Method for preparing Ag/SnO2 composite material

A composite material and ph value technology, which is applied in the direction of contacts, electrical components, circuits, etc., can solve problems such as surface temperature rise, electrical contact material contact resistance increase, electrical performance degradation, etc., to overcome performance degradation and eliminate contact The effect of increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

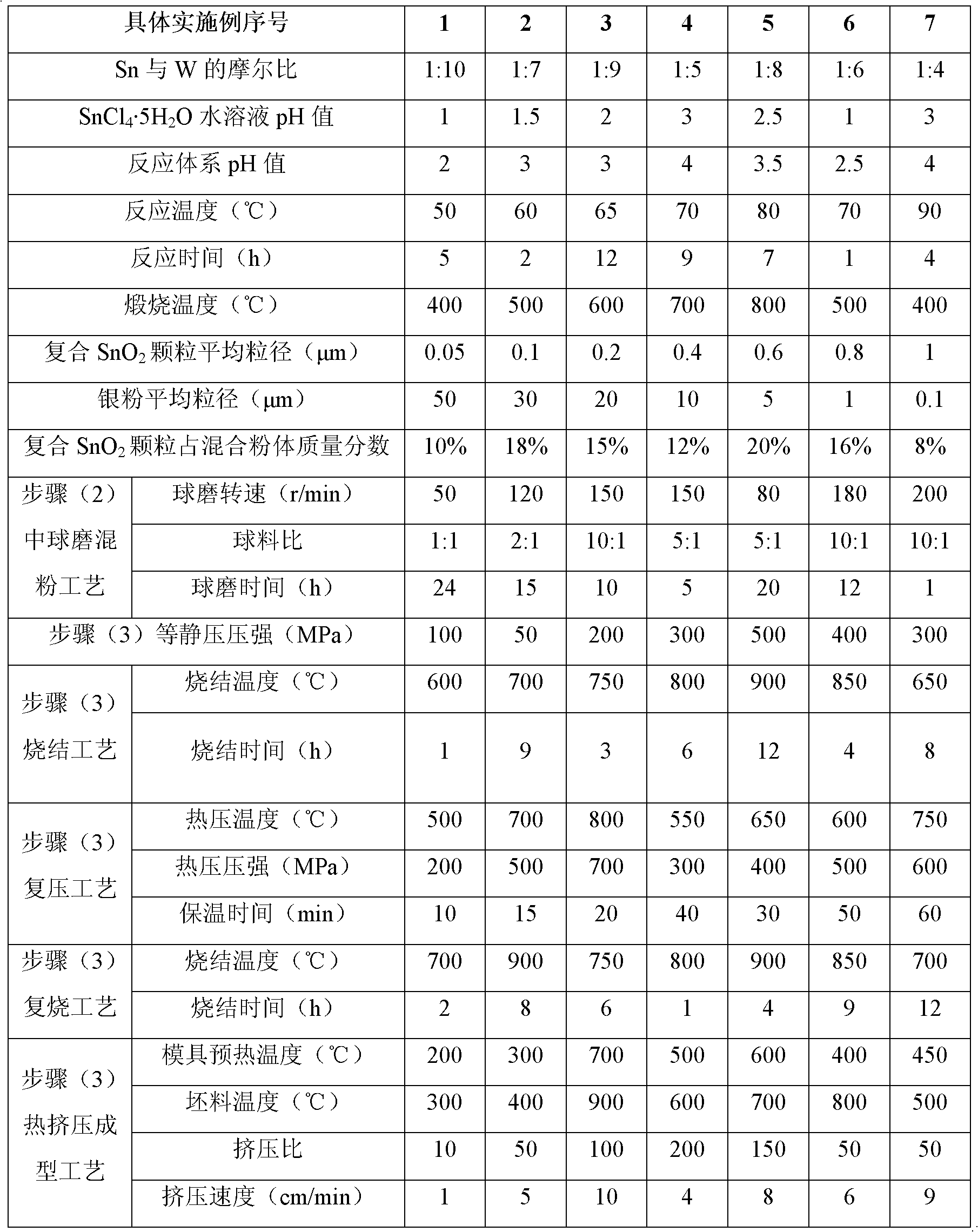

[0019] The present invention is further described by examples below.

[0020] Ag / SnO provided by the invention 2 The preparation method of composite material specifically comprises the following steps:

[0021] (1) Mix ammonia water and SnCl with a pH value of 1 to 3 under stirring conditions 4 ·5H 2 The acidic aqueous solution of O is added dropwise to the WC suspension aqueous solution with a mass fraction of 5% at the same time, so that the pH value of the reaction system is 2 to 4, and the molar ratio of Sn to W is 1:10 to 1:4; at 50 to 90 ° C After reacting for 1-12 hours under the same conditions, the suspension was filtered, washed, vacuum-dried and then calcined to obtain a composite SnO with a core-shell coating structure. 2 particles;

[0022] (2) The above composite SnO 2 Particles and silver powder are ball milled evenly to compound SnO 2 The particles account for 8% to 20% of the total mass of the mixed powder to obtain a mixed powder;

[0023] (3) The unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com