Tunnel reflecting material and preparation method thereof

A technology of reflective materials and tunnels, which is applied in the field of building materials, can solve the problems of inability to achieve natural lighting brightness effects, poor lighting brightness and energy-saving effects, and complicated technological processes, and achieve the effects of enhanced hardness, low manufacturing cost, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

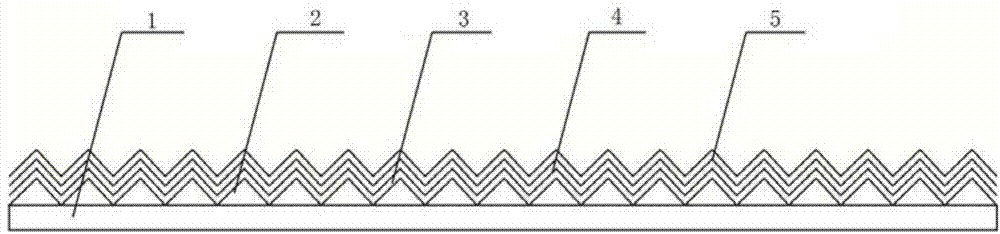

[0017] Embodiment 1: A method for preparing a tunnel reflective material, including a substrate 1 made of ceramic or metal material, pressing a mold on one side of the substrate 1 to form a triangular pyramid protrusion 2, and then subjecting it to a high temperature of 800-1300°C Sintering and forming, spraying paint on the surface of the formed substrate 1 with a pneumatic spray gun or a pneumatic nozzle, drying and curing at 160-220°C for 3-15 minutes to form a color layer 3, and then using a pneumatic spray gun or a pneumatic nozzle to spray glass beads or metal particles or The coating coating is sprayed on the color layer 3, and then dried and cured at 160-220°C for 3-15 minutes to form the reflective layer 4. Finally, the transparent coating is sprayed on the reflective layer 4 with a pneumatic spray gun or a pneumatic nozzle, and the ultraviolet frequency is 250-420nm The light wave is irradiated for about 3-90 seconds, dried and cured to form a protective layer.

Embodiment 2

[0018] Embodiment 2: The rest is the same as Embodiment 1, wherein the protrusion 2 is in the shape of a hexagonal pyramid or an octagonal pyramid.

Embodiment 3

[0019] Embodiment 3: A method for preparing a tunnel reflective material, comprising a substrate 1 made of wood or plastic, setting a triangular pyramid-shaped protrusion 2 on one side of the substrate 1, and then baking at 80-220° C. for 3-15 minutes Dry molding, spray paint on the surface of the formed substrate 1 with a pneumatic spray gun or a pneumatic nozzle, then dry and solidify at 80-220°C for 3-15 minutes to form a color layer 3, and then spray reflective materials on the color layer 3 with a pneumatic spray gun or a pneumatic nozzle. Dry and cure at 80-220°C for 3-15 minutes to form the reflective layer 4, and finally use a pneumatic spray gun or pneumatic nozzle to spray the transparent coating on the reflective layer 4, and then irradiate it with ultraviolet light waves with a frequency of 250-450nm for about 3-90 seconds to dry and cure to form a protective layer. Layer, the reflective material is made of glass beads or metal particles or coated with coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com