Dynamic fin comprising coupled fin sections

a fin and coupled technology, applied in the field of dynamic fins, can solve the problems of increasing production efforts and costs, complicated manufacturing and assembly of components, and prone to contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

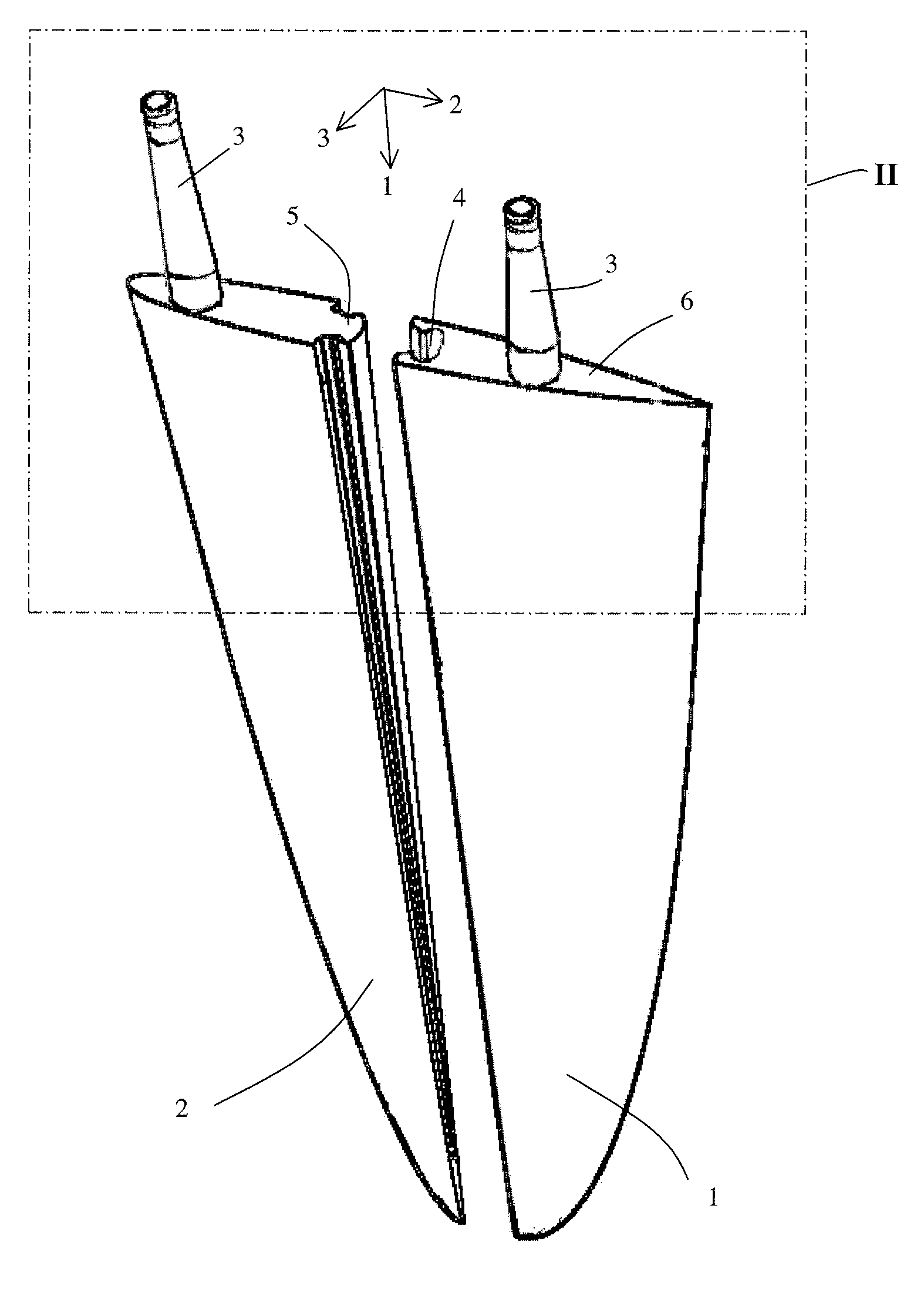

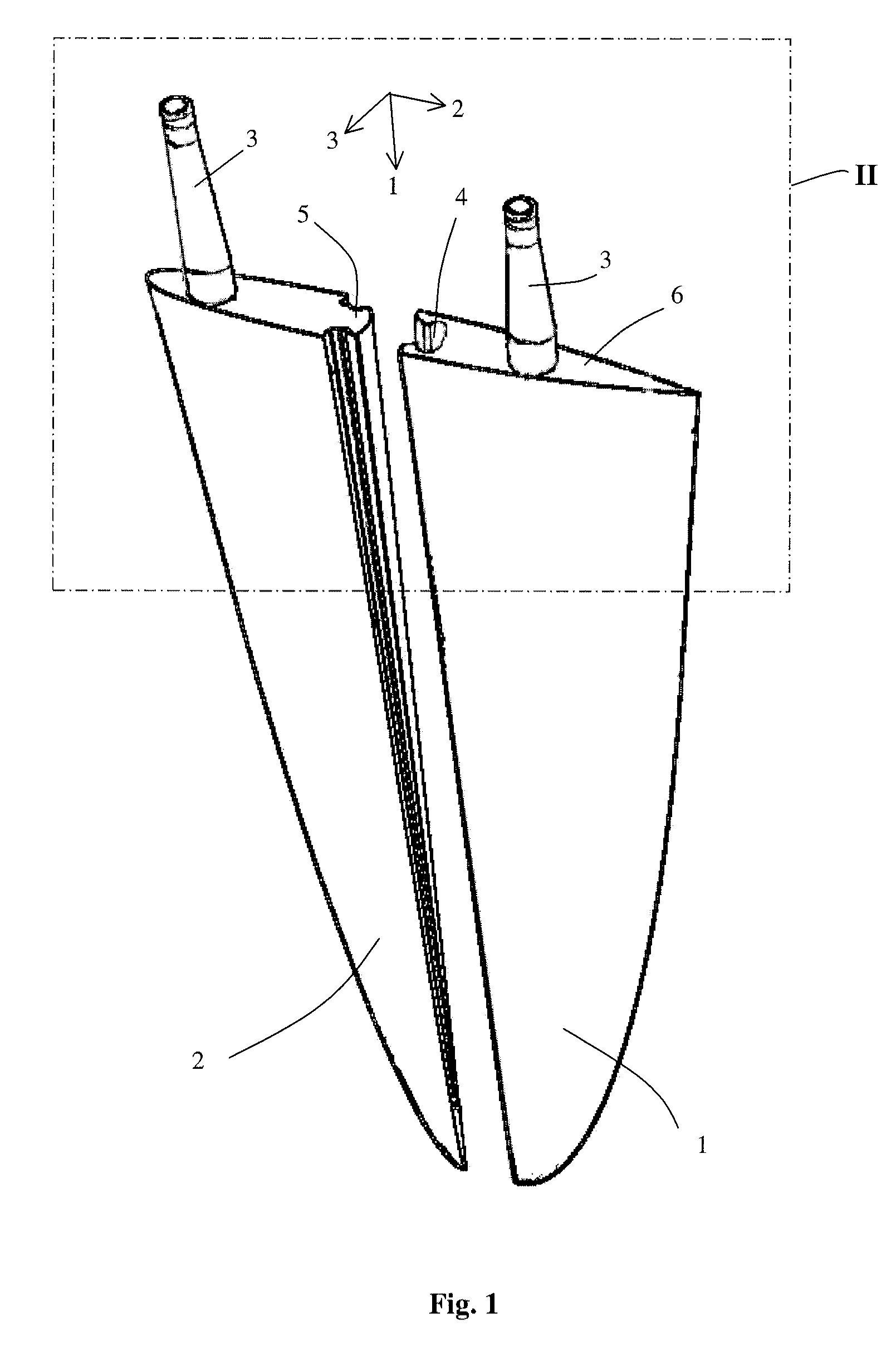

[0030]FIG. 1 shows a dynamic fin according to the invention. The dynamic fin is arranged as a fin which is suitable to serve as a fin for a surf board. The fin has outer side surfaces, a base and a tip. The outer side surfaces are substantially smooth. The dynamic fin comprises two parallelly arranged fin sections. For the application as a smart fin in a surfboard, the fin sections may be made from a plastic material including eventually reinforcing fibres. The fin sections are made sufficient rigid to withstand dynamic loads. The dynamic fin is formed by a first fin section which has a rounded front edge which defines a leading edge and forms a front side of the dynamic fin. The fin has a sharp edge at a tail which defines a trailing edge. During use a fluid may flow backwards along the fin from the rounded front side to the tail. The dynamic fin has a cross-section which is shaped like an airfoil having a chord which defines an upper chamber and a lower chamber.

