Return pipe heat exchanger

A heat exchanger and return pipe technology, applied in the field of return pipe heat exchangers, can solve the problems of only vertical installation, inconvenient use, and large dimensions, and achieve the effects of convenient layout, high reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

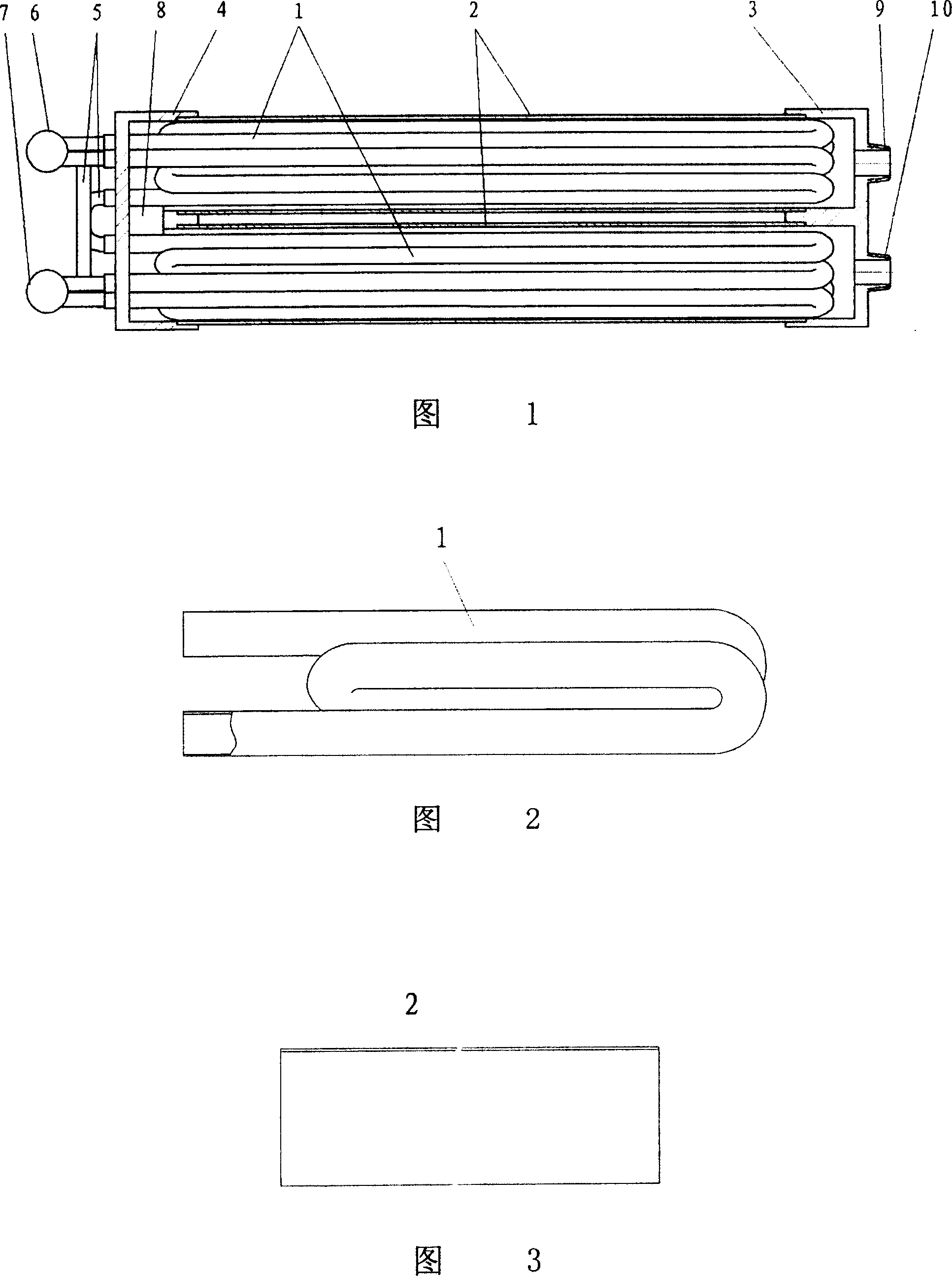

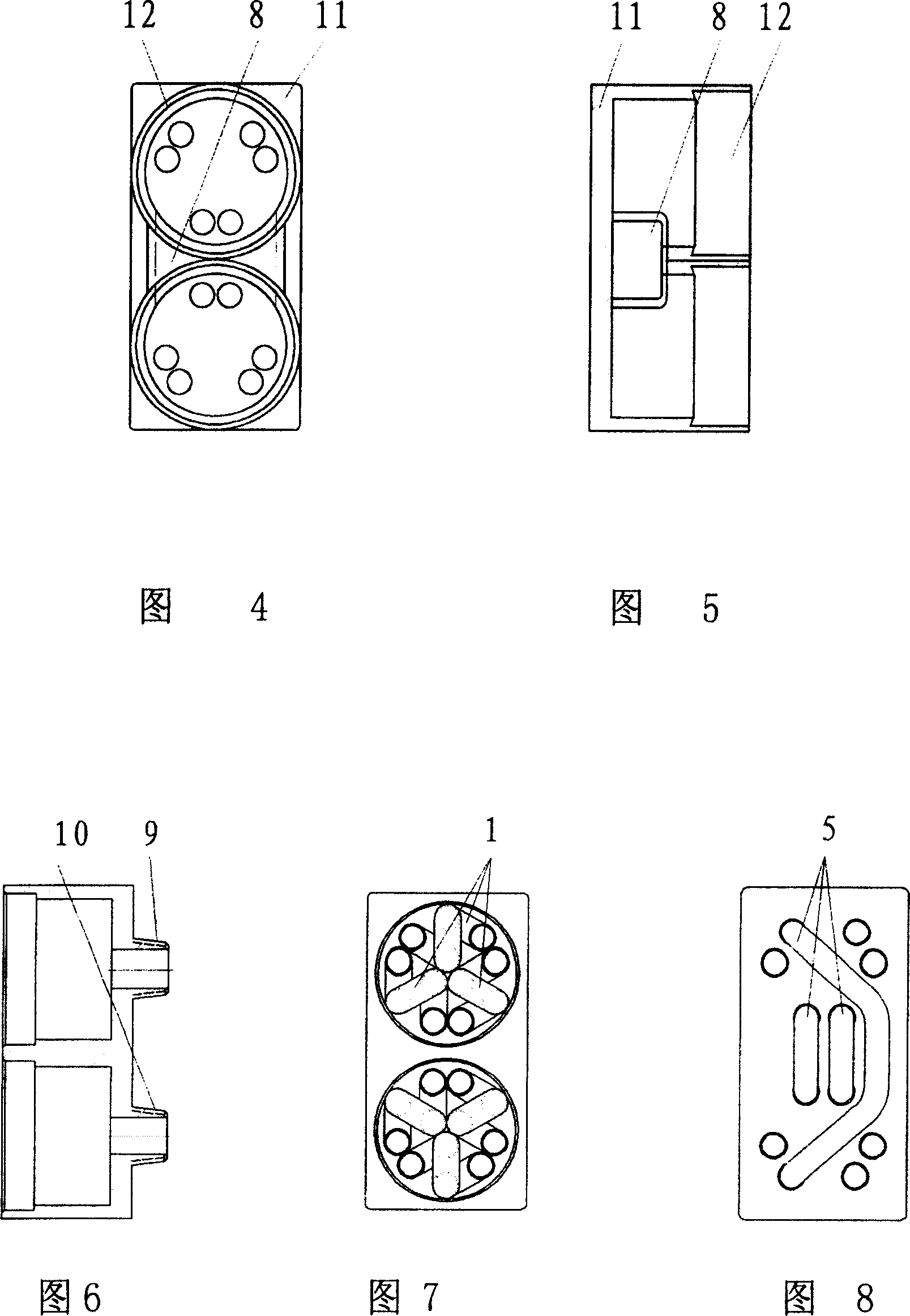

[0032] Example 1: double-tube return pipe heat exchanger

[0033] Combining Figure 1-Figure 3:

[0034] The present embodiment is provided with two cylinders 2, and the cylinders are elongated metal cylinders, and each cylinder 2 has three return pipes 1 that circle back and forth twice. The return pipe 1 in this embodiment is integrally bent. The two cylinders 2 are inserted into the grooves of the two sleeves 12 of the left end cover 4 and the right end cover 3 to form the shell of the heat exchanger. There are inlets 10 and outlets 9 on the end covers, and a total of 12 tube heads for return pipes. Pass through the cover plate 11 of the left end cover 4. The adjacent head and tail pipe heads of the same group of return pipes are connected through the connecting elbow 5, and the inlet and outlet ends of each group of return pipes are respectively connected through the upper distributor 6 and the lower distributor 7 to form a main pipe, and there are communication holes bet...

