Preparation method of vertical ultraviolet LED chip

A LED chip and ultraviolet technology, which is applied in the field of vertical ultraviolet LED chip preparation, can solve the problems of high price and unstable preparation process, and achieve the effects of low production cost, facilitating current flow, and overcoming absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

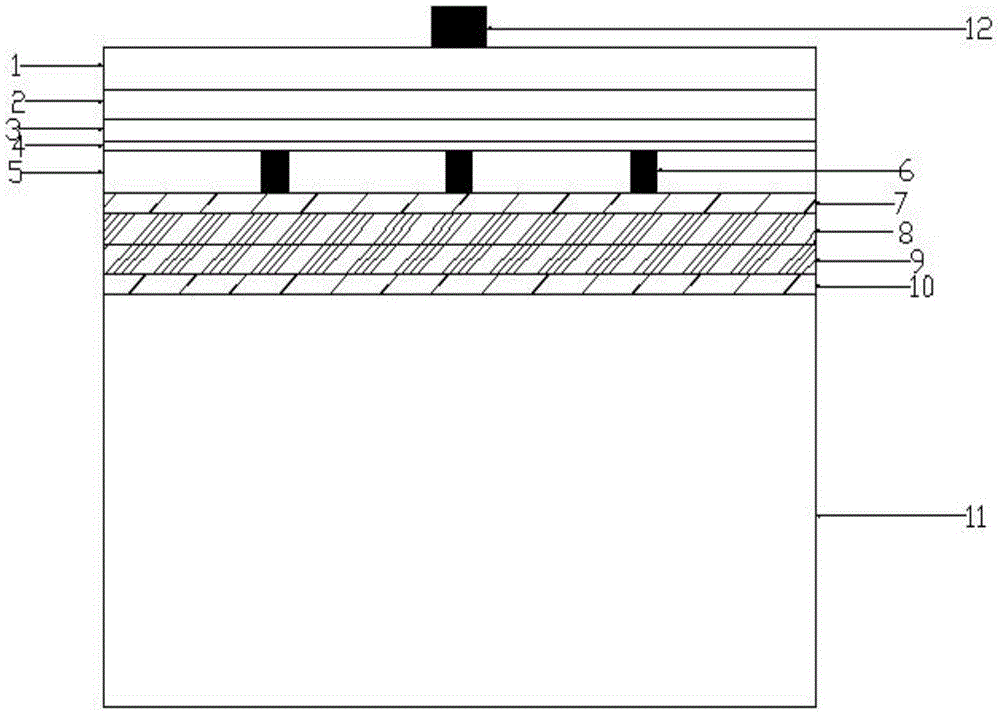

[0044] The preparation method of a vertical ultraviolet LED chip of the present embodiment, the steps are as follows:

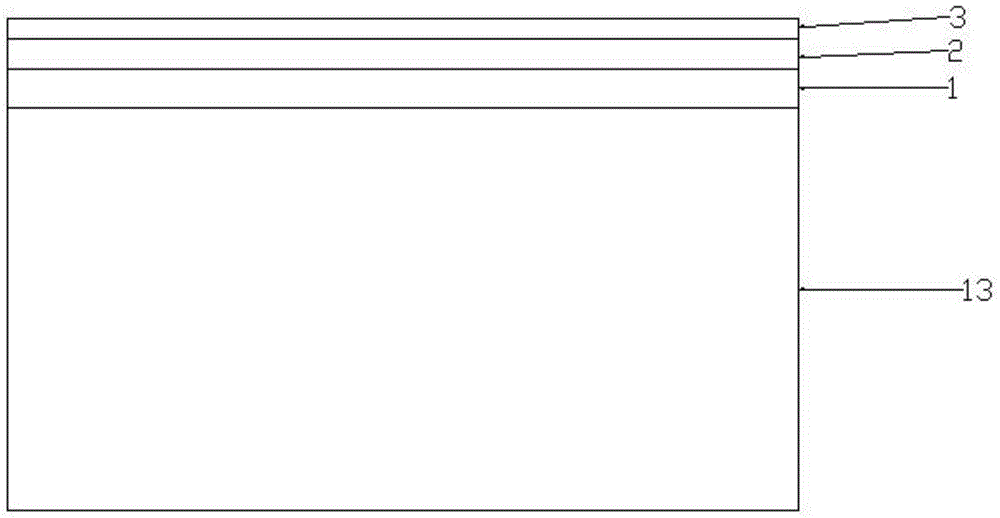

[0045] The first step is to grow the N-type epitaxial layer, the multiple quantum well layer and the P-type epitaxial layer sequentially on the sapphire substrate wafer by MOCVD, and use the mass percentage concentration of 98% H on the grown epitaxial wafer. 2 SO 4 with a mass percentage concentration of 30% H 2 O 2 The mixed solution with volume ratio=3:1 was heated to 80°C, soaked for 10 minutes, then rinsed with deionized water for 5 minutes, and finally dried with a spin dryer for 20 minutes;

