Aluminum alloy hard anodic oxidation device and method

A hard anodizing and anodizing technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as solution temperature rise and anodizing energy consumption, and achieve uniform void distribution and film formation. Densification, the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

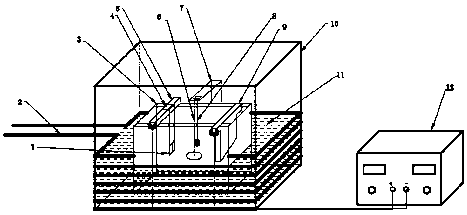

[0041] Such as figure 1 As shown, this embodiment provides an aluminum alloy hard anodizing device, including a temperature control and heat preservation system, an anodizing system, an auxiliary control system and a power supply. The temperature control and heat preservation system includes a vacuum heat preservation container 10, which is made of stainless steel. The vacuum heat preservation container includes an outer shell and an inner shell, and a vacuum inner cavity is arranged between the outer shell and the inner shell to achieve heat preservation effect. A cooling copper pipe 2 is arranged in the vacuum heat preservation container 10 , and the cooling copper pipe 2 is arranged around the inner wall of the vacuum heat preservation container 10 . The water inlet and the water outlet of the cooling copper pipe 2 are connected with a compressor (not shown in the figure), and R600a refrigerant is housed in the cooling copper pipe 2 . The compressor can be any one of a pis...

Embodiment 2

[0046] This embodiment provides an aluminum alloy anodic oxidation method, comprising the following steps:

[0047] S1. Pretreatment: Ultrasonic cleaning and drying are performed on the aluminum alloy sample and cathode plate made of 2a96 aluminum alloy, and the aluminum alloy sample and cathode plate are respectively fixed in the anode hanger and the electrolytic cell. The aluminum alloy sample and cathode plate are The distance is 10cm;

[0048] S2. Lowering the temperature: Injecting H at a concentration of 120g / L into the reaction tank 2 SO 4 The solution is used as the electrolyte, and the compressor is turned on to cool the electrolyte to -5°C;

[0049] S3. Anodizing: Turn on the stirring device and power supply for anodizing, and the anodizing time is 25 minutes;

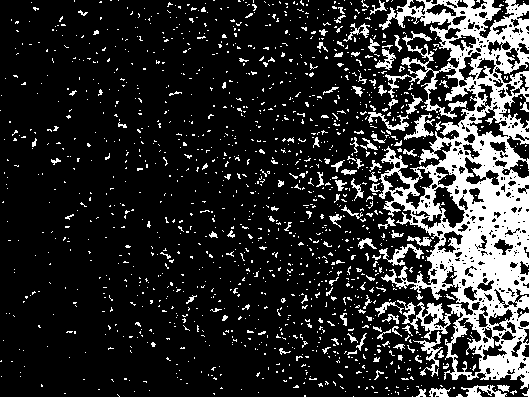

[0050] S4. Sealing: use boiling deionized water to seal the anodized aluminum alloy sample, and the sealing time is 15 minutes. figure 2 Metallographic photograph of the oxide film prepared for this exampl...

Embodiment 3

[0052] This embodiment provides an aluminum alloy anodic oxidation method, comprising the following steps:

[0053] S1. Pretreatment: Ultrasonic cleaning and drying are performed on the aluminum alloy sample and cathode plate made of 2a96 aluminum alloy, and the aluminum alloy sample and cathode plate are respectively fixed in the anode hanger and the electrolytic cell. The aluminum alloy sample and cathode plate are The distance is 8cm;

[0054] S2. Lowering the temperature: Injecting H at a concentration of 120g / L into the reaction tank 2 SO 4 The solution is used as the electrolyte, and the compressor is turned on to cool the electrolyte to -10°C;

[0055] S3. Anodizing: Turn on the stirring device and power supply for anodizing, and the anodizing time is 35 minutes;

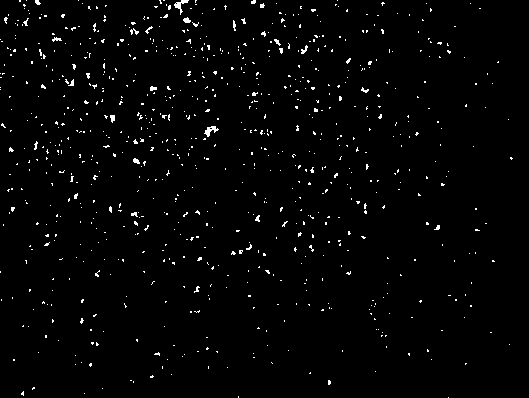

[0056] S4. Sealing: use boiling deionized water to seal the anodized aluminum alloy sample, and the sealing time is 15 minutes. image 3 Metallographic photograph of the oxide film prepared for this examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com