Embodiment 2

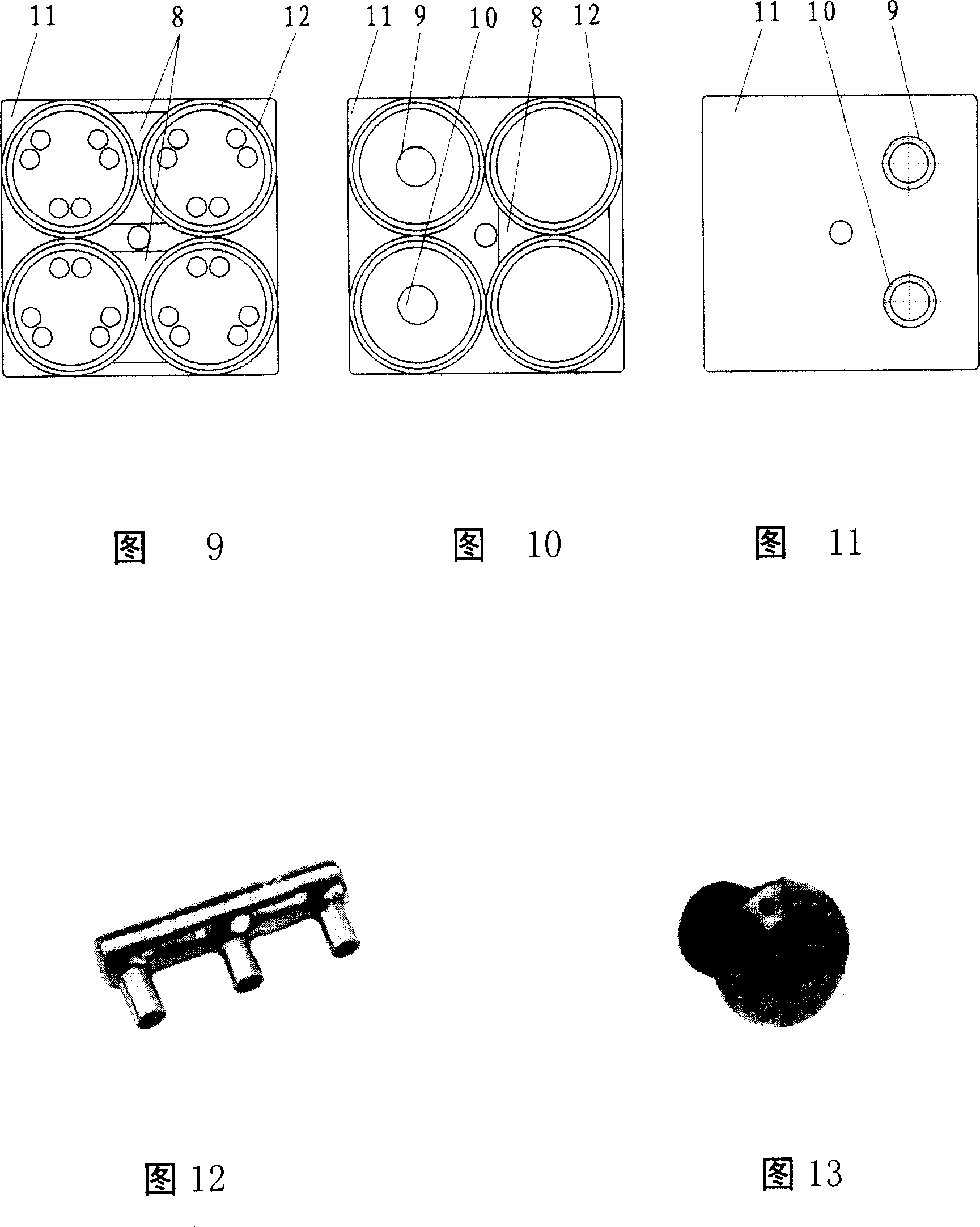

[0038] Example 2: 4 tubes (2×2 matrix arrangement) return tube heat exchanger

[0039] Combined with Figure 9-Figure 11:

[0040] The difference from Example 1 is that 6 groups of return pipes 1 are respectively placed in 4 cylinders 2 to form a (2×2 matrix arrangement), and the number of sockets 12 is the same as the number of cylinders, which are 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com