TPU film and preparation method thereof

A film and antioxidant technology, applied in the field of TPU, can solve the problems of easy falling off of special effect powder and poor effect, and achieve the effects of low cost, simple preparation method and good catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

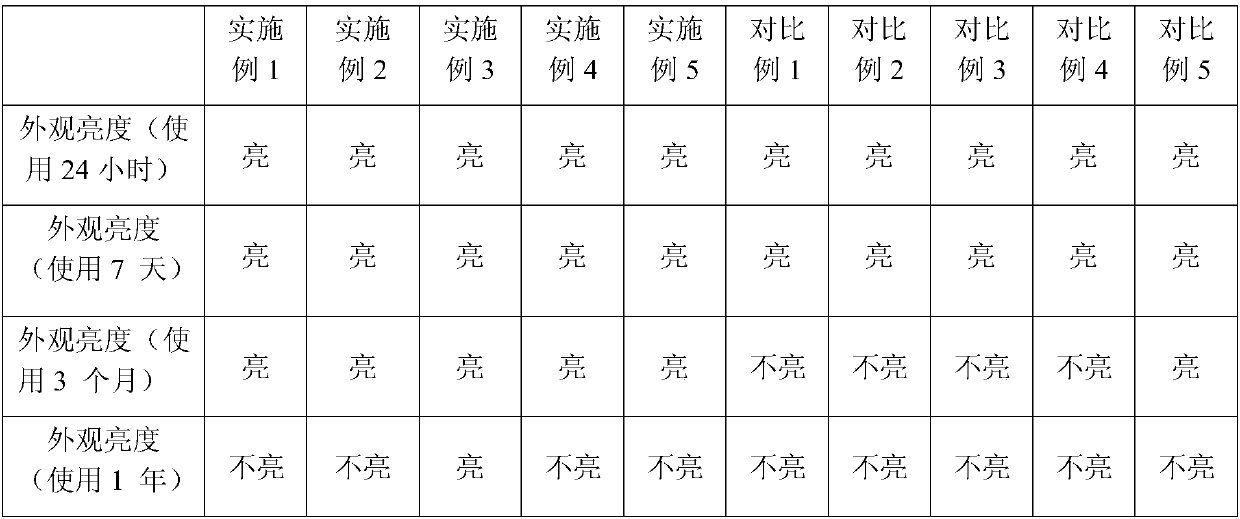

Examples

preparation example Construction

[0023] A preparation method for a TPU film, comprising the steps of:

[0024] (1) After uniformly mixing the raw materials in the formula quantity, dry at a temperature of 50°C to 130°C for 3 to 4 hours;

[0025] (2) Take out the dried raw materials, extrude through single-screw or twin-screw extruder after melting, and cast to form a film. The melting temperature is 140 ° C ~ 230 ° C. After cooling, coiling and packaging, TPU film is obtained. . The preparation method proposed by the invention is simple, the TPU can be obtained without using large-scale equipment for processing, and the cost is low.

Embodiment 1

[0027] A preparation method for a TPU film, comprising the steps of:

[0028] (1) After uniformly mixing 90 parts of TPU, 0.5 part of antioxidant 1010, 0.5 part of gold powder and 0.5 part of erucamide, dry it at 50°C for 3 hours;

[0029] (2) Take out the raw materials after drying, extrude after being melted by a single-screw extruder, cast to form a film, the melt extrusion temperature is 140 ° C, after cooling, coiling and packaging, a TPU film is obtained. The thickness of the TPU film is 0.1-2.0 mm.

[0030] The film is applied to the lamination of artificial leather and genuine leather to make the surface bright and colorful. It can also be directly applied to luggage, handbag surface window, sports shoe upper decoration.

Embodiment 2

[0032] A preparation method for a TPU film, comprising the steps of:

[0033] (1) After uniformly mixing 100 parts of TPU, 1.5 parts of antioxidant 2450, 2.5 parts of silver powder and 0.8 parts of oleic acid amide, dry at 130°C for 4 hours;

[0034] (2) Take out the raw materials after drying, extrude after being melted by a twin-screw extruder, cast to form a film, the melt extrusion temperature is 230 ° C, after cooling, coiling and packaging, a TPU film is obtained. The thickness of the TPU film is 0.1-2.0 mm.

[0035] The film is applied to the lamination of artificial leather and genuine leather, so that the surface has a metallic effect. It can also be directly applied to luggage, handbag surface window, sports shoe upper decoration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com