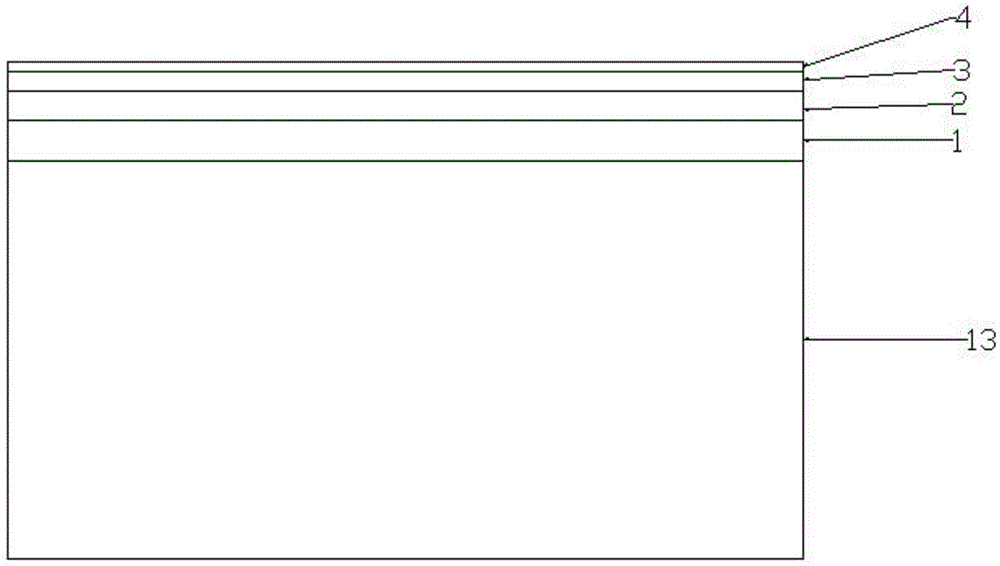

[0046] In the second step, on the surface of the P-type epitaxial layer of the sapphire substrate treated in the first step, an ultra-thin metal Ni / Ag was evaporated with an electron beam evaporation stage as a current spreading layer, and the thickness of Ni was controlled exist The thickness of Ag is controlled at The metal current spreading layer is requ...

Embodiment 2

[0053] The preparation method of a vertical ultraviolet LED chip of the present embodiment, the steps are as follows:

[0054] The first step is the same as in Example 1;

[0055] In the second step, on the surface of the P-type epitaxial layer of the sapphire substrate treated in the first step, an ultra-thin metal Ni / Ag was evaporated with an electron beam evaporation stage as a current spreading layer, and the thickness of Ni was controlled exist The thickness of Ag is controlled at The metal current spreading layer is required to form an ohmic contact with the P-type epitaxial layer after the next step of annealing;

[0056] In the third step, except that the annealing temperature is 370°C and the annealing time is 8 minutes, the rest is the same as in Example 1;

[0057] The fourth step is to prepare a DBR layer on the Ni / Ag metal current spreading layer annealed in the third step, and the material used is SiO 2 and TiO 2 Evaporation source, use electron beam evapo...

Embodiment 3

[0062] The preparation method of a vertical ultraviolet LED chip of the present embodiment, the steps are as follows:

[0063] The first step is the same as in Example 1;

[0064] In the second step, on the surface of the P-type epitaxial layer of the sapphire substrate treated in the first step, an ultra-thin metal Ni / Ag was evaporated with an electron beam evaporation stage as a current spreading layer, and the thickness of Ni was controlled exist The thickness of Ag is controlled at The metal current spreading layer is required to form an ohmic contact with the P-type epitaxial layer after the next step of annealing;

[0065] In the third step, except that the annealing temperature is 400°C and the annealing time is 10 minutes, the rest is the same as in Example 1;

[0066] The fourth step is to prepare a DBR layer on the Ni / Ag metal current spreading layer annealed in the third step, and the material used is SiO 2 and TiO 2 Evaporation source, use electron beam evap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com