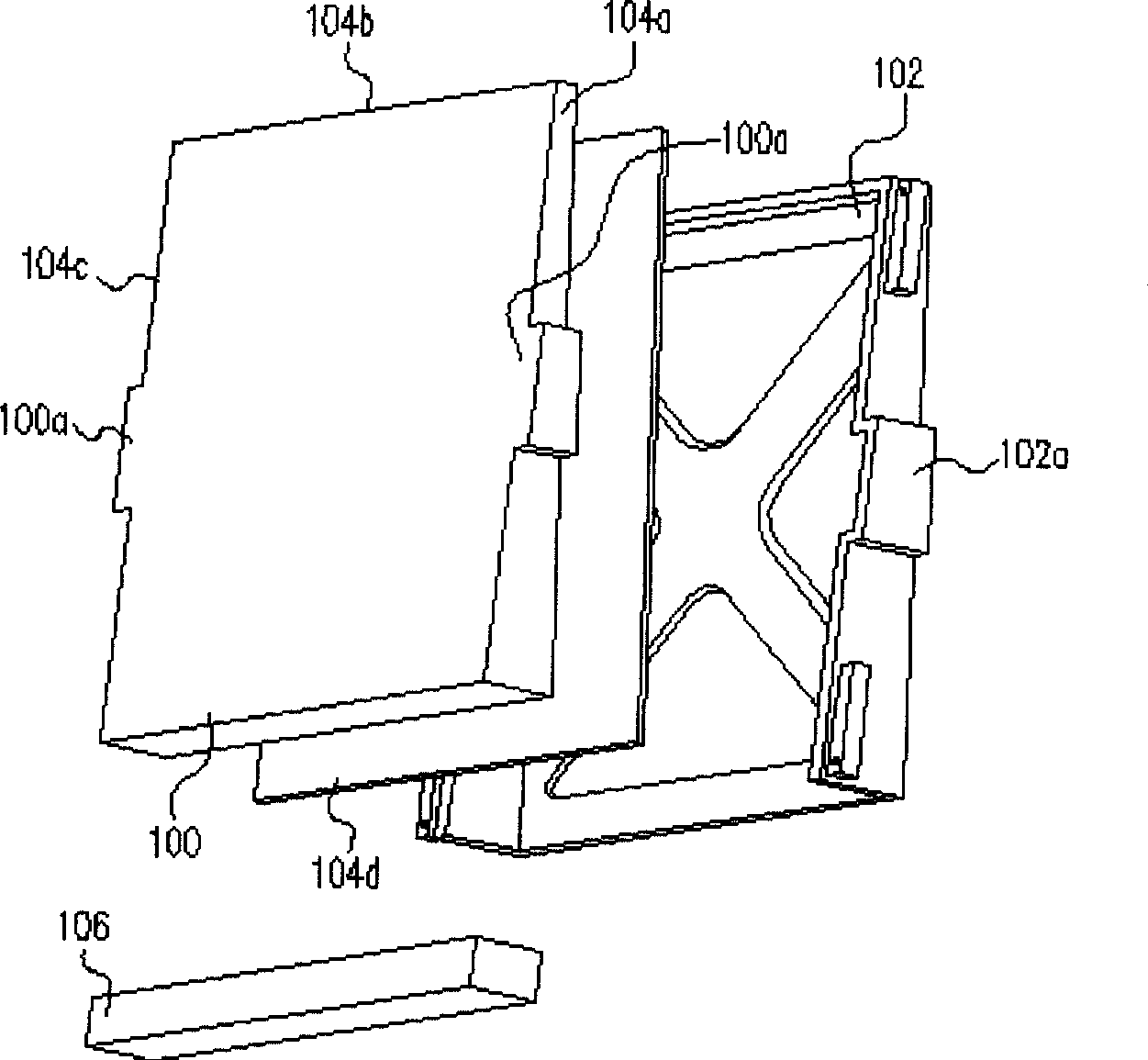

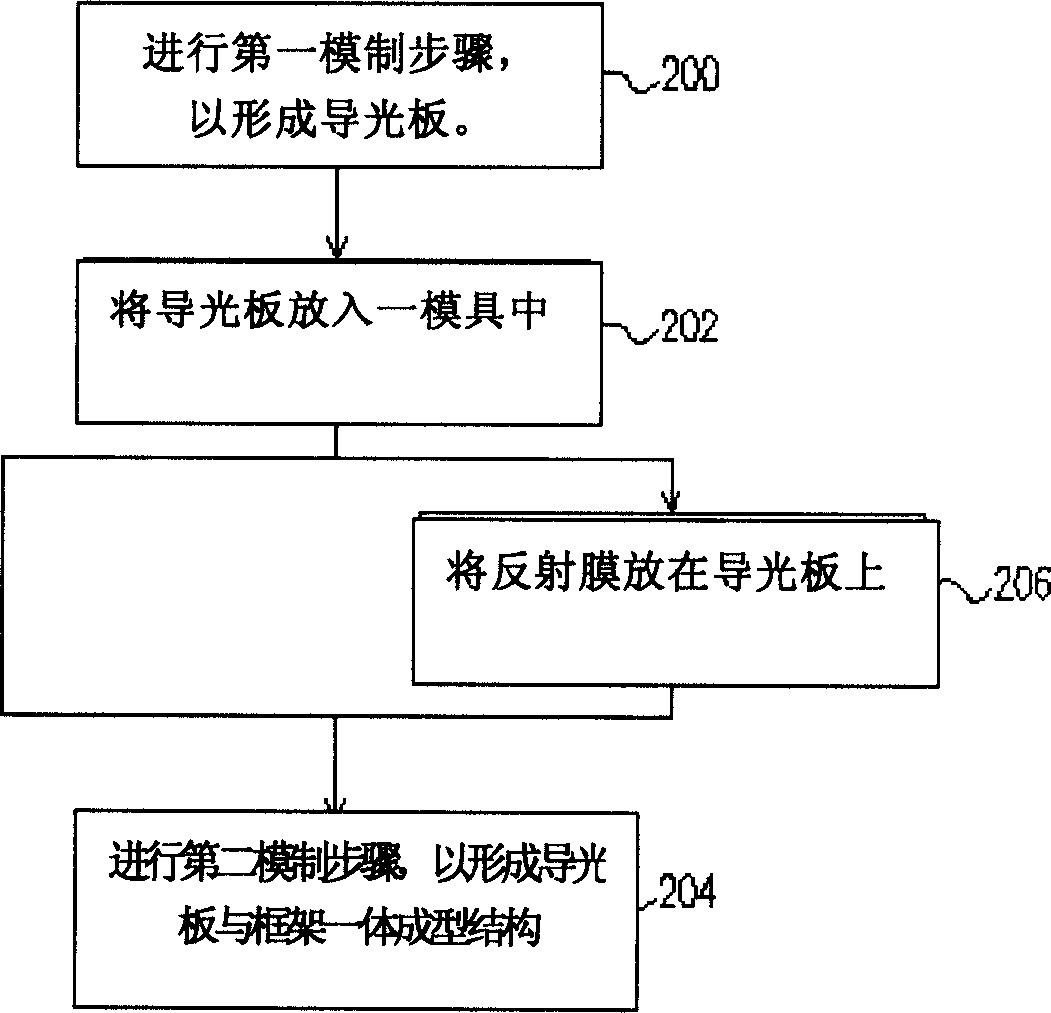

[0035] Such as figure 2 Shown is a manufacturing flow chart of the light guide plate and the frame in the backlight module according to a preferred embodiment of the present invention.

[0036] Please refer to figure 2 , first perform a first molding step (such as an injection molding step or an injection molding step) to form a light guide plate (step 200), the formed light guide plate is as Figure 4 As shown, the light guide plate 400 is a wedge-shaped light guide plate, and its material can be a transparent plastic material. It is particularly worth mentioning that the side surfaces 408, 412 of the light guide plate 400 of the present invention do not need to be designed with protrusions for assembling and combining with the frame, so the sides of the light guide plate 400 of the present invention are flat planes. The problem of easy to gather light will not happen due to the unique design.

