Resistance strain gauge

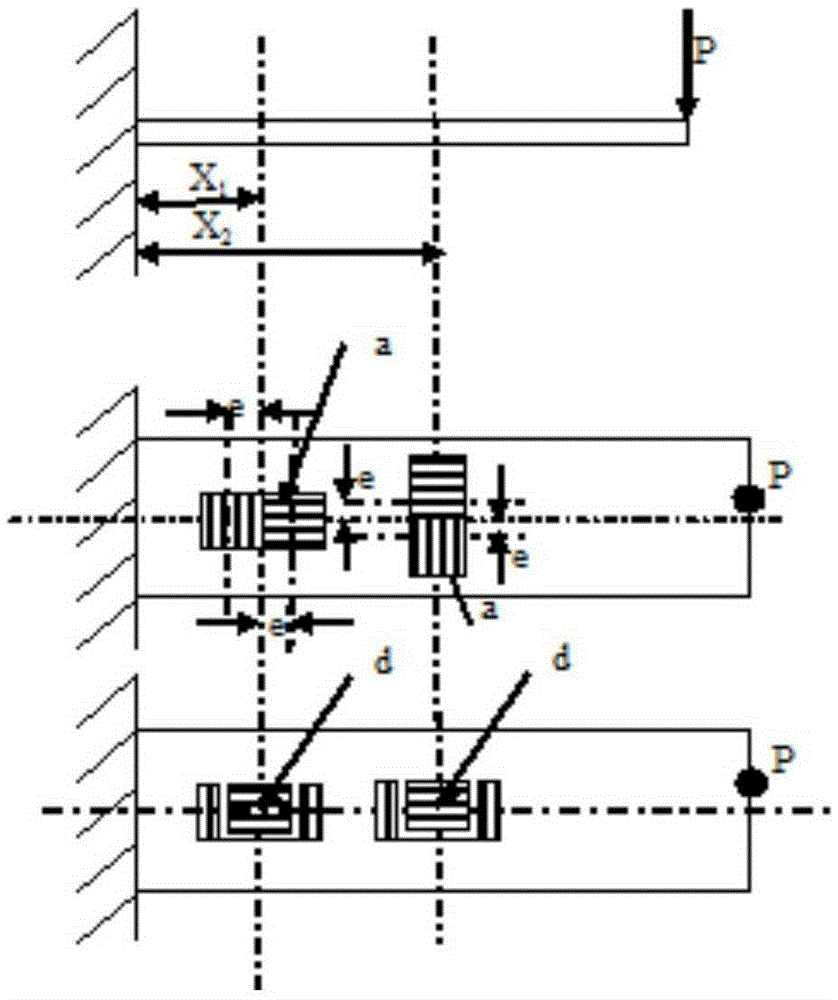

A resistance strain gauge, longitudinal technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring device, measuring device, etc., can solve problems such as errors, difficult positioning, difficulty in observing the pasting coordinates of strain gauges, etc., to achieve convenient pasting, reduce small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

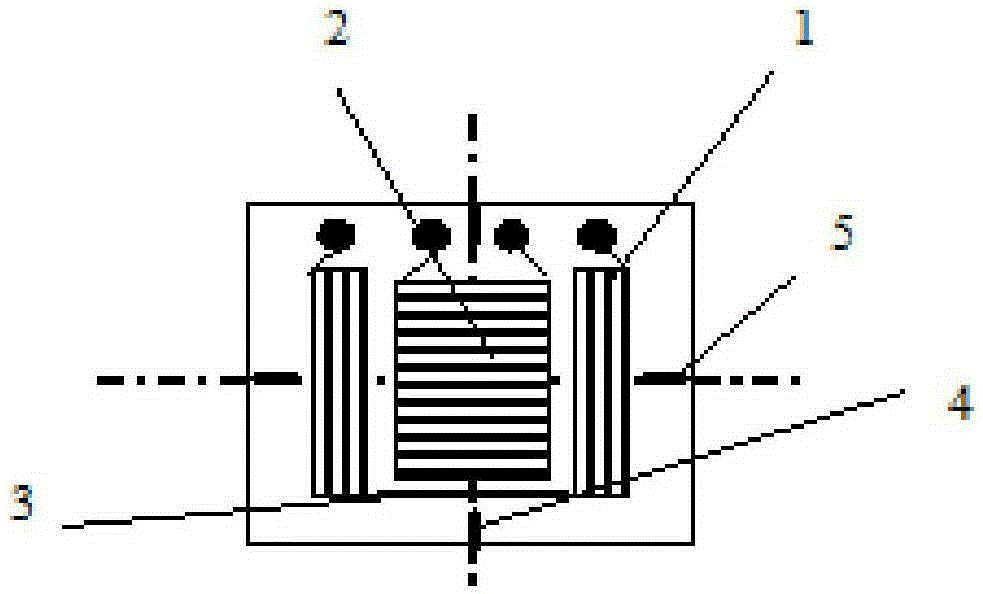

[0018] Such as figure 2 As shown, a new type of resistance strain gauge consists of two units of vertical sensitive grid 1, horizontal sensitive grid 2, shorting wire 3, and longitudinal coordinate 4 and horizontal coordinate 5 with reflective performance.

[0019] The vertical sensitive grid 1 and the horizontal sensitive grid 2 are structurally symmetrical on the longitudinal coordinate 4 and the transverse coordinate 5, which are used to eliminate measurement errors under the action of non-simple loads. The longitudinal sensitive grid 1 is divided into two units, and the two units are connected by a shorting wire 3, and the shorting wire 2 is connected to the strain gauge substrate without solidification, the shorting wire 3 does not participate in deformation, and the transverse sensitive grid 2 is embedded in the In the region of the vertical sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com