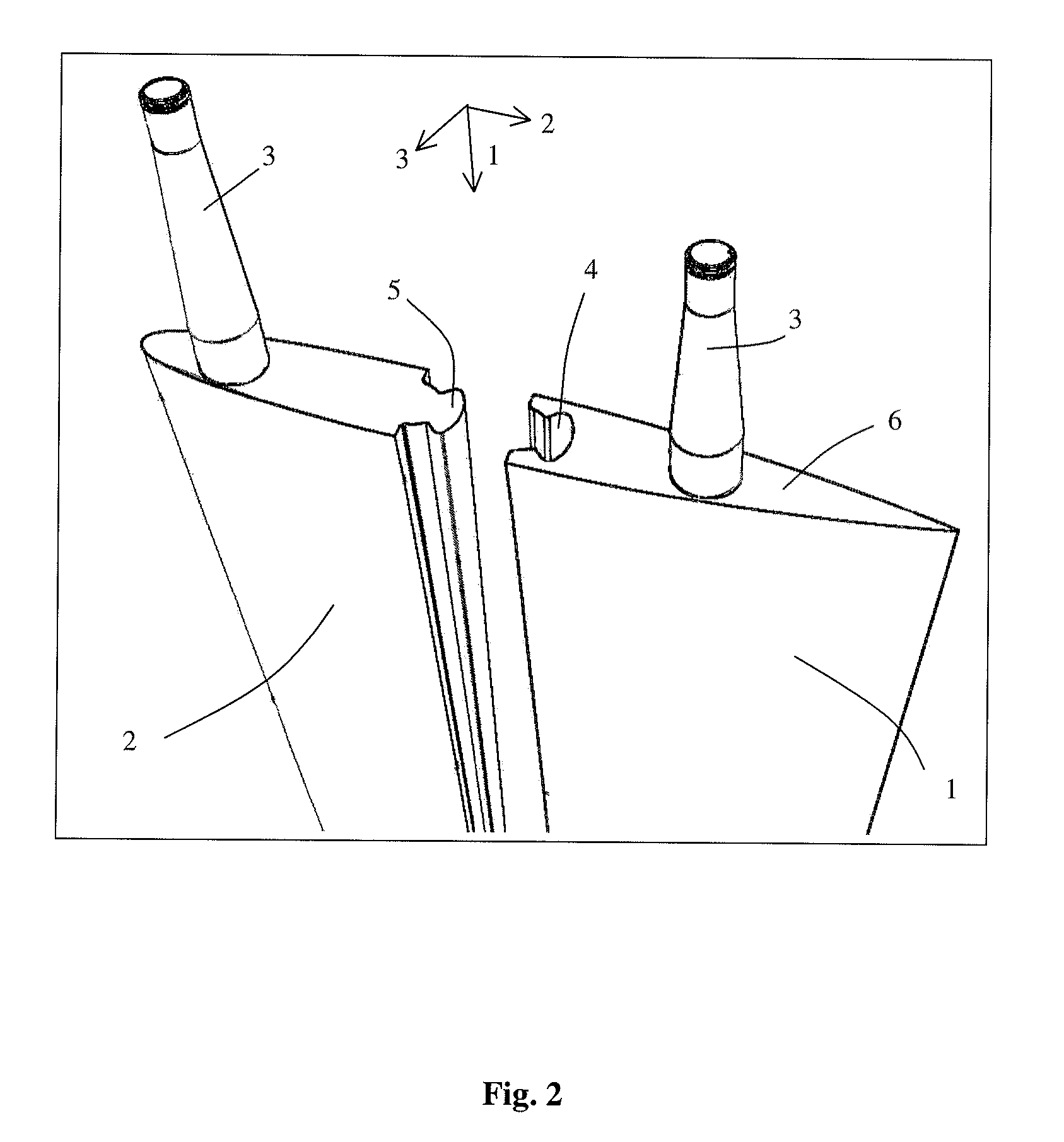

[0031]FIG. 2 shows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com