[0037] Afterwards, the light guide plate is put into a mold (step 202 ), whe...

no. 2 example

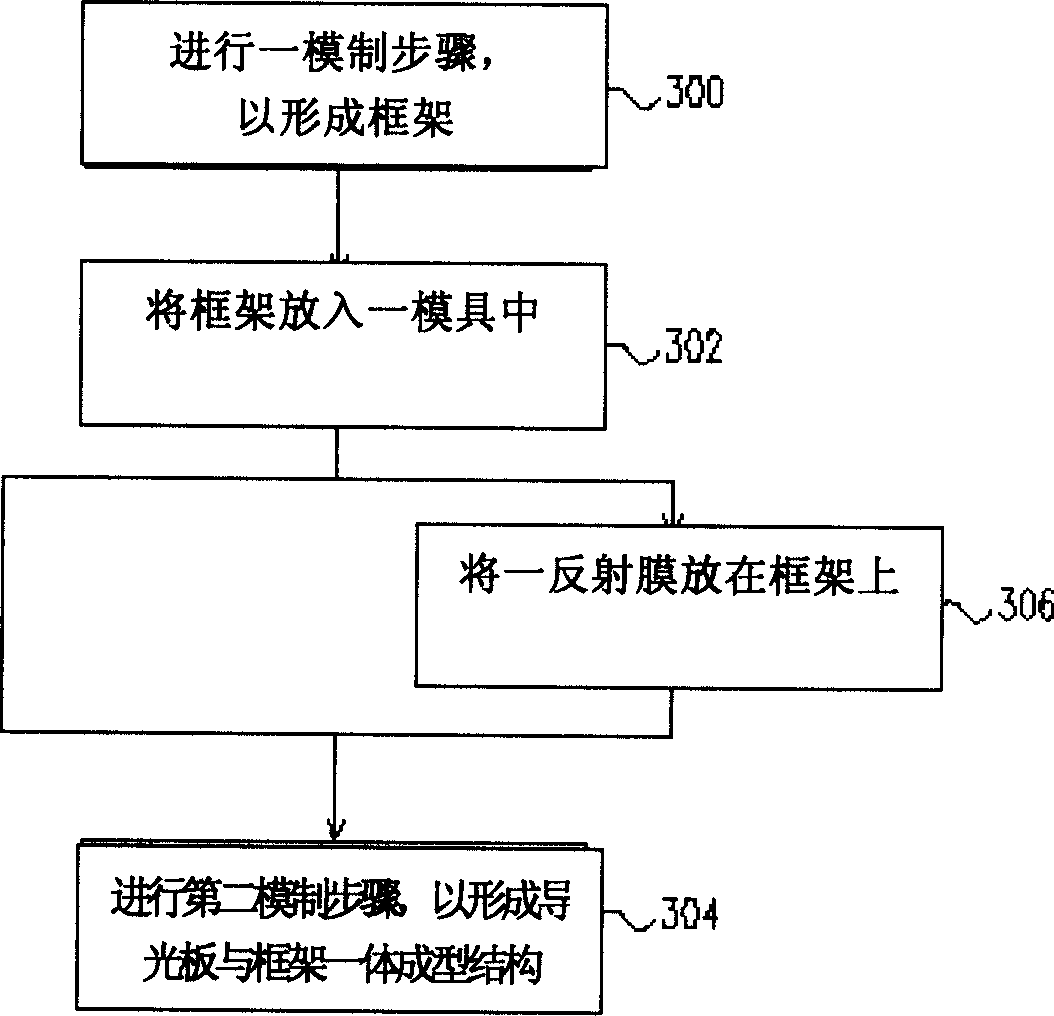

[0042] Such as image 3 Shown is a manufacturing flow chart of the light guide plate and the frame in the backlight module according to another preferred embodiment of the present invention.

[0043] Please refer to image 3 , first perform a first molding step (such as an injection molding step or an injection molding step) to form the frame (step 300), wherein in one embodiment, the material used in the first molding step can be It is a reflective material, so that the formed frame has reflective properties, and the formed frame has its specific frame shape according to the design, such as Figure 6 shown.

[0044] Afterwards, the frame is put into a mold (step 302), wherein the bottom surface of the frame is flat against the bottom of the mold. Then perform a second molding step (for example, an injection molding step or an injection molding step) to form an integrally formed structure of the light guide plate and the frame (step 304), and the formed integrally formed stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com