PET anti-grass cloth and production method thereof

A production method and technology of weed-proof cloth, which is applied in the field of horticultural applications, can solve the problems of easy deformation, easy breakage, and low strength of PET grass-proof cloth, and achieve the effects of not easy to break, good aging resistance, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

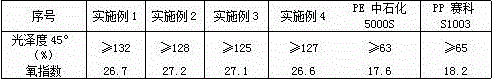

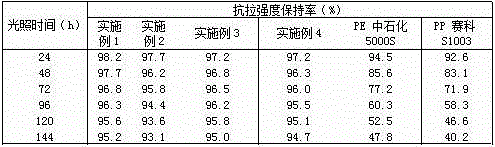

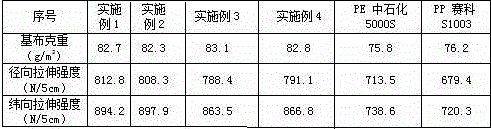

Examples

Embodiment 1

[0045] Embodiment 1, a kind of PET grass-proof cloth and production method, comprises the following steps:

[0046] (1) 89 parts of fiber-grade PET chips (IG703, Yizheng Chemical Fiber, intrinsic viscosity 0.80-1.0dL / g), 3 parts of solid toughening agent (solid toughening agent produced by a domestic company), 2 parts of antioxidant (PolyOne , CC10008704WE), 3 parts of filler (PET special filler masterbatch, TOYOINK Group) and color 3 parts of masterbatch (FG-010-1802, AstraPolymers) mixed with 0.1 part of nano-silver, nano-silver coated with polypropylene, and dried in vacuum Pre-crystallize at 120-150°C in the tank, and then add to the extruder. The temperature of the extruder is 265-280°C. The raw material is in a molten state through the extruder, passes through the metering pump, the melt filter to the die head, and from the die head Extruded in a narrow slit, cast onto a cooling roll at 20-28°C and quenched to form a PET film;

[0047](2) The diaphragm obtained after co...

Embodiment 2

[0049] Embodiment 2, a kind of PET grass-proof cloth and production method, comprises the following steps:

[0050] (1) 89 parts of fiber-grade PET chips (IG703, Yizheng Chemical Fiber, intrinsic viscosity 0.70-1.0dL / g), 3 parts of solid toughening agent (AX8900, Arkema), 2 parts of antioxidant (PolyOne, CC10008704WE), 3 parts 1 part of filler (PET-specific filler masterbatch, TOYOINK Group) and color 3 parts of masterbatch (FG-010-1802, AstraPolymers) and 0.1 part of nano-silver mixed with nano-silver coated with polypropylene, in a vacuum drying tank at 120-150 ° C Pre-crystallize, then add to the extruder, the temperature of the extruder is 265-280°C, the raw material is melted through the extruder, passes through the metering pump, the melt filter to the die, and is extruded from the narrow slit of the die , casting to 20-28 ℃ cooling roll quenching to form PET film;

[0051] (2) The diaphragm obtained after cooling is preheated from 60°C to 90°C by a set of 8 preheating ...

Embodiment 3

[0053] Embodiment 3, a kind of PET grass-proof cloth and production method, comprises the following steps:

[0054] (1) 88 parts of waste PET bottle flakes (intrinsic viscosity 0.65-0.72dL / g), 3 parts of solid toughening agent (solid toughening agent produced by a domestic company), 2 parts of antioxidant (CC10008704WE, PolyOne), 1 1 part tackifier (epoxy tackifier produced by the company), 3 parts filler (PET special filler masterbatch, TOYOINK Group) and 3 parts color masterbatch (FG-010-1802, AstraPolymers) mixed with 0.1 part nano silver , Nano-silver is coated with polypropylene, pre-crystallized in a vacuum drying tank at 120-150°C, and then added to the extruder, the temperature of the extruder is 255-275°C, and the intrinsic viscosity of PET is increased to 0.88 after reactive extrusion -1.1dL / g, the raw material goes through the extruder into a molten state, passes through the metering pump, the melt filter to the die head, and is extruded from the narrow slit of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com